Abstract

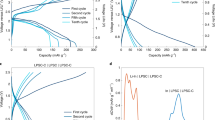

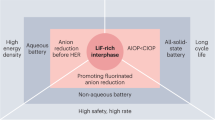

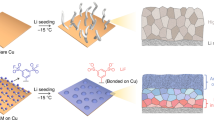

Given their high theoretical specific energy, lithium–oxygen batteries have received enormous attention as possible alternatives to current state-of-the-art rechargeable Li–ion batteries. However, the maximum discharge capacity in non-aqueous lithium–oxygen batteries is limited to a small fraction of its theoretical value due to the build-up of insulating lithium peroxide (Li2O2), the battery’s primary discharge product. The discharge capacity can be increased if Li2O2 forms as large toroidal particles rather than as a thin conformal layer. Here, we show that trace amounts of electrolyte additives, such as H2O, enhance the formation of Li2O2 toroids and result in significant improvements in capacity. Our experimental observations and a growth model show that the solvating properties of the additives prompt a solution-based mechanism that is responsible for the growth of Li2O2 toroids. We present a general formalism describing an additive’s tendency to trigger the solution process, providing a rational design route for electrolytes that afford larger lithium–oxygen battery capacities.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Imanishi, N., Luntz, A. C. & Bruce, P. G. The Lithium Air Battery (Springer, 2014).

Bruce, P. G., Freunberger, S. A., Hardwick, L. J. & Tarascon, J-M. Li–O2 and Li–S batteries with high energy storage. Nature Mater. 11, 19–29 (2012).

Hummelshoj, J. S. et al. Communications: elementary oxygen electrode reactions in the aprotic Li–air battery. J. Chem. Phys. 132, 071101 (2010).

Laoire, C. O., Mukerjee, S., Abraham, K. M., Plichta, E. J. & Hendrickson, M. A. Influence of nonaqueous solvents on the electrochemistry of oxygen in the rechargeable lithium–air battery. J. Phys. Chem. C 114, 9178–9186 (2010).

Laoire, C. O., Mukerjee, S., Abraham, K. M., Plichta, E. J. & Hendrickson, M. A. Elucidating the mechanism of oxygen reduction for lithium–air battery applications. J. Phys. Chem. C 113, 20127–20134 (2009).

Abraham, K. M. & Jiang, Z. A polymer electrolyte-based rechargeable lithium/oxygen battery. J. Electrochem. Soc. 143, 1–5 (1996).

Ogasawara, T., Débart, A., Holzapfel, M., Novák, P. & Bruce, P. G. Rechargeable Li2O2 electrode for lithium batteries. J. Am. Chem. Soc. 128, 1390–1393 (2006).

McCloskey, B. D., Scheffler, R., Speidel, A., Girishkumar, G. & Luntz, A. C. On the mechanism of nonaqueous Li–O2 electrochemistry on C and its kinetic overpotentials: some implications for Li–air batteries. J. Phys. Chem. C 116, 23897–23905 (2012).

Girishkumar, G., McCloskey, B., Luntz, A. C., Swanson, S. & Wilcke, W. Lithium–air battery: promise and challenges. J. Phys. Chem. Lett. 1, 2193–2203 (2010).

Christensen, J. et al. A critical review of Li/air batteries. J. Electrochem. Soc. 159, R1–R30 (2011).

McCloskey, B. D. et al. Limitations in rechargeability of Li–O2 batteries and possible origins. J. Phys. Chem. Lett. 3, 3043–3047 (2012).

McCloskey, B. D. et al. Combining accurate O2 and Li2O2 assays to separate discharge and charge stability limitations in nonaqueous Li–O2 batteries. J. Phys. Chem. Lett. 4, 2989–2993 (2013).

Freunberger, S. A. et al. The lithium–oxygen battery with ether-based electrolytes. Angew. Chem. Int. Ed. 50, 8609–8613 (2011).

Shao, Y. et al. Making Li–air batteries rechargeable: material challenges. Adv. Funct. Mater. 23, 987–1004 (2013).

Bryantsev, V. S. et al. Predicting solvent stability in aprotic electrolyte Li–air batteries: nucleophilic substitution by the superoxide anion radical (O2•–). J. Phys. Chem. A 115, 12399–12409 (2011).

Bryantsev, V. S. et al. The identification of stable solvents for nonaqueous rechargeable Li–air batteries. J. Electrochem. Soc. 160, A160–A171 (2013).

Assary, R. S., Lau, K. C., Amine, K., Sun, Y-K. & Curtiss, L. A. Interactions of dimethoxy ethane with Li2O2 clusters and likely decomposition mechanisms for Li–O2 batteries. J. Phys. Chem. C 117, 8041–8049 (2013).

Younesi, R., Norby, P. & Vegge, T. A new look at the stability of dimethyl sulfoxide and acetonitrile in Li–O2 batteries. ECS Electrochem. Lett. 3, A15–A18 (2014).

Albertus, P. et al. Identifying capacity limitations in the Li/oxygen battery using experiments and modeling. J. Electrochem. Soc. 158, A343–A351 (2011).

Luntz, A. C. et al. Tunneling and polaron charge transport through Li2O2 in Li–O2 batteries. J. Phys. Chem. Lett. 4, 3494–3499 (2013).

Viswanathan, V. et al. Electrical conductivity in Li2O2 and its role in determining capacity limitations in non-aqueous Li–O2 batteries. J. Chem. Phys. 135, 214704 (2011).

Radin, M. & Siegel, D. Charge transport in lithium peroxide: relevance for rechargeable metal-air batteries. Energy Environ. Sci. 6, 2370–2379 (2013).

Radin, M. D., Feng, T. & Siegel, D. J. Electronic structure of Li2O2{0001} surfaces. J. Mater. Sci. 47, 7564–7570 (2012).

Adams, B. D. et al. Current density dependence of peroxide formation in the Li–O2 battery and its effect on charge. Energy Environ. Sci. 6, 1772–1778 (2013).

Black, R., Adams, B. & Nazar, L. F. Non-aqueous and hybrid Li–O2 batteries. Adv. Energy Mater. 2, 801–815 (2012).

Zhai, D. et al. Disproportionation in Li–O2 batteries based on a large surface area carbon cathode. J. Am. Chem. Soc. 135, 15364–15372 (2013).

Xu, J-J., Wang, Z-L., Xu, D., Zhang, L-L. & Zhang, X-B. Tailoring deposition and morphology of discharge products towards high-rate and long-life lithium–oxygen batteries. Nature Commun. 4, 2438 (2013).

Fan, W., Cui, Z. & Guo, X. Tracking formation and decomposition of abacus-ball-shaped lithium peroxides in Li–O2 cells. J. Phys. Chem. C 117, 2623–2627 (2013).

Mitchell, R. R., Gallant, B. M., Shao-Horn, Y. & Thompson, C. V. Mechanisms of morphological evolution of Li2O2 particles during electrochemical growth. J. Phys. Chem. Lett. 4, 1060–1064 (2013).

Hummelshoj, J. S., Luntz, A. C. & Norskov, J. K. Theoretical evidence for low kinetic overpotentials in Li–O2 electrochemistry. J. Chem. Phys. 138, 034703–034712 (2013).

Ottakam Thotiyl, M. M. et al. A stable cathode for the aprotic Li–O2 battery. Nature Mater. 12, 1050–1056 (2013).

Gallant, B. M. et al. Influence of Li2O2 morphology on oxygen reduction and evolution kinetics in Li–O2 batteries. Energy Environ. Sci. 6, 2518–2528 (2013).

Horstmann, B. et al. Rate-dependent morphology of Li2O2 growth in Li–O2 batteries. J. Phys. Chem. Lett. 4, 4217–4222 (2013).

Guo, Z., Dong, X., Yuan, S., Wang, Y. & Xia, Y. Humidity effect on electrochemical performance of Li–O2 batteries. J. Power Sources 264, 1–7 (2014).

Cho, M. H. et al. The effects of moisture contamination in the Li–O2 battery. J. Power Sources 268, 565–574 (2014).

Meini, S., Piana, M., Tsiouvaras, N., Garsuch, A. & Gasteiger, H. A. The effect of water on the discharge capacity of a non-catalyzed carbon cathode for Li–O2 batteries. Electrochem. Solid-State Lett. 15, A45–A48 (2012).

Jung, H-G. et al. A transmission electron microscopy study of the electrochemical process of lithium–oxygen cells. Nano. Lett. 12, 4333–4335 (2012).

Tian, F., Radin, M. D. & Siegel, D. J. Enhanced charge transport in amorphous Li2O2 . Chem. Mater. 26, 2952–2959 (2014).

McCloskey, B. D. et al. Twin problems of interfacial carbonate formation in nonaqueous Li–O2 batteries. J. Phys. Chem. Lett. 3, 997–1001 (2012).

Peng, Z. et al. Oxygen reactions in a non-aqueous Li+ electrolyte. Angew. Chem. Int. Ed. 50, 6351–6355 (2011).

Mo, Y., Ong, S. P. & Ceder, G. First-principles study of the oxygen evolution reaction of lithium peroxide in the lithium–air battery. Phys. Rev. B 84, 205446 (2011).

Che, Y. et al. Water-induced disproportionation of superoxide ion in aprotic solvents. J. Phys. Chem. 100, 20134–20137 (1996).

Acknowledgements

The authors thank R. Shelby for Raman measurements, D. Bethune and G. Wallraff for discussions and help with experiments and the IBM model shop for support with the DEMS system. N.B.A. acknowledges guidance from H.C. Kim and W.W. Wilcke. V.V. is supported by a faculty startup grant from Carnegie Mellon University.

Author information

Authors and Affiliations

Contributions

All authors contributed to the design of the research. N.B.A., J.M.G. and L.E.K. performed the experimental measurements and N.B.A. performed the experimental data analysis. V.V. and A.C.L. designed the theoretical calculations, which V.V. then performed. N.B.A., B.D.M., V.V. and A.C.L. co-wrote the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary information

Supplementary information (PDF 15472 kb)

Supplementary movie 1

Supplementary movie 1 (MP4 175 kb)

Rights and permissions

About this article

Cite this article

Aetukuri, N., McCloskey, B., García, J. et al. Solvating additives drive solution-mediated electrochemistry and enhance toroid growth in non-aqueous Li–O2 batteries. Nature Chem 7, 50–56 (2015). https://doi.org/10.1038/nchem.2132

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nchem.2132

This article is cited by

-

Li–air batteries: air stability of lithium metal anodes

Science China Chemistry (2024)

-

Can We Intuitively Tune Electrochemical Reactions by Changing Electrolyte Species?

JOM (2024)

-

Triarylmethyl cation redox mediators enhance Li–O2 battery discharge capacities

Nature Chemistry (2023)

-

Addressing Transport Issues in Non-Aqueous Li–air Batteries to Achieving High Electrochemical Performance

Electrochemical Energy Reviews (2023)

-

C60 as a metal-free catalyst for lithium-oxygen batteries

Nano Research (2023)