Abstract

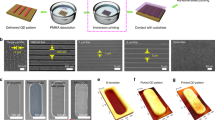

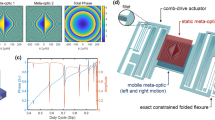

Current lens systems are restricted in size, shape and dimensions by limitations of manufacturing. Multi-lens elements with non-spherical shapes are required for high optical performance and to correct for aberrations when imaging at wide angles and large fields. Here we present a novel concept in optics that overcomes all of the aforementioned difficulties and opens the new field of 3D printed micro- and nano-optics with complex lens designs. We demonstrate the complete process chain, from optical design, manufacturing by femtosecond two-photon direct laser writing and testing to the application of multi-lens objectives with sizes around 100 µm, and validate their high performance and functionality by quantitative measurements of the modulation transfer function and aberrations. The unprecedented flexibility of our method paves the way towards printed optical miniature instruments such as endoscopes, fibre-imaging systems for cell biology, new illumination systems, miniature optical fibre traps, integrated quantum emitters and detectors, and miniature drones and robots with autonomous vision.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$209.00 per year

only $17.42 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Change history

06 July 2016

In the version of this Article originally published online, ref. 23 'Gissibl, T., Thiele, S., Herkommer, A. & Giessen, H. Sub-micrometre accurate free-form optics by three-dimensional printing on single-mode fibres. Nature Commun. 7, 11763 (2016)' was missing. This reference has now been added to the main text and the reference list and subsequent references have been renumbered in all versions of the Article.

References

Vaezi, M., Seitz, H. & Yang, S. A review on 3D micro-additive manufacturing technologies. Int. J. Adv. Manuf. Technol. 67, 1721–1754 (2013).

Popovic, Z. D., Sprague, R. A. & Connell, G. A. N. Technique for monolithic fabrication of microlens arrays. Appl. Opt. 27, 1281–1284 (1988).

Lee, S.-K., Lee, K.-C. & Lee, S. S. A simple method for microlens fabrication by the modified LIGA process. J. Micromech. Microeng. 12, 334–340 (2002).

Lee, B.-K., Kim, D. S. & Kwon, T. H. Replication of microlens arrays by injection molding. Microsyst. Technol. 10, 531–535 (2004).

Kim, J. Y. et al. Hybrid polymer microlens arrays with high numerical apertures fabricated using simple ink-jet printing technique. Opt. Mater. Express 1, 259–269 (2011).

Völkel, R., Eisner, M. & Weible, K. J. Miniaturized imaging systems. Microelectron. Eng. 67–68, 461–472 (2003).

Kuang, D., Zhang, X., Gui, M. & Fang, Z. Hexagonal microlens array fabricated by direct laser writing and inductively coupled plasma etching on organic light emitting devices to enhance the outcoupling efficiency. Appl. Opt. 48, 974–978 (2009).

Yang, R., Wang, W. & Soper, S. A. Out-of-plane microlens array fabricated using ultraviolet lithography. Appl. Phys. Lett. 86, 1–3 (2005).

Völkel, R. et al. Technology trends of microlens imprint lithography and wafer level cameras (WL). In MOC'08, Conference on Micro-Optics. Brussels, Belgium, 25–27 September (Microoptics Group, 2008).

Hoy, C. L. et al. Miniaturized probe for femtosecond laser microsurgery and two-photon imaging. Opt. Express 16, 9996–10005 (2008).

Biehl, S., Danzebrink, R., Oliveira, P. & Aegerter, M. A. Refractive microlens fabrication by ink-jet process. J. Sol-Gel Sci. Technol. 13, 177–182 (1998).

Brückner, A. et al. Ultra-thin wafer-level camera with 720p resolution using micro-optics. In Proc. SPIE: Novel Optical Systems Design and Optimization XVII 91930W (eds Gregory, G. G. & Davis, A. J.) (SPIE, 2014).

Cumpston, B. H. et al. Two-photon polymerization initiators for three-dimensional optical data storage and microfabrication. Nature 398, 51–54 (1999).

Deubel, M. et al. Direct laser writing of three-dimensional photonic-crystal templates for telecommunications. Nature Mater. 3, 444–447 (2004).

Farsari, M. & Chichkov, B. N. Materials processing: two-photon fabrication. Nature Photon. 3, 450–452 (2009).

Sinzinger, S. & Jahns, J. Microoptics (Wiley Verlag GmbH & Co. KGaA, 2003).

Zappe, H. Fundamentals of Micro-Optics (Cambridge Univ. Press, 2010).

Malinauskas, M. et al. A femtosecond laser-induced two-photon photopolymerization technique for structuring microlenses. J. Opt. 12, 035204 (2010).

Malinauskas, M. et al. Femtosecond laser polymerization of hybrid/integrated micro-optical elements and their characterization. J. Opt. 12, 124010 (2010).

Williams, H. E., Freppon, D. J., Kuebler, S. M., Rumpf, R. C. & Melino, M. A. Fabrication of three-dimensional micro-photonic structures on the tip of optical fibers using SU-8. Opt. Express 19, 22910–22922 (2011).

Malinauskas, M., Farsari, M., Piskarskas, A. & Juodkazis, S. Ultrafast laser nanostructuring of photopolymers: a decade of advances. Phys. Rep. 533, 1–31 (2013).

Gissibl, T., Schmid, M. & Giessen, H. Spatial beam intensity shaping using phase masks on single-mode optical fibers fabricated by femtosecond direct laser writing. Optica 3, 448–451 (2016).

Gissibl, T., Thiele, S., Herkommer, A. & Giessen, H. Sub-micrometre accurate free-form optics by three-dimensional printing on single-mode fibres. Nature Commun. 7, 11763 (2016).

Han, H., Kriman, M. & Boomgarden, M. Wafer level camera technology - from wafer level packaging to wafer level integration. In 11th International Conference on Electronic Packaging Technology and High Density Packaging (IEEE, 2010).

Bückmann, T. et al. Tailored 3D mechanical metamaterials made by dip-in direct-laser-writing optical lithography. Adv. Mater. 24, 2710–2714 (2012).

Dunkel, J. et al. Fabrication of refractive freeform array masters for artificial compound eye cameras. Proc. SPIE: Micro-Optics 9130, 91300P (2014).

Kowalczyk, M., Haberko, J. & Wasylczyk, P. Microstructured gradient-index antireflective coating fabricated on a fiber tip with direct laser writing. Opt. Express 22, 12545–12550 (2014).

Blattmann, M., Ocker, M., Zappe, H. & Seifert, A. Jet printing of convex and concave polymer micro-lenses. Opt. Express 23, 24525–24536 (2015).

Zhang, W., Aljasem, K., Zappe, H. & Seifert, A. Highly flexible MTF measurement system for tunable micro lenses. Opt. Express 18, 12458–12469 (2010).

Werber, A. & Zappe, H. Tunable microfluidic microlenses. Appl. Opt. 44, 3238–3245 (2005).

Friese, C., Werber, A., Krogmann, F., Mönch, W. & Zappe, H. Materials, effects and components for tunable micro-optics. IEEJ Trans. Electr. Electron. Eng. 2, 232–248 (2007).

Song, C., Nguyen, N.-T., Tan, S.-H. & Asundi, A. K. Modelling and optimization of micro optofluidic lenses. Lab Chip 9, 1178–1184 (2009).

Michel, A. K. U. et al. Using low-loss phase-change materials for mid-infrared antenna resonance tuning. Nano Lett. 13, 3470–3475 (2013).

Yu, N. & Capasso, F. Flat optics with designer metasurfaces. Nature Mater. 13, 139–150 (2014).

Yin, X. et al. Active chiral plasmonics. Nano Lett. 15, 4255–4260 (2015).

Acknowledgements

We gratefully acknowledge financial support from the DFG (SPP1391, FOR730 and GI 269/11-1), BMBF (13N10146, PRINTOPTICS), Baden-Württemberg Stiftung (Internationale Spitzenforschung II and Intelligente Optische Sensorik) and ERC (COMPLEXPLAS). We would like to thank B. Frank for performing atomic force microscope measurements and T. Mappes from Carl Zeiss AG for help with the lens characterization. We would like to thank M. Grauer for strong support.

Author information

Authors and Affiliations

Contributions

T.G., S.T. and H.G. conceived the concept. T.G. performed simulations, structural designs, direct laser writing and experimental characterization. S.T. and A.H. were responsible for optical and structural design. H.G. participated in planning the experiments and supervised the project. All authors participated in discussions and contributed to writing of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary information

Supplementary information (PDF 791 kb)

Rights and permissions

About this article

Cite this article

Gissibl, T., Thiele, S., Herkommer, A. et al. Two-photon direct laser writing of ultracompact multi-lens objectives. Nature Photon 10, 554–560 (2016). https://doi.org/10.1038/nphoton.2016.121

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nphoton.2016.121

This article is cited by

-

Direct laser-written optomechanical membranes in fiber Fabry-Perot cavities

Nature Communications (2024)

-

Real time full-color imaging in a Meta-optical fiber endoscope

eLight (2023)

-

Overcoming delamination in two-photon lithography for improving fabrication of 3D microstructures

Micro and Nano Systems Letters (2023)

-

Apochromatic X-ray focusing

Light: Science & Applications (2023)

-

3D-patterned inverse-designed mid-infrared metaoptics

Nature Communications (2023)