Abstract

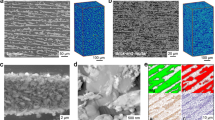

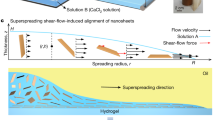

Finding a synthetic pathway to artificial analogs of nacre and bones represents a fundamental milestone in the development of composite materials. The ordered brick-and-mortar arrangement of organic and inorganic layers is believed to be the most essential strength- and toughness-determining structural feature of nacre. It has also been found that the ionic crosslinking of tightly folded macromolecules is equally important. Here, we demonstrate that both structural features can be reproduced by sequential deposition of polyelectrolytes and clays. This simple process results in a nanoscale version of nacre with alternating organic and inorganic layers. The macromolecular folding effect reveals itself in the unique saw-tooth pattern of differential stretching curves attributed to the gradual breakage of ionic crosslinks in polyelectrolyte chains. The tensile strength of the prepared multilayers approached that of nacre, whereas their ultimate Young modulus was similar to that of lamellar bones. Structural and functional resemblance makes clay– polyelectrolyte multilayers a close replica of natural biocomposites. Their nanoscale nature enables elucidation of molecular processes occurring under stress.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Sarikaya, M. & Aksay, I.A. Design and Processing of Materials by Biomimetics (American Institute of Physics, 1995).

Aksay, I.A. et al. Biomimetic pathways for assembling inorganic thin films. Science 273, 892–898 ( 1996).

Sellinger, A. et al. Continuous self-assembly of organic–inorganic nanocomposite coatings that mimic nacre. Nature 394, 256–260 ( 1998).

Smith, B.L. et al. Molecular mechanistic origin of the toughness of natural adhesives, fibres and composites. Nature 399, 761–763 ( 1999).

Atlan, G. et al. Interface between bone and nacre implant in sheep. Biomaterials 20, 1017–1022 ( 1999).

Mann, S. Molecular recognition in biomineralization. Nature 332, 119–124 ( 1988).

Addadi, L. & Weiner, S. Biomineralization: Crystals, asymmetry and life. Nature 411, 753–755 ( 2001).

Tirrell, M., Kokkoli, E. & Biesalski, M. The role of surface science in bioengineered materials. Surf. Sci. 500, 61–83 ( 2002).

LeBaron, P.C., Wang, Z. & Pinnavaia, T.J. Polymer-layered silicate nanocomposites: an overview. Appl. Clay Sci. 15, 11–29 ( 1999).

Schmidt, D., Shah, D. & Giannelis, E.P. New advances in polymer/layered silicate nanocomposites. Curr. Opin. Solid State Mater. Sci. 6, 205–212 ( 2002).

Ozin, G.A. Morphogenesis of biomineral and morphosynthesis of biomimetic forms. Acc. Chem. Res. 30, 17–27 ( 1997).

Messersmith, P.B. & Giannelis, E.P. Synthesis and characterization of layered silicate-epoxy nanocomposites. Chem. Mater. 6, 1719–1725 ( 1994).

Ray, S.S., Yamada, K., Okamoto, M. & Ueda, K. Polylactide-layered silicate nanocomposite: a novel biodegradable material. Nano Lett. 2, 1093–1096 ( 2002).

Manias, E. et al. Polypropylene/montmorillonite nanocomposites. Review of the synthetic routes and materials properties. Chem. Mater. 13, 3516–3523 ( 2001).

Wang, R.Z., Suo, Z., Evans, A.G., Yao, N. & Aksay, I.A. Deformation mechanism in nacre. J. Mater. Res. 16, 2485–2493 ( 2001).

Thompson, J.B. et al. Bone indentation recovery time correlates with bond reforming time. Nature 414, 773–776 ( 2001).

Levi-Kalisman, Y., Falini, G., Addadi, L. & Weiner, S. Structure of the nacreous organic matrix of a bivalve mollusk shell examined in the hydrated state using cryo-TEM. J. Struct. Biol. 135, 8–17 ( 2001).

Lu, Y. et al. Self-assembly of mesoscopically ordered chromatic polydiacetylene/silica nanocomposites. Nature 410, 913–917 ( 2001).

Antonietti, M. New polymers for molecular biotechnology. Rev. Molec. Biotechnol. 90, 1–2 ( 2002).

Fendler, J.H. Biomineralization inspired preparation of nanoparticles and nanoparticulate films. Curr. Opin. Solid State Mater. Sci. 2, 365–369 ( 1997).

Almqvist, N. et al. Methods for fabricating and characterizing a new generation of biomimetic materials. Mater. Sci. Eng. C 7, 37–43 ( 1999).

Decher, G. Fuzzy nanoassemblies toward layered polymeric multicomposites. Science 277, 1232–1237 ( 1997).

Lvov, Y., Haas, H., Decher, G., Möhwald, H. & Kalachev, A. Assembly of polyelectrolyte molecular films onto plasma-treated glass. J. Phys. Chem. 97, 12835–12841 ( 1993).

Kotov, N.A. Ordered layered assemblies of nanoparticles. Mater. Res. Bull. 26, 992–997 ( 2001).

Ferreira, M., Cheung, J.H. & Rubner, M.F. Molecular self-assembly of conjugated polyions: a new process for fabricating multilayer thin film heterostructures. Thin Solid Films 244, 806–809 ( 1994).

Kleinfeld, E.R. & Ferguson, G.S. Stepwise formation of multilayered nanostructural films from macromolecular precursors. Science 265, 370–373 ( 1994).

Kotov, N.A. et al. Mechanism of and defect formation in the self assembly of polymeric polycation montmorillonite ultrathin films. J. Amer. Chem. Soc. 119, 6821–6832 ( 1997).

Keller, S.W., Kim, H.N. & Mallouk, T.E. Layer-by-layer assembly of intercalation compounds and heterostructures on surfaces: toward molecular “beaker” epitaxy. J. Am. Chem. Soc. 116, 8817–8818 ( 1994).

Glinel, K., Laschewsky, A. & Jonas, A.M. Ordered polyelectrolyte “multilayers”. 4. Internal structure of clay-based multilayers. J. Phys. Chem. B 106, 11246–11252 ( 2002).

Glinel, K., Laschewsky, A. & Jonas, A.M. Ordered polyelectrolyte “multilayers”. 3. Complexing clay platelets with polycations of varying structure. Macromolecules 34, 5267–5274 ( 2001).

Biswas, M. & Ray, S.S. Recent progress in synthesis and evaluation of polymer-montmorillonite nanocomposites. Adv. Polym. Sci. 155, 167–221 ( 2001).

Wang, L. & Kanatzidis, M.G. Laminated TaS2/polymer nanocomposites through encapsulative precipitation of exfoliated layers. Chem. Mater. 13, 3717–3727 ( 2001).

LeBaron, P.C., Wang, Z. & Pinnavaia, T.J. Polymer-layered silicate nanocomposites: an overview. Appl. Clay Sci. 15, 11–29 ( 1999).

Mamedov, A.A. et al. Molecular design of strong SWNT/polyelectrolyte multilayers composites. Nature Mater. 1, 190–194 ( 2002).

Hsieh, M.C., Farris, R.J. & McCarthy, T.J. Mechanical properties of layer-by-layer deposited polyelectrolyte assemblies. PMSE-059 Abstracts of 218th ACS National Meeting, New Orleans, August 22–26 1999 218, 136–137 ( 1999).

Gao, C., Donath, E., Moya, S., Dudnik, V. & Möhwald, H. Elasticity of hollow polyelectrolyte capsules prepared by the layer-by-layer technique. Eur. Phys. J. E. 5, 21–27 ( 2001).

Evans, A.G. et al. Model for the robust mechanical behavior of nacre. J. Mater. Res. 16, 2475–2484 ( 2001).

Weiner, S. & Wagner, H.D. The material bone: Structure-mechanical function relations. Annu. Rev. Mater. Sci. 28, 271–298 ( 1998).

Katti, D.R., Katti, K.S., Sopp, J.M. & Sarikaya, M. 3D finite element modeling of mechanical response in nacre-based hybrid nanocomposites. Comput. Theor. Polym. Sci. 11, 397–404 ( 2001).

Hackett, E., Manias, E. & Giannelis, E.P. Computer simulation studies of PEO/layer silicate nanocomposites. Chem. Mater. 12, 2161–2167 ( 2000).

Zax, D.B. et al. Dynamical heterogeneity in nanoconfined poly(styrene) chains. J. Chem. Phys. 112, 2945–2951 ( 2000).

Acknowledgements

N.A.K. thanks the financial support of this project from the National Science Foundation (NSF) CAREER, NSF-Biophotonics, Air Force Office of Scientific Research (AFOSR), Oklahoma Center for Advancement of Science and Technology (OCAST) and Nomadics. The authors are grateful to Arif Mamedov (Nomadics) for LBL consultations, R. Ruoff, F. Fisher, and P. Messersmith (Northwestern University) for helpful critical suggestions and to Phoebe Doss (Oklahoma State University) for assistance with TEM and SEM.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Figure S1 Effect of delaminating agent on the structure of the multilayers.

Figure S2 Optical microphotograph of the broken edge in (P/C)100 film. (PDF 1811 kb)

Rights and permissions

About this article

Cite this article

Tang, Z., Kotov, N., Magonov, S. et al. Nanostructured artificial nacre. Nature Mater 2, 413–418 (2003). https://doi.org/10.1038/nmat906

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat906

This article is cited by

-

Heterostructured metal matrix composites for structural applications: a review

Journal of Materials Science (2024)

-

Bending response and energy dissipation of interlayer slidable friction booklike-plates

Acta Mechanica Sinica (2023)

-

Nanostructured block copolymer muscles

Nature Nanotechnology (2022)

-

Self-assembled inorganic chiral superstructures

Nature Reviews Chemistry (2022)

-

Behaviors of Removing Diesel Oil from Water with PS/Ti4O7 Composite Nanofibers: Modeling Diesel Oil Sorption Capacity for Tap Water and Investigation of the Effects of pH on Sorption at Different Temperatures for Times

Arabian Journal for Science and Engineering (2022)