Abstract

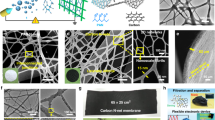

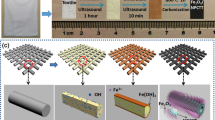

We present a rational and general method to fabricate a high-densely packed and aligned single-walled carbon-nanotube (SWNT) material by using the zipping effect of liquids to draw tubes together. This bulk carbon-nanotube material retains the intrinsic properties of individual SWNTs, such as high surface area, flexibility and electrical conductivity. By controlling the fabrication process, it is possible to fabricate a wide range of solids in numerous shapes and structures. This dense SWNT material is advantageous for numerous applications, and here we demonstrate its use as flexible heaters as well as supercapacitor electrodes for compact energy-storage devices.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Frank, S. P., Poncharal, P., Wang, Z. L. & de Heer, W. A. Carbon nanotube quantum resistors. Science 280, 1744–1746 (1998).

Liang, W. et al. Fabry–Perot interference in a nanotube electron waveguide. Nature 411, 665–669 (2001).

Baughman, R. H., Zakhidov, A. A. & de Heer, W. A. Carbon nanotubes-the route toward applications. Science 297, 787–792 (2002).

Kim, P., Shi, L., Majumdar, A. & McEuen, P. L. Thermal transport measurements of individual multiwalled nanotubes. Phys. Rev. Lett. 87, 215502 (2001).

Kociak, M. et al. Superconductivity in ropes of single-walled carbon nanotubes. Phys. Rev. Lett. 86, 2416–2419 (2001).

Tang, Z. K. et al. Superconductivity in 4 Angstrom single-walled carbon nanotubes. Science 292, 2462–2465 (2001).

Wong, E. W., Sheehan, P. E. & Lieber, C. M. Nanobeam mechanics: Elasticity, strength, and toughness of nanorods and nanotubes. Science 277, 1971–1975 (1997).

Walters, D. A. et al. Elastic strain of freely suspended single-walled carbon nanotube ropes. Appl. Phys. Lett. 74, 3803–3805 (1999).

Yu, M.-F., Files, B. S., Arepalli, S. & Ruoff, R. S. Tensile loading of ropes of single wall carbon nanotubes and their mechanical properties. Phys. Rev. Lett. 84, 5552–5555 (2000).

Thess, A. et al. Crystalline ropes of metallic carbon nanotubes. Science 273, 483–487 (1996).

Vigolo, B. et al. Macroscopic fibers and ribbon of oriented carbon nanotubes. Science 290, 1331–1334 (2000).

Zhu, H. W. et al. Direct synthesis of long single-walled carbon nanotube strands. Science 296, 884–886 (2002).

Ericson, L. M. et al. Macroscopic, neat, single-walled carbon nanotube fibers. Science 305, 1447–1450 (2004).

Li, Y., Kinloch, I. A. & Windle, A. H. Direct spinning of carbon nanotube fibers from chemical vapor deposition synthesis. Science 304, 276–278 (2004).

Jiang, K., Li, Q. & Fan, S. Spinning continuous carbon nanotube yarns. Nature 419, 801 (2002).

Zhang, M. et al. Multifunctional carbon nanotube yarns by downsizing an ancient technology. Science 306, 1358–1361 (2004).

Rinzler, A. G. et al. Large-scale purification of single-wall carbon nanotubes: Process, product, and characterization. Appl. Phys. A 67, 29–37 (1998).

Ren, Z. F. et al. Synthesis of large arrays of well-aligned carbon nanotubes on glass. Science 282, 1105–1107 (1998).

Fan, S. et al. Self-oriented regular arrays of carbon nanotubes and their field emission properties. Science 283, 512–514 (1999).

Murakami, Y. et al. Growth of vertically aligned single-walled carbon nanotube films on quartz substrates and their optical anisotropy. Chem. Phys. Lett. 385, 298–303 (2004).

Hata, K. et al. Water-assisted highly efficient synthesis of impurity-free single-walled carbon nanotubes. Science 306, 1362–1364 (2004).

Cao, A., Dickrell, P. L., Sawyer, W. G., Ghasemi-Nejhad, M. N. & Ajayan, P. M. Super compressible foamlike carbon nanotube films. Science 310, 1307–1310 (2005).

Zhang, M. et al. Strong, transparent, multifunctional, carbon nanotube sheets. Science 309, 1215–1219 (2005).

Nguyen, C. V. et al. Preparation of nucleic acid functionalized carbon nanotube arrays. Nano Lett. 2, 1079–1081 (2002).

Lau, K. K. S. et al. Superhydrophobic carbon nanotube forests. Nano Lett. 3, 1701–1705 (2003).

Fan, J. G., Dyer, D., Zhang, G. & Zhao, Y.-P. Nanocarpet effect: Pattern formation during the wetting of vertically aligned nanorod arrays. Nano Lett. 4, 2133–2138 (2004).

Correa-Duarte, M. A. et al. Fabrication and biocompatibility of carbon nanotube-based 3D networks as scafolds for cell seeding and growth. Nano Lett. 4, 2233–2236 (2004).

Liu, H. et al. Self-assembly of large-scale micropatterns on aligned carbon nanotube films. Angew. Chem. 43, 1146–1149 (2004).

Chakrapani, N., Wei, B., Carrillo, A., Ajayan, P. & Kane, R. S. Capillary-driven assembly of two-dimensional cellular carbon nanotube foams. Proc. Natl Acad. Sci. 101, 4009–4013 (2004).

Ko, H., Peleshanko, S. & Tsukruk, V. V. Combing and bending of carbon nanotube arrays with confined microfluidic flow on patterned surfaces. J. Phys. Chem. 108, 4385–4393 (2004).

Whitten, P. G., Spinks, G. M. & Wallace, G. G. Mechanical properties of carbon nanotube paper in ionic liquid and aqueous electrolytes. Carbon 43, 1891–1896 (2005).

Zhong, G. et al. Large-area synthesis of carbon nanofibers by low-power microwave plasma-assisted CVD. Chem. Vapor Dep. 10, 125–128 (2004).

Futaba, D. N. et al. 84% Catalyst activity of water-assisted growth of single walled carbon nanotube forest characterization by a statistical and macroscopic approach. J. Phys. Chem. B 110, 8035–8038 (2006).

Duesberg, G. S., Loa, I., Burghard, M., Syassen, K. & Roth, S. Polarized raman spectroscopy on isolated single-wall carbon nanotubes. Phys. Rev. Lett. 85, 5436–5439 (2000).

Murakami, Y. et al. Polarization dependence of resonant Raman scattering from vertically aligned single-walled carbon nanotube films. Phys. Rev. B 71, 085403 (2005).

Klug, H. & Alexander, L. E. (eds) in X-ray Diffraction Procedures 2nd edn (Wiley, New York, 1974).

Lovell, R. & Mitchell, G. R. Moleular-orientation distribution derived from an arbitrary reflection. Acta Crystallogr. A 37, 135–137 (1981).

Yang, C.-M., Kaneko, K., Yudasaka, M. & Iijima, S. Effect of purification on pore structure of hipco single-walled carbon nanotube aggregates. Nano Lett. 2, 385–388 (2002).

Zhao, D. et al. Triblock copolymer synthesis of mesoporous silica with periodic 50–300 Angstrom pores. Science 279, 548–552 (1998).

Zhao, D. et al. Nonionic triblock and star diblock copolymer and oligomeric surfactant synthesis of highly ordered, hydrothermally stable, mesoporous silica structures. J. Am. Chem. Soc. 120, 6024–6036 (1998).

Yamada, T., Zhou, H.S., Asai, K. & Honma, I. Pore size controlled mesoporous silicate powder prepared by triblock copolymer templates. Mater. Lett. 56, 93–96 (2002).

Shirashi, S., Kurihara, H., Okabe, K., Hulicova, D. & Oya, A. Electric double layer capacitance of highly pure single-walled carbon nanotubes (HiPco ™ Buckytubes ™) in propylene carbonate electrolytes. Electrochem. Commun. 4, 593–598 (2002).

Niu, C., Sichel, E. K., Hoch, R., Moy, D. & Tennent, H. High power electrochemical capacitors based on carbon nanotube electrodes. Appl. Phys. Lett. 70, 1480–1482 (1997).

Du, C., Yeh, J. & Pan, N. High power density supercapacitors using locally aligned carbon nanotube electrodes. Nanotechnology 16, 350–353 (2005).

Xu, B. et al. Room temperature molten salt as electrolyte for carbon nanotube-based electric double layer capacitors. J. Power Sources 158, 773–778 (2006).

Hiraoka, T. et al. Synthesis of single- and double-walled carbon nanotube forests on conducting metal foils. J. Am. Chem. Soc. 128, 13338–13339 (2006).

International Tables for X-ray Crystallography Vol. II (Reidel, Boston, MA, 1959 and 1972).

Acknowledgements

We gratefully acknowledge S. Usuba for the use of the microhardness tester and the contributions by T. Namai, M. Mizuno, A. Otsuka, K. Ozawa and S. Yamada. We also gratefully acknowledge M. Goto and K. Nakayama for their discussions and assistance on X-ray diffraction. Partial support by the New Energy and Industrial Technology Development Organization (NEDO) Nano-Carbon Technology project is acknowledged.

Author information

Authors and Affiliations

Contributions

D.N.F. and K.H. conceived and designed the experiments; D.N.F. performed the experiments; T.Y. and T.H. contributed to material analyses; Y.H. contributed to material preparation; T.H., O.T. and H.H. contributed to super-capacitor preparation/characterization; Y.K. contributed XRD analysis tools and D.N.F. and K.H. co-wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary information and figures S1-S6 (PDF 397 kb)

Supplementary Information

Supplementary movie S1 (MOV 1010 kb)

Supplementary Information

Supplementary movie S2 (MOV 2182 kb)

Rights and permissions

About this article

Cite this article

Futaba, D., Hata, K., Yamada, T. et al. Shape-engineerable and highly densely packed single-walled carbon nanotubes and their application as super-capacitor electrodes. Nature Mater 5, 987–994 (2006). https://doi.org/10.1038/nmat1782

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat1782

This article is cited by

-

Robust alternating multilayered cellulose nanofiber composite membranes fabricated by high-efficiency calcium ion-precomplexed vacuum-assisted self-assembly towards electromagnetic interference shielding

Advanced Composites and Hybrid Materials (2024)

-

Acid enhanced zipping effect to densify MWCNT packing for multifunctional MWCNT films with ultra-high electrical conductivity

Nature Communications (2023)

-

Aligned carbon nanotubes for lithium-ion batteries: A review

Nano Research (2023)

-

Electrospun deposited Mn2O3/GO nanofiber composite electrode for hybrid coin cell supercapacitor devices

Journal of Materials Science: Materials in Electronics (2022)