Abstract

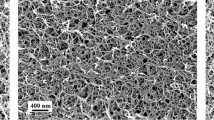

Natural porous materials such as bone, wood and pith evolved to maximize modulus for a given density1. For these three-dimensional cellular solids, modulus scales quadratically with relative density2,3. But can nanostructuring improve on Nature’s designs? Here, we report modulus–density scaling relationships for cubic (C), hexagonal (H) and worm-like disordered (D) nanoporous silicas prepared by surfactant-directed self-assembly. Over the relative density range, 0.5 to 0.65, Young’s modulus scales as (density)n where n(C)<n(H)<n(D)<2, indicating that nanostructured porous silicas exhibit a structure-specific hierarchy of modulus values D<H<C. Scaling exponents less than 2 emphasize that the moduli are less sensitive to porosity than those of natural cellular solids, which possess extremal moduli based on linear elasticity theory4. Using molecular modelling and Raman and NMR spectroscopy, we show that uniform nanoscale confinement causes the silica framework of self-assembled silica to contain a higher portion of small, stiff rings than found in other forms of amorphous silica. The nanostructure-specific hierarchy and systematic increase in framework modulus we observe, when decreasing the silica framework thickness below 2 nm, provides a new ability to maximize mechanical properties at a given density needed for nanoporous materials integration5.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Vincent, J. F. V. & Currey, J. D. 34th Symp. Soc. Exp. Biol. (Cambridge Univ. Press, Cambridge, 1980).

Gibson, L. J. The mechanical behaviour of cancellous bone. J. Biomech. 18, 317–328 (1985).

Gibson, L. J. & Ashby, M. F. The mechanics of three-dimensional cellular materials. Proc. R. Soc. Lond. A 382, 43–59 (1982).

Hashin, Z. & Shtrikman, S. A variational approach to the theory of the elastic behavior of multiphase materials. J. Mech. Phys. Solids 11, 127–140 (1963).

Brinker, C. J. & Scherer, G. W. Sol-Gel Science: The Physics and Chemistry of Sol-Gel Processing (Academic, San Diego, 1990).

Woignier, T. & Phalippou, J. Scaling law variation of the mechanical-properties of silica aerogels. J. Phys. 50, C4179–C4184 (1989).

Miller, R. D. Device physics: In search of low-k dielectrics. Science 286, 421 (1999).

The International Technology Roadmap for Semiconductors 2005 (ITRS 2005), Interconnect section.

Lu, Y. F. et al. Continuous formation of supported cubic and hexagonal mesoporous films by sol–gel dip-coating. Nature 389, 364–368 (1997).

Ting, C. Y., Ouyan, D. F. & Wan, B. Z. Preparation of ultra-low dielectric constant porous silica films using Tween 80 as a template. J. Electrochem. Soc. 150, F164 (2003).

Cassiers, K. et al. A detailed study of thermal; hydrothermal; and mechanical stabilities of a wide range of surfactant assembled mesoporous silicas. Chem. Mater. 14, 2317–2324 (2002).

Gusev, V. Y., Feng, X. B., Bu, Z., Haller, G. L. & O’Brien, J. A. Mechanical stability of pure silica mesoporous MCM-41 by nitrogen adsorption and small-angle X-ray diffraction measurements. J. Phys. Chem. 100, 1985–1988 (1996).

Hartmann, M. & Bischof, C. Mechanical stability of mesoporous molecular sieve MCM-48 studied by adsorption of benzene; n-heptane; and cyclohexane. J. Phys. Chem. B 103, 6230–6235 (1999).

Wu, J. J., Liu, X. Y. & Tolbert, S. H. High-pressure stability in ordered mesoporous silicas: Rigidity and elasticity through nanometer scale arches. J. Phys. Chem. B 104, 11837–11841 (2000).

Kirsch, B. L., Chen, X., Richman, E. K., Gupta, V. & Tolbert, S. H. Probing the effects of nanoscale architecture on the mechanical properties of hexagonal silica/polymer composites thin films. Adv. Funct. Mater. 15, 1319 (2005).

Fan, H. Y. et al. Rapid prototyping of patterned functional nanostructures. Nature 405, 56–60 (2000).

Smarsly, B., Gibaud, A., Ruland, W., Sturmayr, D. & Brinker, C. J. Quantitative SAXS analysis of oriented 2D hexagonal cylindrical silica mesostructures in thin films obtained from nonionic surfactants. Langmuir 21, 3858 (2005).

Frye, G. C. et al. in Better Ceramics Through Chemistry IV (eds Zelinski, B. J. J., Brinker, C. J., Clark, D. E. & Ulrich, D. R.) 583–593 (Mater. Res. Soc., San Francisco, 1990).

Oliver, W. C. & Pharr, G. M. An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564–1583 (1992).

Jain, A. et al. Effects of processing history on the modulus of silica xerogel films. J. Appl. Phys. 90, 5832–5834 (2001).

Jiang, Y.-B., Liu, N., Gerung, H., Cecchi, J. L. & Brinker, C. J. Nanometer-thick conformal pore sealing of self-assembled mesoporous silica by plasma-assisted atomic layer deposition. J. Am. Chem. Soc. 128, 11018–11019 (2006).

Zha, C. S., Hemley, R. J., Mao, H. K., Duffy, T. S. & Meade, C. Acoustic velocities and refractive-index of SiO2 glass to 57. 5-GPa by Brillouin-scattering. Phys. Rev. B 50, 13105–13112 (1994).

Lacks, D. J. Localized mechanical instabilities and structural transformations in silica glass under high pressure. Phys. Rev. Lett. 80, 5385–5388 (1998).

Lacks, D. J. First-order amorphous-amorphous transformation in silica. Phys. Rev. Lett. 84, 4629–4632 (2000).

Sugiura, H., Ikeda, R., Kondo, K. & Yamadaya, T. Densified silica glass after shock compression. J. Appl. Phys. 81, 1651–1655 (1997).

Brinker, C. J., Kirkpatrick, R. J., Tallant, D. R., Bunker, B. C. & Montez, B. NMR confirmation of strained defects in amorphous silica. J. Non-Cryst. Solids 99, 418–428 (1988).

Galeener, F. L. in The Structure of Non-Crystalline Materials (eds Gaskell, P. H., Parker, J. M. & Davis, E. K.) 337–359 (Taylor and Francis, London, 1982).

Gibaud, A. et al. Wall thickness and core radius determination in surfactant templated silica thin films using GISAXS and X-ray reflectivity. Europhys. Lett. 63, 833 (2003).

Trofymluk, O., Levchenko, A. A., Tolbert, S. H. & Navrotsky, A. Energetics of mesoporous silica: Investigation into pore size and symmetry. J. Phys. Chem. B 17, 3772–3783 (2005).

Borodko, Y. et al. Structure sensitivity of vibrational spectra of mesoporous silica SBA-15 and Pt/SBA-15. J. Phys. Chem. B 109, 17386–17390 (2005).

Oestrike, R. et al. High-resolution Na-23; Al-27; and Si-29 NMR-spectroscopy of framework aluminosilicate glasses. Geochim. Cosmochim. Acta 51, 2199–2209 (1987).

O’Keefe, M. & Gibbs, G. V. Defects in amorphous silica: Ab intio MO Calculations. J. Chem. Phys. 81, 876 (1984).

Torquato, S. & Donev, A. Minimal surfaces and multifunctionality. Proc. R. Soc. Lond. A 460, 1849–1856 (2004).

Torquato, S. Effective stiffness tensor of composite media: II. Applications to isotropic dispersions. J. Mech. Phys. Solids 46, 1411–1440 (1998).

Tatsumi, T., Koyano, K., Tanaka, Y. & Nakata, S. Mechanochemical collapse of M41S mesoporous molecular sieves through hydrolysis of siloxane bonds. Chem. Lett. 469–470 (1997).

Torquato, S., Donev, A., Evans, A. G. & Brinker, C. J. Manufacturable extremal low-dielectric, high-stiffness porous materials. J. Appl. Phys. 97, 124103 (2005).

Alud, B. Acoustic Fields and Waves in Solids (Wiley, New York, 1973).

Van Beest, B. W. H., Kramer, G. J. & van Santen, R. A. Force-fields for silicas and aluminophosphates based on ab initio calculations. Phys. Rev. Lett. 64, 1955 (1990).

Acknowledgements

We thank D. Doshi (UNM), A. Gibaud (Université du Maine), B. Smarsly (Max Planck Institute of Colloids and Interfaces) and R. Köhn (Munich) for GISAXS and SRSAXS, N. Liu (UNM) for molecular simulations of the cyclo-tetrasiloxane and G. Scherer (Princeton University) for many useful discussions. This work was supported by the US Department of Energy Office of Science, Air Products and Chemicals, Incorporated, Sematech, the US Air Force (FA9550-04-1-0087-CJB; F49620-03-1-0406-ST), the Army Research Office (DAAD19-03-1-0227-CJB), NSF (0402867-DJL) and the University of New Mexico/Rutgers/NSF Ceramics and Composites Research Center. TEM investigations were carried out in the Department of Earth and Planetary Sciences at the University of New Mexico. Sandia is a multiprogram laboratory operated by Sandia Corporation, a Lockheed-Martin Company, for the US DOE.

Author information

Authors and Affiliations

Contributions

H.F. prepared the nanostructured silicas, devising the means to achieve three different architectures at each density, carried out TEM and other structural characterization and oversaw the experimental work. C.H. under the guidance of T.B. carried out the nano-indentation experiments. R.S. and D.T. carried out Raman spectroscopy on thin-film nanostructures and (earlier) bulk silica gels. R.A. carried out 29Si magic-angle-spinning NMR spectroscopy. D.J.K. developed acoustic means to measure Poisson’s ratio of thin-film samples. D.J.L. carried out molecular simulations. S.L. carried out theoretical analyses of modulus–density scaling relationships. C.J.B. directed the research and contributed to the interpretation of the combined experimental, modelling and theoretical studies.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary information and tables (PDF 317 kb)

Rights and permissions

About this article

Cite this article

Fan, H., Hartshorn, C., Buchheit, T. et al. Modulus–density scaling behaviour and framework architecture of nanoporous self-assembled silicas. Nature Mater 6, 418–423 (2007). https://doi.org/10.1038/nmat1913

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat1913

This article is cited by

-

Mechanical properties of ordered mesoporous oxides thin films

Journal of Sol-Gel Science and Technology (2022)

-

Effective photodegradation of 2,4-dichlorophenoxyacetic acid on TiO2 nanocrystals anchored on SBA-15 mesoporous material

International Journal of Environmental Science and Technology (2022)

-

Mechanical properties and structural integrity of devices based on sol–gel mesoporous oxides thin films

Journal of Sol-Gel Science and Technology (2022)

-

Slow-sound propagation in aerogel-inspired hybrid structure with backbone and dangling branch

Advanced Composites and Hybrid Materials (2021)

-

Complex silica composite nanomaterials templated with DNA origami

Nature (2018)