Abstract

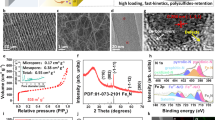

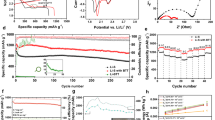

Lithium–sulfur batteries are a promising energy-storage technology due to their relatively low cost and high theoretical energy density. However, one of their major technical problems is the shuttling of soluble polysulfides between electrodes, resulting in rapid capacity fading. Here, we present a metal–organic framework (MOF)-based battery separator to mitigate the shuttling problem. We show that the MOF-based separator acts as an ionic sieve in lithium–sulfur batteries, which selectively sieves Li+ ions while efficiently suppressing undesired polysulfides migrating to the anode side. When a sulfur-containing mesoporous carbon material (approximately 70 wt% sulfur content) is used as a cathode composite without elaborate synthesis or surface modification, a lithium–sulfur battery with a MOF-based separator exhibits a low capacity decay rate (0.019% per cycle over 1,500 cycles). Moreover, there is almost no capacity fading after the initial 100 cycles. Our approach demonstrates the potential for MOF-based materials as separators for energy-storage applications.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Tarascon, J. M. & Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 414, 359–367 (2001).

Bruce, P. G., Freunberger, S. A., Hardwick, L. J. & Tarascon, J. M. Li–O2 and Li–S batteries with high energy storage. Nature Mater. 11, 19–29 (2012).

Pang, Q., Kundu, D., Cuisinier, M. & Nazar, L. F. Surface-enhanced redox chemistry of polysulphides on a metallic and polar host for lithium–sulphur batteries. Nature Commun. 5, 4759 (2014).

Yao, H. B. et al. Improving lithium–sulphur batteries through spatial control of sulphur species deposition on a hybrid electrode surface. Nature Commun. 5, 3943 (2014).

Zhou, G. M. et al. A graphene–pure-sulfur sandwich structure for ultrafast, long-life lithium–sulfur batteries. Adv. Mater. 26, 625–631 (2014).

Ji, X. L., Lee, K. T. & Nazar, L. F. A highly ordered nanostructured carbon–sulphur cathode for lithium-sulphur batteries. Nature Mater. 8, 500–506 (2009).

Zhou, G. M., Paek, E., Hwang, G. S. & Manthiram, A. Long-life Li/polysulphide batteries with high sulphur loading enabled by lightweight three-dimensional nitrogen/sulphur-codoped graphene sponge. Nature Commun. 6, 7760 (2015).

Yin, L. C., Wang, J. L., Lin, F. J., Yang, J. & Nuli, Y. Polyacrylonitrile/graphene composite as a precursor to a sulfur-based cathode material for high-rate rechargeable Li–S batteries. Energy Environ. Sci. 5, 6966–6972 (2012).

Chen, S. G. et al. Nanostructured polyaniline-decorated Pt/C@PANI core-shell catalyst with enhanced durability and activity. J. Am. Chem. Soc. 134, 13252–13255 (2012).

Seh, Z. W. et al. Two-dimensional layered transition metal disulphides for effective encapsulation of high-capacity lithium sulphide cathodes. Nature Commun. 5, 5017 (2014).

Seh, Z. W. et al. Sulphur-TiO2 yolk-shell nanoarchitecture with internal void space for long-cycle lithium–sulphur batteries. Nature Commun. 4, 1331 (2013).

Liang, X., Garsuch, A. & Nazar, L. F. Sulfur cathodes based on conductive MXene nanosheets for high-performance lithium–sulfur batteries. Angew. Chem. Int. Ed. 54, 3907–3911 (2015).

Demir-Cakan, R. et al. Cathode composites for Li–S batteries via the use of oxygenated porous architectures. J. Am. Chem. Soc. 133, 16154–16160 (2011).

Zhou, J. W. et al. Rational design of a metal-organic framework host for sulfur storage in fast, long-cycle Li–S batteries. Energy Environ. Sci. 7, 2715–2724 (2014).

Zheng, J. M. et al. Lewis acid-base interactions between polysulfides and metal organic framework in lithium sulfur batteries. Nano Lett. 14, 2345–2352 (2014).

Yin, Y. X., Xin, S., Guo, Y. G. & Wan, L. J. Lithium–sulfur batteries: electrochemistry, materials, and prospects. Angew. Chem. Int. Ed. 52, 13186–13200 (2013).

Park, K. et al. Trapping lithium polysulfides of a Li–S battery by forming lithium bonds in a polymer matrix. Energy Environ. Sci. 8, 2389–2395 (2015).

Peng, Y. et al. Metal-organic framework nanosheets as building blocks for molecular sieving membranes. Science 346, 1356–1359 (2014).

Wang, B., Cote, A. P., Furukawa, H., O’Keeffe, M. & Yaghi, O. M. Colossal cages in zeolitic imidazolate frameworks as selective carbon dioxide reservoirs. Nature 453, 207–211 (2008).

Bai, S. et al. Distinct anion sensing by a 2D self-assembled Cu(I)-based metal–organic polymer with versatile visual colorimetric responses and efficient selective separations via anion exchange. J. Mater. Chem. A 1, 2970–2973 (2013).

Talin, A. A. et al. Tunable electrical conductivity in metal-organic framework thin-film devices. Science 343, 66–69 (2014).

Mao, Y. Y. et al. General incorporation of diverse components inside metal-organic framework thin films at room temperature. Nature Commun. 5, 5532 (2014).

Huang, J. Q. et al. Ionic shield for polysulfides towards highly-stable lithium–sulfur batteries. Energ. Environ. Sci. 7, 347–353 (2014).

Yao, H. B. et al. Improved lithium–sulfur batteries with a conductive coating on the separator to prevent the accumulation of inactive S-related species at the cathode-separator interface. Energy Environ. Sci. 7, 3381–3390 (2014).

Liang, X. et al. A highly efficient polysulfide mediator for lithium–sulfur batteries. Nature Commun. 6, 5682 (2015).

Peng, H. J. et al. Janus separator of polypropylene-supported cellular graphene framework for sulfur cathodes with high utilization in lithium–sulfur batteries. Adv. Sci. 3, 1500268 (2016).

Chung, S. H. & Manthiram, A. Bifunctional separator with a light-weight carbon-coating for dynamically and statically stable lithium–sulfur batteries. Adv. Funct. Mater. 24, 5299–5306 (2014).

Dikin, D. A. et al. Preparation and characterization of graphene oxide paper. Nature 448, 457–460 (2007).

Joshi, R. K. et al. Precise and ultrafast molecular sieving through graphene oxide membranes. Science 343, 752–754 (2014).

Su, Y. S. & Manthiram, A. Lithium–sulphur batteries with a microporous carbon paper as a bifunctional interlayer. Nature Commun. 3, 1166 (2012).

Huang, J. Q. et al. Permselective graphene oxide membrane for highly stable and anti-self-discharge lithium–sulfur batteries. ACS Nano 9, 3002–3011 (2015).

Chui, S. S. Y., Lo, S. M. F., Charmant, J. P. H., Orpen, A. G. & Williams, I. D. A chemically functionalizable nanoporous material [Cu3(TMA)2(H2O)3]n . Science 283, 1148–1150 (1999).

Vijayakumar, M. et al. Molecular structure and stability of dissolved lithium polysulfide species. Phys. Chem. Chem. Phys. 16, 10923–10932 (2014).

Cuisinier, M. et al. Sulfur speciation in Li–S batteries determined by operando X-ray absorption spectroscopy. J. Phys. Chem. Lett. 4, 3227–3232 (2013).

Chen, S. R. et al. Ordered mesoporous carbon/sulfur nanocomposite of high performances as cathode for lithium–sulfur battery. Electrochim. Acta 56, 9549–9555 (2011).

Meini, S., Elazari, R., Rosenman, A., Garsuch, A. & Aurbach, D. The use of redox mediators for enhancing utilization of Li2S cathodes for advanced Li–S battery systems. J. Phys. Chem. Lett. 5, 915–918 (2014).

Bouchet, R. et al. Single-ion BAB triblock copolymers as highly efficient electrolytes for lithium-metal batteries. Nature Mater. 12, 452–457 (2013).

Christie, A. M., Lilley, S. J., Staunton, E., Andreev, Y. G. & Bruce, P. G. Increasing the conductivity of crystalline polymer electrolytes. Nature 433, 50–53 (2005).

Lerf, A. et al. Hydration behavior and dynamics of water molecules in graphite oxide. J. Phys. Chem. Solids 67, 1106–1110 (2006).

Raidongia, K. & Huang, J. X. Nanofluidic ion transport through reconstructed layered materials. J. Am. Chem. Soc. 134, 16528–16531 (2012).

Scrosati, B. Conducting polymers: advanced materials for new design, rechargeable lithium batteries. Polym. Int. 47, 50–55 (1998).

Barpanda, P. et al. LiZnSO4F made in an ionic liquid: a ceramic electrolyte composite for solid-state lithium batteries. Angew. Chem. Int. Ed. 50, 2526–2531 (2011).

Zhu, K. et al. Synergetic effects of Al3+ doping and graphene modification on the electrochemical performance of V2O5 cathode materials. ChemSusChem 8, 1017–1025 (2015).

Acknowledgements

The partial financial support from Mitsubishi Motors Corporation is acknowledged. We thank Y. Wang for help with language support.

Author information

Authors and Affiliations

Contributions

S.B. designed and performed the experiments. K.Z. helped with synthesis of the graphene oxide materials and calculation of the ion conductivity. X.L. and S.W. provided advice about the electrochemical experiments. H.Z. designed and supervised the work.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Figures 1–16, Supplementary Tables 1–2, Supplementary Notes 1–3, Supplementary References. (PDF 3173 kb)

Rights and permissions

About this article

Cite this article

Bai, S., Liu, X., Zhu, K. et al. Metal–organic framework-based separator for lithium–sulfur batteries. Nat Energy 1, 16094 (2016). https://doi.org/10.1038/nenergy.2016.94

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/nenergy.2016.94

This article is cited by

-

Janus Quasi-Solid Electrolyte Membranes with Asymmetric Porous Structure for High-Performance Lithium-Metal Batteries

Nano-Micro Letters (2024)

-

MOF and its derivative materials modified lithium–sulfur battery separator: a new means to improve performance

Rare Metals (2024)

-

Recent advances in multifunctional metal-organic frameworks for lithium metal batteries

Science China Chemistry (2024)

-

Ultrafast Carbonized Wood of Electrode-Scaled Aligned-Porous Structure for High-Performance Lithium Batteries

Transactions of Tianjin University (2023)

-

Li-S Batteries: Challenges, Achievements and Opportunities

Electrochemical Energy Reviews (2023)