Abstract

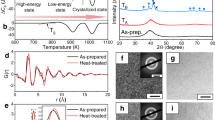

It is known that the cooling rate from the liquid state is an important factor in the production of bulk metallic glasses. However, the effects of other factors such as electric and magnetic fields have not been thoroughly investigated. Here, we present a new method for producing bulk metallic glasses by using electromagnetic vibrations with simultaneous imposition of an alternating electric current and a magnetic field. This method was found to be effective in enhancing apparent glass-forming ability in Mg65-Cu25-Y10 (atomic percent) alloys. Indeed, larger bulk metallic glasses could be obtained by the electromagnetic vibration process under the same cooling conditions. We presume that disappearance or decrement of clusters by the electromagnetic vibrations applied to the liquid state cause suppression of crystal nucleation. This electromagnetic vibration process should be effective in other bulk metallic glass systems if the clusters in the liquid state cause the crystal nucleation.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Inoue, A. Bulk Amorphous Alloys 2–36 (Trans Tech Publications, Switzerland, 1998).

Klement, W. Jr, Willens, R. H. & Duwez, P. Non-crystalline structure in solidified gold-silicon alloys. Nature 187, 869–870 (1960).

He, Y., Poon, S. J. & Shiflet, G. J. Synthesis and properties of metallic glasses that contain aluminum. Science 241, 1640–1642 (1988).

Greer, A. L. Metallic glasses. Science 267, 1947–1953 (1995).

Asai, S. Birth and recent activities of electromagnetic processing of materials. ISIJ Int. 29, 981–992 (1989).

Yavari, A. R., Oliveira, M. F., de Kiminami, C. S., Inoue, A. & Botta F. W. J. Electromechanical shaping, assembly and engraving of bulk metallic glasses. Mater. Sci. Eng. A 375–377, 227–234 (2004).

Vives, C. Effects of electromagnetic vibrations on the microstructure of continuously cast-aluminum alloys. Mater. Sci. Eng. A 173, 169–172 (1993).

Vives, C. Effects of forced electromagnetic vibrations during the solidification of aluminum alloys.2. Solidification in the presence of colinear variable and stationary magnetic fields. Metall. Mater. Trans. B 27, 457 (1996).

Radjai, A., Miwa, K. & Nishio, T. An investigation of the effects caused by electromagnetic vibrations in a hypereutectic Al-Si alloy melt. Metall. Mater. Trans. A 29, 1477–1484 (1998).

Radjai, A. & Miwa, K. Effects of the intensity and frequency of electromagnetic vibrations on the microstructural refinement of Hypoeutectic Al-Si alloys. Metall. Mater. Trans. A 31, 755–762 (2000).

Radjai, A. & Miwa, K. Structural refinement of gray iron by electromagnetic vibrations. Metall. Mater. Trans. A 33, 3025–3030 (2002).

Inoue, A., Kato, A., Zhang, T., Kim, S. G. & Masumoto, T. Mg-Cu-Y amorphous alloys with high mechanical strengths produced by a metallic mold casting method. Mater. Trans. JIM 32, 609–616 (1991).

Madge, S. V., Alexander, D. T. L. & Greer, A. L. An EFTEM study of compositional variations in Mg-Ni-Nd bulk metallic glasses. J. Non-Cryst. Solids 317, 23–29 (2003).

Madge, S. V. & Greer, A. L. Effect of Ag addition on the glass-forming ability and thermal stability of Mg-Cu-Y alloys. Mater. Sci. Eng. A 375–377, 759–762 (2004).

Matsubara, E. et al. Structural study of amorphous Mg50Ni30La20 alloy by the anomalous X-ray scattering (AXS) method. Mater. Trans. JIM 31, 228–231 (1990).

Niikura, A., Tsai, A. P., Inoue, A. & Masumoto, T. Chemical structural relaxation-induced embrittlement in amorphous Mg-Cu-Y alloys. J. Non-Cryst. Solids 159, 229–234 (1993).

Zhang, L. et al. Short-range and medium-range order in liquid and amorphous Al90Fe5Ce5 alloys. J. Non-Cryst. Solids 262, 169–176 (2000).

Acknowledgements

This work has been supported by a grant for the Metallic Glasses Project of the Material Industrial Competitiveness Strengthening Program from New Energy and Industrial Technology Development Organization (NEDO). The authors are grateful to N. Nishiyama for numerous helpful discussions. The authors also thank K. Yasue, Y. Sakaguchi and H. Matsubara for technical assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Tamura, T., Amiya, K., Rachmat, R. et al. Electromagnetic vibration process for producing bulk metallic glasses. Nature Mater 4, 289–292 (2005). https://doi.org/10.1038/nmat1341

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat1341

This article is cited by

-

Segmentation and Alignment of Nd2Fe14B Platelets in Nd-Cu Eutectic Alloys Using the Electromagnetic Vibration Technique

Metallurgical and Materials Transactions A (2020)

-

Crystalline orientation control of the platelet Nd2Fe14B phase to produce magnetic anisotropy via electromagnetic vibration processing

Scientific Reports (2019)

-

Deposition of Bismuth Telluride Thick Film by Solidification under Centrifugal Pressure

Journal of Electronic Materials (2009)

-

Motion of Crystal Particles by the Electromagnetic Vibrations in Mg-Cu-Y Bulk Metallic Glasses

Metallurgical and Materials Transactions A (2008)