Abstract

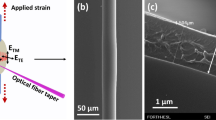

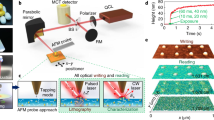

Spider silk is a tough, elastic and lightweight biomaterial, although there is a lack of tools available for non-invasive processing of silk structures. Here we show that nonlinear multiphoton interactions of silk with few-cycle femtosecond pulses allow the processing and heterostructuring of the material in ambient air. Two qualitatively different responses, bulging by multiphoton absorption and plasma-assisted ablation, are observed for low- and high-peak intensities, respectively. Plasma ablation allows us to make localized nanocuts, microrods, nanotips and periodic patterns with minimal damage while preserving molecular structure. The bulging regime facilitates confined bending and microwelding of silk with materials such as metal, glass and Kevlar with strengths comparable to pristine silk. Moreover, analysis of Raman bands of microwelded joints reveals that the polypeptide backbone remains intact while perturbing its weak hydrogen bonds. Using this approach, we fabricate silk-based functional topological microstructures, such as Mobiüs strips, chiral helices and silk-based sensors.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Vollrath, F. & Knight, D. P. Liquid crystalline spinning of spider silk. Nature 410, 541–548 (2001).

Omenetto, F. G. & Kaplan, D. L. New opportunities for an ancient material. Science 329, 528–531 (2010).

Vollrath, F. & Porter, D. Spider silk as archetypal protein elastomer. Soft Matter 2, 377–385 (2006).

Romer, L. & Scheibel, T. The elaborate structure of spider silk: structure and function of a natural high performance fiber. Prion 4, 154–161 (2008).

Zheng, Y. et al. Directional water collection on wetted spider silk. Nature 463, 640–643 (2010).

Perrone, G. S. et al. The use of silk-based devices for fracture fixation. Nat. Commun. 5, 3385–3394 (2014).

Chun, K. Y. et al. Hybrid carbon nanotube yarn artificial muscle inspired by spider dragline silk. Nat. Commun. 5, 3322–3331 (2014).

Lee, S. M. et al. Greatly increased toughness of infiltrated spider silk. Science 324, 488–492 (2009).

Steven, E. et al. Carbon nanotubes on a spider silk scaffold. Nat. Commun. 4, 2435–2443 (2013).

Samal, S. K. et al. Biomimetic magnetic silk scaffolds. ACS Appl. Mater. Interfaces 7, 6282–6292 (2015).

Simmons, A. H., Michal, C. A. & Jelinski, L. W. Molecular orientation and two-component nature of the crystalline fraction of spider dragline silk. Science 271, 84–87 (1996).

vanBeek, J. D., Hess, S., Vollrath, F. & Meier, B. H. The molecular structure of spider dragline silk: folding and orientation of protein backbone. Proc. Natl Acad. Sci. USA 99, 10266–10271 (2002).

Keten, S. & Buehler, M. J. Atomistic model of the spider silk nanostructure. Appl. Phys. Lett. 96, 153701 (2010).

Keten, S., Xu, Z., Ihle, B. & Buehler, M. J. Nano confinement controls stiffness, strength and mechanical toughness of beta-sheet crystals in silk. Nat. Mater. 9, 359–367 (2010).

Sponner, A. et al. Composition and hierarchical organization of a spider silk. PLoS ONE 2, e998 (2007).

Liu, Y., Shao, Z. & Vollrath, F. Relationships between supercontraction and mechanical properties of spider silk. Nat. Mater. 4, 901–905 (2005).

Zeplin, P. H. et al. Spider silk coatings as a bioshield to reduce periprosthetic fibrous capsule formation. Adv. Funct. Mater. 24, 2658–2666 (2014).

Brenckle, M. A. et al. Protein-protein nanoimprinting of silk fibroin films. Adv. Mater. 25, 2409–2414 (2013).

Cebe, P. et al. Beating the heat—fast scanning melts silk beta-sheet crystals. Sci. Rep. 3, 1130 (2013).

Applegate, M. B. et al. Laser-based three-dimensional multiscale micropatterning of biocompatible hydrogels for customized tissue engineering scaffolds. Proc. Natl Acad. Sci. USA 112, 12052–12057 (2015).

Moore, A., Koch, M., Mueller, K. & Stuke, M. Precise laser ablation processing of black widow spider silk. Appl. Phys. A 77, 353–357 (2003).

Gattass, R. R. & Mazur, E. Femtosecond laser micromachining in transparent materials. Nat. Photon. 2, 219–225 (2008).

Tirlapur, U. K. & König, K. Targeted transfection by femtosecond laser. Nature 418, 290–291 (2002).

Sundaram, S. K. & Mazur, E. Inducing and probing non-thermal transitions in semiconductors using femtosecond laser pulses materials. Nat. Mater. 1, 217–224 (2002).

Uchugonova, A., König, K., Bueckle, R., Isemann, A. & Tempea, G. Targeted transfection of stem cells with sub-20 femtosecond laser pulses. Opt. Express 16, 9357–9364 (2008).

Hanczyc, P., Samoc, M. & Norden, B. Multiphoton absorption in amyloid protein fibres. Nat. Photon. 7, 969–972 (2013).

Applegate, M. B., Marelli, B., Kaplan, D. L. & Omenetto, F. G. Determination of multiphoton absorption of silk fibroin using the Z-scan technique. Opt. Exp. 21, 29637–29642 (2013).

Lefèvre, T., Mercier, F. P., Dubé, J.-F. R. & Pézolet, M. Structure of silk by Raman spectromicroscopy: from spinning glands to the fiber. Biopolymers 97, 322–336 (2011).

Sirichaisit, J., Young, R. J. & Vollrath, F. Molecular deformation in spider dragline silk subjected to stress. Polymer 41, 1223–1227 (2000).

Shao, Z., Vollrath, F., Sirichaisit, J. & Young, R. J. Analysis of spider silk in native and supercontracted state using Raman spectroscopy. Polymer 40, 2493–2500 (1999).

Kumar, B. & Singh, K. P. Fatigueless response of spider draglines in cyclic torsion facilitated by reversible molecular deformation. Appl. Phys. Lett. 105, 213705 (2014).

Kitagawa, T., Yabukia, K. & Young, R. J. An investigation into the relationship between processing, structure and properties for high-modulus PBO fibres. Part 1. Raman band shifts and broadening in tension and compression. Polymer 42, 2101–2112 (2001).

Norte, R. A., Moura, J. P. & Gröblacher, S. Mechanical resonators for quantum optomechanics experiments at room temperature. Phys. Rev. Lett. 116, 147202 (2016).

Reinhardt, C., Müller, C., Bourassa, A. & Sankey, J. C. Ultralow-noise SiN trampoline resonators for sensing and optomechanics. Phys. Rev. X 6, 021001 (2016).

Porter, D. & Vollrath, F. Silk as a biomimetic ideal for structural polymers. Adv. Mater. 21, 487–492 (2009).

Altman, D. G. et al. Silk-based biomaterials. Biomaterials 24, 401–416 (2003).

Qin, Z. et al. Structural optimization of 3D-printed synthetic spider webs for high strength. Nat. Commun. 6, 7038–7045 (2015).

Buehler, M. J. & Yung, Y. C. Deformation and failure of protein materials in physiologically extreme conditions and disease. Nat. Mater. 8, 175–188 (2009).

Cohen Stuart, M. A. et al. Emerging applications of stimuli-responsive polymer materials. Nat. Mater. 9, 101–113 (2010).

Acknowledgements

We acknowledge the central facilities of IISER Mohali for Raman spectra, SEM micrographs and optical absorption spectra. We thank R. Yadav for his help with confocal microscopy. K.P.S. acknowledges P. P. Singh and T. Pfeifer for many fruitful discussions. We acknowledge funding from DST, India and IISER Mohali.

Author information

Authors and Affiliations

Contributions

K.P.S. conceived the idea. M.S.S. and K.P.S. designed the research. K.P.S. and M.S.S. developed the full processing set-up, performed experiments, and analysed data including Raman analysis, pulling tests, welding silk to other materials, and multiphoton measurements. B.K. participated in an early version of the set-up with K.P.S. K.P.S. and M.S.S. wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 1978 kb)

Supplementary Information

Supplementary movie 1 (AVI 2896 kb)

Supplementary Information

Supplementary movie 2 (WMV 5392 kb)

Supplementary Information

Supplementary movie 3 (WMV 345 kb)

Supplementary Information

Supplementary movie 4 (WMV 1994 kb)

Rights and permissions

About this article

Cite this article

Sidhu, M., Kumar, B. & Singh, K. The processing and heterostructuring of silk with light. Nature Mater 16, 938–945 (2017). https://doi.org/10.1038/nmat4942

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat4942

This article is cited by

-

Silk Fibroin Nacre

Advanced Fiber Materials (2022)

-

Pioneering Works of N. S. Kapany in Biomedical Optics

Resonance (2021)

-

Micro/nano processing of natural silk fibers with near-field enhanced ultrafast laser

Science China Materials (2020)

-

Ablation of silicon and ultrathin fibers using single femtosecond pulse

Indian Journal of Physics (2019)

-

Quantum dots-reinforced luminescent silkworm silk with superior mechanical properties and highly stable fluorescence

Journal of Materials Science (2019)