Abstract

Charge separation is crucial for increasing the activity of semiconductor-based photocatalysts, especially in water splitting reactions. Here we show, using monoclinic bismuth vanadate crystal as a model photocatalyst, that efficient charge separation can be achieved on different crystal facets, as evidenced by the reduction reaction with photogenerated electrons and oxidation reaction with photogenerated holes, which take place separately on the {010} and {110} facets under photo-irradiation. Based on this finding, the reduction and oxidation cocatalysts are selectively deposited on the {010} and {110} facets respectively, resulting in much higher activity in both photocatalytic and photoelectrocatalytic water oxidation reactions, compared with the photocatalyst with randomly distributed cocatalysts. These results show that the photogenrated electrons and holes can be separated between the different facets of semiconductor crystals. This finding may be useful in semiconductor physics and chemistry to construct highly efficient solar energy conversion systems.

Similar content being viewed by others

Introduction

Charge separation has a key role in determining solar energy conversion efficiency of semiconductor-based systems for producing solar electricity and solar fuels through solar cells1,2,3,4, photoelectrocatalysis5,6,7,8 and photocatalysis9,10,11,12,13. As a key step in energy conversion, electron-hole pairs generated by light absorption need to be separated and transferred to the surface of the semiconductors1,9,14,15,16,17. Hence, an in-depth understanding of charge separation within semiconductors is desirable for the construction of an efficient solar energy conversion system.

Recent investigations on crystal facet engineering of semiconductors have demonstrated that photoexcited electrons and holes may be driven to different crystal facets. Thus, certain facets of a semiconductor prefer reduction while others favour oxidation18,19,20. However, reports on the reduction and oxidation reaction facets on the same semiconductor crystal (such as TiO2) were often contradictory in the literature21,22,23,24,25,26. For example, it was reported that rutile {011} and anatase {001} faces provided the sites for oxidation, while the rutile {110} and anatase {101} faces offered the sites for reduction24. Similar phenomena were also reported in other references27,28,29. However, some references observed higher photocatalytic oxidation activity of organics on anatase nanocrystals with well-faceted {101} surfaces than that of the above-mentioned {001} facet30,31,32. Farneth et al.21 concluded that the fine Ag particles are mostly deposited by reduction of Ag+ on the {110} face of TiO2, while Hotsenpiller et al.22 reached the conclusion that the Ag particles were photocatalytically deposited at higher velocities on the {001} and {011} facets than on the {110} and {010} facets. A possible reason for the contrary conclusions is that the reaction selectivity on different facets is also affected by adsorption/desorption behaviours of reactant molecules and reaction intermediates on different facets33,34. A semiconductor with 1-D nanostructure and different crystal orientations has been proposed to lead to more efficient separation of electrons and holes with respect to the bulk material to explain the increased solar energy conversion efficiency35,36,37,38,39, though experimental evidence on the separation of electrons and holes on different crystal facets remains elusive.

Here, we present experimental evidence for the separation of electrons and holes between the {010} and {110} crystal facets of the model semiconductor bismuth vanadate (BiVO4). Facet-selective photo-deposition of metal ions, combined with promotion of water oxidation in photoelectrochemical and photocatalytic processes, clearly indicates the separation of electrons and holes to different facets. Meanwhile, various precursors of different metal ions as well as some distinct electron donors/acceptors were employed for the metal photo-deposition to rule out the adsorption effect.

Results

Selection of BiVO4 as a model photocatalyst

BiVO4, as a visible-light-responsive photocatalyst, has attracted increasing attention in photocatalytic15,40,41,42 and photoelectrochemical43,44,45 water oxidation. In addition, the BiVO4 with large crystal size and controllable exposed facets can be easily prepared. Combined with advantages such as superior light absorbance, good photocatalytic activity, smooth exposed facets and non-toxic properties, BiVO4 is chosen as an ideal model photocatalyst.

A large single crystal of monoclinic BiVO4 was prepared by the hydrothermal method46,47, and characterised by XRD patterns, UV–vis spectra and SEM images. The as-prepared BiVO4 powder shows a smooth surface, regular decahedron shape, good crystallinity and characteristic visible-light absorption (Supplementary Fig. S1).

Facet-selective photo-deposition of metals/metal oxides

The photo-depositions of metals on the surface of BiVO4 were carried out using HAuCl4 (H2PtCl6 and AgNO3) as precursors and water as a hole scavenger. SEM images (Fig. 1a–d) clearly show that the particles of Ag, Au and Pt (although with different particle sizes) are all solely deposited on the {010} facets. XPS spectra of Au 4f, Pt 4f and Ag 3d reveal that the deposited elements on the BiVO4 are all in metallic form except that a small portion of incompletely reduced PtO species remained for the Pt/BiVO4 sample (Supplementary Fig. S2). Decrease of the metal valence with respect to the metal ion precursors indicates that the metal ions are photo-reduced on the {010} facets. Namely, the photogenerated electrons are readily available for the reduction reaction on the {010} facets. The photo-reduction of metal ions (equation 1) accompanying the elimination of photogenerated holes by water oxidation (equation 2) can be described as follows:

Photo-oxidation depositions of Mn2+ or Pb2+ ions on BiVO4 were performed with IO3− as electron acceptors. Sponge-like manganese oxide deposits (Fig. 1e) and large lead oxide particles (Fig. 1f) are formed selectively on the {110} facets instead of the {010} facets. According to the binding energies of Pb 4f and Mn 2p in XPS (Supplementary Fig. S3), the deposited lead and manganese species can be ascribed to PbO2 and MnOx, respectively, where x is between 1.5 and 2.0 because the observed binding energies of manganese oxides are between those of Mn2O3 and MnO2. High-resolution TEM images (Supplementary Fig. S4) show that the planar spaces of 2.715 Å and 1.663 Å well match the (222) and (440) planes of cubic Mn2O3, and the planar space of 1.663 Å is in accordance with the (102) plane of hexagonal MnO2, further confirming the formation of MnOx. The formation of PbO2 and MnOx oxides is an indication that the photo-oxidation selectively takes place on the {110} facets, that is, the photogenerated holes tend to migrate to the {110} facets for selective metal oxidation. The reactions can be summarised in equations (3) and (4):

Following the selective photo-deposition of single metals and metal oxides, we further investigated the photo-deposition of dual precursors with simultaneous reduction and oxidation reactions. The as-prepared samples are denoted as Au/MnOx/BiVO4, Pt/MnOx/BiVO4, Ag/MnOx/BiVO4, Ag/PbO2/BiVO4, Au/PbO2/BiVO4 and Pt/PbO2/BiVO4. It is interesting to note that the Au, Pt and Ag particles are still selectively photo-deposited on the {010} facets, while the MnOx and PbO2 particles are loaded only on the {110} facets of BiVO4. This demonstrates that the facet-selective photo-deposition rules are also applied for the photo-deposition of dual components regardless of their combination order (Fig. 2). The selective photo-deposition of the precursors is not obviously affected by the experimental conditions, supporting the fact that the {110} and {010} facets prefer the oxidation and reduction reaction, respectively. The mechanisms of the above-mentioned photo-depositions are schematically described in Fig. 3, and the detailed experimental parameters are summarised in Supplementary Table S1. All these results unambiguously reveal that the photogenerated electrons and holes tend to accumulate on the {010} and {110} facets, respectively, which results in the reduction and oxidation reactions taking place on the corresponding {010} and {110} facets.

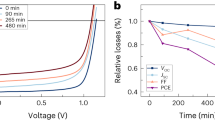

Water oxidation by photoelectrochemical process

In order to further illustrate the existence of the redox functional facets, the photoelectrochemical water oxidation of BiVO4 with oxidation cocatalyst selectively deposited on different facets were examined. In this study, we prepared four typical photoanode electrodes denoted as BiVO4, MnOx (P.D.)/BiVO4, MnOx (imp)/BiVO4 and IrO2 (P.D.)/BiVO4, respectively. To achieve different deposition morphologies of the cocatalysts, the MnOx particles were deposited on the surface of BiVO4 by two approaches. One is the selective photo-oxidation deposition introduced in this work (noted as MnOx(P.D.)/BiVO4), and the other is the impregnation method that normally results in random dispersion (noted as MnOx(imp)/BiVO4). Compared with the parent BiVO4 electrode, the photoanode current in Fig. 4 is obviously increased when the oxidation cocatalyst MnOx is selectively deposited on the {110} facets, while the randomly dispersed MnOx on both {010} and {110} facets results in a slightly enhanced photocurrent. This demonstrates the photocurrent can be efficiently promoted only when the hole-trapping oxidation cocatalyst is selectively deposited on the {110} facets. On the other hand, the IrO2 particles were firstly deposited by selective photo-deposition of metallic Ir particles on the {010} facets and subsequent calcination in air to convert the metallic iridium particles into IrO2. Decrease of photocurrent was observed for this sample with IrO2 deposited on the {010} facets. This result indicates that if the cocatalysts deposited on the wrong facets, the photocurrent will be decreased. The typical SEM images (Supplementary Fig. S5) of the deposited oxides confirmed that the photo-deposited MnOx and IrO2 are selectively located on the {110} and {010} facets, respectively, while the MnOx(imp) particles are randomly dispersed on all facets.

Photochemical performances of four typical photoelectrodes. Black line: BiVO4; red line: MnOx (P.D.)/BiVO4; blue line: MnOx (imp)/BiVO4; green line: IrO2 (P.D.)/BiVO4. P.D., photo-deposition, imp, impregnation. The MnOx nanoparticles on the MnOx (P.D.)/BiVO4 are selectively deposited on the {110} facets, the MnOx particles on the MnOx (imp)/BiVO4 photoelectrodes are randomly dispersed on both {110} and {010} facets, and the IrO2 nanoparticles on the IrO2 (P.D.)/BiVO4 electrode was deposited selectively on the {010} facets. The contents of the deposited cocatalysts are all 0.1 wt %. Reaction conditions: 0.5 M Na2SO4 aqueous solution (pH=6.8). Light source, 300 W Xe lamp (λ≥420 nm), Scan rate: 10 mV s−1.

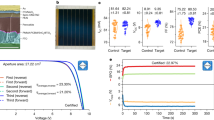

Water oxidation by photocatalysis

Photocatalytic water oxidation using a powder photocatalyst was also evaluated for the BiVO4 samples modified with reduction or/and oxidation cocatalysts. The cocatalysts were deposited by two methods: one is the facet-selective photo-deposition employed in this work to realise the selective deposition on a specific facet, the other is impregnation method normally resulting in random dispersion of deposited cocatalysts on all facets of BiVO4 (Supplementary Fig. S6). As shown in Fig. 5, the photocatalytic oxygen evolution activity is strongly dependent on the species of cocatalyst and the deposition methods. The highest water oxidation activity is achieved for the Pt(P.D.)/MnOx(P.D.)/BiVO4 sample with metallic platinum and MnOx particles selectively photo-deposited on the {010} and {110} facets, respectively. It should be pointed out that the contents of the deposited MnOx and Pt for photocatalytic water oxidation were all optimised to 0.1 wt% per ICP–AES analysis. The deposited metallic platinum on the {010} facets can collect electrons to reduce IO3− ions, and the MnOx particles photo-deposited selectively on the {110} facets can accumulate holes for water oxidation. Although sizes of the deposited platinum particles are similarly in the range of 10~30 nm for the cocatalysts located by both photo-deposition and impregnation methods, the promotion effect of cocatalysts deposited by impregnation method is not as evident as that by the photo-deposition. This result indicates that when the reduction/oxidation cocatalysts are selectively deposited on the corresponding reduction/oxidation reaction facets, namely when the cocatalysts are on the right facets of BiVO4, the photocatalytic performance can be most greatly enhanced.

Discussion

Photocatalytic reactions can usually be used to explore the reduction and oxidation sites of photocatalysts, because the photogenerated electrons just work for the photo-reduction reaction, while the photogenerated holes are only available for the photo-oxidation48. It is reasonable to deduce that if a crystal facet selectively accumulates electrons or holes, the facet will just work for reduction or oxidation separately. As a result, metals/oxides can be selectively deposited on the specific facets via photo-reduction or photo-oxidation reactions. On the other hand, if a certain crystal facet of a semiconductor equally traps both photogenerated electrons and holes, the photo-reduction and photo-oxidation reactions could proceed on the same crystal facet. In this case, the selective photo-deposition of metal ions on the facets would also occur due to the existence of two possibilities: one is the accumulation of electrons or holes on the facet, the other is the selective adsorption of the reactants on the given facet34.

The possibility for preferential adsorption of anions or selective adsorption of metal ions, leading to selective photo-deposition, can be ruled out in this work because of the following experimental facts. On the one hand, various metal precursors (AgNO3, HAuCl4, H2PtCl6, Pb(NO3)2, MnSO4) with different anionic species such as Cl−, NO3− and SO42− are employed, but the selective photo-deposition of metals and oxides are not changed. For example, the deposition of noble metals Au, Pt and Ag from precursors with distinct anions always selectively proceeded on the {010} facets of BiVO4 photocatalyst. On the contrary, the deposition of Ag and PbO2 on the {010} and {110} facets, respectively, are observed when the precursors with the same NO3− anions are applied. Moreover, the manganese ions are similarly deposited on the {110} facets (Supplementary Fig. S7) even though the precursors with distinct anions, such as Cl−, SO42− and NO3− and so on, are applied.

On the other hand, the isoelectric point of BiVO4 was measured to be about 3.5, close to the values reported in the literature49,50, which is slightly lower than the pH values of the photo-deposition solutions (Supplementary Table S1), indicating that the surfaces of BiVO4 are negatively charged during the photo-deposition. As a consequence, the adsorption of AuCl4− or PtCl62− anions on the surface of BiVO4 should be less favourable than that of Ag+, Pb2+ or Mn2+ cations in consideration of adsorption competition of ions with the same charge. However, the gold and platinum complex anions (AuCl4−, PtCl62−) and silver cations (Ag+) are all photo-reduced selectively on the {010} facets, while both the lead and manganese cations are photo-oxidised on the {110} facets. In addition, we also attempted to deposit noble Au, Pt and Ag by employing methanol instead of water as hole scavengers, and found that all of these metals are selectively deposited on the {010} facets of BiVO4 (Supplementary Fig. S8). Therefore, the influence of adsorption on the selective photo-deposition behaviours caused by the pH environment, absorption of special ions and organic sacrificial reagent like methanol can also be ruled out.

Exclusion of the adsorption effect originating from the precursor ions and preparative environments renders us to reasonably ascribe the facet-selective photo-deposition of metals and oxides to the accumulation of electrons and holes on the {010} and {110} facets of BiVO4, respectively, which correspondingly function as reduction and oxidation facets. It is reasonable to deduce that the accumulation of electrons and holes originates from charge separation on different facets. The origin of the charge separation on the {010} and {110} crystal facets of TiO2 has been already estimated by theoretical calculation19. Similarly, we also evaluated the energy levels of {010} and {110} facets of BiVO4 by DFT calculation method. A slight difference in energy of the valance and conduction band between {010} and {110} facets (Supplementary Fig. S9) suggests that the electron transfer from {110} to {010} facets is feasible thermodynamically, leading to the accumulation of electrons and holes separately on the {010} and {110} facets. It is worth noting that the band bending of each facet may be distinct due to their different surface electronic structures, as should be another factor affecting the spatial charge separation.

To further confirm the efficient charge separation on different crystal facets, the influence of temperature on the facet-selective photo-deposition was also examined (Supplementary Fig. S10). The morphology of the facet selectively deposited Au and MnOx is independent of the temperature in the experimental conditions (<100 °C), except that the particle size of the deposited metals is slightly varied with increasing deposition temperature. The temperature-independent facet-selective metal deposition also indicates that the facet-selective deposition is not due to the selective adsorption effect which is usually temperature dependent.

The separation of the photogenerated electrons and holes on the {010} and {110} facets of BiVO4 is further supported by our photoelectrochemical or photocatalystic water oxidation reaction. It has been known that if the oxidation cocatalyst is deposited on the oxidation sites of the photoelectrode, the photoanode currents can be increased because hole trapping on the oxidation cocatalyst can lead to better charge separation51,52,53,54,55. Indeed, our photoelectrochemical measurements show that the photoanode current was remarkably enhanced when the MnOx was selectively photo-deposited on the hole-concentrated {110} facets of BiVO4 (Fig. 3). In contrast, when the oxidation cocatalyst IrO2 was controllably deposited on the electron-accumulated {010} facet, the performance of water oxidation is inhibited. Similarly, only when reduction cocatalyst Pt and oxidation cocatalyst MnOx are selectively photo-deposited on the {010} and {110} facets of BiVO4, the photocatalytic activity of water oxidation can be most greatly enhanced (Fig. 4). Based on these observations, we conclude that the photogenerated electrons and holes on the surface of BiVO4 are accumulated on the {010} and {110} facets for reduction and oxidation reaction, respectively.

In summary, taking BiVO4 as a model semiconductor, we confirm the existence of oxidation and reduction facets, which are evidenced by facet-selective photo-deposition of metals and oxides, and promotion of photocatalytic or photoelectrochemical water oxidation reaction by controllable deposition of the oxidation/reduction cocatalysts on the corresponding oxidation/reduction facets. The observation of the functional facets of the BiVO4 crystal reveals spatial separation of the photogenerated electrons and holes between {010} and {110} facets of BiVO4, which are mainly owing to the difference of energy levels of these facets. Our results also show the importance of the cocatalysts loading on the right crystal facets for efficient photocatalytic water splitting. The findings of functional redox facets, selective deposition of redox cocatalysts on the different facets of a single crystal, and efficient charge separation between different facets should be promising and intriguing for understanding the mechanism of photocatalytic reactions, and designing highly efficient solar energy conversion photocatalysts/devices.

Methods

Facet-selective photo-deposition of metals and/or oxides

BiVO4 sample was synthesised by a hydrothermal procedure (Supplementary Methods). For the facet-selective photo-depositions, three ways containing single reduction, single oxidation as well as simultaneous reduction and oxidation were carried out at room temperature without pH value adjusted. Normally, 0.50 g BiVO4 powder and a calculated amount of metal precursors (5 wt%) were mixed in 100 ml deionised water. The suspension was then irradiated by a 300-W Xe lamp (λ≥420 nm) under continuous stirring. After 5 h photo-deposition, the suspension was filtered, washed with deionised water for more than three times, and finally dried at 60 °C for overnight. For comparison, the simultaneous photo-deposition of gold and manganese was also carried out at 50 and 90 °C, respectively. The as-obtained powder was used for characterizations and/or activity tests.

Preparation of photoelectrodes

The BiVO4 film electrodes were prepared by electrophoretic deposition on FTO substrate (1 × 2 cm2)47, followed by drying in air and calcination at 573 K for 1 h. On the surface of the BiVO4 electrode, different cocatalysts containing MnOx or IrO2 were subsequently deposited. As for the MnOx deposition, two methods were employed for comparison. One is the {110} facet-selective photo-deposition method that was carried out in a Pyrex reactor in 0.01 M MnSO4 solution containing 0.02 M NaIO3, and illuminated from the top using a 300-W Xe lamp. The other is the conventional impregnation method, that is, impregnation of Mn (NO3)2 solutions (0.01 M) on the BiVO4 electrode followed by calcination under 573 K for 1 h. The as-prepared electrodes are denoted as MnOx(P.D.)/BiVO4 and MnOx(imp)/BiVO4, respectively. The IrO2(P.D.)/BiVO4 electrode was prepared by selective photo-deposition of metallic iridium on the {010} facet of BiVO4 from 1 mM Na2IrCl6 solution, which was transferred into IrO2 by calcination in air at 573 K for 1 h.

Water oxidation by photoelectrochemical process

The Photoelectrochemical performances of the photoanodes were measured in a three-electrode setup, where Pt electrode and saturated mercury electrode were employed as counter and reference electrode, respectively. Electrolyte was 0.5 M Na2SO4 (pH=6.8) solution. For linear sweep voltammetry, the potential was swept with scan rate of 10 mV s−1. A shutter was used to record both the dark and photocurrent during a single scan. A 300-W Xe lamp (Ushio-CERMAXLX300) and optical cutoff filter (Kenko, L-42; λ≥420 nm) was used as light source. The contents of the deposited cocatalysts are all 0.1 wt% regardless of the methods, which were confirmed by ICP–AES analysis.

Water oxidation by photocatalysis

The photocatalytic O2 evolution reactions were carried out in a closed gas circulation and evacuation system using a 300-W Xe lamp (Ushio-CERMAXLX300) and optical cutoff filter (Kenko, L-42; λ≥420 nm). Normally, 0.15 g photocatalyst was dispersed in 150 ml 0.02 M NaIO3 aqueous solution in a Pyrex reaction cell. Before irradiation, the reaction system was thoroughly degassed by evacuation in order to drive off the air inside. The amount of evolved O2 was determined by an online gas chromatograph (Agilent, GC-7890, TCD, Ar carrier). The rate of O2 evolution in the initial 1 h was recorded for comparison. The contents of the deposited cocatalysts are all 0.1 wt% regardless of the methods, which were confirmed by ICP–AES analysis.

Additional information

How to cite this article: Li, R. et al. Spatial Separation of Photogenerated Electrons and Holes among {010} and {110} Crystal Facets of BiVO4. Nat. Commun. 4:1432 doi: 10.1038/ncomms2401 (2013).

References

Ardo, S. & Meyer, G. J. . Photodriven heterogeneous charge transfer with transition-metalcompounds anchored to TiO2 semiconductor surfaces. Chem. Soc. Rev. 38, 115–164 (2008).

Bakulin, A. A. et al. Rao, A. et al. Pavelyev, V. G. et al. The role of driving energy and delocalized states for charge separation in organic semiconductors. Science 335, 1340–1344 (2012).

Tisdale, W. A. et al. Williams, K. et al. Timp, B. et al. Hot-electron transfer from semiconductor nanocrystals. Science 328, 1543–1547 (2010).

Hagfeldt, A. & Grätzel, M. . Molecular photovoltaics. Acc. Chem. Res. 33, 269–277 (2000).

Hagfeldt, A., Björkstén, U. & Lindquist, S. E. . Photoelectrochemical studies of colloidal TiO2-films: the charge separation process studied by means of action spectra in the UV region. Sol. Energy Mater. Sol. Cells 27, 293–304 (1992).

Higashimoto, S. et al. Sakiyama, M. et al. Azuma, M. et al. Photoelectrochemical properties of hybrid WO3/TiO2 electrode. Effect of structures of WO3 on charge separation behavior. Thin Solid Films 503, 201–206 (2006).

Kavan, L. et al. Grätzel, M. et al. Gilbert, S. et al. Electrochemical and photoelectrochemical investigation of single-crystal anatase. J. Am. Chem. Soc. 118, 6716–6723 (1996).

Poznyak, S. et al. Kokorin, A. et al. Kulak, A. et al. Effect of electron and hole acceptors on the photoelectrochemical behaviour of nanocrystalline microporous TiO2 electrodes. J. Electroanal. Chem. 442, 99–105 (1998).

Tachibana, Y., Vayssieres, L. & Durrant, J. . Artificial photosynthesis for solar water-splitting. Nat. Photon. 6, 511–518 (2012).

Chen, X. et al. Shen, S. et al. Mao, S. S. et al. Semiconductor-based photocatalytic hydrogen generation. Chem. Rev. 110, 6503 (2010).

Ariando et al. Electronic phase separation at the LaAlO3/SrTiO3 interface. Nat. Commun. 2, 1–7 (2011).

Zhang, J., Xu, Q., Feng, Z., Li, M. & Li, C. . Importance of the relationship between surface phases and photocatalytic activity of TiO2 . Angew. Chem. Int. Ed. 47, 1766–1769 (2008).

Kim, H. G. et al. Borse, P. H. et al. Choi, W. et al. Lee, J. S. et al. Photocatalytic nanodiodes for visible-light photocatalysis. Angew. Chem. Int. Ed. 117, 4661–4665 (2005).

Fujishima, A. et al. Electrochemical photolysis of water at a semiconductor electrode. Nature 238, 37–38 (1972).

Kudo, A. & Miseki, Y. . Heterogeneous photocatalyst materials for water splitting. Chem. Soc. Rev. 38, 253–278 (2009).

Linsebigler, A. L. & Lu, G. . Photocatalysis on TiO2 surfaces: principles, mechanisms and selected results. Chem. Rev. 95, 735–758 (1995).

McFarland, E. W. & Tang, J. . A photovoltaic device structure based on internal electron emission. Nature 421, 616–618 (2003).

Liu, G. et al. Jimmy, C. Y. et al. Cheng, H. M. et al. Crystal facet engineering of semiconductor photocatalysts: motivations, advances and unique properties. Chem. Commun. 47, 6763–6783 (2011).

Pan, J. et al. Liu, G. et al. Cheng, H. M. et al. On the true photoreactivity order of {001},{010}, and {101} facets of anatase TiO2 crystals. Angew. Chem. Int. Ed. 50, 2133–2137 (2011).

Yang, H. G. et al. Anatase TiO2 single crystals with a large percentage of reactive facets. Nature 453, 638–641 (2008).

Farneth, W. E. et al. McLean, R. S. et al. Barteau, M. A. et al. Tapping mode atomic force microscopy studies of the photoreduction of Ag+ on individual submicrometer TiO2 particles. Langmuir 15, 8569–8573 (1999).

Hotsenpiller, P. A. M. et al. Bolt, J. et al. Rohrer, G. et al. Orientation dependence of photochemical reactions on TiO2 surfaces. J. Phys. Chem. B 102, 3216–3226 (1998).

Lowekamp, J. et al. Rohrer, G. et al. Farneth, W. et al. Anisotropic photochemical reactivity of bulk TiO2 crystals. J. Phys. Chem. B 102, 7323–7327 (1998).

Ohno, T. et al. Sarukawa, K. et al. Matsumura, M. et al. Crystal faces of rutile and anatase TiO2 particles and their roles in photocatalytic reactions. New J. Chem. 26, 1167–1170 (2002).

Oliver, P. M. et al. Watson, G. W. et al. Parker, S. C. et al. Atomistic simulation of the surface structure of the TiO2 polymorphs rutileand anatase. J. Mater. Chem. 7, 563–568 (1997).

Tachikawa, T. et al. Yamashita, S. et al. Majima, T. et al. Evidence for crystal-face-dependent TiO2 photocatalysis from single-molecule imaging and kinetic analysis. J. Am. Chem. Soc. 133, 7197–7204 (2011).

Selloni, A. . Crystal growth: anatase shows its reactive side. Nat. Mater. 7, 613–615 (2008).

Zhu, J. et al. Yang, H. et al. Li, H. et al. Solvothermally controllable synthesis of anatase TiO2 nanocrystals with dominant {001} facets and enhanced photocatalytic activity. Cryst. Eng. Comm. 12, 2219–2224 (2010).

Yang, X. et al. Li, Z. et al. Li, C. et al. Ultra-thin anatase TiO2 nanosheets dominated with {001} facets: thickness-controlled synthesis, growth mechanism and water-splitting properties. Cryst. Eng. Comm. 13, 1378–1383 (2011).

Wu, N. et al. Wang, J. et al. Manivannan, A. et al. Shape-enhanced photocatalytic activity of single-crystalline anatase TiO2 (101) nanobelts. J. Am. Chem. Soc. 132, 6679–6685 (2010).

Murakami, N. et al. Tsubota, T. et al. Ohno, T. et al. Shape-controlled anatase titanium (IV) oxide particles prepared by hydrothermal treatment of Peroxo titanic acid in the presence of polyvinyl alcohol. J. Phys. Chem. C 113, 3062–3069 (2009).

Cho, C. H. et al. Han, M. H. et al. Kim, D. K. et al. Morphology evolution of anatase TiO2 nanocrystals under a hydrothermal condition (pH=9.5) and their ultra-high photo-catalytic activity. Mater. Chem. Phys. 92, 104–111 (2005).

Miseki, Y. et al. Kato, H. et al. Kudo, A. et al. Water splitting into H2 and O2 over niobate and titanate photocatalysts with (111) plane-type layered perovskite structure. Energy Environ. Sci. 2, 306–314 (2009).

Read, C. G. et al. Steinmiller, E. M. P. et al. Choi, K. S. et al. Atomic plane-selective deposition of gold nanoparticles on metal oxide crystals exploiting preferential adsorption of additives. J. Am. Chem. Soc. 131, 12040–12041 (2009).

Wang, Z. & Song, J. . Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 312, 242–246 (2006).

Jennings, J. R. et al. Ghicov, A. et al. Walker, A. B. et al. Dye-sensitized solar cells based on oriented TiO2 nanotube arrays: transport, trapping, and transfer of electrons. J. Am. Chem. Soc. 130, 13364–13372 (2008).

Kumar, S. et al. Jones, M. et al. Scholes, G. D. et al. Nanorod heterostructures showing photoinduced charge separation. Small 3, 1633–1639 (2007).

Mor, G. K. et al. Shankar, K. et al. Grimes, C. A. et al. Use of highly-ordered TiO2 nanotube arrays in dye-sensitized solar cells. Nano Lett. 6, 215–218 (2006).

Wu, K. et al. Zhu, H. et al. Lian, T. et al. Ultrafast charge separation and long-lived charge separated state in photocatalytic CdS-Pt nanorod heterostructures. J. Am. Chem. Soc. 134, 10337–10340 (2012).

Kudo, A. et al. Omori, K. et al. Kato, H. et al. A novel aqueous process for preparation of crystal form-controlled and highly crystalline BiVO4 powder from layered vanadates at room temperature and its photocatalytic and photophysical properties. J. Am. Chem. Soc. 121, 11459–11467 (1999).

Kudo, A. et al. Ueda, K. et al. Mikami, I. et al. Photocatalytic O2 evolution under visible light irradiation on BiVO4 in aqueous AgNO3 solution. Catal. Lett. 53, 229–230 (1998).

Xi, G. & Ye, J. . Synthesis of bismuth vanadate nanoplates with exposed {001} facets and enhanced visible-light photocatalytic properties. Chem. Commun. 46, 1893–1895 (2010).

Jo, W. J. et al. Phosphate doping into monoclinic BiVO4 for enhanced photoelectrochemical water oxidation activity. Angew. Chem. Int. Ed. 51, 3147–3152 (2012).

Ng, Y. H. et al. Kudo, A. et al. Amal, R. et al. Reducing graphene oxide on a visible-light BiVO4 photocatalyst for an enhanced photoelectrochemical water splitting. J. Phys. Chem. Lett. 1, 2607–2612 (2010).

Sayama, K. et al. Photoelectrochemical decomposition of water into H2 and O2 on porous BiVO4 thin-film electrodes under visible light and significant effect of Ag ion treatment. J. Phys. Chem. B 110, 11352–11360 (2006).

Wang, D. et al. Crystal facet dependence of water oxidation on BiVO4 sheets under visible light irradiation. Chem. Eur. J. 17, 1275–1282 (2011).

Wang, D. et al. Photocatalytic Water oxidation on BiVO4 with the electrocatalyst as an oxidation co-catalyst: essential relations between electrocatalyst and photocatalyst. J. Phys. Chem. C 116, 5082–5089 (2012).

Kraeutler, B. & Bard, A. J. . Heterogeneous photocatalytic preparation of supported catalysts. Photodeposition of platinum on titanium dioxide powder and other substrates. J. Am. Chem. Soc. 100, 4317–4318 (1978).

Castillo, N. C. et al. Ding, L. et al. Pulgarin, C. et al. On the photocatalytic degradation of phenol and dichloroacetate by BiVO4: the need of a sacrificial electron acceptor. J. Photochem. Photobiol. A 216, 221–227 (2010).

Zhou, B. et al. Zhao, X. et al. Huang, C. et al. Visible-light sensitive cobalt-doped BiVO4(Co-BiVO4) photocatalytic composites for the degradation of methylene blue dye in dilute aqueous solutions. Appl. Catal. B Environ. 99, 214–221 (2010).

Allongue, P., Blonkowski, S. & Souteyrand, E. . Experimental investigation of charge transfer at the semiconductor/electrolyte junction. Electrochim. Acta 37, 781–797 (1992).

Bach, U. et al. Solid-state dye-sensitized mesoporous TiO2 solar cells with high photon-to-electron conversion efficiencies. Nature 395, 583–585 (1998).

Hill, J. C. & Choi, K. S. . Effect of electrolytes on the selectivity and stability of n-type WO3 photoelectrodes for use in solar water oxidation. J. Phys. Chem. C 116, 7612–7620 (2012).

Maeda, K. et al. Higashi, M. et al. Domen, K. et al. SrNbO2N as a water-splitting photoanode with a wide visible light absorption band. J. Am. Chem. Soc. 133, 12334–12337 (2011).

Wang, Y. et al. Photoelectrochemical properties of metal-ion-doped TiO2 nanocrystalline electrodes. Thin Solid Films 349, 120–125 (1999).

Acknowledgements

This work was financially supported by National Natural Science Foundation of China (No. 21061140361, 21090340); Solar Energy Action Plan of Chinese Academy of Sciences (ACS); Hundred Talents Programme of DICP, ACS; SKLC Independent Research Projects and 973 National Basic Research Programme of the Ministry of Science and Technology (Grant 2009CB220010).

Author information

Authors and Affiliations

Contributions

C.L. and R.L. designed the experiments, R.L. performed the photo-deposition, water oxidation and most of characterizations, D.W. synthesized the BiVO4, J.Y. and X.Z. carried out theoretical estimations. M.L. performed HR-TEM experiment. C.L., F.Z. and R.L. together wrote and revised the manuscript. H.H. took part in the revision of the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Figures S1-S10, Supplementary Table S1, Supplementary Methods and Supplementary References (PDF 787 kb)

Rights and permissions

About this article

Cite this article

Li, R., Zhang, F., Wang, D. et al. Spatial separation of photogenerated electrons and holes among {010} and {110} crystal facets of BiVO4. Nat Commun 4, 1432 (2013). https://doi.org/10.1038/ncomms2401

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/ncomms2401

This article is cited by

-

Liquid metal-embraced photoactive films for artificial photosynthesis

Nature Communications (2024)

-

Recent progress in photocatalytic NAD(P)H regeneration for photocatalytic-enzymatic-coupling system

Frontiers of Chemical Science and Engineering (2024)

-

Function-reversible facets enabling SrTiO3 nanocrystals for improved photocatalytic hydrogen evolution

Frontiers in Energy (2024)

-

Improved photocatalytic performance of acetaldehyde degradation via crystal plane regulation on truncated octahedral CeO2

Rare Metals (2024)

-

The reformation of catalyst: From a trial-and-error synthesis to rational design

Nano Research (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.