Abstract

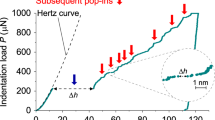

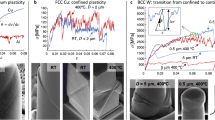

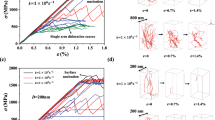

Nanoindentation has become ubiquitous for the measurement of mechanical properties at ever-decreasing scales of interest, including some studies that have explored the atomic-level origins of plasticity in perfect crystals. With substantial guidance from atomistic simulations, the onset of plasticity during nanoindentation is now widely believed to be associated with homogeneous dislocation nucleation. However, to date there has been no compelling quantitative experimental support for the atomic-scale mechanisms predicted by atomistic simulations. Our purpose here is to significantly advance the quantitative potential of nanoindentation experiments for the study of dislocation nucleation. This is accomplished through the development and application of high-temperature nanoindentation testing, and the introduction of statistical methods to quantitatively evaluate data. The combined use of these techniques suggests an unexpected picture of incipient plasticity that involves heterogeneous nucleation sites, and which has not been anticipated by atomistic simulations.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Gerberich, W. W., Venkataraman, S. K., Huang, H., Harvey, S. E. & Kohlstedt, D. L. The injection of plasticity by millinewton contacts. Acta Metall. Mater. 43, 1569–1576 (1995).

Gerberich, W. W., Nelson, J. C., Lilleodden, E. T., Anderson, P. & Wyrobek, J. T. Indentation induced dislocation nucleation: The initial yield point. Acta Mater. 44, 3585–3598 (1996).

Li, J., Van-Vliet, K. J., Zhu, T., Yip, S. & Suresh, S. Atomistic mechanisms governing elastic limit and incipient plasticity in crystals. Nature 418, 307–310 (2002).

Fago, M., Hayes, R. L., Carter, E. A. & Ortiz, M. Density-functional-theory-based local quasicontinuum method: Prediction of dislocation nucleation. Phys. Rev. B 70, 100102 (2004).

Suresh, S., Nieh, T. G. & Choi, B. W. Nano-indentation of copper thin films on silicon substrates. Scripta Mater. 41, 951–957 (1999).

Knap, J. & Ortiz, M. Effect of indenter-radius size on Au(001) nanoindentation. Phys. Rev. Lett. 90, 226102 (2003).

Kelchner, C. L., Plimpton, S. J. & Hamilton, J. C. Dislocation nucleation and defect structure during surface indentation. Phys. Rev. B 58, 11085 (1998).

de la Fuente, O. R. et al. Dislocation emission around nanoindentations on a (001) fcc metal surface studied by scanning tunneling microscopy and atomistic simulations. Phys. Rev. Lett. 88, 036101 (2002).

Lilleodden, E. T., Zimmerman, J. A., Foiles, S. M. & Nix, W. D. Atomistic simulations of elastic deformation and dislocation nucleation during nanoindentation. J. Mech. Phys. Solids 51, 901–920 (2003).

Miller, R. E. & Acharya, A. A stress-gradient based criterion for dislocation nucleation in crystals. J. Mech. Phys. Solids 52, 1507–1525 (2004).

Zhu, T. et al. Predictive modeling of nanoindentation-induced homogeneous dislocation nucleation in copper. J. Mech. Phys. Solids 52, 691–724 (2004).

Corcoran, S. G., Colton, R. J., Lilleodden, E. T. & Gerberich, W. W. Anomalous plastic deformation at surfaces: Nanoindentation of gold single crystals. Phys. Rev. B 55, R16057–R16060 (1997).

Kiely, J. D. & Houston, J. E. Nanomechanical properties of Au (111), (001), and (110) surfaces. Phys. Rev. B 57, 12588–12594 (1998).

Michalske, T. A. & Houston, J. E. Dislocation nucleation at nano-scale contacts. Acta Mater. 46, 391–396 (1998).

Gouldstone, A., Koh, H. -J., Zeng, K. -Y., Giannakopoulos, A. E. & Suresh, S. Discrete and continuous deformation during nanoindentation of thin films. Acta Mater. 48, 2277–2295 (2000).

Chiu, Y. L. & Ngan, A. H. W. Time-dependent characteristics of incipient plasticity in nanoindentation of a Ni3Al single crystal. Acta Mater. 50, 1599–1611 (2002).

Wo, P. C. & Ngan, A. H. W. Incipient plasticity during nano-scratch in Ni3Al. Phil. Mag. 84, 3145–3157 (2004).

Wo, P. C., Zuo, L. & Ngan, A. H. W. Time-dependent incipient plasticity in Ni3Al as observed in nanoindentation. J. Mater. Res. 20, 489–495 (2005).

Page, T. F., Oliver, W. C. & McHargue, C. J. The deformation behavior of ceramic crystals subjected to very low load (nano)indentations. J. Mater. Res. 7, 450–473 (1992).

Gane, N. & Bowden, F. P. Microdeformation of solids. J. Appl. Phys. 39, 1432–1435 (1968).

Chiu, Y. L. & Ngan, A. H. W. A TEM investigation on indentation plastic zones in Ni3Al (Cr, b) single crystals. Acta Mater. 50, 2677–2691 (2002).

Minor, A. M., Morris, J. W. & Stach, E. A. Quantitative in situ nanoindentation in an electron microscope. Appl. Phys. Lett. 79, 1625–1627 (2001).

Minor, A. M., Lilleodden, E. T., Stach, E. A. & Morris, J. W. Direct observations of incipient plasticity during nanoindentation of Al. J. Mater. Res. 19, 176–182 (2004).

Wang, W., Jiang, C. B. & Lu, K. Deformation behavior of Ni3Al single crystals during nanoindentation. Acta Mater. 51, 6169–6180 (2003).

Mann, A. B. & Pethica, J. B. The effect of tip momentum on the contact stiffness and yielding during nanoindentation testing. Phil. Mag. A 79, 577–592 (1999).

Shibutani, Y. & Koyama, A. Surface roughness effects on the displacement bursts observed in nanoindentation. J. Mater. Res. 19, 183–188 (2004).

Schuh, C. A. & Lund, A. C. Application of nucleation theory to the rate dependence of incipient plasticity during nanoindentation. J. Mater. Res. 19, 2152–2158 (2004).

Chinh, N. Q., Horváth, G., Kovács, Z. & Lendvai, J. Characterization of plastic instability steps occurring in depth-sensing indentation tests. Mater. Sci. Eng. A 324, 219–224 (2002).

Syed-Asif, S. A. & Pethica, J. B. Nanoindentation creep of single-crystal tungsten and gallium arsenide. Phil. Mag. A 76, 1105–1118 (1997).

Kramer, D. E., Yoder, K. B. & Gerberich, W. W. Surface constrained plasticity: Oxide rupture and the yield point process. Phil. Mag. A 81, 2033–2058 (2001).

Volinsky, A. A., Moody, N. R. & Gerberich, W. W. Nanoindentation of Au and Pt/Cu thin films at elevated temperatures. J. Mater. Res. 19, 2650–2657 (2004).

Lucas, B. N. & Oliver, W. C. Time dependent indentation testing at non-ambient temperatures utilizing the high temperature mechanical properties microprobe. Mater. Res. Soc. Symp. Proc. 356, 645–650 (1995).

Lucas, B. N. & Oliver, W. C. Indentation power-law creep of high-purity indium. Metall. Mater. Trans. A 30, 601–610 (1999).

Bahr, D. F., Wilson, D. E. & Crowson, D. A. Energy considerations regarding yield points during indentation. J. Mater. Res. 14, 2269–2275 (1999).

Beake, B. D. & Smith, J. F. High-temperature nanoindentation testing of fused silica and other materials. Phil. Mag. A 82, 2179–2186 (2002).

Xia, J., Li, C. X. & Dong, H. Hot-stage nano-characterizations of an iron aluminide. Mater. Sci. Eng. A 354, 112–120 (2003).

Smith, J. F. & Zheng, S. High temperature nanoscale mechanical property measurements. Surf. Eng. 16, 143–146 (2000).

Lund, A. C., Hodge, A. M. & Schuh, C. A. Incipient plasticity during nanoindentation at elevated temperatures. Appl. Phys. Lett. 85, 1362–1364 (2004).

Fischer-Cripps, A. C. Introduction to Contact Mechanics (Springer, New York, 2000).

Hirth, J. P. & Lothe, J. Theory of Dislocations (Wiley, New York, 1982).

Wollenberger, H. in Physical Metallurgy (eds Cahn, R. W. & Haasen, P.) Ch. 18, 1621–1722 (North Holland, Amsterdam, 1996).

Seitz, F. On the formation of dislocations from vacancies. Phys. Rev. 79, 890–891 (1950).

Zimmerman, J. A., Kelchner, C. L., Klein, P. A., Hamilton, J. C. & Foiles, S. M. Surface step effects on nanoindentation. Phys. Rev. Lett. 87, 165507 (2001).

Conrad, H. in High Strength Materials (ed. Zackay, V. F.) Ch. 11, 436–509 (Wiley, New York, 1965).

Pokluda, J., Cerny, M., Sandera, P. & Sob, M. Calculations of theoretical strength: State of the art and history. J. Comput.-Aided Mater. Design 11, 1–28 (2004).

Acknowledgements

This work was supported by the US Office of Naval Research; the views expressed herein are not endorsed by the sponsor. The collaborative support of Hysitron and the collaborative involvement of A. Hodge (Lawrence Livermore National Laboratory) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Schuh, C., Mason, J. & Lund, A. Quantitative insight into dislocation nucleation from high-temperature nanoindentation experiments. Nature Mater 4, 617–621 (2005). https://doi.org/10.1038/nmat1429

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat1429

This article is cited by

-

Quantifying the Dislocation Cell Contribution to the Yield Strength of 316L Steel

Metals and Materials International (2024)

-

Effect of indentation rate on deformation behavior and mechanical properties of FeO/Fe is simulated based on molecular dynamics

Applied Physics A (2023)

-

Incipient Plasticity of a Non-equiatomic Co21.5Cr21.5Fe21.5Mn21.5Ni14 Multi-principal Element Alloy

Metallurgical and Materials Transactions A (2023)

-

Gradient plastic zone model in equiatomic face-centered cubic alloys

Journal of Materials Science (2022)

-

Chemomechanical weakening of muscovite quantified with in situ liquid nanoindentation

Journal of Materials Science (2022)