Abstract

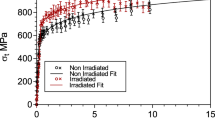

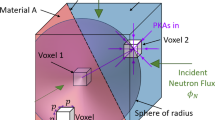

Increasing demand for energy and reduction of carbon dioxide emissions has revived interest in nuclear energy. Designing materials for radiation environments necessitates a fundamental understanding of how radiation-induced defects alter mechanical properties. Ion beams create radiation damage efficiently without material activation, but their limited penetration depth requires small-scale testing. However, strength measurements of nanoscale irradiated specimens have not been previously performed. Here we show that yield strengths approaching macroscopic values are measured from irradiated ~400 nm-diameter copper specimens. Quantitative in situ nanocompression testing in a transmission electron microscope reveals that the strength of larger samples is controlled by dislocation–irradiation defect interactions, yielding size-independent strengths. Below ~400 nm, size-dependent strength results from dislocation source limitation. This transition length-scale should be universal, but depends on material and irradiation conditions. We conclude that for irradiated copper, and presumably related materials, nanoscale in situ testing can determine bulk-like yield strengths and simultaneously identify deformation mechanisms.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Grimes, R. W. & Nuttall, W. J. Generating the option of a two-stage nuclear renaissance. Science 329, 799–803 (2010).

Odette, G. R., Alinger, M. J. & Wirth, B. D. Recent developments in irradiation-resistant steels. Annu. Rev. Mater. Res. 38, 471–503 (2008).

Greenfield, I. & Wilsdorf, H. G. Effect of neutron irradiation on plastic deformation of copper single crystals. J. Appl. Phys. 32, 827–839 (1961).

Bei, H., Shim, S., Miller, M. K., Pharr, G. M. & George, E. P. Effects of focused ion beam milling on the nanomechanical behaviour of a molybdenum-alloy single crystal. Appl. Phys. Lett. 91, 111915 (2007).

Mansur, L. K. Theory and experimental background on dimensional changes in irradiated alloys. J. Nucl. Mater. 216, 97–123 (1994).

Was, G. S. et al. Emulation of neutron irradiation effects with protons: Validation of principle. J. Nucl. Mater. 300, 198–216 (2002).

Oliver, W. C. & Pharr, G. M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564–1583 (1992).

Pharr, G. M., Herbert, E. G. & Gao, Y. The indentation size effect: A critical examination of experimental observations and mechanistic interpretations. Annu. Rev. Mater. Res. 40, 271–292 (2010).

Hosemann, P. et al. An exploratory study to determine applicability of nano-hardness and micro-compression measurements for yield stress estimation. J. Nucl. Mater. 375, 135–143 (2008).

Kiener, D., Durst, K., Rester, M. & Minor, A. M. Revealing deformation mechanisms with nanoindentation. JOM 61, 14–23 (2009).

Uchic, M. D., Dimiduk, D. M., Florando, J. N. & Nix, W. D. Sample dimensions influence strength and crystal plasticity. Science 305, 986–989 (2004).

Uchic, M. D., Shade, P. A. & Dimiduk, D. Plasticity of micrometer-scale single crystals in compression. Annu. Rev. Mater. Res. 39, 361–386 (2009).

Li, N., Mara, N. A., Wang, Y. Q., Nastasi, M. & Misra, A. Compressive flow behaviour of Cu thin films and Cu/Nb multilayers containing nanometer-scale helium bubbles. Scr. Mater. 64, 974–977 (2011).

Shan, Z. W., Mishra, R. K., Asif, S. A. S., Warren, O. L. & Minor, A. M. Mechanical annealing and source-limited deformation in submicrometre-diameter Ni crystals. Nature Mater. 73, 115–119 (2008).

Oh, S. H., Legros, M., Kiener, D. & Dehm, G. In situ observation of dislocation nucleation and escape in a submicron Al single-crystal. Nature Mater. 8, 95–100 (2009).

Jang, D. C. & Greer, J. R. Transition from a strong-yet-brittle to a stronger-and-ductile state by size reduction of metallic glasses. Nature Mater. 9, 215–219 (2010).

Gianola, D. S. & Eberl, C. Micro- and nanoscale tensile testing of materials. JOM 61, 24–35 (2009).

Yu, Q. et al. Strong crystal size effect on deformation twinning. Nature 463, 335–338 (2010).

Marian, J., Martinez, E., Lee, H. J. & Wirth, B. D. Micro/meso-scale computational study of dislocation-stacking-fault tetrahedron interactions in copper. J. Mater. Res. 24, 3628–3635 (2009).

Kadoyoshi, T. et al. Molecular dynamics study on the formation of stacking fault tetrahedra and unfaulting of Frank loops in fcc metals. Acta Mater. 55, 3073–3080 (2007).

Bacon, D. J., Gao, F. & Osetsky, Y. N. The primary damage state in fcc, bcc and hcp metals as seen in molecular dynamics simulations. J. Nucl. Mater. 276, 1–12 (2000).

Robach, J. S., Robertson, I. M., Lee, H. J. & Wirth, B. D. Dynamic observations and atomistic simulations of dislocation-defect interactions in rapidly quenched copper and gold. Acta Mater. 54, 1679–1690 (2006).

Matsukawa, Y., Briceno, M. & Robertson, I. M. Combining in situ transmission electron microscopy and molecular dynamics computer simulations to reveal the interaction mechanisms of dislocations with stacking-fault tetrahedron in nuclear materials. Microsc. Res. Tech. 72, 284–292 (2009).

Matsukawa, Y., Osetsky, Y. N., Stoller, R. E. & Zinkle, S. J. Destruction processes of large stacking fault tetrahedra induced by direct interaction with gliding dislocations. J. Nucl. Mater. 351, 285–294 (2006).

Minor, A. M., Morris, J. W. & Stach, E. A. Quantitative in situ nanoindentation in an electron microscope. Appl. Phys. Lett. 79, 1625–1627 (2001).

Minor, A. M. et al. A new view of the onset of plasticity during the nanoindentation of aluminium. Nature Mater. 5, 697–702 (2006).

Greer, J. R. Bridging the gap between computational and experimental length scales: A review on nanoscale plasticity. Rev. Adv. Mater. Sci. 13, 59–70 (2006).

Kiener, D. & Minor, A. M. Source controlled yield and hardening of Cu(100) studied by in situ transmission electron microscopy. Acta Mater. 59, 1328–1337 (2011).

Dai, Y. & Victoria, M. Defect structures in deformed FCC metals. Acta Mater. 45, 3495–3501 (1997).

Singh, B. N. & Zinkle, S. J. Defect accumulation in pure fcc metals in the transient regime: A review. J. Nucl. Mater. 206, 212–229 (1993).

Arzt, E. Size effects in materials due to microstructural and dimensional constraints: A comparative review. Acta Mater. 46, 5611–5626 (1998).

Girault, B., Schneider, A. S., Frick, C. P. & Arzt, E. Strength effects in micropillars of a dispersion strengthened superalloy. Adv. Eng. Mater. 12, 385–388 (2010).

Rao, S. I. et al. Estimating the strength of single-ended dislocation sources in micron-sized single crystals. Phil. Mag. 87, 4777–4794 (2007).

Singh, B. N., Horsewell, A., Toft, P. & Edwards, D. J. Temperature and dose dependencies of microstructure and hardness of neutron irradiated OFHC copper. J. Nucl. Mater. 224, 131–140 (1995).

Ziegler, J. F., Biersack, J. P. & Littmark, U. The Stopping Range of Ions in Matter (Pergamon, 1985).

Hosemann, P., Maloy, S. A., Greco, R. R., Swadener, J. G. & Romero, T. Oxygen effects on irradiated tantalum alloys. J. Nucl. Mater. 384, 25–29 (2009).

Acknowledgements

Funding was provided by the Berkeley Nuclear Research Centre (BNRC), established by the University of California Office of the President and the UC-National Laboratory Fee Research Program. D.K. gratefully acknowledges the financial support of the Austrian Science Fund (FWF) through the Erwin Schrödinger fellowship J2834-N20 and help with high-resolution imaging from Z. Zhang at the Erich Schmid Institute. The in situ TEM experiments were performed at the National Center for Electron Microscopy, Lawrence Berkeley National Laboratory, which is supported by the US Department of Energy under Contract # DE-AC02-05CH11231. The ion-beam irradiation was performed with the support of the staff at the Ion Beam Materials Laboratory at Los Alamos National Laboratory. The authors acknowledge inspiring discussions with T. E. Mitchell.

Author information

Authors and Affiliations

Contributions

D.K. and P.H. designed the research and conducted the experiments. A.M.M. helped with the interpretation of the results and all authors contributed to the writing of the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Movie

Supplementary Movie (AVI 2445 kb)

Supplementary Information

Supplementary Information (PDF 719 kb)

Rights and permissions

About this article

Cite this article

Kiener, D., Hosemann, P., Maloy, S. et al. In situ nanocompression testing of irradiated copper. Nature Mater 10, 608–613 (2011). https://doi.org/10.1038/nmat3055

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat3055

This article is cited by

-

Time-resolved transmission electron microscopy for nanoscale chemical dynamics

Nature Reviews Chemistry (2023)

-

Specimen Size Effect of Tensile Behavior of Al-4.0 wt pct Cu Alloy Sheets: Effects of Precipitates and Cyclic Predeformation

Metallurgical and Materials Transactions A (2022)

-

Room-temperature plasticity in diamond

Science China Technological Sciences (2021)

-

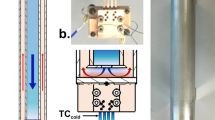

Novel Methods for Recording Stress-Strain Curves in Proton Irradiated Material

Scientific Reports (2020)

-

Effect of Ion Irradiation Introduced by Focused Ion-Beam Milling on the Mechanical Behaviour of Sub-Micron-Sized Samples

Scientific Reports (2020)