Abstract

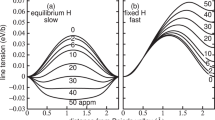

Hydrogen embrittlement in metals has posed a serious obstacle to designing strong and reliable structural materials for many decades, and predictive physical mechanisms still do not exist. Here, a new H embrittlement mechanism operating at the atomic scale in α-iron is demonstrated. Direct molecular dynamics simulations reveal a ductile-to-brittle transition caused by the suppression of dislocation emission at the crack tip due to aggregation of H, which then permits brittle-cleavage failure followed by slow crack growth. The atomistic embrittlement mechanism is then connected to material states and loading conditions through a kinetic model for H delivery to the crack-tip region. Parameter-free predictions of embrittlement thresholds in Fe-based steels over a range of H concentrations, mechanical loading rates and H diffusion rates are found to be in excellent agreement with experiments. This work provides a mechanistic, predictive framework for interpreting experiments, designing structural components and guiding the design of embrittlement-resistant materials.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Johnson, W. H. On some remarkable changes produced in iron and steels by the action of hydrogen acids. Proc. R. Soc. Lond. 23, 168–175 (1875).

Fukai, Y. The Metal–Hydrogen System: Basic Bulk Properties 2nd edn (Springer, 2005).

Hardie, D., Charles, E. A. & Lopez, A. H. Hydrogen embrittlement of high strength pipeline steels. Corros. Sci. 48, 4378–4385 (2006).

Staehle, R. W. in Stress Corrsosion Cracking and Hydrogen Embrittlement of Iron Based Alloys (eds Hochmann, J., McCright, R. D. & Slater, J. E.) (National Association of Corrosion Engineers, 1977).

Troiano, A. R. The role of hydrogen and other interstitials in the mechanical behavior of metals. Trans. ASM 52, 54–80 (1960).

Oriani, R. A. A mechanistic theory of hydrogen embrittlement of steels. Ber. Bunsenges. Phys. Chem. 76, 848–857 (1972).

Jiang, D. E. & Carter, E. A. First principles assessment of ideal fracture energies of materials with mobile impurities: Implications for hydrogen embrittlement of metals. Acta Mater. 52, 4801–4807 (2004).

Gerberich, W. W., Oriani, R. A., Lii, M. J., Chen, X. & Foecke, T. The necessity of both plasticity and brittleness in the fracture thresholds of iron. Phil. Mag. A 63, 363–376 (1991).

Song, J., Soare, M. & Curtin, W. A. Testing continuum concepts for hydrogen embrittlement in metals using atomistics. Model Simul. Mater. Sci. 18, 045003 (2010).

Chen, X. & Gerberich, W. W. The kinetics and micromechanics of hydrogen-assisted cracking in Fe3 pct Si single-crystals. Metall. Trans. A 22, 59–69 (1991).

Beacham, C. D. A new model for hydrogen-assisted cracking (hydrogen ‘embrittlement’). Metall. Mater. Trans. B 3, 441–455 (1972).

Birnbaum, H. K. & Sofronis, P. Hydrogen-enhanced localized plasticity—a mechanism for hydrogen-related fracture. Mater. Sci. Eng. A 176, 191–202 (1994).

Robertson, I. M. The effect of hydrogen on dislocation dynamics. Eng. Fract. Mech. 68, 671–692 (2001).

Ferreira, P. J., Robertson, I. M. & Birnbaum, H. K. Hydrogen effects on the interaction between dislocations. Acta Mater. 46, 1749–1757 (1998).

Sofronis, P. & Robertson, I. M. Transmission electron microscopy observations and micromechanical/continuum models for the effect of hydrogen on the mechanical behaviour of metals. Phil. Mag. A 82, 3405–3413 (2002).

Abraham, D. P. & Altstetter, C. J. Hydrogen-enhanced localization of plasticity in an austenitic stainless-steel. Metall. Mater. Trans. A 26, 2859–2871 (1995).

Abraham, D. P. & Altstetter, C. J. The effect of hydrogen on the yield and flow-stress of an austenitic stainless-steel. Metall. Mater. Trans. A 26, 2849–2858 (1995).

Asano, S. & Otsuka, R. Lattice hardening due to dissolved hydrogen in iron and steel. Scr. Metall. Mater. 10, 1015–1020 (1976).

Matsumoto, R., Taketomi, S., Matsumoto, S. & Miyazaki, N. Atomistic simulations of hydrogen embrittlement. Int. J. Hydrogen Energy 34, 9576–9584 (2009).

Taketomi, S., Matsumoto, R. & Miyazaki, N. Atomistic study of the effect of hydrogen on dislocation emission from a mode II crack tip in alpha iron. Int. J. Mech. Sci. 52, 334–338 (2010).

Hu, Z., Fukuyama, S., Yokogawa, K. & Okamoto, S. Hydrogen embrittlement of a single crystal of iron on a nanometre scale at a crack tip by molecular dynamics. Model Simul. Mater. Sci. 7, 541–551 (1999).

Wen, M., Fukuyama, S. & Yokogawa, K. Atomistic simulations of effect of hydrogen on kink-pair energetics of screw dislocations in bcc iron. Acta Mater. 51, 1767–1773 (2003).

Xu, X. J., Wen, M., Hu, Z., Fukuyama, S. & Yokogawa, K. Atomistic process on hydrogen embrittlement of a single crystal of nickel by the embedded atom method. Comput. Mater. Sci. 23, 131–138 (2002).

Von Pezold, J., Lymperakis, L. & Neugebauer, J. Hydrogen-enhanced local plasticity at dilute bulk H concentrations: The role of H–H interactions and the formation of local hydrides. Acta Mater. 59, 2969–2980 (2011); 59, 5868 (2011).

Chandler, M. Q. et al. Hydrogen effects on nanovoid nucleation in face-centered cubic single-crystals. Acta Mater. 56, 95–104 (2008).

Thomas, R. L. S., Scully, J. R. & Gangloff, R. P. Internal hydrogen embrittlement of ultrahigh-strength AERMET 100 steel. Metall. Mater. Trans. A 34, 327–344 (2003).

Hoover, W., Iannucci, J., Robinson, S., Spingarn, J. & Stoltz, R. Hydrogen compatibility of structural materials for energy storage and transmission Report No. SAND80-8202 (Sandia National Laboratories, 1980).

Cialone, H. & Holbrook, J. in Hydrogen Embrittlement: Prevention and Control, ASTM STP 962 (ed. Raymond, L) 134–152 (American Society for Testing and Materials, 1988).

San Marchi, C. & Somerday, B. Technical reference on hydrogen compatibility of materials Report No. SAND2008-1163 (Sandia National Laboratories, 2008).

Hoover, W., Robinson, S., Stoltz, R. & Spingarn, J. Hydrogen Compatibility of Structural Materials for Energy Storage and Transmission Final Report (Sandia National Laboratories, 1981).

Cherepanov, G. P. Mechanics of Brittle Fracture (McGraw-Hill, 1979).

Ramasubramaniam, A., Itakura, M., Ortiz, M. & Carter, E. A. Effect of atomic scale plasticity on hydrogen diffusion in iron: Quantum mechanically informed and on-the-fly kinetic Monte Carlo simulations. J. Mater. Res. 23, 2757–2773 (2008).

Hale, L. M. et al. Molecular dynamics simulation of delamination of a stiff, body-centered cubic crystalline film from a compliant Si substrate. J. Appl. Phys. 106 (2009).

Lynch, S. P. Environmentally assisted cracking—overview of evidence for an adsorption-induced localized-slip process. Acta Metall. Mater. 36, 2639–2661 (1988).

Friedel, J. Dislocations 1st English edn (Pergamon, 1964).

Song, J. & Curtin, W. A. A nanoscale mechanism of hydrogen embrittlement in metals. Acta Mater. 59, 1557–1569 (2011).

Vehoff, H. & Rothe, W. Overview 30 gaseous-hydrogen embrittlement in FeSi-single and Ni-single crystals. Acta Metall. Mater. 31, 1781–1793 (1983).

Alefeld, G. & Völkl, J. Hydrogen in Metals (Springer, 1978).

Plimpton, S. Fast parallel algorithms for short-range molecular-dynamics. J. Comput. Phys. 117, 1–19 (1995).

Hoover, W. G. Canonical dynamics—equilibrium phase-space distributions. Phys. Rev. A 31, 1695–1697 (1985).

Nose, S. A unified formulation of the constant temperature molecular-dynamics methods. J. Chem. Phys. 81, 511–519 (1984).

Swope, W. C., Andersen, H. C., Berens, P. H. & Wilson, K. R. A computer-simulation method for the calculation of equilibrium-constants for the formation of physical clusters of molecules—application to small water clusters. J. Chem. Phys. 76, 637–649 (1982).

Finnis, M. W. & Sinclair, J. E. A simple empirical n-body potential for transition-metals. Phil. Mag. A 50, 45–55 (1984).

Daw, M. S. & Baskes, M. I. Embedded-atom method—derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B 29, 6443–6453 (1984).

Babu, S. S. et al. Hydrogen Pipeline R&D, Project Review Meeting (Oak Ridge, 2005).

Luppo, M. I. & Ovejerogarcia, J. The influence of microstructure on the trapping and diffusion of hydrogen in a low-carbon steel. Corros. Sci. 32, 1125–1136 (1991).

Huang, H. & Shaw, W. J. D. Hydrogen embrittlement interactions in cold-worked steel. Corrosion 51, 30–36 (1995).

Bethlehem Steel Corporation Modern Steels and their Properties: Carbon and Alloy Steel Bars and Rods. (Bethlehem Steel Corporation, 1978).

Acknowledgements

The authors acknowledge partial support of this work by the US Office of Naval Research (grant # N00014-05-1-0504), by the General Motors/Brown Collaborative Research Lab on Computational Materials and by the NSERC Discovery grant (grant # RGPIN 418469-2012).

Author information

Authors and Affiliations

Contributions

The project was planned and supervised by W.A.C. The simulations were performed and the data were collected by J.S. The results were analysed and discussed by J.S. and W.A.C. The manuscript was prepared by J.S. and W.A.C.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 1000 kb)

Rights and permissions

About this article

Cite this article

Song, J., Curtin, W. Atomic mechanism and prediction of hydrogen embrittlement in iron. Nature Mater 12, 145–151 (2013). https://doi.org/10.1038/nmat3479

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat3479

This article is cited by

-

Engineering metal-carbide hydrogen traps in steels

Nature Communications (2024)

-

Molecular dynamics study of hydrogen-induced cracking behavior of ferrite–pearlite gas transmission pipeline steel

Journal of Iron and Steel Research International (2024)

-

Quantitative tests revealing hydrogen-enhanced dislocation motion in α-iron

Nature Materials (2023)

-

One dislocation at a time

Nature Materials (2023)

-

Nanoscale ductile fracture and associated atomistic mechanisms in a body-centered cubic refractory metal

Nature Communications (2023)