Abstract

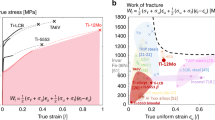

Dislocation-based deformation in crystalline solids is almost always plastic. Here we show that polycrystalline samples of Ti3SiC2 loaded cyclically at room temperature, in compression, to stresses up to 1 GPa, fully recover on the removal of the load, while dissipating about 25% (0.7 MJ m−3) of the mechanical energy. The stress–strain curves outline fully reversible, rate-independent, closed hysteresis loops that are strongly influenced by grain size, with the energy dissipated being significantly larger in the coarse-grained material. At temperatures greater than 1,000 °C, the loops are open, the response is strain-rate dependent, and cyclic hardening is observed. This hitherto unreported phenomenon is attributed to the reversible formation and annihilation of incipient kink bands at room-temperature deformation. At higher temperatures, the incipient kink bands dissociate and coalesce to form regular irreversible kink bands. The loss factor for Ti3SiC2 is higher than most woods, and comparable to polypropylene and nylon. The technological implications of having a stiff, lightweight machinable ceramic that can dissipate up to 25% of the mechanical energy per cycle are discussed.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Barsoum, M.W. The MN+1AXN phases: A new class of solids: thermodynamically stable nanolaminates. Prog. Solid State Chem. 28, 201–281 (2000).

Nowotny, H. Struktuchemie Einiger Verbindungen der Ubergangsmetalle mit den elementen C, Si, Ge, Sn. Prog. Solid State Chem. 2, 27 (1970).

Pietzka, M.A. & Schuster, J.C. Summary of constitution data of the system Al-C-Ti. J. Phase Equilib. 15, 392–400 (1994).

Rawn, C.J. et al. Structure of Ti4AlN3−x- a layered Mn+1AXn nitride. Mater. Res. Bull. 35, 1785–1796 (2000).

Barsoum, M.W. & El-Raghy, T. Synthesis and characterization of a remarkable ceramic: Ti3SiC2 . J. Am. Ceram. Soc. 79, 1953–1956 (1996).

Pampuch, R., Lis, J., Stobierski, L. & Tymkiewicz, M. Solid combustion synthesis of Ti3SiC2 . J. Eur. Ceram. Soc. 5, 283–287 (1989).

Finkel, P., Barsoum, M.W. & El-Raghy, T. Low temperature dependencies of the elastic properties of Ti3Al1.1C1.8, Ti4AlN3 & Ti3SiC2 . J. Appl. Phys. 87, 1701–1703 (2000).

Gilbert C.J. et al. Fatigue-crack growth and fracture properties of coarse and fine-grained Ti3SiC2 . Scripta Mater. 42, 761–767 (2000).

Radovic, M., Barsoum, M.W., El-Raghy, T. & Wiederhorn, S. Tensile creep of fine-grained (3–5 μm) Ti3SiC2 in the 1000–1200 °C temperature range. Acta Mater. 49, 4103–4112 (2001).

Radovic, M., Barsoum, M.W., El-Raghy, T., Wiederhorn, S. & Luecke, W. Effect of temperature, strain rate and grain size on the mechanical response of Ti3SiC2 in tension. Acta Mater. 50 1297–1306 (2002).

Farber, L., Levin, I. & Barsoum, M.W. HRTEM study of a low-angle boundary in plastically deformed Ti3SiC2 . Phil. Mag. Lett. 79, 163–170 (1999).

Barsoum, M.W., Farber, L. & El-Raghy, T. Dislocations, kink banks and room temperature plasticity of Ti3SiC2 . Metall. Mater. Trans. A 30, 1727–1738 (1999).

Barsoum, M.W. & El-Raghy, T. Room temperature ductile carbides. Metall. Mater. Trans. A 30, 363–369 (1999).

El-Raghy, T. & Barsoum, M.W. Processing and mechanical properties of Ti3SiC2: Part I: Reaction path and microstructure evolution. J. Am. Ceram. Soc. 82, 2849–54 (1999).

El-Raghy, T., Barsoum, M.W., Zavaliangos, A. & Kalidindi, S.R. Processing and mechanical properties of Ti3SiC2: II, Effect of grain size and deformation temperature. J. Am. Ceram. Soc. 82, 2855–2860 (1999).

Li, J–F., Pan, W., Sato, F. & Watanabe, R. Mechanical properties of polycrystalline Ti3SiC2 at ambient and elevated temperatures. Acta. Mater. 49, 937–945 (2001).

Orowan, E. A type of plastic deformation new in metals. Nature 149, 463–464 (1942).

Hess, J.B. & Barrett, C.S. Structure and nature of kink bands in zinc. Trans. Am. Inst. Min. Eng. 185, 599–606 (1949).

Frank, F.C. & Stroh, A.N. On the theory of kinking. Proc. Phys. Soc. 65, 811–821 (1952).

Nowick, A.S. & Berry, B.S. Anelastic Relaxation in Crystalline Solids (Academic, New York, 1972).

Schaller, R., Fantozzi, G. & Gremaud, G. (eds) Mechanical Spectroscopy 2001 (Trans. Tech., Zürich, Switzerland, 2001).

Roberts, J.M. & Brown, N. Low frequency friction in zinc single crystals. Acta. Metall. 10, 430–441 (1962).

Washburn, J. & Roper, E.R. Kinking in Zn single crystal tension specimens. J. Metals 1076–1078 (1952).

El-Danaf, E., Kalidindi, S.R. & Doherty, R.D. Influence of grain size and stacking fault energy and on deformation twinning in FCC metals. Metall. Mater. Trans. A 30, 1223–1233 (1999).

Inokuti Y. & Cantor, B. Acta Metall. 30, 343–356 (1982).

Acknowledgements

The authors would like to thank Y. Gogotsi of Drexel University for his critical reading of the paper. This work was funded by the Army Research Office (DAAD19-00-1-0435) and the Division of Materials Research of the National Science Foundation (DMR-0072067).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Barsoum, M., Zhen, T., Kalidindi, S. et al. Fully reversible, dislocation-based compressive deformation of Ti3SiC2 to 1 GPa. Nature Mater 2, 107–111 (2003). https://doi.org/10.1038/nmat814

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat814

This article is cited by

-

Mechanical properties of SPS-processed Cr2AlC MAX phase with different impurity contents

Emergent Materials (2023)

-

Rational Synthesis of Mixed Metal Oxide Clusters Supported on a Partially Etched MAX Phase for Efficient Electrocatalytic CO2 Conversion

Topics in Catalysis (2022)

-

Laser Additive Manufacturing on Metal Matrix Composites: A Review

Chinese Journal of Mechanical Engineering (2021)

-

The rise of plastic deformation in boron nitride ceramics

Science China Materials (2021)

-

Thermo-Mechanical Simulation of Self-Heating of a High-Power Diode Made of Ti3SiC2 (MAX) Phase-on-4H-SiC Substrate

Journal of Thermal Science (2021)