Abstract

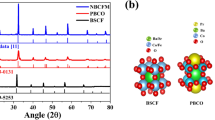

Different layered perovskite-related oxides are known to exhibit important electronic, magnetic and electrochemical properties. Owing to their excellent mixed-ionic and electronic conductivity and fast oxygen kinetics, cation layered double perovskite oxides such as PrBaCo2O5 in particular have exhibited excellent properties as solid oxide fuel cell oxygen electrodes1. Here, we show for the first time that related layered materials can be used as high-performance fuel electrodes. Good redox stability with tolerance to coking and sulphur contamination from hydrocarbon fuels is demonstrated for the layered perovskite anode PrBaMn2O5+δ (PBMO). The PBMO anode is fabricated by in situ annealing of Pr0.5Ba0.5MnO3−δ in fuel conditions and actual fuel cell operation is demonstrated. At 800 °C, layered PBMO shows high electrical conductivity of 8.16 S cm−1 in 5% H2 and demonstrates peak power densities of 1.7 and 1.3 W cm−2 at 850 °C using humidified hydrogen and propane fuels, respectively.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Choi, S et al. Highly efficient and robust cathode materials for low-temperature solid oxide fuel cells: PrBa0.5Sr0.5Co2−xFexO5+δ . Sci. Rep. 3, 2426 (2013).

Wang, W., Su, C., Wu, Y., Ran, R. & Shao, Z. Progress in solid oxide fuel cells with nickel-based anodes operating on methane and related fuels. Chem. Rev. 113, 8104–8151 (2013).

Atkinson, A. et al. Advanced anodes for high-temperature fuel cells. Nature Mater. 3, 17–27 (2004).

Liu, M., Lynch, M. E., Blinn, K., Alamgir, F. M. & Choi, Y. Rational SOFC material design: New advances and tools. Mater. Today 14, 534–546 (2011).

Park, S., Vohs, J. M. & Gorte, R. J. Direct oxidation of hydrocarbons in a solid-oxide fuel cell. Nature 404, 265–267 (2000).

Cheng, Z. From Ni-YSZ to sulfur-tolerant anode materials for SOFCs: Electrochemical behavior, in situ characterization, modeling, and future perspectives. Energy Environ. Sci. 4, 4380–4409 (2011).

He, H., Gorte, R. J. & Vohs, J. M. Highly sulfur tolerant Cu-ceria anodes for SOFCs. Electrochem. Solid State Lett. 8, A279–A280 (2005).

Zhan, Z. & Barnett, S. A. An octane-fueled solid oxide fuel cell. Science 308, 844–847 (2005).

Liu, M. et al. Direct octane fuel cells: A promising power for transportation. Nano Energy 1, 448–455 (2012).

Yang, L. et al. Enhanced sulfur and coking tolerance of a mixed ion conductor for SOFCs: BaZr0.1Ce0.7Y0.2−xYbxO3−δ . Science 326, 126–129 (2009).

Ryu, K. H. & Haile, S. M. Chemical stability and proton conductivity of doped BaCeO3–BaZrO3 solid solutions. Solid State Ion. 125, 355–367 (1999).

Sengodan, S, Yeo, H. J., Shin, J. Y. & Kim, G. Assessment of perovskite-type La0.8Sr0.2ScxMn1−xO3−δ oxides as an anode for intermediate temperature solid oxide fuel cells using hydrocarbon. J. Power Sources 196, 3083–3088 (2011).

Corre, G. Activation and ripening of impregnated manganese containing perovskite SOFC electrodes under redox cycling. Chem. Mater. 21, 1077–1084 (2009).

Sengodan, S. et al. Electrochemical performance of YST infiltrated and Fe doped YST infiltrated YSZ anodes for IT-SOFC. ECS Electrochem. Lett. 2, F45–F49 (2013).

Tao, S. & Irvine, J. T. S. A redox-stable efficient anode for solid-oxide fuel cells. Nature Mater. 2, 320–323 (2003).

Huang, Y-H., Dass, R. I., Xing, Z-L. & Goodenough, J. B. Double perovskites as anode materials for solid-oxide fuel cells. Science 312, 254–257 (2006).

Yang, C. et al. Sulfur-tolerant redox-reversible anode material for direct hydrocarbon solid oxide fuel cells. Adv. Mater. 24, 1439–1443 (2012).

Shin, T. H., Ida, S. & Ishihara, T. Doped CeO2–LaFeO3 composite oxide as an active anode for direct hydrocarbon-type solid oxide fuel cells. J. Am. Chem. Soc. 48, 19399–19407 (2011).

Kim, G., Corre, G., Irvine, J. T. S., Vohs, J. M. & Gorte, R. J. Engineering composite oxide SOFC anodes for efficient oxidation of methane. Electrochem. Solid State Lett. 11, B16–B19 (2008).

Trukhanov, S.V. et al. Study of A-site ordered PrBaMn2O6−δ manganite properties depending on the treatment conditions. J. Phys. Condens. Matter 17, 6495–6506 (2005).

Trukhanov, S. V., Trukhanov, A. V., Szymczak, H., Szymczak, R. & Baran, M. Thermal stability of A-site ordered PrBaMn2O6 manganites. J. Phys. Chem. Solids 67, 675–681 (2006).

Taskin, A. A., Lavrov, A. N. & Ando, Y. Fast oxygen diffusion in A-site ordered perovskites. Prog. Solid State Chem. 35, 481–490 (2007).

Danilovic, N. et al. Correlation of fuel cell anode electrocatalytic and ex situ catalytic activity of perovskites La0.75Sr0.25Cr0.5X0.5O3−δ (X = Ti, Mn, Fe, Co). Chem. Mater. 22, 957–965 (2009).

Motohashi, T. et al. Remarkable oxygen intake/release capability of BaYMn2O5+δ: Applications to oxygen storage technologies. Chem. Mater. 22, 3192–3196 (2010).

Oishi, M., Yashiro, K., Sato, K., Mizusaki, J. & Kawada, T. Oxygen nonstoichiometry and defect structure analysis of B-site mixed perovskite-type oxide (La, Sr)(Cr, M)O3−δ (M = Ti, Mn and Fe). J. Solid State Chem. 181, 177–184 (2008).

Marrero-López, D. Redox behaviour, chemical compatibility and electrochemical performance of Sr2MgMoO6−δ as SOFC anode. Solid State Ion. 180, 1672–1682 (2010).

Volkan, A. G. & April, G. C. Survey of propane pyrolysis literature. Ind. Eng. Chem. Process Des. Dev. 16, 429–436 (1977).

Sasaki, K. & Teraoka, Y. Equilibria in fuel cell gases I. Equilibrium compositions and reforming conditions. J. Electrochem. Soc. 150, A878–A884 (2003).

Sengodan, S., Ahn, S., Shin, J. & Kim, G. Oxidation–reduction behavior of La0.8Sr0.2ScyMn1−yO3±δ (y = 0.2, 0.3, 0.4): Defect structure, thermodynamic and electrical properties. Solid State Ion. 228, 25–31 (2012).

Acknowledgements

This research was supported by the New & Renewable Energy of the Korea Institute of Energy Technology Evaluation and Planning (KETEP) (20113020030060) grant by the Korea government Ministry of Trade, Industry and Energy, the (2013R1A2A2A04015706) through the National Research Foundation of Korea, funded by the Ministry of Science, ICT and Future Planning and the Basic Science Research Program (2013R1A2A2A01007170 and 2010-0021214) through the National Research Foundation of Korea funded by Ministry of Education. We thank The Royal Society for a Wolfson Merit Award (JI) and EPSRC for a research grant (EP/I022570/1).

Author information

Authors and Affiliations

Contributions

S.S., S.C. and A.J. contributed to fabricating the samples and conducted data analysis of all kinds of electrochemical experiment, SEM, coulometric titration, X-ray diffraction and gas chromatography. Y.W.J. fabricated samples and discussed electrochemical data. T.H.S. carried out the high-temperature X-ray diffraction and dilatometer analyses. H.Y.J. collected and analysed the TEM data. J.S., J.T.S.I. and G.K. conceived and designed the project. All authors contributed to writing the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 3075 kb)

Rights and permissions

About this article

Cite this article

Sengodan, S., Choi, S., Jun, A. et al. Layered oxygen-deficient double perovskite as an efficient and stable anode for direct hydrocarbon solid oxide fuel cells. Nature Mater 14, 205–209 (2015). https://doi.org/10.1038/nmat4166

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat4166

This article is cited by

-

Oxygen pressure annealing enhances the B-site ordering degree of double perovskite La2CoMnO6 ceramics

Journal of Materials Science: Materials in Electronics (2023)

-

Evolution of crystal structure and redox activity of LnBaMn2O6−δ upon various external conditions: in-situ characterization

Journal of Materials Science (2023)

-

Microstructure, dielectric relaxation, optical, and ferroelectric studies of a lead-free double perovskite: BaLiFeMoO6

Journal of the Korean Ceramic Society (2023)

-

A highly active and stable Sr2Fe1.5Mo0.5O6-δ-Ce0.8Sm0.2O1.95 ceramic fuel electrode for efficient hydrogen production via a steam electrolyzer without safe gas

International Journal of Coal Science & Technology (2022)

-

Fuel Cell Reactors for the Clean Cogeneration of Electrical Energy and Value-Added Chemicals

Electrochemical Energy Reviews (2022)