Abstract

Multiple lithium-ion transport pathways and local phase changes upon lithiation in silver hollandite are revealed via in situ microscopy including electron diffraction, imaging and spectroscopy, coupled with density functional theory and phase field calculations. We report unexpected inter-nanorod lithium-ion transport, where the reaction fronts and kinetics are maintained within the neighbouring nanorod. Notably, this is the first time-resolved visualization of lithium-ion transport within and between individual nanorods, where the impact of oxygen deficiencies is delineated. Initially, fast lithium-ion transport is observed along the long axis with small net volume change, resulting in two lithiated silver hollandite phases distinguishable by orthorhombic distortion. Subsequently, a slower reaction front is observed, with formation of polyphase lithiated silver hollandite and face-centred-cubic silver metal with substantial volume expansion. These results indicate lithium-ion transport is not confined within a single nanorod and may provide a paradigm shift for one-dimensional tunnelled materials, particularly towards achieving high-rate capability.

Similar content being viewed by others

Introduction

Porous manganese oxides such as α-MnO2 hollandites (termed OMS-2, octahedral molecular sieves-2) have gained significant attention as electroactive materials1 as their tunnel-based crystallographic structure may provide sufficient structural rigidity to enable repeated ion exchange within their one-dimensional (1D) forms2,3,4,5,6,7,8,9. Specifically, 1+ or 2+ cations often partially occupy the tunnels resulting in mixed Mn 3+/4+ oxidation states in the MnO6 octahedra10,11. Typically, ions within the tunnels are inert; however, in the case of silver hollandite, the Ag+ centres are electrochemically active.

While some hollandite-type materials have been previously studied for battery use12,13,14, preparation of pure silver hollandite at sufficient scale for electrochemical assessment was elusive until enabled by hydrothermal methods in 2007 (ref. 15) and a low-temperature reflux-based synthesis in 2010 (ref. 16). Recently, the ability to synthetically tune AgyMn8O16 material properties by manipulation of silver content (y) was reported, affirming the critical roles of composition and physical property control for lithium-ion battery applications17,18. Investigation of AgyMn8O16 (y=1.2 or 1.6) indicated nanorod morphology with longitudinal alignment of the tunnels (c axis) and the presence of oxygen vacancies near the surface. Furthermore, the sample with greater quantities of oxygen vacancies exhibited a seven-fold increase in discharge capacity in lithium based batteries19, where the significant differences in capacity were retained upon extended discharge–charge cycling17,20. In this prior work, it was hypothesized that the MnO6 octahedral distortions and oxygen vacancies facilitated lateral (a–b plane) Li+ diffusion19.

Here, using an in situ scanning/transmission electron microscopy (S/TEM) approach developed at Brookhaven National Laboratory21, lithiation of Ag1.6Mn8O16 nanorods is observed ‘operando’, revealing not only Li+ diffusion along an individual nanorod, but also the first direct experimental observation of lateral (a–b oriented) transfer of Li+ between nanorods. In situ measurements show two distinct regimes of lithiation: an initial, β regime formed by fast Li diffusion and a subsequent γ regime formed following the passage of a reaction front (RF) and characterized by substantial volume expansion. With electron energy-loss spectroscopy (EELS), we further characterize these two regimes of lithiation, finding that in the β regime x∼1 Li+ while in the γ regime, x>6 in LixAg1.6Mn8O16. Local imaging and diffraction clearly show polyphase material in both regimes, including nanoscale fcc Ag0 particle formation in the γ regime. Lateral transfer of Li+ between LixAg1.6Mn8O16 nanorods in the a–b direction is observed. Atomic scale calculations, based on density functional theory (DFT), are used to demonstrate crystal phases with Li concentrated in local planes that disrupt the tunnel walls in the x∼1 regime and the enthalpic driving force for the expulsion of Ag in the x>6 regime. Coarse-grained thermodynamic simulations capture the formation of polyphase material in the β regime and the evolution of the RF that separates the γ regime.

Results

In situ visualization of lithium-ion transport pathways

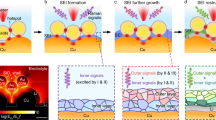

Silver hollandite was synthesized and characterized as summarized in Methods. The conceptual schematic for in situ lithiation is in Fig. 1a. The real-time morphological evolution observed in the dotted square region in Fig. 1b was sampled by a series of still images shown in Fig. 1c–m (also see Video Clip V1 in the Supplementary Materials). As shown in Fig. 1b, two distinguishable nanorods were contacted directly, and the sample contained an additional nanorod that contacted the other two, but not the Li tip. Thus, we were able to observe two distinct lithium transport pathways.

(a) Schematic illustration of the experiment setup. Electrochemical lithiation was initiated by applying a constant potential of −1.0 V to the nanorods with respect to the Li counter electrode. (b) The panoramic image of the region with Li/Li2O on the left. Scale bar, 500 nm. (c–m) Snapshots of the lithiation process from video, showing the three types of Li-transport pathways for three nanorods (I-III) in the boxed area in b. Scale bars, 20 nm. (c) Morphology upon applying potential. (d,e) Magnified images from the red and green boxed area in c, showing the early stage of lithiation with needle-like domains. (f–i) Propagation of the RF (marked by red arrows) with considerable volume expansion of the fully lithiated region. (j,k) RF in nanorod II propagates through lateral contacts between nanorods I and II. (l,m) RF in nanorod III propagates through lateral contacts between nanorods II and III, as well as longitudinally from left. Dashed lines and arrows represent the Li diffusion pathways.

First, lithium transport in nanorod I propagated along the longitudinal direction starting from the point of contact with the lithium tip. Upon applying the potential, we observed changes in the interior contrast of nanorod I where many needle-like regions became visible, Fig. 1c–e. After 3 s, a distinct lithiation RF appeared, specifically characterized by substantial cross-sectional expansion, and propagated longitudinally, Fig. 1f–k, while the region behind it underwent a 27.6% radial expansion (47–60 nm). The RF propagated ∼105 nm within 21 s, corresponding to a speed of ∼5 nm s−1. For the region of nanorod I behind the RF, the image contrast indicated a change from the morphology observed in Fig. 1d,e. Numerous tiny crystallites appeared coincident with expansion of nanorod I, while nanorods II and III retained their initial morphology. This observation confirms that the observed morphological changes were due to electrochemical lithiation rather than beam-induced phase decomposition22. Repeated careful experiments suggested that the high-intensity electron beam did not yield a similar structure change of our samples after a prolonged irradiation of 10 min, Supplementary Fig. 1.

After ∼24 s, the RF from nanorod I reached nanorod II where a second pathway for lithium transport was observed. The expansion of nanorod I created lateral contact points between the nanorods, Fig. 1i–m. At 34 s, the RF has crossed the boundary between the two rods and formed a reacted area centred at the top part of nanorod II, as indicated by the small white-vertical arrow (Fig. 1j). During this 10 s, the reaction has extended ∼10 nm deep into nanorod II and ∼48 nm along its c axis. The RF reached the bottom edge of the nanorod II at 42 s (Fig. 1k). It also continued to propagate along the c axis of nanorod II. Thus, lithiation proceeded in both directions, away from the point of contact with nanorod I. In particular, although the initial source of Li+ was different (lateral transfer), the resulting radial expansion of nanorod II was essentially the same as that observed in nanorod I. Furthermore, analysis of the RF progress in nanorod II indicated an estimated velocity of 1.9 nm s−1 across the diameter of the rod and a velocity of ∼4.4 nm s−1 longitudinally. While these values were somewhat less certain due to the altered focus conditions of nanorod II, they clearly show an asymmetry for RF motion in the a–b direction compared to along the c axis. Also, the rate along the c axis is similar that observed in nanorod I, suggesting that once established, the inter-rod Li transfer is not rate limiting. This first experimental observation of lateral transport between nanorods was fully reproducible. To further test this observation with another sample, a prelithiated nanorod A was used to laterally contact a pristine nanorod B, Supplementary Fig. 2, and the electrochemical lithiation was easily transferred to the pristine nanorod B, proving an unhindered lateral transport pathway between the nanorods. Nanorod B exhibited a radial expansion of 28.1% similar to 27.6% of nanorod I, Fig. 1. The observation of facile, local transfer of Li between nanorods in a localized contact region clearly indicated a–b plane diffusion of Li within the nanorods, as hypothesized previously19.

Starting at ∼42 s, the lateral and longitudinal lithium transport pathways were observed simultaneously for nanorod III, Fig. 1k,l. Nanorod III was laterally lithiated by the lithiated nanorod II. The expansion of nanorod II also repositioned nanorod III so as to establish contact with the Li electrode. Thus lithiation also propagated along the c axis of the nanorod III, similar to nanorod I. The final state of nanorod III also showed expansion, from 37 to 47 nm in diameter, ∼27%. This value is consistent with the expansion of nanorods I and B, Supplementary Fig. 2, indicating similar degrees of lithiation. Figure 1m shows the three fully lithiated nanorods after an elapsed time of 610 s. Despite the different pathways, they exhibit no apparent differences in morphology and no cracks or fracture formation, in contrast to Si which undergoes a much larger volume expansion upon lithiation23.

Structural evolution as a result of lithiation

More detailed analysis of the structural evolution during lithiation was obtained from another in situ TEM experiment, in which the observed region also had three nanorods with their c axis longitudinally aligned, Fig. 2. As before, two distinct regimes were observed: ahead of (right, denoted β) and behind (left, denoted γ) the RF (dashed rectangle). After the RF had propagated, Fig. 2b, the previously unreacted area (right part of Fig. 2a) showed the same morphology and volume expansion as γ. As shown by high-resolution TEM from the fully lithiated region (image in Fig. 2c), the hollandite broke into small grains with the c axis off the longitudinal axis of the nanorod, as marked by the dashed circles in Fig. 2c. The spacing of the (001) lattice fringes was slightly increased in comparison with that of pristine hollandite.

(a) In the fully lithiated area (left, denoted as γ), granular contrast and volume expansion are visible. The RF is marked by the dashed rectangle. Scale bar, 50 nm. (b) The same area of the right part of a), marked by the vertical dashed line, after RF propagates through the region. Scale bar, 50 nm. (c) HRTEM image shows fully lithiated area near the edge of the rods, consisting of small Ag nanoparticles (solid circles) and hollandite grains (dash circles). Scale bar, 5 nm. (d–g) EDPs show the corresponding structural evolution during lithiation. (d) EDP taken from the area marked as β (right in a) showing the well-preserved tetragonal structure with crystal-grains aligned along the c axis (longitudinal direction) of the nanorods. (e–g) EDPs from (e) RF area, (f) lithiated area (g, left in (a)), and (g) after extended lithiation (far left). Ag spots gradually evolve to diffusive rings due to their small size and structural distortion (see (c)), indicating increased Ag particle precipitation during lithiation. The Hollandite spots elongate into an arc, indicating that the single crystalline nanorod breaks to small grains with their c axis rotating off the longitudinal axis (see the dash circles in c). (h) EELS of Li-K edge comparing ex situ chemical lithiated (0e-6e) and in situ TEM-lithiated samples. The spectra are normalized by the Mn-M2,3 peak intensity. The Li-K edges from β- and γ-regions are compared with those from chemical lithiated samples (0e-6e), revealing the Li concentration in the β-region is about 0.9e equivalent, while the γ-region is more than 6e equivalent. (i) MLLS fitting of the Mn-M2,3 and Li-K edge of the β-region with the reference spectra of chemical lithiation 0e and 2e. HRTEM, high-resolution TEM; MLLS, multiple linear least square.

The structure of each region was characterized by local area electron diffraction patterns (EDP, Fig. 2d–g). The EDP from the β regime, Fig. 2d, showed well-preserved tetragonal structure with crystal-grains aligned along the c axis (longitudinal direction), while the EDP from the RF area, Fig. 2e, showed noticeable changes with diffraction spots beginning to elongate into circular arcs. Furthermore, some diffraction spots attributable to fcc Ag0 (indicated by black arrows) developed, although they were quite diffuse. The EDP taken from the γ regime, Fig. 2f, showed both fcc Ag0 diffraction spots, and arc-shaped hollandite diffraction spots, indicating breakdown of the c axis alignment. Although the Ag0 particles had the fcc-based structure, defects and distortion were observed, with corresponding diffraction spot broadening, Fig. 2e–g. Finally, although the EDP taken after the RF had passed showed some further structural evolution, the hollandite component could still be indexed as a tetragonal structure with an increased a-lattice parameter (a∼1.38 nm), indicating some retention of the parent manganese oxide framework.

To further quantify local lithium concentration, we compared local EELS measurements near the Li K-edge from the different areas observed in situ with spectra taken ex situ from chemically lithiated reference samples denoted by Faradaic equivalents of lithium ions (Li+) and electrons (e−) corresponding to 0–6 equivalents per Mn8O16, Fig. 2h. While the lithiation process for the in situ TEM may have been different from the ex situ one, nonetheless the chemically lithiated samples were useful to assess the degree of lithiation. Up to 4e−, the Li K-edge peak was weak and overlapped with the tail of the Mn-M2,3 edge, but clearly the intensity increased with lithiation. In comparison, the integrated peak intensity of Li in the β-region was noticeably higher than the Mn2,3 tail from the pristine sample (0e−) but lower than that of the 2e− sample. By interpolating the reference spectra for 0e− and 2e− with multiple linear least square fitting, Fig. 2i, we estimated that the β-region corresponded to ∼0.9e−. For the 6e− nanorods, a strong lithium peak intensity was typical (the second spectrum from top in Fig. 2h) although the intensity varied from rod to rod indicative of non-uniform lithiation in the ex situ samples. The EELS spectra for the γ-region observed in situ showed higher integrated intensity than the reference 6e− spectra, thus we concluded that the lithium concentration in the γ-region exceeds 6 Li+/Mn8O16.

DFT, described in Methods, was used to better understand the local atomic structure associated with each phase24,25,26,27,28,29. Previous studies for Li occupancy of pure α-MnO2 found orthorhombic distortion, but intact tunnel structures up to x=4, and substantial disruption of the MnO2 wall structure for larger x (ref. 30). The presence of Ag altered this picture significantly. Competing structures for LixAgyMn8O16 across the full stoichiometry range (up to x=8 and y=2) have been considered. When competing structures in AgyMn8O16 were compared in a convex hull, a mild enthalpic driving force stabilized several structures with 1≤y≤1.75 in which Ag occupied the 2a Wyckoff positions in the tetragonal space group I4/m, specifically high-symmetry sites at the centres of the hollandite tunnels. However, the energy between competing structures was sufficiently small (<10 meV/Ag) to suggest that for y in this range, the vacancies in the Ag occupancy within the supercell considered would be essentially randomly distributed, consistent with high-resolution TEM observations that indicated significant variation in Ag occupancy among tunnels19.

The initial stable site for Li was a vacancy in the Ag occupancy, but off-centre in the 8 h’ Wyckoff position, to better coordinate to oxygen centres. Such stable phases included Li0.25Ag1.5Mn8O16, Li0.5Ag1.5Mn8O16, and Li1Ag1Mn8O16 (Supplementary Fig. 4). For higher Li concentration, the calculations indicated that the Li concentrated in selected planes, as illustrated by two stable phases in Fig. 3a,b. With two Li ions per Mn8O16 formula unit locally in a single tunnel, the wall structure was disrupted in one direction. All of the structures found up to x=2 exhibited rhombohedral distortion, but only a small increase in volume. For large x, the wall structure fully opened and the cell cross section area was substantially increased. Overall, the structures for Li6Ag2, Li7Ag1 and Li8 were nearly the same, with minimal rhombohedral distortion, but substantial volume expansion. However, the calculated energies showed a clear enthalpic driving force towards phase segregation, displacing the larger Ag+ ions from the matrix to form Ag metal, Fig. 3c.

Once initial lithiation concentration exceeds the local Ag vacancy concentration, there is a driving force for Li to aggregate in sheets and laterally disrupt the tunnel walls. Two examples are shown representing stable phases: (a) Li1Ag1.5Mn8O16 and (b) Li2Ag1Mn8O16. They differ primarily in the spacing between the lithiated layers. (c) High Li concentration phases, such as Li8Ag2Mn8O16 exhibit complete disruption of the tunnel walls and are calculated to phase segregate, expelling Ag to form fcc-Ag.

A clear picture has emerged for the observed γ regime. It was polyphase, characterized by internal disorder in which the nanorods broke into smaller grains and the emergence of Ag0. The DFT results were fully consistent: they showed phase segregation for the x≥6 Li+ inserted and large lattice expansion along the a/b directions. Further, the substantial disruption of wall structure shown by the calculations and the experimentally observed short crystallite length (10 nm scale, Fig. 2c) were both fully consistent with rapid lateral diffusion of lithium within the rods as well as between rods, as observed in Fig. 1j–l.

For the β regime, with an average Li concentration of x∼1, two contrast regions were distinguishable in the TEM bright-field image with little change in volume, Fig. 2a. The DFT calculations indicated that stable phases with the right local concentration of Li and an extended, open morphology would facilitate Li diffusion. The observed phase segregation could correspond to one that was Li-rich (such as illustrated in Fig. 3a,b) and one that was Ag-rich/Li-poor (that is, Li0.25Ag1.5Mn8O16) where Li at most fills the Ag vacancies. There were two distinct orientations for the extended planes of local Li concentration and the orthorhombic distortion. So, while the difference of in-plane lattice parameters, b−a=1.2 Å, was large, the volume or cross-section area change was small (<1%), with the orientation of the orthorhombic distortion of different local phases nucleating randomly. This agreed with the diffraction contrast distinguishing the phases during the in situ observations, but no evident expansion in the width of the rod for the β phase.

Dynamics and phase field model of nanorod lithation

We have seen that lithiation occurred in two steps separated by a RF, Fig. 4a,b. During the early stage of lithiation, neither the initial diffusion of Li+ to form the β regime nor the initial phase segregation leading to nucleation and growth of the β1+β2 phases, could be resolved. This suggests a high diffusion rate of Li+ into the region up to a concentration of about x∼1. Using a lower bound diffusion coefficient D=1 × 10−13 m2 s−1 based on the Einstein–Smoluchowski relation, D=L2/2t (ref. 31), diffusion along the 500 nm extent of the nanorod inside the highlighted box in Fig. 1b would take ∼1 s. The dynamic time scale that we directly observed was the motion of the RF, which moved ∼105 nm from the snapshot in Fig. 1f to the snapshot in Fig. 1i in a period of 21 s. Interpreting this as diffusive motion implied D∼2.6 × 10−16 m2 s−1.

(a) An experimental snap shot from the in situ TEM study of lithiation of Ag1.63Mn8O16 nanorods (see Fig. 1), showing three distinct regions: the lithiation RF, the area in front of the RF (β1+β2), and behind (γ). The γ area was measured to have Li concentration greater than 6 per Mn8O16 unit cell, while the β1+β2-region has ∼1 Li. (b) Schematic representations of the co-existing phases in a. (c–e) Snap shot from two-dimensional phase-field simulation illustrating dynamical evolution of the microstructure (β1+β2 phase and the motion of the RF) for three instants of time, t=0, 103 and 105. The electrochemical boundary condition is applied on the left-hand side, representing the source of Li ions, marked by the arrows. The top row (c,d) shows two-dimensional maps with the colour legend indicating normalized Li concentration and the bottom row (f–h) shows one-dimensional Li-concentration (number of Li per unit cell: N. Li) as a function of distance (rescale length in phase-field simulation: R.L.).

Lithium diffusion coefficients were determined for composite silver hollandite electrodes in bulk-lithium-based cells for comparison with the in situ results. Galvanostatic intermittent titration technique (GITT) type testing under 40 or 100 mA g−1 currents was utilized, see Supplementary Fig. 5. The diffusion coefficients determined from these bulk measurements ranged from 7 × 10−11 initially to 1 × 10−13 m2 s−1 after reduction by 1 e−, with evidence of lower polarization initially (<0.5 e−) and higher polarization at higher levels of reduction (>0.5 e−) consistent with the multiple phase model described below. Electrochemical impedance spectra (EIS) collected at several states of discharge were also used, Supplementary Fig. 5. The diffusion coefficients from EIS ranged from 8 × 10−11 initially to 1 × 10−15 m2 s−1 after reduction by two electron equivalents. Although the driving force for lithiation was different for the in situ and bulk tests, since the former used a ‘constant potential’ of −1.0 V versus Li (for different constant potential and multicycle in situ experiment, see Supplementary Fig. 3) while the latter used ‘constant current’ of 9.1 mA g−1 during the discharge steps. For the bulk system, the apparent lithium-ion diffusion coefficients were determined using three experimental methods. The EIS method perturbed the system the least, as the measurement was done at open circuit voltage after 22 h of rest. In contrast, the GITT methods used higher current to perturb the system and shorter relaxation times. An examination of the resulting diffusion coefficients between ∼0 and 1 electron equivalents of discharge indicates that the effective diffusion coefficient determined under EIS conditions was slightly higher than that for the GITT measurements. Notably, for the EIS measurements which were determine beyond two electron equivalents, the effective diffusion coefficient continued to decrease with discharge. Therefore the value determined from the in situ results of 2.6 × 10−16 m2 s−1 is reasonable and consistent with the bulk data given the high driving force and advanced state of lithiation as part of the in situ measurement. Thus, the bulk tests affirmed that Li-transport timescales were concentration dependent up to a moderate state of discharge and were in general agreement with the values determined from the in situ experiment.

To provide more insight into the observed dynamics, we employed a phase field model in which the driven dynamics of the Li concentration inside the material were determined from the Cahn–Hilliard equation, an internal free energy functional, and boundary conditions for the electrochemical interface derived from the Butler-Volmer equation32,33. For modelling purposes, we assumed the material had a stable phase for Li concentrations of x=0, 1 and 8. The multiphase γ-region was treated as a single phase without regard to the internal phase segregation. We started with the initial influx of Li which had reached an average concentration x=0.7 and simulated the evolution of the system on the time scale characterized by the RF movement. Model parameters, carefully chosen to qualitatively capture the regime observed in the experiments are listed in Supplementary Table 1.

Starting from an initial state of uniform Li concentration x=0.7 (Fig. 4c), subsequent lithiation led to phase separation with co-existence of Ag-rich/Li-free (x∼0,β1) and Li-poor (x∼1,β2) phases (Fig. 4d). As lithiation continued, the high Li concentration (x∼8, γ-phase) nucleated and grew from the electrolyte/electrode interface. Then, the RF moved down the nanorod, expanding the volume of the γ-phase. At the same time the coarsening of β1+β2 continued slowly. Our simulations indicated that the details of the microstructure evolution were sensitive to the coefficients in the free energy function. The evolution of β1 and β2 depended on the energy barrier between the two phases. Other physical features, such as evolution of the RF width and the growth rate of the γ phase, were also analysed. Supplementary Materials contain additional details of parametric dependence (Supplementary Figs 6–9 and simulation Video Clips V2). The simulations presented in Fig. 4 exhibit the balance between the time scale associated to the RF motion and the β1-phase coarsening, consistent with the experimental observations, Fig. 1.

Discussion

We have conducted a systematic study of the discharge process in silver hollandite, including detailed elucidation of the phase evolution upon intra-rod and inter-rod lithiation. Using in situ electron diffraction, imaging, and spectroscopy, supported by comparison to chemically lithiated ex situ reference samples, we identified two regimes of intra-rod lithiation and multiple lithium-ion transport pathways including lateral inter-rod lithiation. Dynamics of the lithiation process were correlated at the local and bulk levels. DFT and phase field computations validated the observed phase evolution.

In less than one second, Li+ diffused 100 nm into the nanorod resulting in an average composition of LixAg1.63Mn8O16 with x∼1, but with a morphology that indicated co-existence of two phases. In∼100 s, we observed the steady advance of a RF along the nanorod. Behind the RF, the nanorod diameter expanded ∼30%. Based on electron energy-loss spectroscopy, the area behind the RF corresponded to x>6 on average, but imaging and electron diffraction clearly showed polycrystalline material with lithiated hollandite and fcc-Ag0 nanoscale regions.

Notably, in both phases, all data pointed to a rapid diffusion of lateral Li+ transport across the a–b planes, perpendicular to the nanorod axis, despite the c axis orientation of the inherent tunnels in the hollandite crystal structure. Furthermore, the same high level of lithiation (x>6) was observed in both nanorods due to lateral lithium transfer between rods. Atomic scale calculations based on DFT suggested structural motifs, in the x∼1 and x>6 regimes consistent with all the observations, including rapid internal Li diffusion in the a–b planes. The observed diffusivity values determined at the nanoscale via TEM were consistent with those measured in bulk via GITT and EIS. Thermodynamic phase field simulation results illustrated the phase evolution processes of the microstructure, consistent with TEM observations of the microstructure changes and progression of the RF.

Understanding transport limitations and available diffusion pathways is critical for several classes of 1D materials, including materials structurally34 and compositionally35 related to the silver hollandite material, and has been an active area of experimental and theoretical study for 1D diffusion in LiFePO4 (ref. 36). For materials limited to 1D diffusion pathways, the presence of point defects or dopants blocking the tunnels can have significant impact on diffusion, where very high diffusivity at the nanoscale may not be sustained in large crystals37. The work presented here provides an important new context for consideration of kinetic limitations for lithium-ion transport in 1D materials. In some 1D materials, such as the silver hollandite material studied here, inclusion of 2D (a–b) planar diffusion is necessary to adequately describe lithium-ion transport. Thus, this work may motivate research to revisit transport in other 1D materials using complementary bulk and nanoscale techniques.

Methods

Synthesis and characterization

The synthesis of silver hollandite, AgyMn8O16·nH2O, was performed using an ambient pressure reflux reaction approach as previously described16,17. Samples were heat treated at 300°C under air prior to microscopic analysis. X-ray powder diffraction patterns were collected on a Rigaku SmartLab and indexed to Ag1.8Mn8O16 (JCPDS no. 87-087)38. Crystallite sizes were determined by applying the Scherrer equation to the (211) peak after LaB6 correction. Inductively coupled plasma-optical emission spectroscopy (Inductively coupled plasma-optical emission spectroscopy ) was employed on a ThermoScientific iCap 6,000. Thermogravimetric analysis (TGA) was collected on a TA Instruments SDT Q600, where water content was estimated based on weight loss to 360 °C (refs 7, 15). On the basis of results of X-ray powder diffraction, ICP-OES and TGA, the composition was assigned as Ag1.63Mn8O15.7·0.84H2O. In addition, a series of chemically lithiated materials were prepared using LiBH4 as a lithiating reagent and studied as reference samples for ex situ TEM.

In situ configuration

The in situ electrochemical cell for directly observing the all-solid nano-LIB was constructed inside a TEM by adapting a commercially available biasing system, Fig. 1a. The hollandite AgyMn8O16 nanowires as the cathode were glued to the half copper grid with conductive epoxy. A lithium metal counter electrode was attached to a sharp tungsten tip that was associated to a piezo-driven biasing-probe built into the sample stage (Nanofactory Instruments AB). After the Li2O/Li electrode contacted the nanorods, electrochemical lithiation was initiated by applying a constant potential of −1.0 V to the nanorods with respect to the Li counter electrode. This constant potential was applied throughout the in situ lithiation process. The native thin Li2O coating formed on the Li tip due to local oxidation acted as a solid-state electrolyte in this configuration21.

Electron microscopy

High-resolution S/TEM (STEM and TEM) imaging, diffraction, and spectroscopy, including chemical and Mn valence mapping, were performed using the double aberration-corrected JEOL-ARM200CF microscope with a cold-field emission gun and operated at 200 kV. The microscope is equipped with JEOL and Gatan HAADF detectors for incoherent HAADF (Z-contrast) imaging, Gatan GIF Quantum ER Energy Filter with dual EELS for spectroscopy. In situ electric biasing experiments were carried out using the modified Nanofactory piezo-controlled sample holder.

Electrochemical assessment

Two electrode electrochemical cells were assembled with lithium metal anodes and cathodes utilizing Ag1.66Mn8O16. Electrochemical testing was measured on a BioLogic model VSP multichannel electrochemical analyser. The galvanostatic intermittent technique (GITT) used two tests: the first with a current density of 40 mA g−1 applied to the cell for 90 s followed by a rest time of 2 h, and the second with a current density of 100 mA/g applied to the cell for 180 s followed by a rest time of 10 h. The diffusion coefficient from GITT was derived using equation (1):39,40,41

where L=finite diffusion length, I=applied current, Vm=molar volume of Ag1.66Mn8O16, F=Faraday’s constant, S=electrode surface area, dE/dδ=slope of the coulometric titration curve and dE/d =slope of voltage versus square root of time plot during constant current pulse.

=slope of voltage versus square root of time plot during constant current pulse.

Electrochemical impedance spectroscopy (EIS) was measured during rest steps with a frequency range of 0.1 Hz to 100 kHz where the cell was discharged with a current density of 9.1 mA/g for 2 h followed by a rest time of 22 h. The diffusion coefficients from EIS used equation (2):42,43,44

where ω=angular frequency, L=finite diffusion length, Vm=molar volume of Ag1.66Mn8O16, F=Faraday’s constant, S=geometric surface area of electrode, dE/dx=slope of the coulometric titration curve and σ=Warburg coefficient, obtained from the slope of Re(Z) versus ω−1/2.

DFT calculations

DFT total energy calculations and geometry optimization were performed with the VASP package24, using the projector augmented wave approach25,26 and the generalized gradient approximation (GGA) of Perdew, Burke and Ernzerhof (PBE)27 for the exchange-correlation density functional. The semi-empirical DFT+U method was applied to the Mn 3d electrons to approximately account for the strong Coulomb interactions28, specifically with the fully anisotropic version, guided by prior results for β-MnO2 (ref. 29). Values chosen (U=6.2 eV and J=1.0 eV) follow the literature30. Calculations included spin polarization, with the strong local moment on Mn ions that result assumed to be parallel. Exploration of the impact of a simple, short-range anti-parallel ordering did not substantially alter the atomic structure or the energetics. The fundamental α-MnO2 cell contained eight formula units and two independent large tunnels in the tetragonal space group I4/m (No. 87). For the primitive cell (including up to two Ag atoms and/or eight Li atoms), the Brillouin zone was sampled by 2 × 2 × 8 mesh cantered on the origin. The energy cutoff for the Kohn–Sham orbitals was 520 eV. Internal atomic positions and cell parameters were optimized to a tight force criterion, 0.01 eV/A. Crystal structures were visualized using VESTA45.

Phase field calculations

The evolution of the Li concentration inside the material was determined from the Cahn–Hilliard equation and a supporting internal free energy functional:32,33,46

where M is the mobility tensor (here taken to be isotropic and constant) and the internal chemical potential Δμ derives from the homogeneous concentration dependent free energy and the Cahn–Hilliard gradient energy coefficient κ. The free energy functional is approximated as a piece-wise continuous polynomial. All parameters are rescaled to dimensionless form and the concentration scale is normalized to the range c=[0, 1]. The boundary conditions describing the external electrochemical interface kinetics derive from the Butler-Volmer equation:33,46,47

where α, is the electron-transfer symmetry factor, ne is the net charge transferred from the solution to the electrode, kB is the Boltzmann’s constant and T is the temperature. The local voltage drop across the interface ΔΦ is included through

and the exchange current can be written as

where K0 contains the details of the interface kinetics, here taken to be a reference constant. The total current integrated over the active facet is controlled by ΔΦ

where A is the surface area. A constant current boundary condition was implemented by solving equations (5, 6, 7, 8) for the interface voltage drop and then updating the source term for the Cahn–Hilliard equation via equation (5). As a further simplification, once c=1 at the interface was reached, it was held fixed. Stable numerical solutions of the Cahn–Hilliard equation were obtained using an implicit finite-difference method and incorporating a small, stochastic variation in the concentration. Details of the parameters chosen and the solutions to the model appear in the Supplementary Materials.

Data availability

The data that support the findings of this study are available from the corresponding author upon request.

Additional information

How to cite this article: Xu, F. et al. Visualization of lithium-ion transport and phase evolution within and between manganese oxide nanorods. Nat. Commun. 8, 15400 doi: 10.1038/ncomms15400 (2017).

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Brock, S. L. et al. A review of porous manganese oxide materials. Chem. Mater. 10, 2619–2628 (1998).

Nicolas-Tolentino, E., Tian, Z.-R., Zhou, H., Xia, G. & Suib, S. L. Effects of Cu2+ Ions on the structure and reactivity of todorokite- and cryptomelane-type manganese oxide octahedral molecular sieves. Chem. Mater. 11, 1733–1741 (1999).

Tsuji, M. & Komarneni, S. Selective exchange of divalent transition metal ions in cryptomelane-type manganic acid with tunnel structure. J. Mater. Res. 8, 611–616 (1993).

Li, L. & King, D. L. Synthesis and characterization of silver hollandite and its application in emission control. Chem. Mater. 17, 4335–4343 (2005).

Dyer, A. et al. Sorption behavior of radionuclides on crystalline synthetic tunnel manganese oxides. Chem. Mater. 12, 3798–3804 (2000).

Dharmarathna, S., King’ondu, C. K., Pedrick, W., Pahalagedara, L. & Suib, S. L. Direct sonochemical synthesis of manganese octahedral molecular sieve (OMS-2) nanomaterials using cosolvent systems, their characterization, and catalytic applications. Chem. Mater. 24, 705–712 (2012).

Huang, H. et al. Microwave-assisted hydrothermal synthesis of cryptomelane-type octahedral molecular sieves (OMS-2) and their catalytic studies. Chem. Mater. 22, 3664–3669 (2010).

Ching, S. & Suib, S. L. Synthetic routes to microporous manganese oxides. Commun. Inorg. Chem. 19, 263–282 (1997).

Yuan, Y. et al. Asynchronous crystal cell expansion during lithiation of K+-stabilized α-MnO2 . Nano Lett. 15, 2998–3007 (2015).

Vicat, J., Fanchon, E., Strobel, P. & Tran Qui, D. The structure of K1.33Mn8O16 and cation ordering in Hollandite-type structures. Acta Crystallogr. B 42, 162–167 (1986).

Ozawa, T., Suzuki, I. & Sato, H. Structural, magnetic and electronic transport properties of novel Hollandite-type molybdenum oxide, Rb1.5Mo8O16 . J. Phys. Soc. Jpn 75, 014802–014802 (2006).

Dai, J., Li, S. F. Y., Siow, K. S. & Gao, Z. Synthesis and characterization of the Hollandite-type MnO2 as a cathode material in lithium batteries. Electrochim. Acta 45, 2211–2217 (2000).

Kijima, N. et al. Synthesis and lithium ion insertion/extraction properties of Hollandite-type MnO2 prepared by acid digestion of Mn2O3 . Solid State Ionics 180, 616–620 (2009).

Kijima, N., Takahashi, Y., Akimoto, J. & Awaka, J. Lithium ion insertion and extraction reactions with Hollandite-type manganese dioxide free from any stabilizing cations in its tunnel cavity. J. Solid State Chem. 178, 2741–2750 (2005).

Chen, J. et al. Synthesis and characterization of Ag-Hollandite nanofibers and its catalytic application in ethanol oxidation. Chem. Mater. 19, 4292–4299 (2007).

Zhu, S., Marschilok, A. C., Lee, C.-Y., Takeuchi, E. S. & Takeuchi, K. J. Synthesis and electrochemistry of silver Hollandite. Electrochem. Sol. State Lett. 13, A98–A100 (2010).

Takeuchi, K. J., Yau, S. Z., Menard, M. C., Marschilok, A. C. & Takeuchi, E. S. Synthetic control of composition and crystallite size of silver Hollandite, AgxMn8O16: impact on electrochemistry. ACS Appl. Mater. Interfaces 4, 5547–5554 (2012).

Takeuchi, K. J., Yau, S. Z., Subramanian, A., Marschilok, A. C. & Takeuchi, E. S. The electrochemistry of silver Hollandite nanorods, AgxMn8O16: enhancement of electrochemical battery performance via dimensional and compositional control. J. Electrochem. Soc. 160, A3090–A3094 (2013).

Wu, L. et al. Structural defects of silver Hollandite, AgxMn8Oy, nanorods: dramatic impact on electrochemistry. ACS Nano 9, 8430–8439 (2015).

Huang, J. et al. Silver-containing α-MnO2 nanorods: electrochemistry in Na-based battery systems. ACS Appl. Mater. Interfaces 9, 4333–4342 (2017).

Wang, F. et al. Tracking lithium transport and electrochemical reactions in nanoparticles. Nat. Commun. 3, 1201 (2012).

Tan, H., Verbeeck, J., Abakumov, A. & Van Tendeloo, G. Oxidation state and chemical shift investigation in transition metal oxides by EELS. Ultramicroscopy 116, 24–33 (2012).

Liu, X. H. et al. Anisotropic swelling and fracture of silicon nanowires during lithiation. Nano Lett. 11, 3312–3318 (2011).

Kresse, G. & Furthmüller, J. Efficiency of Ab-Initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Vladimir, I. A., Aryasetiawan, F. & Lichtenstein, A. I. First-principles calculations of the electronic structure and spectra of strongly correlated systems: the LDA+U method. J. Phys. Condens Matter 9, 767–808 (1997).

Tompsett, D. A., Middlemiss, D. S. & Islam, M. S. Importance of anisotropic Coulomb interactions and exchange to the band gap and antiferromagnetism of b-MnO2 from DFT+U. Phys. Rev. B 86, 205126 (2012).

Tompsett, D. A. & Islam, M. S. Electrochemistry of Hollandite α-MnO2: Li-ion and Na-ion insertion and Li2O incorporation. Chem. Mater. 25, 2515–2526 (2013).

Lanz, M. et al. Large-agglomerate-size lithium manganese oxide spinel with high rate capability for lithium-ion batteries. J. Electrochem. Soc. 147, 3997–4000 (2000).

Cahn, J. W. & Hilliard, J. E. Free energy of nonuniform system. I. Interfacial free energy. J. Chem. Phys. 28, 258–267 (1958).

Bazant, M. Z. Theory of chemical kinetics and charge transfer based on nonequilibrium thermodynamics. Acc. Chem. Res. 46, 1144–1160 (2013).

Sakao, M., Kijima, N., Akimoto, J. & Okutani, T. Lithium insertion and extraction properties of Hollandite-type KxTiO2 with different K content in the tunnel space. Solid State Ionics 243, 22–29 (2013).

Byles, B. W., West, P., Cullen, D. A., More, K. L. & Pomerantseva, E. Todorokite-type manganese oxide nanowires as an intercalation cathode for Li-ion and Na-ion batteries. RSC Adv. 5, 106265–106271 (2015).

Ouyang, C., Shi, S., Wang, Z., Huang, X. & Chen, L. First-principles study of Li ion diffusion in LiFePO4 . Phys. Rev. B 69, 104303 (2004).

Malik, R., Burch, D., Bazant, M. & Ceder, G. Particle size dependence of the ionic diffusivity. Nano Lett. 10, 4123–4127 (2010).

Chang, F. M. & Jansen, M. Ag1.8Mn8O16: square planar coordinated Ag+ ions in the channels of a novel Hollandite variant. Angew. Chem. Int. Edn Engl. 23, 906–907 (1984).

Weppner, W. & Huggins, R. A. Determination of the kinetic parameters of mixed-conducting electrodes and application to the system Li3Sb. J. Electrochem. Soc. 124, 1569–1578 (1977).

Wen, C. J., Boukamp, B. A., Huggins, R. A. & Weppner, W. Thermodynamic and mass transport properties of LiAl. J. Electrochem. Soc. 126, 2258–2266 (1979).

Zhang, Y. et al. Improved electrochemical performance of nitrogen doped TiO2-B nanowires as anode materials for Li-ion batteries. Nanoscale 7, 12215–12224 (2015).

Ho, C., Raistrick, I. D. & Huggins, R. A. Application of A-C techniques to the study of lithium diffusion in tungsten trioxide thin films. J. Electrochem. Soc. 127, 343–350 (1980).

Kanoh, H., Feng, Q., Hirotsu, T. & Ooi, K. AC impedance analysis for Li+ insertion of a Pt /λ-MnO2 electrode in an aqueous phase. J. Electrochem. Soc. 143, 2610–2615 (1996).

Zhang, D., Popov, B. N. & White, R. E. Electrochemical investigation of CrO2.65 doped LiMn2O4 as a cathode material for lithium-ion batteries. J. Power Sources 76, 81–90 (1998).

Momma, K. & Izumi, F. VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J. Appl. Crystallogr. 44, 1272–1276 (2011).

Bai, P., Cogswell, D. A. & Bazant, M. Z. Suppression of phase separation in LiFePO4 nanoparticles during battery discharge. Nano Lett. 11, 4890–4896 (2011).

Newman, J. Electrochemical Systems Prentice Hall, Inc. (1991).

Acknowledgements

Structural characterization using electron microscopy, and phase field calculations were supported by the US DOE-BES, Materials Science and Engineering Division, under Contract No. DESC0012704. Materials synthesis, electrochemistry and DFT was supported by the Center for Mesoscale Transport Properties, an Energy Frontier Research Center supported by the US Department of Energy (DOE), Office of Science, Basic Energy Sciences (BES), under award #DE-SC0012673. Theory and computational resources at the Center for Functional Nanomaterials at Brookhaven National Laboratory were supported by DOE-BES User Facility Division, under Contract No. DE-SC0012704. This research also used the resources of the Handy computing system at the Institute for Advanced Computational Science at Stony Brook University, and of the National Energy Research Scientific Computing Center, a DOE Office of Science User Facility supported by the Office of Science of the US Department of Energy under Contract No. DE-AC02-05CH11231. F.X. acknowledges the support of the 973 Program, under Grant No. 2015CB352106. The authors declare that the data supporting the findings of this study are available within the paper and its supporting information files.

Author information

Authors and Affiliations

Contributions

F.X. collected the ‘operando’ electron microscopy data. L.W. collected electron microscopy, diffraction, and electron energy-loss spectroscopy data on ex situ prepared samples. Q.M. did the initial density functional theory calculations and developed the phase field model with input from M.S.H. M.K., M.F.-S. and M.S.H. did the density functional theory calculations for the LixAgyMn8O16 phase diagram. K.J.T. developed the material synthesis method. J.H. and J.L.D. completed the bulk materials synthesis, characterization and electrochemistry. A.C.M., K.J.T. and E.S.T. designed the electrochemistry experiments. Y.Z. designed the local characterization measurements and directed their interpretation. All authors contributed to writing of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Figures, Supplementary Table 1, Supplementary Notes and Supplementary References (PDF 1090 kb)

Supplementary Movie 1

clips of microstructure evolution - in-situ experimental observations (AVI 3419 kb)

Supplementary Movie 2

clips of microstructure evolution - phase-field simulations with different parameters. (WMV 1681 kb)

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Xu, F., Wu, L., Meng, Q. et al. Visualization of lithium-ion transport and phase evolution within and between manganese oxide nanorods. Nat Commun 8, 15400 (2017). https://doi.org/10.1038/ncomms15400

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/ncomms15400

This article is cited by

-

Electrochemical and Pseudocapacitive Analysis of Rod-Like MoO2@MoSe2@NC Heterostructures for High-Performance Lithium Ion Batteries

Acta Metallurgica Sinica (English Letters) (2021)

-

In situ interface engineering for probing the limit of quantum dot photovoltaic devices

Nature Nanotechnology (2019)

-

Non-uniform Stress-free Strains in a Spherically Symmetrical Nano-sized Particle and Its Applications to Lithium-ion Batteries

Scientific Reports (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.