Abstract

Microfluidic devices have the potential to automate and miniaturize biological experiments, but open-source sharing of device designs has lagged behind sharing of other resources such as software. Synthetic biologists have used microfluidics for DNA assembly, cell-free expression, and cell culture, but a combination of expense, device complexity, and reliance on custom set-ups hampers their widespread adoption. We present Metafluidics, an open-source, community-driven repository that hosts digital design files, assembly specifications, and open-source software to enable users to build, configure, and operate a microfluidic device. We use Metafluidics to share designs and fabrication instructions for both a microfluidic ring-mixer device and a 32-channel tabletop microfluidic controller. This device and controller are applied to build genetic circuits using standard DNA assembly methods including ligation, Gateway, Gibson, and Golden Gate. Metafluidics is intended to enable a broad community of engineers, DIY enthusiasts, and other nontraditional participants with limited fabrication skills to contribute to microfluidic research.

Similar content being viewed by others

Main

The synthetic biology community has adopted many open-source principles and practices including DNA component registries (e.g., Registry of Standard Biological Parts and the Synthetic Biology Engineering Research Center Registry of Parts1), repositories for distributing biological materials (e.g., ATCC, Addgene), genetic circuit design tools (e.g., Clotho), workflow abstraction tools2, and protocol optimization systems (e.g., Aquarium). Refined descriptions3 and legal frameworks for sharing parts (e.g., the BioBrick Public Agreement) and communicating designs4 are also available. The number and variety of open-source hardware projects for synthetic biology is growing as well. Projects ranging from open thermocyclers (e.g., Open PCR and Open qPCR) to 'personal' liquid handlers (e.g., Opentrons) and all-in-one laboratory kits (e.g., Bento Lab and Amino Labs) are available and being tested by both professional researchers and do-it-yourself (DIY) enthusiast communities5. Similarly, the International Genetically Engineered Machine (iGEM) competition supports the development of open hardware for synthetic biology (http://2017.igem.org/Competition/Tracks/Hardware), recognizing a need to interface open-source hardware with the existing open-source ecosystem. Figure 1 gives examples of categories of open-source resources, including community-led repositories through which these are shared.

Microfluidic technologies have several advantages over traditional methods. Microfluidics enables single-cell manipulation and analysis, reaction volumes of nano- or picoliters (thereby reducing costs), high-throughput execution of parallel experiments, automated routine liquid handling, integration of multiple biological processes in a single system, and programmability for complex protocols. Synthetic biologists have used microfluidics to miniaturize DNA assembly (for oligonucleotides6, genes7, and genetic circuits8), to purify DNA9, to clone DNA10, and to transform11 and transfect12 cells. Multipurpose platforms have been developed that integrate several processes8,13. Despite their utility, microfluidic devices are not widely used by synthetic biologists. Although thousands of proof-of-concept microfluidic devices have been reported in technical journals14, such systems are infrequently adopted. Companies that provide basic services to the synthetic biology community use microfluidics in their technology platforms (e.g., Illumina, a DNA sequencing company and Twist BioScience, a DNA synthesis company), but such systems are rarely part of in-lab experimental workflows for researchers. The availability of consumer microfluidic products has also been limited15, because most systems developed in research laboratories fail to translate to the marketplace. Commercial translation has been hindered by a lack of standards in material selection, process development, sample preparation, and interconnections between devices16,17. The same problems have restricted device development in research laboratories.

There is a continuing need to lower barriers to access microfluidics research. Just as the field of synthetic biology has been built upon the contributions of researchers from many different disciplines, we hope to grow and diversify the microfluidic developer and user communities. To stimulate participation of researchers from multiple disciplines in microfluidic device development, we have established a set of open-source tools and principles for microfluidics. Our aim is to use this open-source infrastructure to increase technical innovation. For example, open sharing of microfluidic designs could encourage the development of derivative designs. Although common features in microfluidic device designs—so-called device primitives, like chaotic mixers18 and cross-flow droplet generators19—have been widely adopted by the microfluidic developer community, the direct modification of previous designs is surprisingly rare.

If the number of users of microfluidics is to increase, devices and accompanying hardware must be easily made or purchased. The advent of soft lithography was a groundbreaking enabling technology for microfluidics20, but photolithography requirements—from clean rooms to technology for silicon processing—still present a substantial obstacle for both developers and users. Increasingly, commodity digital fabrication technologies like three-dimensional (3D) printing21 are being used to manufacture molds for soft lithography22 and milli- and microfluidic systems23,24, including programmable valves25 and devices for synthetic biology applications26. Crucially, 3D printing eliminates the photolithographic step and obviates the need for expensive silicon-processing infrastructure. Recently, paper microfluidics has shown promise in reducing cost and increasing ease of device fabrication for diagnostic applications27. The development of these technologies has increased access to microfluidics, but has yet to produce devices that approach the complexity or programmability of those fabricated using photolithography28. Published descriptions of microfluidic devices are often too technical for a broad audience to interpret. We believe that open-source microfluidic designs, coupled with simple fabrication protocols (or linked to commercial fabrication services) will overcome this problem.

The contributions of non-experts and individuals working outside of traditional academic research to generate novel products and solutions to technical problems have been well-documented in the social sciences29,30. In synthetic biology, an emerging network of community laboratories5 provides physical spaces and infrastructure where DIY enthusiasts, artists, and designers can experiment. Their collective work has expanded the sociological, philosophical, and ethical context of synthetic biology research activities31. Citizen science projects, such as the collaborative study of New York City's microbiome by community laboratory Genspace and Cornell University32, are also promising examples of the type of technical and societal impact that is possible when biotechnologies move outside of traditional research institutions.

Open-source microfluidics

Open-source microfluidics requires digital design files, detailed specifications for device (or other hardware) assembly, device software, hardware operation instructions, and inexpensive, simple-to-use fabrication technologies (or fee-for-service production companies) to convert digital designs to physical systems. Developers of microfluidics will need all of these elements. Users only need to make the device from its design, or outsource its manufacture.

Although microfluidic devices have been made using various technologies, all use some form of computer-aided design (CAD) files. For devices with a single layer of fluid channels, or multilayered devices built by assembling single layers, two-dimensional digital representations generated by a vector-based drawing tool are required. Common file types include .ai (Adobe Illustrator) and .dwg and .dxf (AutoCAD) files, all of which can be edited and used directly by commercial companies to generate masks for photolithographic processes. A variety of tools are also available to convert between file formats. For 3D designs, .STL formats are popular and are also suitable for both modification and printing.

Publications describing microfluidic research only rarely include digital design files, making the task of reproducing or extending prior work extraordinarily difficult. For example, Lab on a Chip does not require submission of design files. We believe the field would benefit immensely from both journal policies and a research culture that encourages and facilitates sharing of designs. Furthermore, while traditional publications may provide sufficient detail for a practitioner skilled in microfluidics to execute a fabrication method, more details are needed to enable reproduction by a broader developer community. Ideally, assembly instructions would be annotated and documented together with illustrations (or a tutorial video) and a complete list of parts known as a 'bill of materials'. Where possible, hardware should be built from standard, widely available components, to make reproduction easy. Digital design files, parts lists, assembly specifications and operating software could be made available through online repositories (e.g., GitHub, Thingiverse), but to our knowledge, no such repository exists to aggregate information for the microfluidics community. Therefore, we established Metafluidics (http://www.metafluidics.org/), an open online repository of fluidic parts.

Metafluidics

Metafluidics is a not-for-profit, community-driven repository featuring a collection of fluidic parts and the information required to reproduce, refine, and operate them. A subset of the collection from the Metafluidics homepage is shown in Figure 2. Digital device designs, a clear bill of materials, assembly specifications, and operation software (if necessary) are available for each part (Fig. 3). Metafluidics entries may be microfluidic devices or complementary hardware, such as fluidic controllers. Parts can be tagged with keywords for function, materials, fabrication method, or research discipline (Fig. 3). Each tag is searchable, thereby allowing a user to discover relevant parts.

The individual part shows social media data, such as the number of views and likes, comments from the community, and the number of times each type of sharable information (e.g., 'Design Files') has been downloaded. Each part is also described by searchable tags that can indicate, for example, the function of the part (e.g., DNA Synthesizer), the field of research (e.g., Synthetic Biology), or the materials the part is built from.

The site also has social features. For example, users can 'like' parts and comment on them, enabling interaction between community members. Because the site supports the sorting of parts by the number of design downloads, likes, or user comments, highly rated parts can emerge. Anyone who creates a user profile can contribute or download a fluidic part. Quality control is provided in part by an editorial team, who can highlight featured parts, but also by the Metafluidics community itself through collective rating of parts using the social functions.

Currently, most novel fluidic systems are produced by an expert team of researchers skilled in microfluidic design, fabrication, and experimentation. Experts begin with an experimental concept, design a device, produce digital design files, fabricate a fluidic system and then conduct experiments with it to produce data that can be published (Fig. 4a). However, this approach often means that the only users of a device are the inventors, and after publication, no reproduction or derivative work occurs.

Four modalities are shown. In each modality, the process begins with an experimental concept—for example, constructing a genetic circuit—from which the 'design' step yields a digital design, the 'fabricate' step produces the tangible fluidic system and the 'experiment' step generates data. Different types of users are capable of producing the 'Digital Design,' 'Fluidic System,' or 'Data.' In the examples described here, we show an 'Expert Team,' a 'DIY Enthusiast,' a 'Designer,' and an 'Artist.' In modality (A), the current paradigm whereby the majority of fluidic systems are produced, an 'Expert Team' executes the entire process from 'Concept' to 'Data.' Modalities (B)–(D) are enabled by Metafluidics. In (B), a 'Fee-for-Service Company' is used to reproduce a fluidic system from the 'Digital Design' created by an 'Expert Team.' In (C), a 'Designer' is able to build upon a previous design in Metafluidics to create a 'Remixed Digital Design.' In (D), a 'DIY Enthusiast' is able to fabricate and experiment with three different fluidic systems built from the digital designs created by three different types of users.

Different workflows are enabled by Metafluidics. For example, for reproduction of a device, a fee-for-service company could be used to fabricate a fluidic system based upon a design created by an expert team and deposited in Metafluidics (Fig. 4b). This act of system reproduction, particularly by a participant who is not a member of the same laboratory or institution as the initial designer, is of considerable significance, as such an act would rarely occur otherwise without an established research collaboration. In a second scenario, a scientist would extend a design deposited in Metafluidics (Fig. 4c). This process might comprise minor modifications that preserve the primary function of the design but increases ease of use (e.g., modifying inlet and outlet dimensions for better coupling to tubing) or major modifications to improve the throughput of the device. A third type of application could be one in which a DIY enthusiast is able to experiment with multiple fluidic systems designed by other participants of the Metafluidics community (Fig. 4d). These examples are intended to be descriptive, not prescriptive, as we envisage organic growth and use of this resource.

Open-source microfluidic genetic circuit assembly

Building and testing genetic circuitry is both a challenge and an opportunity. Genetic components of modest size (up to ∼4,000 bp, with prices ranging from $0.10–0.60 per base pair) or much larger (10,000 bp or more, at higher prices per base pair) are available to buy. Nevertheless, the prices of synthetic DNA parts and the tendency to re-use the same parts in different designs means that scientists and makers often prefer to assemble genetic circuits themselves. As an example of how to apply open-source principles to sharing microfluidic devices for synthetic biology applications33,34, we report here the design and fabrication of an open-source, programmable microfluidic device and microfluidic controller for the on-chip assembly of genetic circuits.

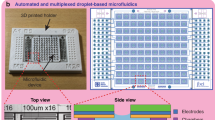

The programmable microfluidic system is a general-purpose tool comprising a polydimethylsiloxane (PDMS)-based ring-mixer device and a tabletop controller. The system is capable of executing a set of common fluidic operations, enabling a variety of possible applications beyond genetic circuit assembly. The PDMS device, fabricated by multilayer soft lithography28, enables programmable mixing of up to three distinct fluid components (Fig. 5) by eight control channels. The controller hardware itself has 32 programmable channels, which, when controlling devices containing microfluidic multiplexors28, can address tens of thousands of flow channels. Our controller, which can be made with commercially available kits and parts, can execute pneumatically driven device operations to complete a genetic circuit assembly protocol at the push of a button. Connection to a computer during operation is not required. Solenoids for pneumatic manipulation are controlled by an open-source Arduino Mega microcontroller. Device operations, written in open-source software (Arduino Sketch) can be customized if needed.

(a) Optical image of the microfluidic ring-mixer device with flow channels loaded with green food dye, control valves loaded with red food dye, and mixing valves loaded with blue food dye. The full genetic circuit assembly protocol consists of four device operations: (b) fill, where three components are loaded into the two quarters and half of the ring mixer; (c) mix, where the mixing valves (light blue) are actuated to mix the three components; (d) incubate, where all valves are latched to incubate the reaction mix; and (e) flow, where reagents are flushed through the ring mixer from left to right. (f,g) The 32-channel microfluidic controller, as seen from a front view (f) showing the LCD display, two banks of eight-solenoid valve outlets, and 16 constant pressure outlets, and an internal top view (g) showing the Arduino Mega board, four sets of eight solenoid valve banks, and the central circuit breadboard.

Similar to BioStream35 (our previous open-source software for programmable microfluidics), microfluidic chip operations can be defined as functions with specific valve configurations. These functions can then be written in serial blocks of code that can be executed to yield fully automated activation of valves and pumps in the device. Thus, at the software level, the underlying microfluidic chip architecture is abstracted to a simpler representation. All of the information required to reproduce, change, and operate our device and controller are available in Metafluidics.

Automated microfluidic genetic circuit assembly reactions were carried out in the ring-mixer device (Fig. 5). This device allows the combination and mixing of up to three different liquid reagents, and could be employed for a wide range of other biochemical reactions. For genetic circuit assembly, the controller executes a protocol consisting of eight stages, composed of four device operations, each with a unique microfluidic valve configuration: “fill” (Fig. 5b), for loading three different reagents into the three segments of the ring mixer; “mix,” for actuating the three mixing valves (Fig. 5c) to combine the three fluid components; “incubate” (Fig. 5d), for actuating all valves to lock all fluid volumes in place and prevent evaporation; and “flow” (Fig. 5e), for flushing fluid through the ring mixer from left to right. These operations are examples of common protocol steps for controlling any PDMS-based microfluidic devices. These general, abstracted representations are important for making device operation simple and understandable to a broad user-base. The full set of Arduino code for executing these operations and the full circuit assembly protocol is shared in Metafluidics and available for download.

Using our device, we assembled genetic circuits several thousands of DNA base pairs long, each from up to five input component parts, employing four widely used assembly biochemistries: BioBrick-based ligation assembly36, Gateway37, Gibson38, and Golden Gate39 assembly (Figs. 5 and 6). Microfluidic assembly reactions employed approximately tenfold lower volumes (300–650 nL) compared to the same (control) reactions performed in test tubes (2–10 μL). DNA assembly efficiencies for each circuit are given in Supplementary Table 1. We note that in our experiments (Supplementary Methods), Golden Gate assembly translated extremely well to the microfluidic format, with no apparent loss of colonies (as monitored by colony forming unit per μL of assembly reaction) relative to the larger-volume tube reactions. Furthermore, the high overall colony yields of the Golden Gate reactions indicate that this method may be scalable to reaction volumes of 1 nL or less while still producing a useful number of colonies. The quality of the assembled circuits was evaluated first by restriction digestion of the resulting plasmids (Supplementary Figs. 1–4 and Supplementary Tables 2–11), then by DNA sequencing to select defect-free clones. These clones were used to characterize genetic circuit functions in living cells (Supplementary Fig. 5). As expected, no notable differences were observed between circuits assembled using a microfluidic device versus those same circuits assembled in a test tube.

Error bars indicate s.d. (a) Schematic of BioBrick-based ligation assembly. (b) Constitutive GFP fluorescence with ligation-assembled circuit. GFP fluorescence was compared for Escherichia coli transformed with microfluidic (four clones) and tube-assembled (three clones) circuits to E. coli lacking the circuit (negative control). When compared to cells lacking the circuit, both microfluidic and tube clones showed similar (>50-fold) increased fluorescence, with microfluidic clones exhibiting 58-fold increased fluorescence and tube clones showing 70-fold increased fluorescence. (c) Schematic of BP Gateway Assembly. (d) Constitutive EGFP fluorescence with Gateway-assembled circuit. EGFP expression was measured by flow cytometry for microfluidic (four clones) and tube (three clones) assembled circuits. Microfluidic and tube clones demonstrated >100-fold increased fluorescence compared to cells lacking the EGFP expression plasmid and did not show significantly different fluorescence relative to each other. (e) Schematic of Gibson assembly. (f) Cell-density-dependent gene expression with Gibson-assembled circuit. Following dilution from overnight culture at time zero, the fraction of cells expressing mCherry decreased to ∼20% after 4 hours. This percentage then rebounded as cell density increased starting at OD600 = 0.2. Microfluidic (five clones) and tube-assembled (three clones) reactions performed similarly, with no significant difference in the percentage of mCherry-positive cells in 5/8 time points. Of the time points with significantly different expression (indicated with asterisks) the greatest discrepancy was at 3 h with a 9.6% difference in percentage of cells expressing mCherry. (g) Schematic of Golden Gate Assembly. (h) aTc induction of GFPmut3b with Golden Gate–assembled circuit. With both microfluidic and tube-assembled circuits, addition of aTc induced more than a tenfold increase in GFPmut3b fluorescent signal in TetR-expressing cells. Microfluidic and tube-assembled circuits showed similar behavior with no significant difference in the induced and uninduced cases.

This demonstration of miniaturized genetic circuit assembly using open-source hardware is a step toward our longer-term goal, which is to make massively parallel assembly of genetic circuits widely accessible through facile assembly using microfluidics. Previously demonstrated microfluidic multiplexors utilize binary valve patterns enabling the control of n fluid channels with only 2log2 n control channels28. The 32-channel open-source controller described here has sufficient capacity to control sophisticated devices featuring tens of thousands of flow channels and thousands of independently addressable reaction chambers. While precise fluid routing of reagents at the pico- and nanoliter scale over milli- and centimeter lengths (without contaminating reactors) can prove challenging, scaling genetic circuit assembly to thousands of parallel reactions is feasible. To our knowledge, this controller enables the manipulation of the largest number of independent fluidic channels to date for an open-source controller.

The application of open-source principles to the design, fabrication, and sharing of our system is a step toward its reproduction by a broader community of engineers, researchers, and DIY enthusiasts. To date, graduate, undergraduate, and high school students working in laboratories at MIT have reproduced the controller, working only from the specifications provided in Metafluidics. This simple act of system reproduction illustrates the potential of Metafluidics to enable anyone to experiment with microfluidic devices.

Outlook for open-source microfluidics

We plan to partner Metafluidics with other open-source community-driven repositories in synthetic biology (Fig. 1). For example, a fluidic system could be associated with the experimental data that it generates, if online repositories are interlinked. Similarly, the full stack of biological design tools, parts, and methods used to generate any experimental data should be attached as metadata to each fluidic part, so that relationships can be studied to better discern sources of error and refine best practices. Our aim is for Metafluidics to support increasingly sophisticated interactions between different technical and creative communities, including the peer production of advanced fluidic systems. Tools like the US Defense Advanced Research Projects Agency's hardware portal Vehicle Forge (http://cps-vo.org/group/avm/vehicleforge) and the European Organization for Nuclear Research (CERN)'s Open Hardware Repository (http://www.ohwr.org/) offer inspiration for the management of open, collaborative projects.

The emergence of standardized digital file types would be an important step toward easier device reproduction. The 3D printing community, for example, has benefited greatly from the adoption of .STL files as a standard. Metafluidics does not currently require users to submit any one specific digital design file type, in part due to the substantial variety of fabrication technologies and associated CAD software, but also because we wish to keep barriers to contribution as low as possible. Over time, Metafluidics may help the community organically converge upon file standards through the establishment of community norms and, eventually, curatorial policies.

As derivative works are contributed to Metafluidics, we aim to incorporate tools to track and visualize a 'family tree' of parts over time. Currently, the site supports the ability to reference other parts in the repository as descendants, but without a networked visualization.

Another goal of our future work is to ensure that the materials required for reproduction of each fluidic part, from the design files to the assembly specifications, increase in their quality and robustness. Highly rated parts that have a track record of easy reproduction will emerge from the site's social functions, while improved policies and requirements for submission of parts could help to increase the overall quality of parts in the repository. These policies will evolve over time as community members demonstrate best practices that can be reinforced by the editorial team.

One notable challenge for the application of open-source principles to microfluidics is licensing. While licensing software typically involves applying terms of use to copyrighted works, hardware is often protected by patents, trademarks, and non-disclosure agreements. Each form of protection has its own laws that require time and cost to process legally, making the establishment of open-source hardware licenses complex. The open hardware movement as a whole must overcome these challenges, and the breadth of communities developing open hardware projects—from space flight40 to photovoltaics41—has led to a similar exploration in alternate license models. Notable examples include licenses modeled after the GNU Public License, Arduino's use of multiple licenses, and those modeled after the Apache Software License40. But much work remains to create an appropriate legal framework, a challenge also being addressed in the synthetic biology community for using and sharing DNA-based parts3 (e.g., the BioBrick Public Agreement).

The adoption of open-source principles could benefit both the microfluidics and synthetic biology communities enormously. We believe that applying this paradigm will enable wider adoption of microfluidics, a technology that has historically remained confined to the laboratories of instrument inventors, while increasing the breadth and diversity of developer and user communities. And therein lies our greatest source of excitement—to see just what an engaged and expanding creative community, empowered with open-source tools, can achieve together.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Change history

28 February 2018

In the version of this article initially published, the wrong Creative Commons Attribution license (cc-by-nc rather than cc-by) was inserted. The error has been corrected in the HTML and PDF versions of the article.

References

Ham, T.S. et al. Design, implementation and practice of JBEI-ICE: an open source biological part registry platform and tools. Nucleic Acids Res. 40, e141 (2012).

Beal, J. et al. An end-to-end workflow for engineering of biological networks from high-level specifications. ACS Synth. Biol. 1, 317–331 (2012).

Canton, B., Labno, A. & Endy, D. Refinement and standardization of synthetic biological parts and devices. Nat. Biotechnol. 26, 787–793 (2008).

Galdzicki, M. et al. The Synthetic Biology Open Language (SBOL) provides a community standard for communicating designs in synthetic biology. Nat. Biotechnol. 32, 545–550 (2014).

Most, N. DIYBio around the world. BioCoder Fall, 17–19 (2013).

Lee, C.-C., Snyder, T.M. & Quake, S.R. A microfluidic oligonucleotide synthesizer. Nucleic Acids Res. 38, 2514–2521 (2010).

Kong, D.S., Carr, P.A., Chen, L., Zhang, S. & Jacobson, J.M. Parallel gene synthesis in a microfluidic device. Nucleic Acids Res. 35, e61 (2007).

Shih, S.C. et al. A versatile microfluidic device for automating synthetic biology. ACS Synth. Biol. 4, 1151–1164 (2015).

Kersaudy-Kerhoas, M. et al. Validation of a fully integrated platform and disposable microfluidic chips enabling parallel purification of genome segments for assembly. Biotechnol. Bioeng. 111, 1627–1637 (2014).

Ben Yehezkel, T. et al. Synthesis and cell-free cloning of DNA libraries using programmable microfluidics. Nucleic Acids Res. 44, e35 (2016).

Gach, P.C. et al. A droplet microfluidic platform for automating genetic engineering. ACS Synth. Biol. 5, 426–433 (2016).

Woodruff, K. & Maerkl, S.J. A high-throughput microfluidic platform for mammalian cell transfection and culturing. Sci. Rep. 6, 23937 (2016).

Linshiz, G. et al. End-to-end automated microfluidic platform for synthetic biology: from design to functional analysis. J. Biol. Eng. 10, http://dx.doi.org/10.1186/s13036-016-0024-5 (2016).

Caicedo, H.H. & Brady, S.T. Microfluidics: the challenge is to bridge the gap instead of looking for a 'killer app'. Trends Biotechnol. 34, 1–3 (2016).

Volpatti, L.R. & Yetisen, A.K. Commercialization of microfluidic devices. Trends Biotechnol. 32, 347–350 (2014).

Klapperich, C.M. Microfluidic diagnostics: time for industry standards. Expert Rev. Med. Devices 6, 211–213 (2009).

van Heeren, H. Standards for connecting microfluidic devices? Lab Chip 12, 1022–1025 (2012).

Stroock, A.D. et al. Chaotic mixer for microchannels. Science 295, 647–651 (2002).

Thorsen, T., Roberts, R.W., Arnold, F.H. & Quake, S.R. Dynamic pattern formation in a vesicle-generating microfluidic device. Phys. Rev. Lett. 86, 4163–4166 (2001).

Berthier, E., Young, E.W.K. & Beebe, D. Engineers are from PDMS-land, Biologists are from Polystyrenia. Lab Chip 12, 1224–1237 (2012).

Gershenfeld, N. How to make almost anything: the digital fabrication revolution. Foreign Aff. 91, 43–57 (2012).

McDonald, J.C. & Whitesides, G.M. Poly(dimethylsiloxane) as a material for fabricating microfluidic devices. Acc. Chem. Res. 35, 491–499 (2002).

Au, A.K., Huynh, W., Horowitz, L.F. & Folch, A. 3D-printed microfluidics. Angew. Chem. Int. Ed. 55, 3862–3881 (2016).

Ho, C.M.B., Ng, S.H., Li, K.H.H. & Yoon, Y.-J. 3D printed microfluidics for biological applications. Lab Chip 15, 3627–3637 (2015).

Keating, S.J. et al. 3D printed multimaterial microfluidic valve. PLoS One 11, e0160624 http://dx.doi.org/10.1371/journal.pone.0160624(2016).

Patrick, W.G. et al. DNA assembly in 3D printed fluidics. PLoS One 10, e0143636 http://dx.doi.org/10.1371/journal.pone.0143636 (2015).

Yetisen, A.K., Akram, M.S. & Lowe, C.R. Paper-based microfluidic point-of-care diagnostic devices. Lab Chip 13, 2210–2251 (2013).

Thorsen, T., Maerkl, S.J. & Quake, S.R. Microfluidic large-scale integration. Science 298, 580–584 (2002).

Jeppesen, L.B. & Lakhani, K.R. Marginality and problem solving effectiveness in broadcast search. Organ. Sci. 21, 1016–1033 (2010).

Poetz, M.K. & Schreier, M.J. The value of crowdsourcing: can users really compete with professionals in generating new product ideas? J. Prod. Innov. Manage. 29, 245–256 (2012).

Ginsberg, D.G., Calvert, J., Schyfter, P., Elfick, A. & Endy, D. Synthetic Aesthetics: Investigating Synthetic Biology's Designs on Nature (MIT Press, 2014).

Afshinnekoo, E. et al. Geospatial resolution of human and bacterial diversity with city-scale metagenomics. Cell Syst. 1, 72–87 (2015).

Gulati, S. et al. Opportunities for microfluidic technologies in synthetic biology. J. R. Soc. Interface 6 (Suppl. 4), S493–S506 (2009).

Shih, S.C.C. & Moraes, C. Next generation tools to accelerate the synthetic biology process. Integr. Biol. 8, 585–588 (2016).

Thies, W., Urbanski, J.P., Thorsen, T. & Amarasinghe, S. Abstraction layers for scalable microfluidic Biocomputing. Nat. Comput. 7, 255–275 (2008).

Sambrook, J., Fritsch, E.F. & Maniatis, T. Molecular Cloning: A Laboratory Manual, 2nd ed. (Cold Spring Harbor Laboratory Press, Cold Spring Harbor, NY, 1989).

Anonymous. Gateway Technology https://tools.thermofisher.com/content/sfs/manuals/gatewayman.pdf (Lifeway Technologies, 2003).

Gibson, D.G. et al. Enzymatic assembly of DNA molecules up to several hundred kilobases. Nat. Methods 6, 343–345 (2009).

Engler, C., Gruetzner, R., Kandzia, R. & Marillonnet, S. Golden gate shuffling: a one-pot DNA shuffling method based on type IIs restriction enzymes. PLoS One 4, e5553 (2009).

Simmons, J., Black, J. & Moran, G. A survey of the open source spaceflight movement. AAIA SPACE 2011 Conference & Exposition, 7225 (2011).

Buitenhuis, A.J. & Pearce, J.M. Open-source development of solar photovoltaic technology. Energy Sustain. Dev. 16, 379–388 (2012).

Acknowledgements

We would like to gratefully acknowledge L. Ngo and E. Bram for genetic circuit design and construction of plasmid parts for Gibson and Golden Gate assembly reactions, respectively. We would also like to acknowledge S. Deneault for assistance with device fabrication and K. Hamad-Schifferli and D. Ricke for helpful discussion. This work is sponsored by the Assistant Secretary of Defense for Research & Engineering under Air Force Contract no. FA8721-05-C-0002. Opinions, interpretations, conclusions and recommendations are those of the author and are not necessarily endorsed by the United States Government. Research reported in this publication was also supported by the National Cancer Institute of the US National Institutes of Health under award number R01CA173712, the National Institute of General Medical Sciences of the US National Institutes of Health under grant number P50 GM098792, and the United States National Science Foundation under grant numbers 1124247, 1522074, 1521925 and 1521759.

Author information

Authors and Affiliations

Contributions

All authors were involved in the design of experiments and manuscript editing. D.S.K. designed and fabricated microfluidic devices, performed on-chip experiments, conducted data analysis, designed and managed the construction of 'Metafluidics,' and wrote the manuscript. T.A.T. designed and assembled the microfluidic controller and wrote hardware assembly instructions. S.T.W. conducted DNA part preparation and genetic circuit analysis, and co-wrote the Supplementary Methods section. J.J.G. and J.B. performed biological verification experiments and co-wrote the Supplementary Methods and results sections. R.W. and P.A.C. supervised the project.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Integrated supplementary information

Supplementary Figure 1 Gel electrophoresis of Ligation assembled GFP expression circuits.

Verification was performed by digestion with restriction enzymes EcoRI and PstI, resulting in 4,413 kb and 949 bp fragments. Five correctly mapped clones are shown.

Supplementary Figure 2 Gel electrophoresis of Gateway assembled GFP expression circuits.

Verification was performed by digestion with enzymes AflII and EcoRV, resulting in 2,317 bp and 1,162 bp fragments. Five correctly mapped clones are shown with two clones (Lanes 5 and 6) incorrectly mapped.

Supplementary Figure 3 Gel electrophoresis of Gibson assembled cell density dependent gene expression circuits.

Verification was performed by digestion with restriction enzymes NcoI, XbaI, XhoI and HindIII, resulting in 2262 bp, 1289 bp, 629 bpm, 405 bp, and 143 bp fragments. Five correctly mapped clones are shown.

Supplementary Figure 4 Gel electrophoresis of Golden Gate assembled aTc-inducible GFP expression circuits.

Verification was performed by digestion with restriction enzymes HindIII and NotI, resulting in 4222 bp, 936 bp and 413 bp fragments.

Supplementary Figure 5 Flow cytometry histogram demonstrating cell density-dependent gene expression for Gibson-assembled constructs.

Validation for a typical microfluidic and tube assembly are shown. The black bar indicates the mCherry positive gate and colors indicate the time following dilution from high cell density.

Supplementary information

Supplementary Text and Figures

Supplementary Figures 1–5, Supplementary Tables 1–11 and Supplementary Methods (PDF 911 kb)

Rights and permissions

This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kong, D., Thorsen, T., Babb, J. et al. Open-source, community-driven microfluidics with Metafluidics. Nat Biotechnol 35, 523–529 (2017). https://doi.org/10.1038/nbt.3873

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nbt.3873

This article is cited by

-

Design automation of microfluidic single and double emulsion droplets with machine learning

Nature Communications (2024)

-

Lab-scale flow chemistry? Just do it yourself!

Journal of Flow Chemistry (2024)

-

Microfluidics-driven high-throughput phenotyping and screening in synthetic biology: from single cells to cell-free systems

Biotechnology and Bioprocess Engineering (2024)

-

Portable all-in-one automated microfluidic system (PAMICON) with 3D-printed chip using novel fluid control mechanism

Scientific Reports (2021)

-

Open software platform for automated analysis of paper-based microfluidic devices

Scientific Reports (2020)