Abstract

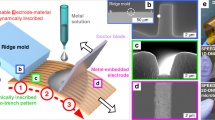

Several techniques for the direct printing of functional materials have been developed to fabricate micro- and nanoscale structures and devices. We report a new direct patterning method, liquid-bridge-mediated nanotransfer moulding, for the formation of two- or three-dimensional structures with feature sizes as small as tens of nanometres over large areas up to 4 inches across. Liquid-bridge-mediated nanotransfer moulding is based on the direct transfer of various materials from a mould to a substrate through a liquid bridge between them. We demonstrate its usefulness by fabricating nanowire field-effect transistors and arrays of pentacene thin-film transistors.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Wallraff, G. M. & Hinsberg, W. D. Lithographic imaging techniques for the formation of nanoscopic features. Chem. Rev. 99, 1801–1822 (1999).

Yao, J. J. RF MEMS from a device perspective. J. Micromech. Microeng. 10, R9–R38 (2000).

Walker, J. A. The future of MEMS in telecommunications networks. J. Micromech. Microeng. 10, R1–R7 (2000).

Spearing, S. M. Materials issue in microelectromechanical systems (MEMS). Acta Mater. 48, 179–196 (2000).

Dong, Y. & Shannon, C. Heterogeneous immunosensing using antigen and antibody monolayers on gold surfaces with electrochemical and scanning probe detection. Anal. Chem. 72, 2371–2376 (2000).

Lahiri, J., Isaacs, L., Tien, J. & Whitesides, G. M. A strategy for the generation of surfaces presenting ligands for studies of binding based on an active ester as a common reactive intermediate: a surface plasmon resonance study. Anal. Chem. 71, 777–790 (1999).

Sirkar, K., Revzin, A. & Pishko, M. V. Glucose and lactate biosensors based on redox polymer/oxidoreductase nanocomposite thin films. Anal. Chem. 72, 2930–2936 (2000).

Wells, M. & Crooks, R. M. Interactions between organized, surface-confined monolayers and vapor-phase probe molecules. 10. Preparation and properties of chemically sensitive dendrimer surfaces. J. Am. Chem. Soc. 118, 3988–3989 (1996).

Beebe, D. J. et al. Microfluidic tectonics: a comprehensive construction platform for microfluidic systems. Proc. Natl Acad. Sci. USA 97, 13488–13493 (2000).

Beebe, D. J., Mensing, G. A. & Walker, G. M. Physics and applications of microfluidics in biology. Annu. Rev. Biomed. Eng. 4, 261–286 (2002).

Rossier, J., Reymond, F. & Michel, P. E. Polymer microfluidic chips for electrochemical and biochemical analyses. Electrophoresis 23, 858–867 (2002).

Becker, H. & Gartner, C. Polymer microfabrication methods for microfluidic analytical applications. Electrophoresis 21, 12–26 (2000).

Maes, H. E. et al. Trends in microelectronics, optical detectors, and biosensors. Adv. Eng. Mater. 3, 781–787 (2001).

Sirringhaus, H. et al. High-resolution inkjet printing of all-polymer transistor circuits. Science 290, 2123–2126 (2000).

Pardo, D. A., Jabbour, G. E. & Peyghambarian, N. Application of screen printing in the fabrication of organic light-emitting devices. Adv. Mater. 12, 1249–1252 (2000).

Harri, L. Microscopic studies of the influence of main exposure time on parameters of flexographic printing plate produced by digital thermal method. Microsc. Res. Tech. 72, 707–716 (2009).

Kopola, P., Tuomikoski, M., Suhonen, R. & Maaninen, A. Gravure printed organic light emitting diodes for lighting applications. Thin Solid Films 517, 5757–5762 (2009).

Kittila, M., Hagberg, J., Jakku, E. & Leppavuori, S. Direct gravure printing (DGP) method for printing fine-line electrical circuits on ceramics. IEEE Trans. Electron. Packag. Manuf. 27, 109–114 (2004).

Pudas, M., Hagberg, J. & Leppavuori, S. Printing parameters and ink components affecting ultra-fine-line gravure-offset printing for electronics applications. J. Eur. Ceram. Soc. 24, 2943–2950 (2004).

Zielke, D. et al. Polymer-based organic field-effect transistor using offset printed source/drain structures. Appl. Phys. Lett. 87, 123508 (2005).

Pudas, M., Hagberg, J. & Leppavuori, S. Roller-type gravure offset printing of conductive inks for high-resolution printing on ceramic substrates. Int. J. Electron. 92, 251–269 (2005).

Zhao, X.-M., Xia, Y. & Whitesides, G. M. Fabrication of three-dimensional micro-structures: microtransfer molding. Adv. Mater. 8, 837–840 (1996).

Yang, H., Deschatelets, P., Brittain, S. T. & Whitesides, G. M. Fabrication of high performance ceramic microstructures from a polymeric precursor using soft lithography. Adv. Mater. 13, 54–58 (2001).

Leung, W. Y. et al. Fabrication of photonic band gap crystal using microtransfer molded templates. J. Appl. Phys. 93, 5866–5870 (2003).

Thibault, C., Severac, C., Trévisiol, E. & Vieu, C. Microtransfer molding of hydrophobic dentrimer. Microelectron. Eng. 83, 1513–1516 (2006).

Kim, M. J., Song, S. & Lee, H. H. A two-step dewetting method for large-scale patterning. J. Micromech. Microeng. 16, 1700–1704 (2006).

Kraus, T. et al. Nanoparticle patterning with single-particle resolution. Nature Nanotech. 2, 570–576 (2007).

Gates, B. D. et al. New approaches to nanofabrication: molding, printing, and other techniques. Chem. Rev. 105, 1171–1196 (2005).

Guo, L. J. Nanoimprint lithography: methods and material requirements. Adv. Mater. 19, 495–513 (2007).

Rolland, J. P. Direct fabrication and harvesting of monodisperse, shape-specific nanobiomaterials. J. Am. Chem. Soc. 127, 10096–10100 (2005).

Yang, K.-Y., Yoon, K.-M., Choi, K.-W. & Lee, H. The direct nano-patterning of ZnO using nanoimprint lithography with ZnO-sol and thermal annealing. Microelectron. Eng. 86, 2228–2231 (2009).

Ko, S. H. et al. Direct nanoimprinting of metal nanoparticles for nanoscale electronics fabrication. Nano Lett. 7, 1869–1877 (2007).

Suh, K. Y. & Lee, H. H. Capillary force lithography: large-area patterning, self-organization, and anisotropic dewetting. Adv. Funct. Mater. 12, 405–413 (2002).

Duan, X. et al. Nanopatterning by an integrated process combining capillary force lithography and microcontact printing. Adv. Funct. Mater. 20, 663–668 (2010).

Loo, Y. -L., Willett, R. L., Baldwind, K. W. & Rogers, J. A. Interfacial chemistries for nanoscale transfer printing. J. Am. Chem. Soc. 124, 7654–7655 (2002).

Zaumseil, J. et al. Three-dimensional and multilayer nanostructures formed by nanotransfer printing. Nano Lett. 3, 1223–1227 (2003).

Rogers, J. A. & Nuzzo, R. G. Recent progress in soft lithography. Mater. Today 8, 50–56 (February 2005).

Lee, B. H. et al. High-resolution patterning of aluminum thin films with a water-mediated transfer process. Adv. Mater. 19, 1714–1718 (2007).

Oh, K. et al. Water-mediated Al metal transfer printing with contact inking for fabrication of thin-film transistors. Small 5, 558–561 (2009).

Jackman, R. J. Fabricating large arrays of microwells with arbitrary dimensions and filling them using discontinuous dewetting. Anal. Chem. 70, 2280–2287 (1998).

Merkel, T. C., Bondar, V. I., Nagai, K., Freeman, B. D. & Pinnau, I. Gas sorption, diffusion, and permeation in poly(dimethylsiloxane). J. Polym. Sci. B 38, 415–434 (2000).

Kim, Y. S., Lee, H. H. & Hammond, P. T. High density nanostructure transfer in soft molding using polyurethane acrylate molds and polyelectrolyte multilayers. Nanotechnology 14, 1140–1144 (2003).

Kim, J. S. et al. Fabrication of nanowire polarizer by using nanoimprint lithography. J. Korean Phys. Soc. 45, 890–892 (2004).

Jeong, S., Jeong, Y. & Moon, J. Solution-processed zinc tin oxide semiconductor for thin-film transistors. J. Phys. Chem. C 112, 11082–11085 (2008).

Kim, D. et al. Inkjet-printed zinc tin oxide thin-film transistor. Langmuir 25, 11149–11154 (2009).

Kim, D. et al. All-solution-processed bottom-gate organic oxide thin-film transistor with improved subthreshold behavior using functionalized pentacene active layer. J. Phys. D 42, 115107 (2009).

Anthony, J. E., Brooks, J. S., Eaton, D. L. & Parkin, S. R. Functionalized pentacene: improved electronic properties from control of solid-state order. J. Am. Chem. Soc. 123, 9482–9483 (2001).

Anthony, J. E., Eaton, D. L. & Parkin, S. R. A road map to stable, soluble, easily crystallized pentacene derivatives. Org. Lett. 4, 15–18 (2002).

Ishizaka, A. & Shiraki, Y. Low temperature surface cleaning of silicon and its application to silicon MBE. J. Electrochem. Soc. 133, 666–671 (1986).

Acknowledgements

This work was supported by the National Research Foundation of Korea (2009-0092807; 2010-0019125; 2009-0086302), the Seoul R&BD programme (ST090839), the IT R&D program of MKE/KEIT (10030559) and the Korea Research Foundation (KRF-2007-313-C00383).

Author information

Authors and Affiliations

Contributions

M.M.S. conceived and designed the experiments. J.K.H., E.B.K., S.C. and J.M.D. performed the experiments. K.S. and J.M. contributed to materials and analysis. S.C. and M.M.S. co-wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary information

Supplementary information (PDF 1431 kb)

Rights and permissions

About this article

Cite this article

Hwang, J., Cho, S., Dang, J. et al. Direct nanoprinting by liquid-bridge-mediated nanotransfer moulding. Nature Nanotech 5, 742–748 (2010). https://doi.org/10.1038/nnano.2010.175

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nnano.2010.175

This article is cited by

-

Nanofabrication for all-soft and high-density electronic devices based on liquid metal

Nature Communications (2020)

-

Controlled open-cell two-dimensional liquid foam generation for micro- and nanoscale patterning of materials

Nature Communications (2019)

-

Review on flexible photonics/electronics integrated devices and fabrication strategy

Science China Information Sciences (2018)

-

Broadband omnidirectional light detection in flexible and hierarchical ZnO/Si heterojunction photodiodes

Nano Research (2017)

-

Controlled Growth of Rubrene Nanowires by Eutectic Melt Crystallization

Scientific Reports (2016)