Abstract

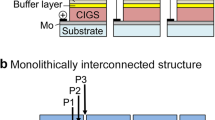

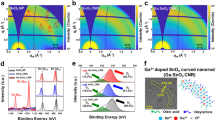

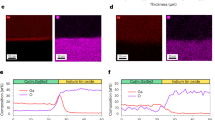

Solar cells based on polycrystalline Cu(In,Ga)Se2 absorber layers have yielded the highest conversion efficiency among all thin-film technologies1,2,3, and the use of flexible polymer films as substrates offers several advantages in lowering manufacturing costs. However, given that conversion efficiency is crucial for cost-competitiveness, it is necessary to develop devices on flexible substrates that perform as well as those obtained on rigid substrates. Such comparable performance has not previously been achieved, primarily because polymer films require much lower substrate temperatures during absorber deposition, generally resulting in much lower efficiencies4. Here we identify a strong composition gradient in the absorber layer as the main reason for inferior performance and show that, by adjusting it appropriately, very high efficiencies can be obtained. This implies that future manufacturing of highly efficient flexible solar cells could lower the cost of solar electricity and thus become a significant branch of the photovoltaic industry.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Green, M. A., Emery, K., Hishikawa, Y. & Warta, W. Solar cell efficiency table (version 37). Prog. Photovolt. 19, 84–92 (2011).

Repins, I. et al. 19.9%-efficient ZnO/CdS/CuInGaSe2 solar cell with 81.2% fill factor. Prog. Photovolt. 16, 235–239 (2008).

Jackson, P. et al. New world record efficiency for Cu(In,Ga)Se2 thin-film solar cells beyond 20%. Prog. Photovolt.http://dx.doi.org/10.1002/pip.1078 (2011).

Shafarman, W. N. & Zhu, J. Effect of substrate temperature and deposition profile on evaporated Cu(InGa)Se2 films and devices. Thin Solid Films 361–362, 473–477 (2000).

Chopra, K. L., Paulson, P. D. & Dutta, V. Thin film solar cells: An overview. Prog. Photovolt. 12, 69–92 (2004).

Grätzel, M. Photoelectrochemical cells. Nature 414, 338–344 (2001).

Bernede, J. C. Organic photovoltaic cells: History, principles and techniques. J. Chilean Chem. Soc. 53, 1549–1564 (2008).

Kessler, F. & Rudmann, D. Technological aspects of flexible CIGS solar cells and modules. Sol. Energy 77, 685–695 (2004).

Niki, S. et al. CIGS absorbers and processes. Prog. Photovolt. 18, 453–466 (2010).

Rudmann, D., Brémaud, D. G., Zogg, H. & Tiwari, A. N. Na incorporation into Cu(In,Ga)Se2 for high-efficiency solar cells on polymer foils. J. Appl. Phys. 97, 084903 (2005).

Caballero, R. et al. High efficiency low temperature grown Cu(In,Ga)Se2 thin film solar cells on flexible substrates using NaF precursor layers. Prog. Photovolt. 19, 547–551 (2011).

Nakada, T. et al. Proc. 24th Eur. PV Solar Energy Conf. (EUPVSEC), 3DO.4.3 (WIP—Renewable Energies, 2010).

Bär, M. et al. Electronic level alignment at the deeply buried absorber/Mo interface in chalcopyrite-based thin film solar cells. Appl. Phys. Lett. 93, 042110 (2008).

Shay, J. L., Wagner, S. & Kasper, H. M. Efficient CuInSe2/CdS solar cells. Appl. Phys. Lett. 27, 89–99 (1975).

Wei, S-H., Zhang, S. B. & Zunger, A. Effects of Ga addition to CuInSe2 on its electronic, structural, and defect properties. Appl. Phys. Lett. 72, 3199–3201 (1998).

Gabor, A. M. et al. High-efficiency CuInxGa1−xSe2 solar cells made from (Inx,Ga1−x)2Se3 precursor films. Appl. Phys. Lett. 65, 198–200 (1994).

Marudachalam, M. et al. Phases, morphology, and diffusion in CuInxGa1−xSe2 thin films. J. Appl. Phys. 82, 2896–2905 (1997).

Contreras, M. A. et al. Graded band-gap Cu(In,Ga)Se2 thin film solar cell absorber with enhanced open-circuit voltage. Appl. Phys. Lett. 63, 1824–1826 (1993).

Seyrling, S. et al. Modification of the three-stage evaporation process for CuIn1−xGaxSe2 absorber deposition. Thin Solid Films 519, 7232–7236 (2011).

Chirilă, A. et al. Influence of high growth rates on evaporated Cu(In,Ga)Se2 layers and solar cells. Prog. Photovolt.http://dx.doi.org/10.1002/pip.1122 (2011).

Rudmann, D. et al. Effects of NaF coevaporation on structural properties of Cu(In,Ga)Se2 thin films. Thin Solid Films 431–432, 37–40 (2003).

Rudmann, D. et al. Sodium incorporation strategies for CIGS growth at different temperatures. Thin Solid Films 480–481, 55–60 (2005).

Chirilă, A. et al. Proc. 35th IEEE Phot. Spec. Conf. (PVSC) 656–660 (IEEE, 2010).

Patent pending No. PCT/IB2011/000857.

Bodegård, M., Lundberg, O., Lu, J. & Stolt, L. Re-crystallisation and interdiffusion in CGS/CIS bilayers. Thin Solid Films 431–432, 46–52 (2003).

Lundberg, O. Band-Gap Profiling and High Speed Deposition of Cu(In,Ga) Se2 for Thin Film Solar Cells. PhD thesis, Uppsala Univ. (2003).

Gloeckler, M. Device Physics of Cu(In,Ga) Se2 Thin-Film Solar Cells. PhD thesis, Colorado State Univ. (2005).

Rau, U. & Schock, H. W. Electronic properties of Cu(In,Ga)Se2 heterojunction solar cells recent achievements, current understanding, and future challenges. Appl. Phys. A 69, 131–147 (1999).

Burgelman, M., Nollet, P. & Degrave, S. Modelling polycrystalline semiconductor solar cells. Thin Solid Films 361–362, 527–532 (2000).

Burgelman, M., Verschraegen, J., Degrave, S. & Nollet, P. Modeling thin-film PV devices. Prog. Photovolt. 12, 143–153 (2004).

Jackson, P. et al. High quality baseline for high efficiency, Cu(In1−x,Gax)Se2 solar cells. Prog. Photovolt. 15, 507–519 (2007).

Acknowledgements

This work was supported by the Swiss National Science Foundation, the Swiss Federal Office of Energy, the European FP7 Project ‘hipo-CIGS’, and the Commission for Technology and Innovation, Switzerland.

Author information

Authors and Affiliations

Contributions

A.C., S.B., F.P., P.B., S.S., S.N., Y.E.R. and A.N.T. designed the research and experiments. A.C. and P.B. fabricated the solar cells. A.C., S.B., F.P., C.G., A.R.U., C.F., L.K., J.P., R.V., G.B. and A.N.T. performed the characterization, simulation and analysis. A.C., S.B., C.G. and A.N.T. wrote the paper. All authors contributed to discussions.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Chirilă, A., Buecheler, S., Pianezzi, F. et al. Highly efficient Cu(In,Ga)Se2 solar cells grown on flexible polymer films. Nature Mater 10, 857–861 (2011). https://doi.org/10.1038/nmat3122

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat3122

This article is cited by

-

High-concentration silver alloying and steep back-contact gallium grading enabling copper indium gallium selenide solar cell with 23.6% efficiency

Nature Energy (2024)

-

Polymer-nanocarbon composites: a promising strategy for enhanced performance of organic solar cells

Emergent Materials (2024)

-

Oxidation-resistant all-perovskite tandem solar cells in substrate configuration

Nature Communications (2023)

-

Sustainability considerations for organic electronic products

Nature Materials (2023)

-

Chalcopyrite solar cells —state-of-the-art and options for improvement

Science China Physics, Mechanics & Astronomy (2023)