Abstract

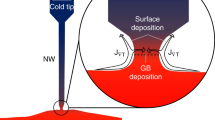

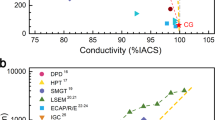

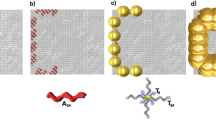

The welding of metals at the nanoscale is likely to have an important role in the bottom-up fabrication of electrical and mechanical nanodevices. Existing welding techniques use local heating, requiring precise control of the heating mechanism and introducing the possibility of damage. The welding of metals without heating (or cold welding) has been demonstrated, but only at macroscopic length scales and under large applied pressures. Here, we demonstrate that single-crystalline gold nanowires with diameters between 3 and 10 nm can be cold-welded together within seconds by mechanical contact alone, and under relatively low applied pressures. High-resolution transmission electron microscopy and in situ measurements reveal that the welds are nearly perfect, with the same crystal orientation, strength and electrical conductivity as the rest of the nanowire. The high quality of the welds is attributed to the nanoscale sample dimensions, oriented-attachment mechanisms and mechanically assisted fast surface-atom diffusion. Welds are also demonstrated between gold and silver, and silver and silver, indicating that the technique may be generally applicable.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Opening remarks. J. Am. Welding Soc. 1, 3 (1919).

Freitas, R. A. & Gilbreath, W. P. (eds) Advanced Automation for Space Missions: Proceedings of the 1980 NASA/ASEE Summer Study, Appendix 4C.1. (NASA, 1980).

Ferguson, G. S., Chaudhury, M. K., Sigal, G. B. & Whitesides, G. M. Contact adhesion of thin gold films on elastomeric supports: cold welding under ambient conditions. Science 253, 776–778 (1991).

Kim, C., Burrows, P. E. & Forrest, S. R. Micropatterning of organic electronic devices by cold-welding. Science 288, 831–833 (2000).

Jin, C., Suenaga, K. & Iijima, S. Plumbing carbon nanotubes. Nature Nanotech. 3, 17–21 (2008).

Wang, M., Wang, J., Chen, Q. & Peng, L. M. Fabrication and electrical and mechanical properties of carbon nanotube interconnections. Adv. Funct. Mater. 15, 1825–1831 (2005).

Hirayama, H., Kawamoto, Y., Hayashi, H. & Takayanagi, K. Nanospot welding of carbon nanotubes. Appl. Phys. Lett. 79, 1169–1171 (2001).

Madsen, D. N. et al. Soldering of nanotubes onto microelectrodes. Nano Lett. 3, 47–49 (2003).

Wu, Y. & Yang, P. Melting and welding semiconductor nanowires in nanotubes. Adv. Mater. 13, 520–523 (2001).

Dong, L., Tao, X., Zhang, L., Zhang, X. & Nelson, B. J. Nanorobotic spot welding: controlled metal deposition with attogram precision from copper-filled carbon nanotubes. Nano Lett. 7, 58–63 (2007).

Misra, A. & Daraio, C. Sharp carbon-nanotube tips and carbon-nanotube soldering irons. Adv. Mater. 20, 1–4 (2008).

Rodríguez-Manzo, J. A. et al. Heterojunctions between metals and carbon nanotubes as ultimate nanocontacts. Proc. Natl Acad. Sci. USA 106, 4591–4595 (2009).

Xu, S. et al. Nanometer-scale modification and welding of silicon and metallic nanowires with a high-intensity electron beam. Small 1, 1221–1229 (2005).

Tohmyoh, H., Imaizumi, T., Hayashi, H. & Saka, M. Welding of Pt nanowires by Joule heating. Scripta Mater. 57, 953–956 (2007).

van Huis, M. A. et al. Low-temperature nanocrystal unification through rotations and relaxations probed by in situ transmission electron microscopy. Nano Lett. 8, 3959–3963 (2008).

Kizuka, T., Yamada, K., Deguchi, S., Naruse, M. & Tanaka, N. Time-resolved high-resolution electron microscopy of atomic scale solid-state direct bonding of gold tips. J. Electron Microsc. 46, 151–160 (1997).

Tohmyoh, H. A governing parameter for the melting phenomenon at nanocontacts by Joule heating and its application to joining together two thin metallic wires. J. Appl. Phys. 105, 014907 (2009).

Kim, S. J. & Jang, D. J. Laser-induced nanowelding of gold nanoparticles. Appl. Phys. Lett. 86, 033112 (2005).

Moskalenko, A. V., Burbridge, D. J., Viau, G. & Gordeev, S. N. Electron-beam-induced welding of 3D nano-objects from beneath. Nanotechnology 18, 025304 (2007).

Peng, Y., Cullis, T. & Inkson, B. Bottom-up nanoconstruction by the welding of individual metallic nanoobjects using nanoscale solder. Nano Lett. 9, 91–96 (2009).

Gu, Z., Ye, H., Smirnova, D., Small, D. & Gracias, D. H. Reflow and electrical characteristics of nanoscale solder. Small 2, 225–229 (2006).

Lu, W. & Lieber, C. M. Nanoelectronics from the bottom up. Nature Mater. 6, 841–850 (2007).

Ji, C. & Searson, P. C. Synthesis and characterization of nanoporous gold nanowires. J. Phys. Chem. B 107, 4494–4499 (2003).

Wang, C., Hu, Y., Lieber, C. M. & Sun, S. Ultrathin Au nanowires and their transport properties. J. Am. Chem. Soc. 130, 8902–8903 (2008).

Howatson, A. M., Lund, P. G. & Todd, J. D. Engineering Tables and Data 41, 2nd edn (Chapman and Hall, 1991).

Gall, K., Diao, J., Agrait, N. & Dunn, M. L. The strength of gold nanowires. Nano. Lett. 4, 2431–2436 (2004).

Wu, B., Heidelberg, A. & Boland, J. J. Mechanical properties of ultrahigh-strength gold nanowires. Nature Mater. 4, 525–529 (2005).

Ramsperger, U., Uchihashi, T. & Nejoh, H. Fabrication and lateral electronic transport measurements of gold nanowires. Appl. Phys. Lett. 78, 85–87 (2001).

Calleja, M., Tello, M., Anguita, J., Garcia, F. & Garcia, R. Fabrication of gold nanowires on insulating substrates by field-induced mass transport. Appl. Phys. Lett. 79, 2471–2473 (2001).

Song, J. H., Wu, Y., Messer, B., Kind, H. & Yang, P. Metal nanowire formation using Mo3Se3− as reducing and sacrificing templates. J. Am. Chem. Soc. 123, 10397–10398 (2001).

José-Yacaman, M. et al. Surface diffusion and coalescence of mobile metal nanoparticles. J. Phys. Chem. B 109, 9703–9711 (2005).

Rez, P. & Glaisher, R. W. Measurement of energy deposition in transmission electron microscopy. Ultramicroscopy 35, 65–69 (1991).

Kizuka, T. Atomic process of point contact in gold studied by time-resolved high-resolution transmission electron microscopy. Phys. Rev. Lett. 81, 4448–4451 (1998).

Sanders, D. E. & DePristo, A. E. Predicted diffusion rates on fcc (001) metal surfaces for adsorbate/substrate combinations of Ni, Cu, Rh, Pd, Ag, Pt, Au. Surf. Sci. 260, 116–128 (1992).

Cho, K. S., Talapin, D. V., Gaschler, W. & Murray, C. B. Designing PbSe nanowires and nanorings through oriented attachment of nanoparticles. J. Am. Chem. Soc. 127, 7140–7147 (2005).

Zhong, Z., Wang, D., Cui, Y., Bockrath, M. W. & Lieber, C. M. Nanowire crossbar arrays as address decoders for integrated nanosystems. Science 302, 1377–1379 (2003).

Whang, D., Jin, S., Wu, Y. & Lieber, C. M. Large-scale hierarchical organization of nanowire arrays for integrated nanosystems. Nano Lett. 3, 1255–1259 (2003).

Huo, F. et al. Polymer pen lithography. Science 321, 1658–1660 (2008).

Acknowledgements

Y.L. and J.L. acknowledge the financial support provided by the Air Force Office of Sponsored Research (AFOSR) YIP award FA9550-09-1-0084 and by National Science Foundation (NSF) grant ECCS-0702766. This work was performed, in part, at the Center for Integrated Nanotechnologies, a US Department of Energy, Office of Basic Energy Sciences user facility. Sandia National Laboratories is a multiprogram laboratory operated by Sandia Corporation, a Lockheed-Martin Company, for the US Department of Energy under contract no. DE-AC04-94AL85000.

Author information

Authors and Affiliations

Contributions

Y.L., J.H. and J.L. conceived and designed the experiments. Y.L. performed the experiments. Y.L., J.H. and J.L. analysed the data. C.W. and S.S. supplied materials. Y.L. and J.L. composed the manuscript. All authors discussed the results and edited the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary information

Supplementary information (PDF 621 kb)

Supplementary information

Supplementary information (MOV 5405 kb)

Supplementary information

Supplementary information (MOV 15115 kb)

Supplementary information

Supplementary information (MOV 14273 kb)

Rights and permissions

About this article

Cite this article

Lu, Y., Huang, J., Wang, C. et al. Cold welding of ultrathin gold nanowires. Nature Nanotech 5, 218–224 (2010). https://doi.org/10.1038/nnano.2010.4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nnano.2010.4

This article is cited by

-

Composition design for modified nickel nanopastes containing a low-melting element as additive for pressureless nanojoining

Welding in the World (2024)

-

Autonomous healing of fatigue cracks via cold welding

Nature (2023)

-

Ultralarge-scale anomalous phase separation discovered in a Cr-Fe-Co-Ni-Zr high-entropy metallic glass system

Science China Materials (2023)

-

Investigation of the effect of wall material on the exchange of information between fluid and surface using the hybrid atomistic-continuum method

Computational Particle Mechanics (2023)

-

Tensile Strength of Thin Pt Wires Welded by Joule Heat

Journal of Materials Engineering and Performance (2023)