Abstract

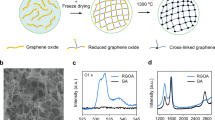

Crumpled graphene films are widely used, for instance in electronics1, energy storage2,3, composites4,5 and biomedicine6. Although it is known that the degree of crumpling affects graphene’s properties and the performance of graphene-based devices and materials3,5,7, the controlled folding and unfolding of crumpled graphene films has not been demonstrated. Here we report an approach to reversibly control the crumpling and unfolding of large-area graphene sheets. We show with experiments, atomistic simulations and theory that, by harnessing the mechanical instabilities of graphene adhered on a biaxially pre-stretched polymer substrate and by controlling the relaxation of the pre-strains in a particular order, graphene films can be crumpled into tailored self-organized hierarchical structures that mimic superhydrophobic leaves. The approach enables us to fabricate large-area conductive coatings and electrodes showing superhydrophobicity, high transparency, and tunable wettability and transmittance. We also demonstrate that crumpled graphene–polymer laminates can be used as artificial-muscle actuators.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Miller, J. R., Outlaw, R. A. & Holloway, B. C. Graphene double-layer capacitor with a.c. line-filtering performance. Science 329, 1637–1639 (2010).

Zhu, Y. et al. Carbon-based supercapacitors produced by activation of graphene. Science 332, 1537–1541 (2011).

Luo, J. et al. Compression and aggregation-resistant particles of crumpled soft sheets. ACS Nano 5, 8943–8949 (2011).

Stankovich, S. et al. Graphene-based composite materials. Nature 442, 282–286 (2006).

Ramanathan, T. et al. Functionalized graphene sheets for polymer nanocomposites. Nature Nanotech. 3, 327–331 (2008).

Chen, Y. et al. Aerosol synthesis of cargo-filled graphene nanosacks. Nano Lett. 12, 1996–2002 (2012).

Pereira, V. M., Castro Neto, A. H., Liang, H. Y. & Mahadevan, L. Geometry, mechanics, and electronics of singular structures and wrinkles in graphene. Phys. Rev. Lett. 105, 156603 (2010).

Geim, A. K. & Novoselov, K. S. The rise of graphene. Nature Mater. 6, 183–191 (2007).

Kim, K. S. et al. Large-scale pattern growth of graphene films for stretchable transparent electrodes. Nature 457, 706–710 (2009).

Li, X. et al. Large-area synthesis of high-quality and uniform graphene films on copper foils. Science 324, 1312–1314 (2009).

Bao, W. et al. Controlled ripple texturing of suspended graphene and ultrathin graphite membranes. Nature Nanotech. 4, 562–566 (2009).

Meyer, J. C. et al. The structure of suspended graphene sheets. Nature 446, 60–63 (2007).

Cranford, S. W. & Buehler, M. J. Packing efficiency and accessible surface area of crumpled graphene. Phys. Rev. B 84, 205451 (2011).

Levy, N. et al. Strain-induced pseudo-magnetic fields greater than 300 T in graphene nanobubbles. Science 329, 544–547 (2010).

Guinea, F., Katsnelson, M. I. & Geim, A. K. Energy gaps and a zero-field quantum Hall effect in graphene by strain engineering. Nature Phys. 6, 30–33 (2010).

Scharfenberg, S. et al. Probing the mechanical properties of graphene using a corrugated elastic substrate. Appl. Phys. Lett. 98, 091908 (2011).

Li, T. & Zhang, Z. Substrate-regulated morphology of graphene. J. Phys. D 43, 075303 (2010).

Cao, Y. & Hutchinson, J. W. Wrinkling phenomena in neo-Hookean film/substrate bilayers. J. Appl. Mech. 79, 031019 (2012).

Wang, Y. et al. Super-elastic graphene ripples for flexible strain sensors. ACS Nano 5, 3645–3650 (2011).

Lee, C., Wei, X., Kysar, J. W. & Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321, 385–388 (2008).

Mei, H., Landis, C. M. & Huang, R. Concomitant wrinkling and buckle-delamination of elastic thin films on compliant substrates. Mech. Mater. 43, 627–642 (2011).

Hutchinson, J. W. & Suo, Z. Mixed-mode cracking in layered materials. Adv. Appl. Mech. 29, 63–191 (1992).

Vella, D., Bico, J., Boudaoud, A., Roman, B. & Reis, P. M. The macroscopic delamination of thin films from elastic substrates. Proc. Natl Acad. Sci. USA 106, 10901–10906 (2009).

Rogers, J. A., Someya, T. & Huang, Y. Materials and mechanics for stretchable electronics. Science 327, 1603–1607 (2010).

Kaltenbrunner, M. et al. Ultrathin and lightweight organic solar cells with high flexibility. Nature Commun. 3, 770 (2012).

Kim, P., Abkarian, M. & Stone, H. A. Hierarchical folding of elastic membranes under biaxial compressive stress. Nature Mater. 10, 952–957 (2011).

Neinhuis, C. & Barthlott, W. Characterization and distribution of water-repellent, self-cleaning plant surfaces. Ann. Bot. 79, 667–677 (1997).

Rafiee, J. et al. Wetting transparency of graphene. Nature Mater. 11, 217–222 (2012).

Zhang, Z., Zhang, T., Zhang, Y. W., Kim, K-S. & Gao, H. Strain-controlled switching of hierarchically wrinkled surfaces between superhydrophobicity and superhydrophilicity. Langmuir 28, 2753–2760 (2012).

Pelrine, R., Kornbluh, R., Pei, Q. B. & Joseph, J. High-speed electrically actuated elastomers with strain greater than 100%. Science 287, 836–839 (2000).

Ruoff, R. A means to an end. Nature 483, S42–S42 (2012).

Stuart, S. J., Tutein, A. B. & Harrison, J. A. A reactive potential for hydrocarbons with intermolecular interactions. J. Chem. Phys. 112, 6472–6486 (2000).

Plimpton, S. Fast parallel algorithms for short-range molecular-dynamics. J. Comput. Phys. 117, 1–19 (1995).

Acknowledgements

The research is primarily funded by the NSF’s Research Triangle MRSEC (DMR-1121107), NSF (CMMI-1200515) and NIH (UH2 TR000505). X.Z. acknowledges the support from the Pratt School of Engineering Seed Grant. S.R. and M.J.B. acknowledge the support from AFOSR (FA9550-11-1-0199) and NSF-MRSEC (DMR-0819762). M.J.B. and N.P. acknowledge the support from the MIT-Italy Program (MITOR). N.P. acknowledges the support from the European Research Council under the European Union’s Seventh Framework Programme (FP7/2007–2013)/ERC Grant agreement number [279985] (ERC StG Ideas 2011 BIHSNAM). J.Z. and X.Z. acknowledge the help from C-H. Chen on contact-angle measurements and B. Wiley on transmittance measurements.

Author information

Authors and Affiliations

Contributions

X.Z. conceived the idea, designed and supervised the experiments, and performed the data interpretation. J.Z. designed and carried out the experiments, and performed the data interpretation. Q.W. and Q.T. supported the experiments and contributed to the data interpretation. S.R. and M.J.B. designed, carried out, analysed and interpreted the atomistic simulations. N.P., S.R., M.J.B. and X.Z. developed the theoretical models and interpreted them. X.Z. drafted the manuscript and all authors contributed to the writing of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 3421 kb)

Supplementary Information

Supplementary Movie S1 (MPG 1647 kb)

Supplementary Information

Supplementary Movie S2 (MPG 1638 kb)

Supplementary Information

Supplementary Movie S3 (WMV 1901 kb)

Rights and permissions

About this article

Cite this article

Zang, J., Ryu, S., Pugno, N. et al. Multifunctionality and control of the crumpling and unfolding of large-area graphene. Nature Mater 12, 321–325 (2013). https://doi.org/10.1038/nmat3542

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat3542

This article is cited by

-

Recent advances in two-dimensional nanomaterials for sustainable wearable electronic devices

Journal of Nanobiotechnology (2024)

-

Mechanically driven assembly of biomimetic 2D-material microtextures with bioinspired multifunctionality

Nano Research (2024)

-

Transfer-free chemical vapor deposition graphene for nitride epitaxy: challenges, current status and future outlook

Science China Chemistry (2024)

-

Free-electron interactions with van der Waals heterostructures: a source of focused X-ray radiation

Light: Science & Applications (2023)

-

A Comprehensive Review on the Classification, Uses, Sources of Nanoparticles (NPs) and Their Toxicity on Health

Aerosol Science and Engineering (2023)