Abstract

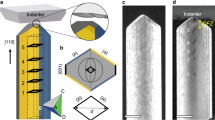

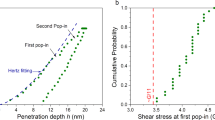

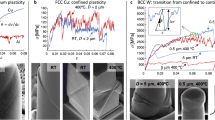

In nanoscale contact experiments, it is generally believed that the shear stress at the onset of plasticity can approach the theoretical shear strength of an ideal, defect-free lattice1,2,3,4, a trend also observed in idealized molecular dynamics simulations5,6,7,8,9. Here we report direct evidence that plasticity in a dislocation-free volume of polycrystalline aluminium can begin at very small forces, remarkably, even before the first sustained rise in repulsive force. However, the shear stresses associated with these very small forces do approach the theoretical shear strength of aluminium (∼2.2 GPa). Our observations entail correlating quantitative load–displacement measurements with individual video frames acquired during in situ nanoindentation experiments in a transmission electron microscope. We also report direct evidence that a submicrometre grain of aluminium plastically deformed by nanoindentation to a dislocation density of ∼1014 m−2 is also capable of supporting shear stresses close to the theoretical shear strength. This result is contrary to earlier assumptions that a dislocation-free volume is necessary to achieve shear stresses near the theoretical shear strength of the material5,6,7,8,9. Moreover, our results in entirety are at odds with the prevalent notion that the first obvious displacement excursion in a nanoindentation test is indicative of the onset of plastic deformation.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Gane, N. & Bowden, F. P. Microdeformation of solids. J. Appl. Phys. 39, 1432–1435 (1968).

Asif, S. A. S. & Pethica, J. B. Nanoindentation creep of single-crystal tungsten and gallium arsenide. Phil. Mag. A 76, 1105–1118 (1997).

Gouldstone, A., Koh, H. J., Zeng, K. Y., Giannakopoulos, A. E. & Suresh, S. Discrete and continuous deformation during nanoindentation of thin films. Acta Mater. 48, 2277–2295 (2000).

Kramer, D. E., Yoder, K. B. & Gerberich, W. W. Surface constrained plasticity: oxide rupture and the yield point process. Phil. Mag. A 81, 2033–2058 (2001).

Gouldstone, A., Van Vliet, K. J. & Suresh, S. Nanoindentation—simulation of defect nucleation in a crystal. Nature 411, 656 (2001).

Kelchner, C. L., Plimpton, S. J. & Hamilton, J. C. Dislocation nucleation and defect structure during surface indentation. Phys. Rev. B 58, 11085–11088 (1998).

Tadmor, E. B., Miller, R., Phillips, R. & Ortiz, M. Nanoindentation and incipient plasticity. J. Mater. Res. 14, 2233–2250 (1999).

Zimmerman, J. A., Kelchner, C. L., Klein, P. A., Hamilton, J. C. & Foiles, S. M. Surface step effects on nanoindentation. Phys. Rev. Lett. 87, 165507 (2001).

Lilleodden, E. T., Zimmerman, J. A., Foiles, S. M. & Nix, W. D. Atomistic simulations of elastic deformation and dislocation nucleation during nanoindentation. J. Mech. Phys. Solids 51, 901–920 (2003).

Courtney, T. H. Mechanical Behavior of Materials (McGraw-Hill, New York, 1990).

Gerberich, W. W. et al. Superhard silicon nanospheres. J. Mech. Phys. Solids 51, 979–992 (2003).

Roundy, D., Krenn, C. R., Cohen, M. L. & Morris, J. W. Ideal shear strengths of fcc aluminum and copper. Phys. Rev. Lett. 82, 2713–2716 (1999).

Li, J., Van Vliet, K. J., Zhu, T., Yip, S. & Suresh, S. Atomistic mechanisms governing elastic limit and incipient plasticity in crystals. Nature 418, 307–310 (2002).

Friak, M., Sob, M. & Vitek, V. Ab initio study of the ideal tensile strength and mechanical stability of transition-metal disilicides. Phys. Rev. B 68, 184101 (2003).

Kramer, D. et al. Yield strength predictions from the plastic zone around nanocontacts. Acta Mater. 47, 333–343 (1998).

Sob, M., Friak, M., Legut, D., Fiala, J. & Vitek, V. The role of ab initio electronic structure calculations in studies of the strength of materials. Mater. Sci. Eng. A 387–389, 148–157 (2004).

Friak, M., Sob, M. & Vitek, V. Ab initio calculation of tensile strength in iron. Phil. Mag. 83, 3529–3537 (2003).

Krenn, C. R., Roundy, D., Cohen, M. L., Chrzan, D. C. & Morris, J. W. Connecting atomistic and experimental estimates of ideal strength. Phys. Rev. B 65, 13411 (2002).

Morris, J. W. et al. Elastic stability and the limits of strength. Thermec’2003, Pts 1-5 426–4, 4429–4434 (2003).

Fischer-Cripps, A. C. Nanoindentation (Springer, New York, 2004).

Kiely, J. D., Jarausch, K. F., Houston, J. E. & Russell, P. E. Initial stages of yield in nanoindentation. J. Mater. Res. 14, 2219–2227 (1999).

Minor, A. M., Morris, J. W. & Stach, E. A. Quantitative in situ nanoindentation in an electron microscope. Appl. Phys. Lett. 79, 1625–1627 (2001).

Minor, A. M., Lilleodden, E. T., Stach, E. A. & Morris, J. W. In-situ transmission electron microscopy study of the nanoindentation behavior of Al. J. Electr. Mater. 31, 958–964 (2002).

Minor, A. M., Lilleodden, E. T., Stach, E. A. & Morris, J. W. Direct observations of incipient plasticity during nanoindentation of Al. J. Mater. Res. 19, 176–182 (2004).

Warren, O. L., Downs, S. A. & Wyrobek, T. J. Challenges and interesting observations associated with feedback-controlled nanoindentation. Z. Metallkd. 95, 287–296 (2004).

Oliver, W. C. & Pharr, G. M. An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564–1583 (1992).

Mullins, W. W. Theory of thermal grooving. J. Appl. Phys. 28, 333–339 (1957).

Johnson, K. L. Contact Mechanics (Cambridge Univ. Press, New York, 1996).

Uchic, M. D., Dimiduk, D. M., Florando, J. N. & Nix, W. D. Sample dimensions influence strength and crystal plasticity. Science 305, 986–989 (2004).

Acknowledgements

The authors acknowledge that the research was supported in part by a US Department of Energy SBIR grant (DE-FG02-04ER83979) awarded to Hysitron, which does not constitute an endorsement by DOE of the views expressed in the article. This work was also supported by the Director, Office of Science, Office of Basic Energy Sciences, of the US Department of Energy under Contract No. DE-AC02-05CH11231.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary video S1 (MOV 2353 kb)

Supplementary Information

Supplementary figure S2 (PDF 791 kb)

Supplementary Information

Supplementary video S3 (MOV 1547 kb)

Rights and permissions

About this article

Cite this article

Minor, A., Syed Asif, S., Shan, Z. et al. A new view of the onset of plasticity during the nanoindentation of aluminium. Nature Mater 5, 697–702 (2006). https://doi.org/10.1038/nmat1714

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat1714

This article is cited by

-

Time-resolved transmission electron microscopy for nanoscale chemical dynamics

Nature Reviews Chemistry (2023)

-

Dislocation-induced stop-and-go kinetics of interfacial transformations

Nature (2022)

-

Review of recent progress on in situ TEM shear deformation: a retrospective and perspective view

Journal of Materials Science (2022)

-

Estimate of theoretical shear strength of C60 single crystal by nanoindentation

Journal of Materials Science (2021)

-

Compressive elastic behavior of single-crystalline 4H-silicon carbide (SiC) nanopillars

Science China Technological Sciences (2021)