Abstract

Amine-containing adsorbents have been extensively investigated for post-combustion carbon dioxide capture due to their ability to chemisorb low-concentration carbon dioxide from a wet flue gas. However, earlier studies have focused primarily on the carbon dioxide uptake of adsorbents, and have not demonstrated effective adsorbent regeneration and long-term stability under such conditions. Here, we report the versatile and scalable synthesis of a functionalized-polyethyleneimine (PEI)/silica adsorbent which simultaneously exhibits a large working capacity (2.2 mmol g−1) and long-term stability in a practical temperature swing adsorption process (regeneration under 100% carbon dioxide at 120 °C), enabling the separation of concentrated carbon dioxide. We demonstrate that the functionalization of PEI with 1,2-epoxybutane reduces the heat of adsorption and facilitates carbon dioxide desorption (>99%) during regeneration compared with unmodified PEI (76%). Moreover, the functionalization significantly improves long-term adsorbent stability over repeated temperature swing adsorption cycles due to the suppression of urea formation and oxidative amine degradation.

Similar content being viewed by others

Introduction

Global warming due to CO2 emissions is an urgent issue because it can cause severe climate change and environmental catastrophe1. The CO2 emissions associated with human activities are mainly due to the use of fossil fuels, and the implementation of CO2 capture and storage technologies in power plants has been proposed as a means of enabling the continued use of fossil fuels in the short term2,3. In particular, post-combustion CO2 capture has attracted a lot of attention because the technology can be easily retrofitted into the existing power plants2,3. Among various CO2 capture methods, CO2 capture using aqueous alkanolamine solutions has been intensively researched and used industrially for over 50 years4. However, the amine scrubbing processes involve the intrinsic limitations of potential environmental and health concerns due to volatile amine loss, corrosion problems and high energy consumption for solvent regeneration2,5. To overcome these limitations, solid adsorbents have emerged as a promising alternative by virtue of their non-corrosive property and lower energy penalty for regeneration2,6,7.

Various solid adsorbents such as amine-functionalized porous materials8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29, zeolites30,31,32,33, carbons34,35 and metal organic frameworks36,37,38,39,40,41 have been widely investigated for CO2 capture. Among these adsorbents, amine-functionalized porous materials have been most extensively investigated due to their effective ability to chemisorb low-concentration CO2 (<15%) from a wet flue gas2,6,7. The adsorbents can be prepared by impregnating polymeric amines such as polyethyleneimine (PEI) into porous supports8,9,10,11,12,13,14,15,16,17,18,19,20,21,22, grafting aminosilanes on the pore surface21,22,23,24,25,26 and in situ polymerization of amine monomers within the support pores26,27. By introducing high-loading amines into large-porosity supports, adsorbents with large CO2 uptakes (generally above 2 mmol g−1) could be readily prepared. However, as critically mentioned in several papers6,7,22,28, most previous studies have primarily focused on increasing the CO2 uptake of adsorbents during the adsorption step, and there have been very few reports describing practically meaningful regeneration methods for the adsorbents. In earlier works, adsorbents were almost always regenerated by increasing temperature under an inert gas purge (for example, N2)8,10,12,13,14,15,17,18,19,20,21,23,26,27, which ultimately does not result in the separation of CO2. Therefore, several critical missing links remain in the development of a practical CO2 capture process, specifically, the demonstration of energy-efficient adsorbent regeneration enabling the purified CO2 separation and long-term material stabilities under such conditions. Another important issue is the cost and scalability of adsorbent synthesis, which has often been ignored in academic studies. Considering that material syntheses requiring the use of corrosive and expensive chemicals and multi-step procedures are difficult to scale up, an enormous gap appears to exist between many of the current academic studies and practical adsorbent development.

The regeneration of solid adsorbents can be carried out using pressure swing adsorption (PSA), vacuum swing adsorption (VSA) and temperature swing adsorption (TSA) processes. However, PSA and VSA require a large amount of energy in compressing or applying a vacuum to large volumes of low-pressure flue gas stream6,7,37,42,43. In addition, the availability of waste heat from a power plant as a source of regeneration energy makes TSA more attractive than PSA and VSA37,42. However, to design a practical TSA process which enables the separation of highly concentrated CO2, the CO2 should be desorbed from the adsorbents under a CO2-rich atmosphere using a primarily thermal driving force (that is, without an inert gas purge; the separated CO2 can be recycled as a purge gas). Unfortunately, in the case of amine-functionalized adsorbents, a relatively high temperature (>120 °C) must be used to desorb CO2 under a CO2-rich atmosphere, where a significant deactivation of amines via urea formation (that is, dehydrative condensation between amines and CO2) takes place16,17,18,19,20,21,22,23,24. Recently, Jones and colleagues7,28 proposed the use of high-temperature steam for regenerating the amine-functionalized adsorbents, because it can suppress the urea formation according to Le Chatelier's principle and reduce the partial pressure of CO2 under the desorption condition. The added steam can be removed as liquid water after condensation. For this process to be feasible, an economic source of steam needs to be available and the adsorbents should have high hydrothermal stability7,15,29.

In the present work, we report a highly versatile and scalable synthesis of functionalized-PEI/silica composite adsorbent that simultaneously exhibits a large CO2 working capacity (2.2 mmol g−1) as well as long-term stability in a TSA condition (adsorbent regeneration under 100% CO2 at 120 °C) even without the addition of steam. The use of 100% CO2 as a purge gas enables the separation of CO2 in a highly concentrated state, but at the same time it is the most unfavourable atmosphere for adsorbent regeneration in terms of CO2 partial pressure and amine deactivation via urea formation. In this work, it will be demonstrated that the controlled functionalization of PEI with 1,2-epoxybutane can enhance CO2 desorption under the TSA cycle by reducing the heat of CO2 adsorption. Furthermore, the functionalization significantly improves the adsorbent stability over the repeated TSA cycles due to the suppression of urea formation and oxidative amine degradation.

Results

Functionalization of PEI and adsorbent preparation

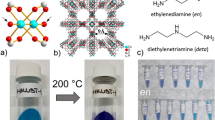

Functionalization of PEI with 1,2-epoxybutane was carried out by a simple single-step addition reaction at ambient conditions (Fig. 1a). To control the degree of functionalization, varied amounts of 1,2-epoxybutane were added dropwise to 17 wt% methanolic solution of PEI (MW 1,200, nitrogen content: 22 mmolN g−1) under stirring. The reaction was carried out at room temperature for 12 h. The functionalized PEIs were denoted as nEB-PEI, where n indicates the molar ratio between 1,2-epoxybutane and the nitrogen content within PEI initially used for the reaction. Elemental analysis after the vacuum evaporation of methanol and possibly unreacted 1,2-epoxybutane at 60 °C for 12 h (Table 1) showed that the O/N elemental ratios of the resultant nEB-PEIs are very close to those predicted from the initial reactants’ stoichiometry (n). The result confirms that the addition reaction goes almost completely. This can be attributed to the high ring-opening reactivity of epoxides in the presence of nucleophilic amines44.

(a) Functionalization of PEI with 1,2-epoxybutane was carried out by a single-step addition reaction. To control the degree of functionalization, varied amounts of 1,2-epoxybutane were added to 17 wt% methanolic solution of PEI and the reaction was carried out at room temperature for 12 h. (b) Silica microspheres having extra-large porosity (1.7 cm3 g−1) were synthesized by spray-drying a water slurry containing 10 wt% fumed silica and 0.5 wt% silica sol as a binder, followed by air calcination at 600 °C to sinter the fumed silica into a 3D porous structure. (c) The methanolic solutions of the functionalized PEIs obtained in a were impregnated into the pre-made silica microspheres.

Liquid-phase 13C NMR (Fig. 2a, Supplementary Fig. 1 and Supplementary Note 1) was used to characterize the amine state distributions in the PEI and nEB-PEIs45,46. According to the quantitative analysis, the unmodified PEI initially possessed the primary (1°):secondary (2°):tertiary (3°) amine ratio of 36:37:27, respectively (Fig. 2b). After the PEI functionalization with 1,2-epoxybutane, the portion of 1° amine gradually decreased, while the portions of 2° and 3° amines increased. It should be noted that the increase in 2° amine portion was much faster than the increase of 3° amine portion. This indicates that the functionalization quite selectively converted 1° amines to 2° amines, while the alkylation of 2° amines to 3° amines was relatively suppressed. For instance, in the case of 0.37EB-PEI, ca. 80% 1,2-epoxybutane appears to have been used for the conversion of 1° amines to 2° amines, while the other 20% was used for the conversion of 2° amines to 3° amines. Such a preferential alkylation of 1° amines to 2° amines is highly desirable in order not to sacrifice the CO2 adsorption capacities, because 3° amines capture CO2 much less efficiently than 1° and 2° amines2,6,7.

(a) Molecular structure and a representative liquid-phase 13C NMR spectrum for a functionalized PEI (0.37EB-PEI). (b) Amine state distributions of PEI and functionalized PEIs (nEB-PEI) analysed by 13C NMR. Quantitative NMR analysis of the amine state distribution was carried out using the following equation; primary(1°):secondary(2°):tertiary(3°)=(Aa+Ab):(Ac+Ad+Ae+A1)/2:(Af+Ag+Ah+A1’)/3, where Ai is the integrated peak area for i species44,45. (c,d) Scanning electron microscope image of the silica microspheres synthesized by a spray-drying of a fumed silica. Scale bars, 50 μm (c), 200 nm (d). (e) N2 adsorption–desorption isotherm of the silica microspheres measured at −196 °C (inset: corresponding pore size distribution obtained using the Barrett−Joyner−Halenda (BJH) equation). (f) Comparison of CO2 adsorption–desorption profiles of various silicas impregnated with 50 wt% PEI in a TSA cycle (adsorption: 15% CO2, 3% H2O, 2% Ar in N2 balance at 40 °C; desorption: 100% CO2 at 120 °C). PEI impregnated in the silica microspheres (PEI/SiO2) showed much higher CO2 uptake than PEIs in ordered mesoporous silicas such as MCM-41 and SBA-15.

As a solid support for the PEI and nEB-PEIs, a porous silica was synthesized by spray-drying a water slurry containing 10 wt% fumed silica and 0.5 wt% silica sol as a binder (Fig. 1b), followed by air calcination at 600 °C to sinter the fractal-like fumed silica particles into a three-dimensional (3D) porous network (Fig. 2d). The silica spheres have the particle sizes mainly in the range of 75–200 μm (Fig. 2c and Supplementary Fig. 2), which is suitable for fluidized bed operations in a large-scale CO2 capture process. The porous silica microspheres showed a slightly smaller BET surface area (299 m2 g−1) but significantly larger pore volume (1.7 cm3 g−1) than the original fumed silica powder (300 m2 g−1 and 1.0 cm3 g−1) having only interparticular porosity (Fig. 2e and Table 1). The silica showed a pore size distribution in the range of 20–100 nm (Fig. 2e). We confirmed that the silica microspheres impregnated with PEI showed CO2 adsorption capacities and kinetics superior even to the adsorbents prepared with ordered mesoporous silicas such as MCM-41 (ref. 47) (pore volume: 1.0 cm3 g−1, Supplementary Fig. 3) and SBA-15 (ref. 48) (1.1 cm3 g−1) at the same 50 wt% PEI loading (Fig. 2f). The result indicates that the ordered arrangement of silica mesoporosity derived from supramolecular templating47,48 is not essential for achieving good CO2 adsorption performance, although many of the earlier studies used this type of silica support8,9,10,12,19,20,21,22. Recently, several groups have reported similar results showing that mesopore order is not important for designing high-performance CO2 adsorbents if a silica support possesses sufficiently large 3D porosity that enables efficient CO2 diffusion11,18. We also compared long-term steam stabilities of the composite adsorbents made from MCM-41, SBA-15 and the present silica microspheres. After the treatment under 100% steam at 120 °C for 7 days, the composite adsorbents were calcined at 600 °C and the pore structures of the silica supports were analysed using N2 adsorption–desorption at −196 °C (Supplementary Fig. 4). The results showed that the N2 adsorption–desorption isotherm of the steam-treated silica microsphere changed only slightly (<5% pore volume loss) compared with that of a pristine silica microsphere. In clear contrast, the isotherms of SBA-15 and MCM-41 significantly changed after the steam treatment compared with those of pristine silicas. In all, 39 and 46% decreases in pore volume were observed for SBA-15 and MCM-41, respectively. The present results clearly indicate that the present silica microspheres possess much higher hydrothermal stability compared with ordered mesoporous silicas such as SBA-15 and MCM-41. The remarkably higher stability of the silica microspheres can be attributed to their significantly larger silica framework thickness (10–15 nm) than those of SBA-15 (ca. 3 nm) (ref. 49) and MCM-41 (ca. 1 nm) (ref. 50). The present synthesis of silica microspheres having large porosity and hydrothermal stability does not require the use of expensive and corrosive chemicals (for example, surfactant and acid/base), and thus it is cost-efficient and environmentally friendly.

For the preparation of the polymer–silica composite CO2 adsorbents, the methanolic solutions of PEI and nEB-PEIs were impregnated into the pre-made porous silica microspheres (Fig. 1c). The nominal polymer loading was fixed as 50 wt% of the composite adsorbents. In the case of nEB-PEIs, the methanolic solutions obtained after the functionalization reaction were directly used for impregnation, without additional purification steps, because the reaction goes to near a complete level as mentioned above. The physical properties of the prepared polymer–silica composite adsorbents are summarized in Table 1. All the adsorbents showed similar pore volumes in the range of 0.34–0.38 cm3 g−1. As the degree of functionalization (n) increased, the N content in the composite adsorbent decreased. This is reasonable because the loaded polymer weight was fixed as 50 wt%, while the molecular weight of the polymer was increased after the functionalization.

CO2 adsorption–desorption behaviour under a TSA cycle

The CO2 adsorption–desorption behaviour of the adsorbents was investigated under a TSA cycle. To simulate a practically meaningful TSA cycle, a wet flue gas (15% CO2, 3% H2O, 2% Ar in N2 balance) was used for CO2 adsorption at 40 °C, and a dry 100% CO2 atmosphere was used for the adsorbent regeneration at 120 °C (Fig. 3a). CO2 adsorption–desorption profiles were measured using a thermogravimetric analyser combined with a mass spectrometer (TGA-MS; Supplementary Fig. 5)25. To confirm the reliability of the measurement system, the CO2 adsorption capacities were also cross-checked using a different breakthrough experimental setup (Supplementary Fig. 6), in which the CO2 concentration was detected by a thermal conductivity detector after removing moisture with a −10 °C cold trap. In the measurements, all samples were diluted 10 times by using sand (quartz) as a diluent for avoiding heat-transfer limitation (Supplementary Fig. 7). Both experimental setups gave consistent CO2 adsorption amounts within an error range of 10% (Supplementary Table 1), which confirmed the reliability of the measurements.

(a) CO2 adsorption–desorption profiles of the adsorbents in a TSA cycle (adsorption: 15% CO2, 3% H2O, 2% Ar in N2 balance at 40 °C; desorption: 100% CO2 at 120 °C). (b) CO2 adsorption/desorption amounts during the TSA cycle (bars) and the heat of CO2 adsorption (line plot) for the adsorbents. The measurements were repeated three times and averaged.

The adsorbent prepared with an unmodified PEI (PEI/SiO2) showed the largest CO2 uptake of 3.8 mmol g−1 in the adsorption step (Fig. 3a,b). This can be attributed to the largest nitrogen content of PEI/SiO2 among the adsorbents (Table 1). In the regeneration step, the sample showed 76% desorption of the initially adsorbed CO2 and thus the working capacity (‘desorbable’ CO2 uptake) was determined to be 2.9 mmol g−1. In the cases of adsorbents with the functionalized PEIs (nEB-PEI/SiO2), CO2 uptake gradually decreased with an increasing degree of functionalization (n) (Fig. 3a,b). This can be attributed to the reduced N contents (Table 1) as well as the slightly increased 3° amine fractions after the functionalization (Fig. 2b). However, it is noteworthy that more efficient CO2 desorption was observed as the degree of functionalization (n) increased (Fig. 3a,b). As a result, the highly functionalized 0.37EB-PEI/SiO2 and 0.54EB-PEI/SiO2 samples showed complete desorption (>99%) of the initially adsorbed CO2. Although PEI/SiO2 showed a larger CO2 uptake than nEB-PEI/SiO2 samples during the adsorption step, the differences in working capacities were relatively smaller due to the more efficient desorption of CO2 in the nEB-PEI/SiO2 samples. The enhanced desorption of CO2 after the functionalization can be attributed to the reduced heat of CO2 adsorption (line plot in Fig. 3b), which can be explained by the fact that the functionalization resulted in the alkylation of amines with 2-ethyl-hydroxyethyl groups (–CH2CH(C2H5)OH). The hydroxyethyl groups are well-known electron-withdrawing groups that can lower the basicity of the amine centre, which can result in the weakened interaction with CO2 (ref. 51). Besides, the side-chain ethyl groups can also increase the steric hindrance near the amine centres and thus destabilize the carbamate species formed after CO2 adsorption51. Indeed, lowing the basicity and increasing the steric hindrance of the amine centres have been used as major strategies to reduce the energy penalty required for solvent regeneration in amine scrubbing process2.

For quantitative analysis of CO2 adsorption kinetics, CO2 uptake profiles measured with the breakthrough experimental setup were fitted with the Avrami kinetic equation52 (Supplementary Fig. 8 and Supplementary Table 2):

where, ka (min−1) is a rate constant, na is the kinetic order of the Avrami model, and Qt (mmol g−1) and Qe (mmol g−1) represent the adsorption capacities at a given time t and equilibrium time, respectively. According to the quantitative analysis, ka increased in the order of PEI/SiO2 (ka=0.67)<0.15EB-PEI/SiO2 (0.81)<0.37EB-PEI/SiO2 (0.92)<0.54EB-PEI/SiO2 (1.2), while na values are all similar in the range of 0.82–0.88. The results showed that the functionalization of PEI with 1,2-epoxybutane can significantly enhance the kinetics of CO2 adsorption.

Long-term stability of the adsorbents

The long-term stabilities of the adsorbents were investigated for 50 consecutive TSA cycles (adsorption: 15% CO2, 3% H2O, 2% Ar in N2 balance at 40 °C; adsorbent regeneration: 100% CO2 at 120 °C). The CO2 adsorption–desorption profiles are shown in Fig. 4a, and the CO2 working capacities at each TSA cycle are summarized in Fig. 4b. The PEI/SiO2 showed the highest CO2 working capacity (2.9 mmol g−1) in the first cycle, but it rapidly decreased to 1.1 mmol g−1 after 50 TSA cycles. On the other hand, nEB-PEI/SiO2 samples showed more steady cyclic behaviour at the sacrifice of a part of CO2 working capacity. Such a trend was more pronounced as the functionalization degree (n) increased. When the functionalization degree was relatively low (0.15EB-PEI/SiO2), the initial working capacity (2.6 mmol g−1) was only slightly smaller than that of PEI/SiO2. However, the working capacity still decreased gradually with repeated TSA cycles, although the decreasing rate became substantially slower than PEI/SiO2. In the case of the optimal functionalization degree (0.37EB-PEI/SiO2), a fairly high CO2 working capacity (2.2 mmol g−1) as well as outstanding stability over the repeated TSA cycles was achieved simultaneously. When the functionalization density was increased further (0.54EB-PEI/SiO2), the additional improvement in cyclic stability was only marginal, but the working capacity became unnecessarily small (1.6 mmol g−1) due to the large decrease in total amine content (Table 1).

(a) CO2 adsorption–desorption profiles of the PEI/SiO2, 0.15EB-PEI/SiO2, 0.37EB-PEI/SiO2 and 0.54EB-PEI/SiO2 during 50 consecutive TSA cycles (adsorption: 15% CO2, 3% H2O, 2% Ar in N2 balance at 40 °C; adsorbent regeneration: 100% CO2 at 120 °C). (b) CO2 working capacities of adsorbents plotted over the number of TSA cycles.

The cyclic stability of adsorbents after the repeated TSA cycles could be correlated with the tendency to form urea. As shown in the Fourier transform infrared (FT-IR) spectra (Fig. 5a), PEI/SiO2 showed highly pronounced peaks for urea species. The infrared spectrum indicated the formation of both open-chain and cyclic urea species, where the formation of cyclic urea is more pronounced. The open-chain urea is formed via dehydrative condensation between CO2 and two amines in different molecules (inter-molecular reaction), while the cyclic urea is formed via the reaction between CO2 and two amines within a single ethylenediamine unit (intra-molecular reaction; Fig. 5b)22. It is notable that nEB-PEI/SiO2 samples showed significantly suppressed urea formation, where the degree of suppression increased with a functionalization degree (n). Consequently, in the cases of highly functionalized 0.37EB-PEI/SiO2 and 0.54EB-PEI/SiO2 samples, no appreciable formation of urea was detected. The results clearly showed that the functionalization of PEI amine groups with 1,2-epoxybutane remarkably suppressed the urea formation, which in turn improved the stability of the adsorbents over the repeated TSA cycles (Fig. 4a,b).

(a) FT-IR spectra of the adsorbents measured after 50 consecutive TSA cycles (adsorption: 15% CO2, 3% H2O, 2% Ar in N2 balance at 40 °C; adsorbent regeneration: 100% CO2 at 120 °C). Dashed lines indicate the spectra for freshly prepared samples, while solid lines indicate those for the samples after 50 consecutive TSA cycles. (b) Possible pathways for the CO2-induced urea formation. These mechanisms are based on the previous studies by Sayari and Belmabkhout21.

Sayari and colleagues23 carried out rigorous mechanistic investigations on urea formation using various amine-functionalized adsorbents19,20,21,22,23, which can be summarized as shown in Fig. 5b. The formation of open-chain urea most likely involves at least one 1° amine and mainly takes place via an isocyanate pathway (Mechanism A, Route 1). The 1° amine reacts with CO2 to form a carbamic acid, which then dehydrates to form isocyanate. The isocyanate can readily react with either 1° or 2° amine to form a urea. The proposed mechanism was strongly supported by earlier observations by Wu et al.53 They reported that the reaction between 1° monoamines can form di-substituted ureas, while the mixtures of 1° and 2° monoamines produce di- and tri-substituted ureas. The formation of tetra-substituted urea between 2° monoamines was not observed, which indicates that the urea formation requires at least one 1° amine that can form isocyanate. DFT calculation by Jones and colleagues24 also supported that the isocyanate pathway is energetically more favoured than the carbamate dehydration pathway (Mechanism A, Route 2). In the case of polyamines (for example, PEI) containing ethylenediamine units (R1NH-CH2-CH2-NHR2), the intra-molecular dehydration to form cyclic ureas (Mechanism B) is favoured22,54. Notably, ethylenediamine moieties containing only 2° amines are also known to form cyclic ureas54, which implies that carbamate dehydration (Mechanism B, Route 2) may also contribute to the formation of a cyclic urea in addition to the energetically favourable isocyanate pathway (Mechanism B, Route 1). It was also reported that steric hindrance near the amine centre can significantly retard the urea formation54. On the basis of the earlier discussions, the suppressed urea formation after the functionalization of PEI with 1,2-epoxybutane can be explained by three reasons. First, the functionalization led to the quite selective elimination of 1° amines (Fig. 2b). Considering the fact that isocyanates are produced via the dehydration of carbamic acids derived only from 1° amines, all the energetically favourable isocyanate pathways (Route 1 of both Mechanism A and B) would be significantly suppressed after the functionalization. Second, the 2-ethyl-hydroxyethyl groups (–CH2CH(C2H5)OH) can increase the steric hindrance near amine groups, which can retard the rates of urea formation. Third, the 2-ethyl-hydroxyethyl groups (–CH2CH(C2H5)OH) generated by the functionalization can strongly interact with carbamic acid or carbamate species via hydrogen bonding (solvation effect), which can significantly stabilize them against dehydration reactions.

Finally, the stabilities of the adsorbents against oxidative degradations were also investigated. To evaluate the stabilities in an accelerated manner, the adsorbents were pre-treated in ‘CO2-free’ synthetic air (20% O2 in N2 balance) at 120 °C for 24 h. It should be noted that the oxidative degradations of amine-containing adsorbents are significantly faster in CO2-free air than in CO2/O2 mixed gases20. As shown in the FT-IR spectra measured after the oxidative aging (Supplementary Fig. 9), PEI/SiO2 showed a newly developed infrared peak at 1,680 cm−1 consistent with the occurrence of a C=O species. In contrast, as the epoxide-functionalization degree (n) increased, the evolution of the infrared peak becomes gradually suppressed. In addition, after the oxidative aging, the PEI/SIO2, 0.15EB-PEI/SiO2, 0.37EB-PEI/SiO2 and 0.54EB-PEI/SiO2 showed 19, 56, 80 and 81% remaining CO2 working capacities, respectively, compared with those of the fresh samples (Supplementary Fig. 10). The results clearly showed that the functionalization with 1,2-epoxybutane can also significantly increase resistance against oxidative degradations, which ensures the enhanced stability of the adsorbents in practical operating conditions involving O2. (Note that 3–4% O2 exists in a typical flue gas2, but O2 concentration will be much lower in the regeneration atmosphere.)

Discussion

The highly scalable synthesis of a functionalized-PEI/silica composite CO2 adsorbent was demonstrated. The best adsorbent (0.37EB-PEI/SiO2) simultaneously exhibited a large CO2 working capacity (2.2 mmol g−1) as well as long-term stability in a practically meaningful TSA process enabling the separation of concentrated CO2 (adsorbent regeneration under 100% CO2 at 120 °C). Most importantly, it was first demonstrated that the functionalization of PEI with 1,2-epoxybutane can significantly enhance CO2 desorption during the adsorbent-regeneration step by reducing the heat of CO2 adsorption. Furthermore, the functionalization resulted in a significantly improved material stability over repeated TSA cycles, due to the marked suppression of urea formation. It was also shown that the functionalization resulted in the significant suppression of the oxidative degradation of amine species, which ensures the long-term stability of the adsorbent in practical operating conditions involving O2. Because the adsorbent synthesis is simple and requires no expensive/corrosive chemicals, it can be readily scaled up. It was also confirmed that 0.37EB-PEI/SiO2 possesses sufficiently high mechanical stability against attrition, which is suitable for fluidized bed operation (Supplementary Note 2). Korea Carbon Capture & Sequestration R&D Center (KCRC) is currently synthesizing the adsorbent with highly reproducible properties at 20 kg scale for test operation in a bench-scale fluidized bed (20 Nm3 h−1 scale; Supplementary Figs 11 and 12, Supplementary Table 3 and Supplementary Note 3). It is reasonably expected that various polyamines other than the PEI used in this work can be functionalized with diverse functional epoxides to develop CO2 adsorbents with engineered CO2 adsorption/desorption properties as well as outstanding long-term stability.

Methods

Material synthesis

Functionalization of PEI (Nippon Shokubai, Epomin SP-012, MW 1,200, 22 mmolN g−1) with 1,2-epoxybutane (Sigma-Aldrich, 99%) was carried out by adding varied amounts of 1,2-epoxybutane dropwise into a 17 wt% methanolic solution of PEI. The reaction was carried out at room temperature for 12 h under stirring. Silica microspheres having large porosity were synthesized by spray-drying of a water slurry containing 10 wt% fumed silica (OCI, KONASIL K-300) and 0.5 wt% silica sol (Young Il Chemical, YGS-30) as a binder. In a typical synthesis, 1 kg fumed silica, 0.05 kg silica sol and 8.95 kg water were mixed, and the resultant slurry was injected for spray-drying. The spray-drying was carried out using a spray dryer with a co-current drying configuration and a rotary atomizer (Zeustec ZSD-25, Supplementary Fig. 13). The slurry-feeding rate was 30 cm3 min−1, and the rotating speed of atomizer was set to 4,000 r.p.m. The air blowing inlet temperature was 210 °C and the outlet temperature was 150 °C. The resultant silica samples were calcined in dry air at 600 °C to sinter the fumed silica into a 3D porous network. MCM-41 and SBA-15 mesoporous silicas were prepared following the procedures reported previously47,48. The polymer–silica composite adsorbents were prepared by wet impregnation of the unmodified PEI and functionalized-PEI methanolic solution (17–28 wt% solution) into the pre-made silica supports. The resultant slurry was dried at 60 °C for 12 h in a vacuum oven to completely remove methanol. The nominal polymer loading was fixed as 50 wt% of the polymer–silica composite adsorbents.

Material characterization

Liquid-phase 13C NMR spectra of the PEI and the functionalized PEIs dissolved in CDCl3 were recorded on an Agilent DD2 400 MHz NMR spectrometer operating at a 13C frequency of 100.6 MHz. The spectra were obtained with a 1.3 s acquisition time, 25 s relaxation delay, 45° pulse and 256 transients. All 13C NMR spectra used for quantitative analysis were recorded using inverse-gated proton decoupling to avoid the nuclear Overhauser effect. Chemical shifts were reported in p.p.m. relative to the internal standard of solvents. The nitrogen and carbon elemental contents of the polymers and composite adsorbents were analysed with a FLASH 2000 (Thermo Scientific). The oxygen contents of PEI and the functionalized PEIs were analysed using a FlashEA 112 (Thermo Finnigan). N2 adsorption–desorption isotherms were measured using a Belsorp Max (BEL Japan) volumetric analyser at a liquid N2 temperature (−196 °C). Before the measurement, all the samples were degassed at 100 °C for 6 h. The heat of CO2 adsorption of the adsorbents was measured by thermogravimetry-differential scanning calorimetry (Setaram Instrumentation, Setsys Evolution). Before the measurements, the samples were degassed at 100 °C for 1 h under N2 flow (50 cm3 min−1). Then, the samples were cooled to 40 °C. Subsequently, the gas was switched to 15% CO2 (50 cm3 min−1). The heat of adsorption was calculated through the integration of the heat-flow curve. For the FT-IR analysis of urea formation, 20 mg of the adsorbents after 50 consecutive TSA cycles were pressed into a self-supporting wafer. Before the FT-IR measurements, each sample was degassed at 100 °C for 6 h under vacuum and cooled to room temperature in an in situ infrared cell. FT-IR spectra were collected using an FT-IR spectrometer (Thermo Nicolet NEXUS 470). The FT-IR spectra of freshly prepared samples were additionally measured. For the FT-IR investigation of the adsorbents after oxidative degradation, the adsorbents were similarly pressed into a self-supporting wafer and pre-treated in a synthetic air (20% O2 in N2 balance) at 120 °C for 24 h in the in situ infrared cell. After degassing under vacuum, FT-IR spectra were collected at room temperature.

CO2 adsorption–desorption experiments

CO2 adsorption–desorption profiles were collected by a TGA-MS setup (Supplementary Fig. 5). Before the measurements, PEI/SiO2 and nEB-PEI/SiO2 were degassed at 100 °C for 1 h under N2 flow (50 cm3 min−1). CO2 adsorption was carried out using a simulated wet flue gas containing 15% CO2, 3% H2O, 2% Ar (the internal standard for MS calibration) and N2 balance at 40 °C. After 30 min adsorption, the gas was switched to 100% CO2 flow (50 cm3 min−1) and the temperature was increased to 120 °C (ramp: 20 °C min−1). Then the temperature was maintained for 30 min for the desorption process. The adsorption–desorption cycle was repeated 50 times. The adsorbed amount of CO2 was calculated by subtraction of the adsorbed H2O amount (determined with MS) from the total mass increase determined from TGA. To confirm the reliability of the TGA-MS results, CO2 uptake was also cross-checked with an automated chemisorption analyser (Micromeritics, Autochem II 2920) specially equipped with a cold trap for H2O removal in front of a thermal conductivity detector (Supplementary Fig. 6). In all measurements, samples were diluted 10 times by using sand (quartz) as a diluent for avoiding heat-transfer limitation.

Data availability

The data that support the findings of this study are available from the corresponding author on request.

Additional information

How to cite this article: Choi, W. et al. Epoxide-functionalization of polyethyleneimine for synthesis of stable carbon dioxide adsorbent in temperature swing adsorption. Nat. Commun. 7:12640 doi: 10.1038/ncomms12640 (2016).

References

Karl, T. R. & Trenberth, K. E. Modern global climate change. Science 302, 1719–1723 (2003).

D’Alessandro, D. M., Smit, B. & Long, J. R. Carbon dioxide capture: prospects for new materials. Angew. Chem. Int. Ed. 49, 6058–6082 (2010).

Haszeldine, R. S. Carbon capture and storage: how green can black be? Science 325, 1647–1652 (2009).

Rochelle, G. T. Amine scrubbing for CO2 capture. Science 325, 1652–1654 (2009).

Figueroa, J. D., Fout, T., Plasynski, S., McIlvried, H. & Srivastava, R. D. Advances in CO2 capture technology–the U.S. department of energy’s carbon sequestration program. Int. J. Greenhouse Gas Control 2, 9–20 (2008).

Choi, S., Drese, J. H. & Jones, C. W. Adsorbent materials for carbon dioxide capture from large anthropogenic point sources. ChemSusChem 2, 796–854 (2009).

Bollini, P., Didas, S. A. & Jones, C. W. Amine-oxide hybrid materials for acid gas separations. J. Mater. Chem. 21, 15100–15120 (2011).

Xu, X., Song, C., Andresen, J. M., Miller, B. G. & Scaroni, A. W. Novel polyethylenimine-modified mesoporous molecular sieve of MCM-41 type as high-capacity adsorbent for CO2 capture. Energy Fuels 16, 1463–1469 (2002).

Xu, X., Song, C., Andrésen, J. M., Miller, B. G. & Scaroni, A. W. Preparation and characterization of novel CO2 ‘molecular basket’ adsorbents based on polymer-modified mesoporous molecular sieve MCM-41. Microporous Mesoporous Mater. 62, 29–45 (2003).

Son, W.-J., Choi, J.-S. & Ahn, W.-S. Adsorptive removal of carbon dioxide using polyethyleneimine-loaded mesoporous silica materials. Microporous Mesoporous Mater. 113, 31–40 (2008).

Goeppert, A., Meth, S., Prakash, G. K. S. & Olah, G. A. Nanostructured silica as a support for regenerable high-capacity organoamine-based CO2 sorbents. Energy Environ. Sci. 3, 1949–1960 (2010).

Qi, G. et al. High efficiency nanocomposite sorbents for CO2 capture based on amine-functionalized mesoporous capsules. Energy Environ. Sci. 4, 444–452 (2011).

Qi, G., Fu, L., Choi, B. H. & Giannelis, E. P. Efficient CO2 sorbents based on silica foam with ultra-large mesopores. Energy Environ. Sci. 5, 7368–7375 (2012).

Zhang, H., Goeppert, A., Czaun, M., Prakash, G. K. S. & Olah, G. A. CO2 capture on easily regenerable hybrid adsorbents based on polyamines and mesocellular silica foam. Effect of pore volume of the support and polyamine molecular weight. RSC Adv. 4, 19403–19417 (2014).

Chaikittisilp, W., Kim, H. J. & Jones, C. W. Mesoporous alumina-supported amines as potential steam-stable adsorbents for capturing CO2 from simulated flue gas and ambient air. Energy Fuels 25, 5528–5537 (2011).

Drage, T. C., Arenillas, A., Smith, K. M. & Snape, C. E. Thermal stability of polyethylenimine based carbon dioxide adsorbents and its influence on selection of regeneration strategies. Microporous Mesoporous Mater. 116, 504–512 (2008).

Choi, S., Gray, M. L. & Jones, C. W. Amine-tethered solid adsorbents coupling high adsorption capacity and regenerability for CO2 capture from ambient air. ChemSusChem 4, 628–635 (2011).

Li, K., Jiang, J., Tian, S., Yan, F. & Chen, X. Polyethyleneimine–nano silica composites: a low-cost and promising adsorbent for CO2 capture. J. Mater. Chem. A 3, 2166–2175 (2015).

Heydari-Gorji, A., Belmabkhout, Y. & Sayari, A. Polyethylenimine-impregnated mesoporous silica: Effect of amine loading and surface alkyl chains on CO2 adsorption. Langmuir 27, 12411–12416 (2011).

Heydari-Gorji, A. & Sayari, A. Thermal, oxidative, and CO2-induced degradation of supported polyethylenimine adsorbents. Ind. Eng. Chem. Res. 51, 6887–6894 (2012).

Sayari, A. & Belmabkhout, Y. Stabilization of amine-containing CO2 adsorbents: dramatic effect of water vapor. J. Am. Chem. Soc. 132, 6312–6314 (2010).

Sayari, A., Heydari-Gorji, A. & Yang, Y. CO2-induced degradation of amine-containing adsorbents: reaction products and pathways. J. Am. Chem. Soc. 134, 13834–13842 (2012).

Sayari, A., Belmabkhout, Y. & Da’na, E. CO2 deactivation of supported amines: does the nature of amine matter? Langmuir 28, 4241–4247 (2012).

Didas, S. A., Zhu, R., Brunelli, N. A., Sholl, D. S. & Jones, C. W. Thermal, oxidative and CO2 induced degradation of primary amines used for CO2 capture: effect of alkyl linker on stability. J. Phys. Chem. C 118, 12302–12311 (2014).

Serna-Guerrero, R., Da’na, E. & Sayari, A. New insights into the interactions of CO2 with amine-functionalized silica. Ind. Eng. Chem. Res. 47, 9406–9412 (2008).

Qi, G., Fu, L. & Giannelis, E. P. Sponges with covalently tethered amines for high-efficiency carbon capture. Nat. Commun. 5, 5796 (2014).

Hicks, J. C. et al. Designing adsorbents for CO2 capture from flue gas-hyperbranched aminosilicas capable of capturing CO2 reversibly. J. Am. Chem. Soc. 130, 2902–2903 (2008).

Li, W. et al. Steam-stripping for regeneration of supported amine-based CO2 adsorbents. ChemSusChem 3, 899–903 (2010).

Li, W. et al. Structural changes of silica mesocellular foam supported amine-functionalized CO2 adsorbents upon exposure to steam. ACS Appl. Mater. Interfaces 2, 3363–3372 (2010).

Cheung, O. & Hedin, N. Zeolites and related sorbents with narrow pores for CO2 separation from flue gas. RSC Adv. 4, 14480–14494 (2014).

Hudson, M. R. et al. Unconventional, highly selective CO2 adsorption in zeolite SSZ-13. J. Am. Chem. Soc. 134, 1970–1973 (2012).

Bae, T.-H. et al. Evaluation of cation-exchanged zeolite adsorbents for post-combustion carbon dioxide capture. Energy Environ. Sci. 6, 128–138 (2013).

Shang, J. et al. Discriminative separation of gases by a ‘molecular trapdoor’ mechanism in chabazite zeolites. J. Am. Chem. Soc. 134, 19246–19253 (2012).

Hao, G. P. et al. Structurally designed synthesis of mechanically stable poly(benzoxazine-co-resol)-based porous carbon monoliths and their application as high-performance CO2 capture sorbents. J. Am. Chem. Soc. 133, 11378–11388 (2011).

Sevilla, M., Valle-Vigón, P. & Fuertes, A. B. N-doped polypyrrole-based porous carbons for CO2 capture. Adv. Funct. Mater. 21, 2781–2787 (2011).

Sumida, K. et al. Carbon dioxide capture in metal-organic frameworks. Chem. Rev. 112, 724–781 (2012).

Mason, J. A., Sumida, K., Herm, Z. R., Krishna, R. & Long, J. R. Evaluating metal–organic frameworks for post-combustion carbon dioxide capture via temperature swing adsorption. Energy Environ. Sci. 4, 3030–3040 (2011).

Millward, A. R. & Yaghi, O. M. Metal−organic frameworks with exceptionally high capacity for storage of carbon dioxide at room temperature. J. Am. Chem. Soc. 127, 17998–17999 (2005).

Llewellyn, P. L. et al. High uptakes of CO2 and CH4 in mesoporous metal-organic frameworks MIL-100 and MIL-101. Langmuir 24, 7245–7250 (2008).

Nakagawa, K. et al. Enhanced selectivity of CO2 from a ternary gas mixture in an interdigitated porous framework. Chem. Commun. 46, 4258–4260 (2010).

Lee, W. R. et al. Diamine-functionalized metal–organic framework: exceptionally high CO2 capacities from ambient air and flue gas, ultrafast CO2 uptake rate, and adsorption mechanism. Energy Environ. Sci. 7, 744–751 (2014).

House, K. Z., Harvey, C. F., Aziz, M. J. & Schrag, D. P. The energy penalty of post-combustion CO2 capture & storage and its implications for retrofitting the U.S. installed base. Energy Environ. Sci. 2, 193–205 (2009).

Hedin, N., Andersson, L., Bergström, L. & Yan, J. Adsorbents for the post-combustion capture of CO2 using rapid temperature swing or vacuum swing adsorption. Appl. Energy 104, 418–433 (2013).

Azizi, N. & Saidi, M. R. Highly chemoselective addition of amines to epoxides in water. Org. Lett. 7, 3649–3651 (2005).

Harpe, V. A., Petersen, H., Li, Y. & Kissel, T. Characterization of commercially available and synthesized polyethylenimines for gene delivery. J. Control. Release 69, 309–322 (2000).

Holycross, D. R. & Chai, M. Comprehensive NMR studies of the structures and properties of PEI polymers. Macromolecules 46, 6891–6897 (2013).

Kresge, C. T., Leonowicz, M. E., Roth, W. J., Vartuli, J. C. & Beck, J. S. Ordered mesoporous molecular sieves synthesized by a liquid-crystal template mechanism. Nature 359, 710–712 (1992).

Zhao, D. et al. Triblock copolymer syntheses of mesoporous silica with periodic 50 to 300 angstrom pores. Science 279, 548–552 (1998).

Choi, M., Heo, W., Kleitz, F. & Ryoo, R. Facile synthesis of high quality mesoporous SBA-15 with enhanced control of the porous network connectivity and wall thickness. Chem. Commun. 75, 1340–1341 (2003).

Chen, C.-Y., Li, H.-X. & Davis, M. E. Studies on mesoporous materials. Microporous Mesoporous Mater. 2, 17–26 (1993).

Vaidya, P. D. & Kenig, E. Y. CO2-alkanolamine reaction kinetics: a review of recent studies. Chem. Eng. Technol. 30, 1467–1474 (2007).

Wang, X., Chen, L. & Guo, Q. Development of hybrid amine-functionalized MCM-41 sorbents for CO2 capture. Chem. Eng. J 260, 573–581 (2015).

Wu, C. et al. Synthesis of urea derivatives from amines and CO2 in the absence of catalyst and solvent. Green Chem. 12, 1811–1816 (2010).

Lepaumier, H., Picq, D. & Carrette, P. L. New amines for CO2 capture. I. Mechanisms of amine degradation in the presence of CO2 . Ind. Eng. Chem. Res. 48, 9061–9067 (2009).

Acknowledgements

This work was supported by the Korea CCS R&D Center (KCRC) grant funded by the Korea government (Ministry of Science, ICT & Future Planning) (NRF-2014M1A8A1049256).

Author information

Authors and Affiliations

Contributions

M.C. designed this study and wrote the manuscript. W.C. and K. M. carried out material synthesis, main material characterizations and CO2 adsorption–desorption experiments. Y.S.K. and J.W.J. carried out FT-IR analysis. H.S. and Y.-K.P. carried out large-scale material synthesis and provided valuable insight into a large-scale CO2 capture process through discussion.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Figures 1-13, Supplementary Tables 1-3, Supplementary Notes 1-3 and Supplementary Reference (PDF 2653 kb)

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Choi, W., Min, K., Kim, C. et al. Epoxide-functionalization of polyethyleneimine for synthesis of stable carbon dioxide adsorbent in temperature swing adsorption. Nat Commun 7, 12640 (2016). https://doi.org/10.1038/ncomms12640

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/ncomms12640

This article is cited by

-

Preparation of electrospun cellulose acetate/polyethylene imine bicomponent nanofibers for CO2 capture

Polymer Bulletin (2024)

-

Guidelines for the Design of Solid CO2 Adsorbents for Mobile Carbon Capture in Heavy-Duty Vehicles: A Review

Korean Journal of Chemical Engineering (2024)

-

Indoor carbon dioxide capture technologies: a review

Environmental Chemistry Letters (2023)

-

Shaping and silane coating of a diamine-grafted metal-organic framework for improved CO2 capture

Communications Materials (2021)

-

Electrochemical and thermodynamic study on the corrosion performance of API X120 steel in 3.5% NaCl solution

Scientific Reports (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.