Abstract

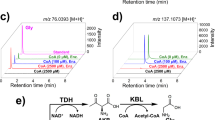

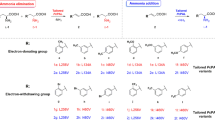

We report the isolation of a Corynebacterium equi strain that produces more than 33 g/l of L–phenylalanine from α–acetamidocinnamic acid in molar yields greater than 99% using immobilised whole cells. The metabolic pathway, by which the cells carry out the conversion, contains an inducible permease, an acylase and a dehydrogenase. The achiral α–acetamidocinnamic acid is actively transported into the cells where it under goes deacetylation and deamination, via the acylase, to yield the stable intermediate, phenylpyruvic acid. An inducible phenylalanine dehydrogenase then catalyses the reductive amination of the phenylpyruvate to yield optically pure L–phenylalanine. The overall reaction was limited by the supply of NADH, but was successfully manipulated by the addition of oxidisable co–substrates, such as lactate, pyruvate and formate. Mutants constitutive for α–acetamidocinnamate conversion contain increased activities of both the acylase and phenylalanine dehydrogenase. One such mutant, OAR1–16, produced L–phenylalanine approximately 2.5 times faster than the parent, was insensitive to end product inhibition and accumulated more than 30 g/l L–phenylalanine. The use of a substrate feedstock containing α–acetamidocinnamate, lactate and NH4OH permitted the continuous production of L–phenylalanine, at pH 7.0 and 34°C, coupling the lactate and phenylalanine dehydrogenases as a system for intra–cellular recycling of reducing equivalents. The commercial viability of this process is discussed.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$209.00 per year

only $17.42 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Klausner, A. 1985. Building for success in phenylalanine. Bio/Technology 3: 301–307.

Tsuchida, T., Matsui, J., Enei, J. and Yoshinaga, F. 1975. L-phenylalanine by fermentation. US Patent 3,909,353.

Choi, J.J. and Tribe, D.E. 1982. Continuous production of phenylalanine using an Escherichia coli regulatory mutant. Biotechnol. Lett. 4: 223–228.

Calton, G.J., Wood, L., Updike, M.H., Lantz, L. and Hamman, J.P. 1986. The Production of L-phenylalanine by polyazetidine immobilised microbes. Bio/Technology 4: 317–320.

Yamada, S., Nabe, K., Izuo, N., Nakamichi, K., Chibata, I. 1981. Production of L-phenylalanine from trans-cinnamic acid with Rhodotorula glutinis containing L-phenylalanine ammonia-lyase activity. Appl. Environ. Microbiol. 42: 773–778.

Marusich, W., Jensen, R. and Zamir, L.O. 1981. Induction of L-phenylalanine ammonia-lyase during utilisation of phenylalanine as carbon or nitrogen source in Rhodotorula glutinis. J. Bacteriol. 146: 1013–1019.

Sikora, L.A. and Marzluf, G.A. 1982. Regulation of L-phenylalanine ammonia-lyase by L-phenylalanine and nitrogen in Neurospora crassa. J. Bacteriol. 150: 1227–1291.

Emes, A.V. and Vining, L.C. 1970. Partial purification and properties of L-phenylalanine ammonia lyase from Streptomyces verticillatus. Can.J. Biochem. 48: 613–622.

Hamilton, B.K., Hsiao, H.-Y., Swann, W., Anderson, D. and Delente, J. 1985. Manufacture of L-amino acids with bioreactors. Trends in Biotechnology 3: 64–68.

Evans, C.T., Hanna, K., Conrad, D., Peterson, W. and Misawa, M. 1986. Production of phenylalanine ammonia-lyase (PAL): Isolation and evaluation of yeast strains suitable for commercial production of L-phenylalanine. Appl. Microbiol. Biotechnol. 25: 406–414.

Evans, C.T., Conrad, D., Hanna, K., Peterson, W., Choma, C. and Misawa, M. 1986. Novel stabilisation of phenylalanine ammonia-lyase catalyst during bioconversion of trans-cinnamate. Appl. Microbiol. Biotechnol. 25: 399–405.

Sakurai, S. 1956. Enzymatic preparation of optically active essential amino acids. I. The preparation of L-phenylalanine. J. Biochem. 43: 851–855.

Asai, T., Aida, K. and Oisha, K. 1960. Preparation of L-phenylalanine by bacterial transaminase. Hakko to Taisha 2: 114–119.

Bulot, E. and Cooney, C.L. 1985. Selective production of phenylalanine from phenylpyruvic acid using growing cells of Corynebacterium glutamicum. Biotechnol. Lett. 7: 93–98.

Lawlis, B., Rastetter, W. and Snedecor, R. 1985. Recombinant process for preparing L-amino acids, recombinant expression reactors and transformed microorganisms for use in the process. Genentech Inc., Eur. Pat. Apple. No. 84305532.8.

Primrose, S.B. 1984. The cloning and utilisation of aminotransferase genes. G. D. Searle & Co. Eur. Pat. Appl. No. 84100521.8.

Rozzell, D.J. 1985. Production of L-amino acids by transamination. Genetics Institute Inc. Eur. Pat. Appl. No. 84110407.8.

Wood, L.L. and Calton, G.J. 1985. Process and compositions for preparing phenylalanine. Purification Engineering Inc., Eur. Pat. Appl. No. 84304966.9.

Fusee, M.C. 1984. Production of L-amino acids from α-keto acids by fermentation. W. R. Grace & Co. UK Patent Application No. 8419142.

Wandrey, C., Wichmann, R., Leuchtenberger, W., Kula, M.-R. and Buckmann, A. 1982. Process for the continuous enzymatic change of water soluble ketocarboxylic acids into the corresponding amino acids. US Patent 4304858.

Nakamichi, K., Nabe, K., Yamada, S., Tosa, T. and Chibata, I. 1984. L-phenylalanine formation from acetamidocinnamic acid by newly isolated bacteria. Appl. Microbiol. Biotechnol. 19: 100–105.

Nakamichi, K., Nishida, Y., Nabe, K. and Tosa, T. 1982. Production of L-phenylalanine using Bacillus sphaericus and Paracoccus denitrificans. Appl. Biochem. Biotechnol. 11: 368–376.

Fujioka, M., Morino, Y. and Wada, H. 1970. Metabolism of Phenylalanine. Methods In Enzymology, 17A: 585–589.

Katsuki, H., Yoshida, T., Tanegashima, C. and Tanaka, S. 1971. Improved direct method for determination of keto acids by 2, 4-dinitrophenylhydrazine. Anal. Chem. 43: 349–356.

Doherty, D. 1970. L-Glutamate dehydrogenases (yeast). Methods In Enzymology, 17: 850–856.

Chaney, A.L. and Marbach, E.B. 1962. Modified reagents for determination of urea and ammonia. Clin. Chem. 8: 130–132.

Evans, C.T., Choma, C., Peterson, W. and Misawa, M. 1987. Bioconversion of trans-cinnamic acid to L-phenylalanine in an immobilised cell reactor. Biotech. Bioeng. In press.

Hill, D.W., Walters, F.H., Wilson, T.D. and Stuart, J.D. 1979. HPLC analysis of amino acids using orthophtaldehyde derivitisation. Anal. Chem. 51: 1338–1341.

Evans, C.T. and Misawa, M. 1986. Bioconversion Process for L-phenylalanine. Eur. Pat. Appl. No. 8620181.

Evans, C.T., Gleeson, M. and Bellamy, W. 1986. Generation of novel microbial strains for the superior production of L-phenylalanine. Eur. Pat. Appl. No. 8620180.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Thomas Evans, C., Bellamy, W., Gleeson, M. et al. A Novel, Efficient Biotransformation for the Production of L–Phenylalanine. Nat Biotechnol 5, 818–823 (1987). https://doi.org/10.1038/nbt0887-818

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1038/nbt0887-818