Abstract

Nanoporous anodic aluminium oxide has been widely used for the development of various functional nanostructures. So far these self-organized pore structures could only be prepared within narrow processing conditions. Here we report a new oxalic-acid-based anodization process for long-range ordered alumina membranes. This process is a new generation of the so-called ‘hard anodization’ approach that has been widely used in industry for high-speed fabrication of mechanically robust, very thick (>100 μm) and low-porosity alumina films since the 1960s. This hard anodization approach establishes a new self-ordering regime with interpore distances, (Dint)=200–300 nm, which have not been achieved by mild anodization processes so far. It offers substantial advantages over conventional anodization processes in terms of processing time, allowing 2,500–3,500% faster oxide growth with improved ordering of the nanopores. Perfectly ordered alumina membranes with high aspect ratios (>1,000) of uniform nanopores with periodically modulated diameters have been realized.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Keller, F., Hunter, M. S. & Robinson, D. L. Structural features of oxide coatings on aluminium. J. Electrochem. Soc. 100, 411–419 (1953).

Hunter, M. S. & Fowle, P. Determination of barrier layer thickness of anodic oxide coating. J. Electrochem. Soc. 101, 481–485 (1954).

Thompson, G. E. & Wood, G. C. Porous anodic film formation on aluminium. Nature 290, 230–232 (1981).

Lohrengel, M. M. Thin anodic oxide layers on aluminium and other valve metals: high field regime. Mater. Sci. Eng. R 11, 243–294 (1993).

Diggle, J. W., Downie, T. C. & Goulding, C. W. Anodic oxide films on aluminium. Chem. Rev. 69, 365–405 (1969).

Thompson, G. E., Furneaux, R. C., Wood, G. C., Richardson, J. A. & Goode, J. S. Nucleation and growth of porous anodic films on aluminium. Nature 272, 433–435 (1978).

Wood, G. C. & O’Sullivan, J. P. The anodizing of aluminium in sulphate solutions. Electrochim. Acta 15, 1865–1876 (1970).

Lee, W., Scholz, R., Nielsch, K. & Gösele, U. A template-based electrochemical method for the synthesis of multisegmented metallic nanotubes. Angew. Chem. Int. Edn 44, 6050–6054 (2005).

Lee, S. B. et al. Antibody-based bio-nanotube membranes for enantiomeric drug separations. Science 296, 2198–2200 (2002).

Park, S., Lim, J.-H., Chung, S.-W. & Mirkin, C. A. Self-assembly of mesoscopic metal-polymer amphiphiles. Science 303, 348–351 (2004).

Kovtyukhova, N. I. & Mallouk, T. E. Nanowire p-n heterojunction diodes made by templated assembly of multilayer carbon-nanotube/polymer/semiconductor-particle shells around metal nanowires. Adv. Mater. 17, 187–192 (2005).

Zhi, L., Wu, J., Li, J., Kolb, U. & Müllen, K. Carbonization of disclike molecules in porous alumina membranes: Toward carbon nanotubes with controlled graphene-layer orientation. Angew. Chem. Int. Edn 44, 2120–2123 (2005).

Mikulskas, I., Juodkazis, S., Tomašiūmas, R. & Dumas, J. G. Aluminium oxide photonic crystals grown by a new hybrid method. Adv. Mater. 13, 1574–1577 (2001).

Hurst, S. J., Payne, E. K., Qin, L. & Mirkin, C. A. Multisegmented one-dimensional nanorods prepared by hard-template synthetic methods. Angew. Chem. Int. Edn 45, 2672–2692 (2006).

Masuda, H. & Fukuda, K. Ordered metal nanohole arrays made by a two-step replication of honeycomb structures of anodic alumina. Science 268, 1466–1468 (1995).

Masuda, H., Hasegwa, F. & Ono, S. Self-ordering of cell arrangement of anodic porous alumina formed in sulphuric acid solution. J. Electrochem. Soc. 144, L127–L130 (1997).

Li, A. P., Müller, F., Birner, A., Nielsch, K. & Gösele, U. Hexagonal pore arrays with a 50–420 nm interpore distance formed by self-organization in anodic alumina. J. Appl. Phys. 84, 6023–6026 (1998).

Masuda, H., Yada, K. & Osaka, A. Self-ordering of cell configuration of anodic porous alumina with large-size pores in phosphoric acid solution. Jpn. J. Appl. Phys. 37, L1340–L1342 (1998).

Shingubara, S., Morimoto, K., Sakaue, H. & Takahagi, T. Self-organization of a porous alumina nanohole array using a sulfuric/oxalic acid mixture as electrolyte. Electrochem. Solid-State Lett. 7, E15–E17 (2004).

Li, F., Zhang, L. & Metzger, R. M. On the growth of highly ordered pores in anodized aluminium oxide. Chem. Mater. 10, 2470–2480 (1998).

Nielsch, K., Choi, J., Schwirn, K., Wehrspohn, R. B. & Gösele, U. Self-ordering regimes of porous alumina: The 10% porosity rule. Nano Lett. 2, 677 (2002).

Csokán, P. Beiträge zur kenntnis der anodischen oxydation von aluminium verdunnter, kalter schwefelsaure. Metalloberfläche 15, B49–B53 (1961).

Csokán, P. & Sc, C. C. Hard anodizing: Studies of the relation between anodizing conditions and the growth and properties of hard anodic oxide coatings. Electroplat. Metal Finish. 15, 75–82 (1962).

Lichtenberger-Bajza, E., Domony, A. & Csokán, P. Untersuchung der struktur und anderer eigenschaften von durch anodische oxydation auf aluminium erzeugten hartoxydschichten. Werkstoffe. Korros. 11, 701–707 (1960).

Csokán, P. Some observations on the growth mechanism of hard anodic oxide coatings on aluminium. Trans. Inst. Metal Finishing 41, 51–56 (1964).

Olbertz, B. Hartanodisieren eröffnet aluminum vielfältige technische Anwendungs-möglichkeiten. Aluminium 3, 268–270 (1988).

Rajendra, A. et al. Hard anodization of aluminium and its application to sensorics. Surf. Eng. 21, 193–197 (2005).

John, S., Balasubramanian, V. & Shenoi, B. A. Hard anodizing aluminium and its alloys—AC in sulphuric acid—sodium sulphate bath. Met. Finish. 82, 33–39 (1984).

Hecker, J. G. Aluminum hard coats. Product Finishing 53, 88–92 (1988).

Ono, S., Saito, M., Ishiguro, M. & Asoh, H. Controlling factor of self-ordering of anodic porous alumina. J. Electrochem. Soc. 151, B473–B478 (2004).

Chu, S. Z., Wada, K., Inoue, S., Isogai, M. & Yasumori, A. Fabrication of ideally ordered nanoporous alumina films and integrated alumina nanotubule arrays by high-field anodization. Adv. Mater. 17, 2115–2119 (2005).

Ono, S., Saito, M. & Asoh, H. Self-ordering of anodic porous alumina induced by local current concentration: Burning. Electrochem. Solid-State Lett. 7, B21–B24 (2004).

Ono, S., Saito, M. & Asoh, H. Self-ordering of anodic porous alumina formed in organic acid electrolytes. Electrochim. Acta 51, 827–833 (2005).

Arrowsmith, D. J., Clifford, A. W. & Moth, D. A. Fracture of anodic oxide formed on aluminium in sulphuric acid. J. Mater. Sci. Lett. 5, 921–922 (1986).

Wada, K., Shimohira, T., Yamada, M. & Baba, N. Microstructure of porous anodic oxide films on aluminium. J. Mater. Sci. Lett. 21, 3810–3816 (1986).

Masuda, H. et al. Square and triangular nanohole array architectures in anodic alumina. Adv. Mater. 13, 189–192 (2001).

Fournier-Bidoz, S., Kitaev, V., Routkevitch, D., Manners, I. & Ozin, G. A. Highly ordered nanosphere imprinted nanochannel alumina (NINA). Adv. Mater. 16, 2193–2196 (2004).

Asoh, H., Nishio, K., Nakao, M., Tamamura, T. & Masuda, H. Conditions for fabrication of ideally ordered anodic porous alumina using pretextured Al. J. Electrochem. Soc. 148, B152–B156 (2001).

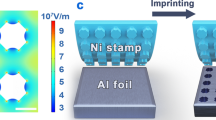

Lee, W., Ji, R., Ross, C. A., Gösele, U. & Nielsch, K. Wafer-scale Ni imprint stamps for porous alumina membranes based on interference lithography. Small 2, 978–982 (2006).

O’Sullivan, J. P. & Wood, G. C. The morphology and mechanism of formation of porous anodic films on aluminium. Proc. R. Soc. London A 317, 511–543 (1970).

Jessensky, O., Müller, F. & Gösele, U. Self-organized formation of hexagonal pore arrays in anodic alumina. Appl. Phys. Lett. 72, 1173–1175 (1998).

Parkhutik, V. P. & Shershulsky, V. I. Theoretical modelling of porous oxide growth on aluminium. J. Phys. D 25, 1258–1263 (1992).

Ebihara, K., Takahashi, H. & Nagayama, M. Structure and density of anodic oxide films formed on aluminium in oxalic acid solutions. J. Met. Finish. Soc. Jpn 34, 548–553 (1983).

Güntherschulze, A. & Betz, H. Die bewegung der ionengitter von isolatoren bei extremen elektrischen feldstärken. Z. Phys. 92, 367–374 (1934).

Cabrera, N. & Mott, N. F. Theory of the oxidation of metals. Rep. Prog. Phys. 12, 163–184 (1948).

Acknowledgements

We thank F. Müller for helpful discussions, D. Hesse for his comments on the manuscript and W. Gruner at the Leibniz-Institut für Festkörper- und Werkstoffforschung Dresden (IFW-Dresden) for chemical anaysis. We acknowledge financial support from the German Federal Ministry for Education and Research (BMBF, Project No. 03N8701).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary figures S1-S6 (PDF 1301 kb)

Rights and permissions

About this article

Cite this article

Lee, W., Ji, R., Gösele, U. et al. Fast fabrication of long-range ordered porous alumina membranes by hard anodization. Nature Mater 5, 741–747 (2006). https://doi.org/10.1038/nmat1717

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat1717

This article is cited by

-

Application of Anodic Titania, Alumina, Zirconia and Tin Oxide in Sensorics

Sensing and Imaging (2023)

-

Single-step nano-engineering of multiple micro-rough metals via anodization

Nano Research (2023)

-

Optimization of Hard Anodizing Process Parameters on 6061-T6 Aluminum Alloy Using Response Surface Methodology

Journal of Materials Engineering and Performance (2023)

-

Capillary Performance of Nanoporous Aluminum Braided Wicks Prepared by Anodic Oxidation

Nanomanufacturing and Metrology (2022)

-

Recent advances in properties and applications of nanoporous materials and porous carbons

Carbon Letters (2022)