Abstract

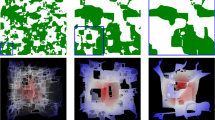

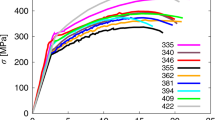

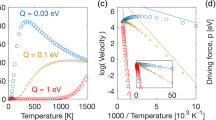

Accurate theoretical predictions of the volume-fraction dependence during diffusion-controlled coarsening of a polydisperse assembly of particles have proved difficult. Here, a new model of coarsening is presented, involving diffusive transport through the coherent interface between ordered and disordered phases, which atomistic calculations show has a ragged structure. The interface is a diffusion bottleneck when the ordered phase is dispersed. It is predicted that the square of the average radius grows linearly with time, that the depletion of solute decreases as the inverse square-root of time, and that there is no effect of volume fraction on kinetics and the scaled particle-size distributions. These differ dramatically from predictions of modern theories of diffusion-controlled coarsening. Data on coarsening in Ni-Al alloys is examined. We show that no other theory is consistent with the experimentally observed absence of an effect of volume fraction on coarsening of ordered γ′ (Ni3Al) precipitates in a disordered Ni-Al (γ) matrix, and the strong volume-fraction dependence of coarsening of γ precipitates in an ordered γ′ matrix.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Lifshitz, I. M. & Slyozov, V. V. The kinetics of precipitation from supersaturated solid solutions. J. Phys. Chem. Solids 19, 35–50 (1961).

Wagner, C. Theorie der alterung von niederschlägen durch umlösen (Ostwald-reifung). Z. Elektrochem. 65, 581–591 (1961).

Ardell, A. J. in Phase Transformations '87 (ed. Lorimer, G. W.) 485–494 (Institute of Metals, London, 1988).

Voorhees, P. W. The theory of Ostwald ripening. J. Stat. Phys. 38, 231–252 (1985).

Voorhees, P. W. Ostwald ripening of two-phase mixtures Annu. Rev. Mater. Sci. 22, 197–215 (1992).

Thornton, K., Akaiwa, N. & Voorhees, P. W. Dynamics of late-stage phase separation in crystalline solids. Phys. Rev. Lett. 86, 1259–1262 (2001).

Ardell, A. J. & Nicholson, R. B. The coarsening of γ´ in Ni-Al alloys. J. Phys. Chem. Solids 27, 1793–1804 (1966).

Ardell, A. J. The growth of gamma prime precipitates in aged Ni-Ti alloys. Metall. Trans. 1, 525–534 (1970).

Maheshwari, A. & Ardell, A. J. Anomalous coarsening behavior of small volume fractions of Ni3Al precipitates in binary Ni-Al alloys. Acta Metall. Mater. 40, 2661–2667 (1992).

Kim, D. M. & Ardell, A. J. Coarsening behavior of Ni3Ga precipitates in Ni-Ga alloys: dependence of microstructure and kinetics on volume fraction. Metall. Mater. Trans. A 35, 3063–3069 (2004).

Kim, D. M. & Ardell, A. J. Coarsening of Ni3Ge in binary Ni-Ge alloys: microstructures and volume fraction dependence of kinetics. Acta Mater. 51, 4073–4082 (2003).

Cho, J.-H. & Ardell, A. J. Coarsening of Ni3Si precipitates at volume fractions from 0.03 to 0.30. Acta Mater. 46, 5907–5916 (1998).

Kim, D. M. & Ardell, A. J. The volume-fraction dependence of Ni3Ti coarsening kinetics—new evidence of anomalous behavior. Scripta Mater. 43, 381–384 (2000).

Ardell, A. J. Observations on the effect of volume fraction on the coarsening of γ′ precipitates in binary Ni-Al alloys. Scripta Metall. Mater. 24, 343–346 (1990).

Chellman, D. J. & Ardell, A. J. The coarsening of γ′ precipitates at large volume fractions. Acta Metall. 22, 577–588 (1974).

Irissari, A. M., Urcola, J. J. & Fuentes, M. Kinetics of growth of γ´-precipitates in Ni-6.75Al alloy. Mater. Sci. Tech. 1, 516–519.

Cornwell, L. R. & Purdy, G. R. Precipitation of γ in γ′ particles in a nickel-aluminum alloy. Metall. Trans. 5, 780–781 (1974).

Ma, Y & Ardell, A. J. The (γ + γ′)/ γ′ phase boundary in the Ni-Al phase diagram from 600 to 1200 °C. Z. Metallkd. 94, 972–975 (2003).

Ma, Y. & Ardell, A. J. Coarsening of γ (Ni-Al solid solution) precipitates in a γ′ (Ni3Al) matrix: a striking contrast in behavior from normal γ/γ′ alloys. Scripta Mater. (in the press).

Ikeda, T. et al. Single-phase interdiffusion in Ni3Al. Acta Mater. 46, 5369–5376 (1998).

Fujiwara, K. & Horita, Z. Measurement of intrinsic diffusion coefficients of Al and Ni in Ni3Al using Ni/NiAl diffusion couples. Acta Mater. 50, 1571–1579 (2002).

Watanabe, M., Horita, Z., Sano T. & Nemoto, M. Electron microscopy study of Ni/Ni3Al diffusion-couple interface - II. Diffusivity measurement. Acta Metall. Mater. 42, 3389–3396 (1994).

Janssen, M. M. P. Diffusion in the nickel-rich part of the nickel-aluminum system at 1000 to 1300 deg. nickel-aluminum (Ni3A1) layer growth, diffusion coefficients, and interface concentrations. Metall. Trans. 4, 1623–1633 (1973).

Ansara, I., Dupin, N., Lukas, H. L. & Sundman, B. Thermodynamic assessment of the Al-Ni system. J. Alloys Compd 247, 20–30 (1997).

Huang, W. & Chang, Y. A. A thermodynamic analysis of the Ni-Al system. Intermetallics 6, 487–498 (1998).

Zhang, F. et al. Application of the cluster-site approximation (CSA) model to the f.c.c. phase in the Ni-Al system. Acta Mater. 51, 207–216 (2003).

Wang, Y. & Khachaturyan, A. G. Effect of antiphase domains on shape and spatial arrangement of coherent ordered intermetallics. Scripta Metall. Mater. 31, 1425–1430 (1994).

Mishin, Y. Atomistic modeling of the γ and γ′-phases of the Ni-Al system. Acta Mater. 52, 1451–1467 (2004).

Hillert, M. On the theory of normal and abnormal grain growth. Acta Metall. 13, 227–238 (1965).

Todes, O. M. & Khrushchev, V. V. Theory of coagulation and particle growth in sols. III. kinetics of particle growth in a polydisperse system in a vacuum. J. Phys. Chem. (USSR) 21, 301–312 (1947).

Greenwood, G. W. The growth of dispersed precipitates in solutions. Acta Metall. 4, 243–248 (1956).

Ardell, A. J. An application of the theory of particle coarsening: the γ´ precipitate in Ni-Al alloys. Acta Metall. 16, 511–516 (1968).

Livingston, J. D. Critical particle size for precipitation hardening. Trans. AIME 215, 566–571 (1959).

Mahalingam, K., Gu, B. P., Liedl, G. L. & Sanders, T. H. Jr. Coarsening of δ´ (Al3Li) precipitates in binary aluminum-lithium alloys. Acta Metall. 35, 483–98 (1987).

Sluiter, M. & Kawazoe, Y. Prediction of matrix-precipitate interfacial free energies: Application to Al-Al3Li. Phys. Rev. B 54, 10381–10384 (1986).

Asta, M. Theoretical study of the thermodynamic properties of α-δ′ interphase boundaries in Al-Li. Acta Mater. 44, 4131–4136 (1996).

Seyhan, I. et al. Ostwald ripening of solid-liquid Pb-Sn dispersions. Metall. Mater. Trans. A 27, 2470–2478 (1996).

Hoyt, J. J., Asta, M. & Karma, A. Atomistic and continuum modeling of dendritic solidification. Mater. Sci. Eng. R 41, 121–163 (2003).

Coriell, S. R. & Turnbull, D. H. Relative roles of heat transport and interface rearrangement rates in the rapid growth of crystals in undercooled melts. Acta Metall. 30, 2135–2139 (1982).

Broughton, J. Q., Gilmer, G. H. & Jackson, K. A. Crystallization rates of a Lennard-Jones liquid. Phys. Rev. Lett. 49, 1496–1500 (1982).

Vaithyanathan, V. & Chen, L. Q. Coarsening of ordered intermetallic precipitates with coherency stress. Acta Mater. 50, 4061–4073 (2002).

Jayanth, C. S. & Nash, P. Experimental evaluation of particle coarsening theories. Mater. Sci. Tech. 6, 405–413 (1990).

Lund, A. C. & Voorhees, P. W. The effects of elastic stress on coarsening in the Ni-Al system. Acta Mater. 50, 2085–2098 (2002).

Kresse, G. & Hafner, J. Ab initio molecular dynamics for liquid metals. Phys. Rev. B 47, 558–561 (1993).

Kresse, G & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented wave method. Phys. Rev. B 59, 1758–1775 (1999).

Calderon, H. A. et al. Ostwald ripening in concentrated alloys. Acta Metall. Mater. 42, 991–1000 (1994).

Ardell, A. J. The Ni-Ni3Al Phase diagram: Thermodynamic modelling and the requirements of coherent equilibrium. Model. Simul. Mater. Sci. 8, 277–286 (2000).

Ardell, A. J. Interfacial free energies and solute diffusivities from data on Ostwald ripening. Interface Sci. 3, 119–125 (1995).

Acknowledgements

We benefited from helpful discussions with Mark Asta. A.J.A. is grateful to the National Science Foundation for financial support of this research under Grant DMR-0209260. V.O. was supported by the MARCO Focus Center for Functional Engineered Nano Architectonics (FENA) and by the National Science Foundation under Grant DMR-0427638.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Ardell, A., Ozolins, V. Trans-interface diffusion-controlled coarsening. Nature Mater 4, 309–316 (2005). https://doi.org/10.1038/nmat1340

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat1340

This article is cited by

-

Phase-field simulation of precipitation kinetics and creep properties of Ni-Al-Cr/Ta superalloys

Science China Technological Sciences (2024)

-

Microstructure and deformation mechanism of Ni-based wrought superalloys for A-USC power plants: a review

Journal of Materials Science (2024)

-

Short-Term Splitting and Long-Term Stability of Cuboidal Nanoparticles in Ni44Co22Cr22Al6Nb6 Multi-Principal Element Alloy

Acta Metallurgica Sinica (English Letters) (2023)

-

Regression based computer vision analysis of volume-fraction effect on Pb–Sn solid–liquid coarsening in microgravity

Applied Physics A (2023)

-

The Elastic Effect of Evolving Precipitate Shapes on the Ripening Kinetics of Tetragonal Phases

Metallurgical and Materials Transactions A (2023)