Abstract

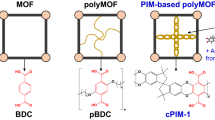

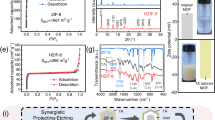

Mixed matrix membranes (MMMs) for gas separation applications have enhanced selectivity when compared with the pure polymer matrix, but are commonly reported with low intrinsic permeability, which has major cost implications for implementation of membrane technologies in large-scale carbon capture projects. High-permeability polymers rarely generate sufficient selectivity for energy-efficient CO2 capture. Here we report substantial selectivity enhancements within high-permeability polymers as a result of the efficient dispersion of amine-functionalized, nanosized metal–organic framework (MOF) additives. The enhancement effects under optimal mixing conditions occur with minimal loss in overall permeability. Nanosizing of the MOF enhances its dispersion within the polymer matrix to minimize non-selective microvoid formation around the particles. Amination of such MOFs increases their interaction with thepolymer matrix, resulting in a measured rigidification and enhanced selectivity of the overall composite. The optimal MOF MMM performance was verified in three different polymer systems, and also over pressure and temperature ranges suitable for carbon capture.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Reiner, D. M. Learning through a portfolio of carbon capture and storage demonstration projects. Nat. Energy 1, 15011 (2016).

Merkel, T. C., Lin, H., Wei, X. & Baker, R. Power plant post-combustion carbon dioxide capture: an opportunity for membranes. J. Membr. Sci. 359, 126–139 (2010).

Lai, Z. et al. Microstructural optimization of a zeolite membrane for organic vapor separation. Science 300, 456–460 (2003).

Kitagawa, S., Kitaura, R. & Noro, S. i. Functional porous coordination polymers. Angew. Chem. Int. Edn 43, 2334–2375 (2004).

Song, Q. et al. Porous organic cage thin films and molecular-sieving membranes. Adv. Mater. 28, 2629–2637 (2016).

Freeman, B. D. Basis of permeability/selectivity tradeoff relations in polymeric gas separation membranes. Macromolecules 32, 375–380 (1999).

Budd, P. M. et al. Polymers of intrinsic microporosity (PIMs): robust, solution-processable, organic nanoporous materials. Chem. Commun. 2, 230–231 (2004).

Ghanem, B. S., McKeown, N. B., Budd, P. M., Selbie, J. D. & Fritsch, D. High-performance membranes from polyimides with intrinsic microporosity. Adv. Mater. 20, 2766–2771 (2008).

Kim, S. & Lee, Y. M. Rigid and microporous polymers for gas separation membranes. Prog. Polym. Sci. 43, 1–32 (2015).

Song, Q. et al. Controlled thermal oxidative crosslinking of polymers of intrinsic microporosity towards tunable molecular sieve membranes. Nat. Commun. 5, 4813 (2014).

Ghalei, B. et al. Surface functionalization of high free-volume polymers as a route to efficient hydrogen separation membranes. J. Mater. Chem. A 5, 4686–4694 (2017).

Park, H. B., Han, S. H., Jung, C. H., Lee, Y. M. & Hill, A. J. Thermally rearranged (TR) polymer membranes for CO2 separation. J. Membr. Sci. 359, 11–24 (2010).

Song, Q. et al. Photo-oxidative enhancement of polymeric molecular sieve membranes. Nat. Commun. 4, 1918 (2013).

Du, N., Dal-Cin, M. M., Robertson, G. P. & Guiver, M. D. Decarboxylation-induced cross-linking of Polymers of Intrinsic Microporosity (Pims) for membrane gas separation. Macromolecules 45, 5134–5139 (2012).

Jones, C. W. & Koros, W. J. Carbon molecular sieve gas separation membranes-I. Preparation and characterization based on polyimide precursors. Carbon 32, 1419–1425 (1994).

Chung, T.-S., Jiang, L. Y., Li, Y. & Kulprathipanja, S. Mixed matrix membranes (MMMs) comprising organic polymers with dispersed inorganic fillers for gas separation. Prog. Polym. Sci. 32, 483–507 (2007).

Rezakazemi, M., Amooghin, A. E., Montazer-Rahmati, M. M., Ismail, A. F. & Matsuura, T. State-of-the-art membrane based CO2 separation using mixed matrix membranes (MMMs): an overview on current status and future directions. Prog. Polym. Sci. 39, 817–861 (2014).

Seoane, B. et al. Metal–organic framework based mixed matrix membranes: a solution for highly efficient CO2 capture? Chem. Soc. Rev. 44, 2421–2454 (2015).

Rangnekar, N., Mittal, N., Elyassi, B., Caro, J. & Tsapatsis, M. Zeolite membranes—a review and comparison with MOFs. Chem. Soc. Rev. 44, 7128–7154 (2015).

Cavka, J. H. et al. A new zirconium inorganic building brick forming metal organic frameworks with exceptional stability. J. Am. Chem. Soc. 130, 13850–13851 (2008).

Tsuruoka, T. et al. Nanoporous nanorods fabricated by coordination modulation and oriented attachment growth. Angew. Chem. Int. Edn 48, 4739–4743 (2009).

Budd, P. M. et al. Solution-processed, organophilic membrane derived from a polymer of intrinsic microporosity. Adv. Mater. 16, 456–459 (2004).

Schaate, A. et al. Modulated synthesis of Zr-based metal–organic frameworks: from nano to single crystals. Chem. A Eur. J. 17, 6643–6651 (2011).

Kandiah, M. et al. Synthesis and stability of tagged UiO-66 Zr-MOFs. Chem. Mater. 22, 6632–6640 (2010).

Rappé, A. K., Casewit, C. J., Colwell, K., Goddard, W. III & Skiff, W. UFF, a full periodic table force field for molecular mechanics and molecular dynamics simulations. J. Am. Chem. Soc. 114, 10024–10035 (1992).

Rappe, A. K. & Goddard, W. A. III Charge equilibration for molecular dynamics simulations. J. Phys. Chem. 95, 3358–3363 (1991).

Øien, S. et al. Detailed structure analysis of atomic positions and defects in zirconium metal–organic frameworks. Crystal Growth Design 14, 5370–5372 (2014).

Semino, R., Ramsahye, N. A., Ghoufi, A. & Maurin, G. Microscopic model of the MOF/polymer interface: a first step towards understanding the compatibility in Mixed Matrix Membranes. ACS Appl. Mater. Interfaces 8, 809–819 (2016).

Mahajan, R. & Koros, W. J. Mixed matrix membrane materials with glassy polymers. Part 1. Polymer Eng. Sci. 42, 1420–1431 (2002).

Li, Y., Chung, T.-S., Cao, C. & Kulprathipanja, S. The effects of polymer chain rigidification, zeolite pore size and pore blockage on polyethersulfone (PES)-zeolite A mixed matrix membranes. J. Membr. Sci. 260, 45–55 (2005).

Vu, D. Q., Koros, W. J. & Miller, S. J. Mixed matrix membranes using carbon molecular sieves: II. Modeling permeation behavior. J. Membr. Sci. 211, 335–348 (2003).

Ren, H., Jin, J., Hu, J. & Liu, H. Affinity between metal–organic frameworks and polyimides in asymmetric mixed matrix membranes for gas separations. Ind. Eng. Chem. Res. 51, 10156–10164 (2012).

Bushell, A. F. et al. Gas permeation parameters of mixed matrix membranes based on the polymer of intrinsic microporosity PIM-1 and the zeolitic imidazolate framework ZIF-8. J. Membr. Sci. 427, 48–62 (2013).

Goh, P. S., Ismail, A. F., Sanip, S. M., Ng, B. C. & Aziz, M. Recent advances of inorganic fillers in mixed matrix membrane for gas separation. Sep. Purif. Technol. 81, 243–264 (2011).

Nik, O. G., Chen, X. Y. & Kaliaguine, S. Functionalized metal organic framework-polyimide mixed matrix membranes for CO2/CH4 separation. J. Membr. Sci. 413, 48–61 (2012).

Anjum, M. W. et al. Modulated UiO-66-based mixed-matrix membranes for CO2 separation. ACS Appl. Mater. Interfaces 7, 25193–25201 (2015).

Rodenas, T. et al. Metal–organic framework nanosheets in polymer composite materials for gas separation. Nat. Mater. 14, 48–55 (2015).

Lau, C. H. et al. Ending aging in super glassy polymer membranes. Angew. Chem. Int. Edn 53, 5322–5326 (2014).

Lau, C. H. et al. Ending aging in super glassy polymer membranes. Angew. Chem. Int. Edn 126, 5426–5430 (2014).

Harms, S. et al. Aging and free volume in a polymer of intrinsic microporosity (PIM-1). J. Adhesion 88, 608–619 (2012).

Tiwari, R. R., Smith, Z. P., Lin, H., Freeman, B. & Paul, D. Gas permeation in thin films of ‘high free-volume’ glassy perfluoropolymers: Part I. Physical aging. Polymer 55, 5788–5800 (2014).

Isfahani, A. P. et al. Plasticization resistant crosslinked polyurethane gas separation membranes. J. Mater. Chem. A 4, 17431–17439 (2016).

Brunauer, S., Emmett, P. H. & Teller, E. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 60, 309–319 (1938).

Khdhayyer, M. R. et al. Mixed matrix membranes based on UiO-66 MOFs in the polymer of intrinsic microporosity PIM-1. Sep. Purif. Technol. 173, 304–313 (2017).

Smith, S. J., Ladewig, B. P., Hill, A. J., Lau, C. H. & Hill, M. R. Post-synthetic Ti exchanged UiO-66 metal-organic frameworks that deliver exceptional gas permeability in mixed matrix membranes. Sci. Rep. 5, 7823 (2015).

Robeson, L. M. The upper bound revisited. J. Membr. Sci. 320, 390–400 (2008).

Acknowledgements

H.H. thanks JST-PRESTO (JPMJPR141B) and City University of Hong Kong for financial support. E.S. gratefully acknowledges JST-PRESTO (JPMJPR1417) and the Japanese Ministry of Environment as part of the project ‘Low Carbon Technology Research, Development and Demonstration Program’. iCeMS is supported by the World Premier International Research Initiative (WPI), MEXT, Japan.

Author information

Authors and Affiliations

Contributions

B.G. conceived and designed the research. K.S. and Y.K. synthesized and analysed PIM-1 MMMs, K.W. synthesized and analysed PEBAX MMMs, A.P. synthesized and analysed polyurethane MMMs, S.F. and S.K. evaluated MOF-related data, Q.S. evaluated mixed membrane data, K.D. and H.H. performed simulations and H.K. S.K. and E.S. supervised researchers in the project. All authors discussed the results and commented on the manuscript at all stages.

Corresponding author

Ethics declarations

Competing interests

The results of this publication have been submitted for a patent filing application.

Supplementary information

Supplementary Information

Supplementary Figures 1–21, Supplementary Tables 1–10, Supplementary Notes 1–3 and Supplementary References. (PDF 4176 kb)

Rights and permissions

About this article

Cite this article

Ghalei, B., Sakurai, K., Kinoshita, Y. et al. Enhanced selectivity in mixed matrix membranes for CO2 capture through efficient dispersion of amine-functionalized MOF nanoparticles. Nat Energy 2, 17086 (2017). https://doi.org/10.1038/nenergy.2017.86

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/nenergy.2017.86

This article is cited by

-

Double-walled Al-based MOF with large microporous specific surface area for trace benzene adsorption

Nature Communications (2024)

-

Remarkable enhancement of gas selectivity on organosilica hybrid membranes using urea-modulated metal-organic framework nanoparticles

Frontiers of Chemical Science and Engineering (2024)

-

Transient and general synthesis of high-density and ultrasmall nanoparticles on two-dimensional porous carbon via coordinated carbothermal shock

Nature Communications (2023)

-

Boosting membrane carbon capture via multifaceted polyphenol-mediated soldering

Nature Communications (2023)

-

Enhancement of CO2 absorption and heat transfer properties using amine functionalized magnetic graphene oxide/MDEA nanofluid

Journal of the Iranian Chemical Society (2023)