Abstract

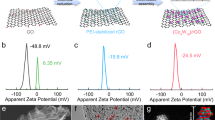

Tremendous efforts have been made to design the cathode of Li–S batteries to improve their energy density and cycling life. However, challenges remain in achieving fast electronic and ionic transport while accommodating the significant cathode volumetric change, especially for the cathode with a high practical mass loading. Here we report a cathode architecture, which is constructed by burning lithium foils in a CS2 vapour. The obtained structure features crystalline Li2S nanoparticles wrapped by few-layer graphene (Li2S@graphene nanocapsules). Because of the improvement on the volumetric efficiency for accommodating sulfur active species and electrical properties, the cathode design enables promising electrochemical performance. More notably, at a loading of 10 mgLi2S cm−2, the electrode exhibits a high reversible capacity of 1,160 mAh g−1s, namely, an area capacity of 8.1 mAh cm−2. Li2S@graphene cathode demonstrates a great potential for Li-ion batteries, where the Li2S@graphene-cathode//graphite-anode cell displays a high capacity of 730 mAh g−1s as well as stable cycle performance.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Ji, X., Lee, K. T. & Nazar, L. F. A highly ordered nanostructured carbon–sulphur cathode for lithium–sulphur batteries. Nat. Mater. 8, 500–506 (2009).

Bruce, P. G., Freunberger, S. A., Hardwick, L. J. & Tarascon, J.-M. Li-O2 and Li-S batteries with high energy storage. Nat. Mater. 11, 19–29 (2012).

Wang, H. et al. Graphene-wrapped sulfur particles as a rechargeable lithium–sulfur battery cathode material with high capacity and cycling stability. Nano Lett. 11, 2644–2647 (2011).

Zhang, Q. et al. Understanding the anchoring effect of two-dimensional layered materials for lithium–sulfur batteries. Nano Lett. 15, 3780–3786 (2015).

Liang, Z. et al. Sulfur cathodes with hydrogen reduced titanium dioxide inverse opal structure. ACS Nano 8, 5249–5256 (2014).

Yang, Y., Zheng, G. & Cui, Y. Nanostructured sulfur cathodes. Chem. Soc. Rev. 42, 3018–3032 (2013).

Manthiram, A., Fu, Y., Chung, S.-H., Zu, C. & Su, Y.-S. Rechargeable lithium–sulfur batteries. Chem. Rev. 114, 11751–11787 (2014).

Xu, R., Lu, J. & Amine, K. Progress in mechanistic understanding and characterization techniques of Li-S batteries. Adv. Energy Mater. 5, 1500408 (2015).

Zheng, G., Yang, Y., Cha, J. J., Hong, S. S. & Cui, Y. Hollow carbon nanofiber-encapsulated sulfur cathodes for high specific capacity rechargeable lithium batteries. Nano Lett. 11, 4462–4467 (2011).

Zheng, G. et al. Amphiphilic surface modification of hollow carbon nanofibers for improved cycle life of lithium sulfur batteries. Nano Lett. 13, 1265–1270 (2013).

Li, W. et al. High-performance hollow sulfur nanostructured battery cathode through a scalable, room temperature, one-step, bottom-up approach. Proc. Natl Acad. Sci. USA 110, 7148–7153 (2013).

Seh, Z. W. et al. Sulphur–TiO2 yolk–shell nanoarchitecture with internal void space for long-cycle lithium–sulphur batteries. Nat. Commun. 4, 1331 (2013).

Chen, R. et al. Graphene-based three-dimensional hierarchical sandwich-type architecture for high-performance Li/S batteries. Nano Lett. 13, 4642–4649 (2013).

Manthiram, A., Fu, Y. & Su, Y.-S. Challenges and prospects of lithium–sulfur batteries. Acc. Chem. Res. 46, 1125–1134 (2012).

Yin, Y. X., Xin, S., Guo, Y. G. & Wan, L. J. Lithium–sulfur batteries: electrochemistry, materials, and prospects. Angew. Chem. Int. Ed. 52, 13186–13200 (2013).

Ji, X., Evers, S., Black, R. & Nazar, L. F. Stabilizing lithium–sulphur cathodes using polysulphide reservoirs. Nat. Commun. 2, 325 (2011).

Qie, L. & Manthiram, A. A facile layer-by-layer approach for high-areal-capacity sulfur cathodes. Adv. Mater. 27, 1694–1700 (2015).

Yang, Y. et al. High-capacity micrometer-sized Li2S particles as cathode materials for advanced rechargeable lithium-ion batteries. J. Am. Chem. Soc. 134, 15387–15394 (2012).

Seh, Z. W. et al. Facile synthesis of Li2S–polypyrrole composite structures for high-performance Li2S cathodes. Energy Environ. Sci. 7, 672–676 (2014).

Hwa, Y., Zhao, J. & Cairns, E. J. Lithium sulfide (Li2S)/graphene oxide nanospheres with conformal carbon coating as a high-rate, long-life cathode for Li/S cells. Nano Lett. 15, 3479–3486 (2015).

Yang, Y. et al. New nanostructured Li2S/silicon rechargeable battery with high specific energy. Nano Lett. 10, 1486–1491 (2010).

Fu, Y., Zu, C. & Manthiram, A. In situ-formed Li2S in lithiated graphite electrodes for lithium–sulfur batteries. J. Am. Chem. Soc. 135, 18044–18047 (2013).

Fu, Y., Su, Y. S. & Manthiram, A. Li2S-carbon sandwiched electrodes with superior performance for lithium–sulfur batteries. Adv. Energy Mater. 4, 1300655 (2014).

Chakrabarti, A. et al. Conversion of carbon dioxide to few-layer graphene. J. Mater. Chem. 21, 9491–9493 (2011).

Xing, Z. et al. Reducing CO2 to dense nanoporous graphene by Mg/Zn for high power electrochemical capacitors. Nano Energy 11, 600–610 (2015).

Cai, K., Song, M.-K., Cairns, E. J. & Zhang, Y. Nanostructured Li2S–C composites as cathode material for high-energy lithium/sulfur batteries. Nano Lett. 12, 6474–6479 (2012).

Ferrari, A. et al. Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 97, 187401 (2006).

Tan, G. et al. Freestanding three-dimensional core-shell nanoarrays for lithium-ion battery anodes. Nat. Commun. 7, 11774 (2016).

Wall, M. The Raman Spectroscopy of graphene and the determination of layer thickness. Thermo Scientific Application Note AN52252 (2011).

Seh, Z. W. et al. High-capacity Li2S–graphene oxide composite cathodes with stable cycling performance. Chem. Sci. 5, 1396–1400 (2014).

Seh, Z. W. et al. Two-dimensional layered transition metal disulphides for effective encapsulation of high-capacity lithium sulphide cathodes. Nat. Commun. 5, 5017 (2014).

Wang, L., Wang, Y. & Xia, Y. A high performance lithium-ion sulfur battery based on a Li2S cathode using a dual-phase electrolyte. Energy Environ. Sci. 8, 1551–1558 (2015).

Wu, F. et al. Harnessing steric separation of freshly nucleated Li2S nanoparticles for bottom-up assembly of high-performance cathodes for lithium–sulfur and lithium-ion batteries. Adv. Energy Mater. 4, 1400196 (2014).

Wu, F., Lee, J. T., Magasinski, A., Kim, H. & Yushin, G. Solution-based processing of graphene–Li2S composite cathodes for lithium-ion and lithium–sulfur batteries. Part. Part. Syst. Charact. 31, 639–644 (2014).

Nan, C. et al. Durable carbon-coated Li2S core–shell spheres for high performance lithium/sulfur cells. J. Am. Chem. Soc. 136, 4659–4663 (2014).

Yang, Z. et al. In situ synthesis of lithium sulfide–carbon composites as cathode materials for rechargeable lithium batteries. J. Mater. Chem. A 1, 1433–1440 (2013).

Liu, J., Nara, H., Yokoshima, T., Momma, T. & Osaka, T. Micro-scale Li2S–C composite preparation from Li2SO4 for cathode of lithium ion battery. Electrochim. Acta 183, 70–77 (2015).

Zhang, K., Wang, L., Hu, Z., Cheng, F. & Chen, J. Ultrasmall Li2S nanoparticles anchored in graphene nanosheets for high-energy lithium-ion batteries. Sci. Rep. 4, 6467 (2014).

Fu, Y. & Manthiram, A. Orthorhombic bipyramidal sulfur coated with polypyrrole nanolayers as a cathode material for lithium–sulfur batteries. J. Phys. Chem. C 116, 8910–8915 (2012).

Su, Q., Dong, Z., Zhang, J., Du, G. & Xu, B. Visualizing the electrochemical reaction of ZnO nanoparticles with lithium by in situ TEM: two reaction modes are revealed. Nanotechnology 24, 255705 (2013).

Assary, R. S., Curtiss, L. A. & Moore, J. S. Toward a molecular understanding of energetics in Li–S batteries using nonaqueous electrolytes: a high-level quantum chemical study. J. Phys. Chem. C 118, 11545–11558 (2014).

Gyulassy, A. et al. Interstitial and interlayer ion diffusion geometry extraction in graphitic nanosphere battery materials. IEEE Trans. Vis. Comput. Graphics 22, 916–925 (2016).

Acknowledgements

This work was financially supported by the US Department of Energy under Contract DE-AC0206CH11357 with the main support provided by the Vehicle Technologies Office, Department of Energy (DOE) Office of Energy Efficiency and Renewable Energy (EERE). X.J. is grateful for the financial support from National Science Foundation Award No. 1551693. The ex situ TEM was conducted at the Electron Microscopy Center in the Center for Nanoscale Materials at Argonne National Laboratory, a DOE-BES Facility, supported under Contract No. DE-AC0206CH11357 by UChicago Argonne, LLC. Use of the Advanced Photon Source (9-BM and 11-ID) was supported by the US Department of Energy, Office of Basic Energy Sciences, under contract No. DE-AC0206CH11357. DFT calculations were supported by the US DOE, Office of Basic Energy Sciences, Division of Chemical Sciences, Geosciences and Biosciences, under Contract DE-AC0206CH11357.

Author information

Authors and Affiliations

Contributions

J.L. conceived the concept and design the experiments. Z.X. and Z.J. synthesized the Li2S@graphene capsule materials; G.T. and R.X. performed materials characterization and electrochemical measurements; J.W. and D.J.M. carried out the TEM observation; L.M. and T.W. carried out the XANES experiments; C.Z. and G.T carried out the in situ EIS measurements; Y.Y. and R.S.-Y. performed the in situTEM observation; Q.L. and Y.R. performed the in situ XRD experiments; C.L. and L.A.C. performed the DFT theoretical calculations; J.L., X.J. and K.A. supervised the project; G.T., X.J. and J.L. wrote the paper. All authors discussed the results and reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Figures 1–14, Supplementary Tables 1–2, Supplementary References. (PDF 1958 kb)

Supplementary Video 1

In-situ TEM time-lapse video of a Li2S@graphene nanocapsule during the prime three (de)-lithiation cycles within the operating bias of 3.0 V. The Li2S@graphene nanocapsule exhibits a good structural integrity during the (de)-lithiation cycling, with a very small volume variation ∼10%. (WMV 8818 kb)

Supplementary Video 2

In-situ TEM time-lapse video of a Li2S nanoparticle during the prime three (de)-lithiation cycles within the operating bias of 3.0 V. The bare Li2S nanoparticle shows a severe structural vulnerability during the (de)-lithiation cycling, where the particle can hardly survive after three cycles. This leads to the drastic decomposition and severe mass loss of Li2S electrode and subsequently the fast capacity fading of the cell. (WMV 2464 kb)

Rights and permissions

About this article

Cite this article

Tan, G., Xu, R., Xing, Z. et al. Burning lithium in CS2 for high-performing compact Li2S–graphene nanocapsules for Li–S batteries. Nat Energy 2, 17090 (2017). https://doi.org/10.1038/nenergy.2017.90

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/nenergy.2017.90

This article is cited by

-

Li-S Batteries: Challenges, Achievements and Opportunities

Electrochemical Energy Reviews (2023)

-

Synergy of in-situ heterogeneous interphases tailored lithium deposition

Nano Research (2023)

-

Enhancing sulfur cathode process via a functionalized complex molecule

Nano Research (2023)

-

Single-dispersed polyoxometalate clusters embedded on multilayer graphene as a bifunctional electrocatalyst for efficient Li-S batteries

Nature Communications (2022)

-

Development of quasi-solid-state anode-free high-energy lithium sulfide-based batteries

Nature Communications (2022)