Abstract

Patches on the surfaces of colloidal particles1,2,3,4,5 provide directional information that enables the self-assembly of the particles into higher-order structures. Although computational tools can make quantitative predictions and can generate design rules that link the patch motif of a particle to its internal microstructure and to the emergent properties of the self-assembled materials6,7,8, the experimental realization of model systems of particles with surface patches (or ‘patchy’ particles) remains a challenge. Synthetic patchy colloidal particles are often poor geometric approximations of the digital building blocks used in simulations9,10 and can only rarely be manufactured in sufficiently high yields to be routinely used as experimental model systems11,12,13,14. Here we introduce a method, which we refer to as colloidal fusion, for fabricating functional patchy particles in a tunable and scalable manner. Using coordination dynamics and wetting forces, we engineer hybrid liquid–solid clusters that evolve into particles with a range of patchy surface morphologies on addition of a plasticizer. We are able to predict and control the evolutionary pathway by considering surface-energy minimization, leading to two main branches of product: first, spherical particles with liquid surface patches, capable of forming curable bonds with neighbouring particles to assemble robust supracolloidal structures; and second, particles with a faceted liquid compartment, which can be cured and purified to yield colloidal polyhedra. These findings outline a scalable strategy for the synthesis of patchy particles, first by designing their surface patterns by computer simulation, and then by recreating them in the laboratory with high fidelity.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Zhang, Z. & Glotzer, S. Self-assembly of patchy particles. Nano Lett. 4, 1407–1413 (2004)

Duguet, E., Hubert, C., Chomette, C., Perro, A. & Ravaine, S. Patchy colloidal particles for programmed self-assembly. C. R. Chim. 19, 173–182 (2016)

Wang, Y. et al. Colloids with valence and specific directional bonding. Nature 491, 51–55 (2012)

Pawar, A. B. & Kretzschmar, I. Fabrication, assembly, and application of patchy particles. Macromol. Rapid Commun. 31, 150–168 (2010)

Hubert, C. et al. Synthesis of multivalent silica nanoparticles combining both enthalpic and entropic patchiness. Faraday Discuss. 181, 139–146 (2015)

van Anders, G., Klotsa, D., Karas, A. S., Dodd, P. M. & Glotzer, S. C. Digital alchemy for materials design: colloids and beyond. ACS Nano 9, 9542–9553 (2015)

Bianchi, E., Largo, J., Tartaglia, P., Zaccarelli, E. & Sciortino, F. Phase diagram of patchy colloids: towards empty liquids. Phys. Rev. Lett. 97, 168301 (2006)

van Anders, G., Ahmed, N. K., Smith, R., Engel, M. & Glotzer, S. C. Entropically patchy particles: engineering valence through shape entropy. ACS Nano 8, 931–940 (2014)

Romano, F. & Sciortino, F. Patterning symmetry in the rational design of colloidal crystals. Nat. Commun. 3, 975 (2012)

Smallenburg, F. & Sciortino, F. Liquids more stable than crystals in particles with limited valence and flexible bonds. Nat. Phys. 9, 554–558 (2013)

Wang, Y. et al. Three-dimensional lock and key colloids. J. Am. Chem. Soc. 136, 6866–6869 (2014)

Pawar, A. B. & Kretzschmar, I. Patchy particles by glancing angle deposition. Langmuir 24, 355–358 (2008)

Chen, Q., Bae, S. C. & Granick, S. Directed self-assembly of a colloidal kagome lattice. Nature 469, 381–384 (2011)

Jiang, S. & Granick, S. A simple method to produce trivalent colloidal particles. Langmuir 25, 8915–8918 (2009)

Manoharan, V., Elsesser, M. & Pine, D. Dense packing and symmetry in small clusters of microspheres. Science 301, 483–487 (2003)

Schade, N. B. et al. Tetrahedral colloidal clusters from random parking of bidisperse spheres. Phys. Rev. Lett. 110, 148303 (2013)

Obey, T. & Vincent, B. Novel monodisperse “silicone oil”/water emulsions. J. Colloid Interface Sci. 163, 454–463 (1994)

Sacanna, S. et al. Shaping colloids for self-assembly. Nat. Commun. 4, 1688 (2013)

Kraft, D. J., Groenewold, J. & Kegel, W. K. Colloidal molecules with well-controlled bond angles. Soft Matter 5, 3823–3826 (2009)

Kraft, D. J. et al. Self-assembly of colloids with liquid protrusions. J. Am. Chem. Soc. 131, 1182–1186 (2009)

Brakke, K. A. The Surface Evolver. Exp. Math. 1, 141–165 (1992)

Berthier, J & Brakke, K. A. The Physics of Microdroplets (Wiley, 2012)

Sacanna, S., Rossi, L., Kuipers, B. & Philipse, A. Fluorescent monodisperse silica ellipsoids for optical rotational diffusion studies. Langmuir 22, 1822–1827 (2006)

Lee, J., Ha, J. U., Choe, S., Lee, C.-S. & Shim, S. E. Synthesis of highly monodisperse polystyrene microspheres via dispersion polymerization using an amphoteric initiator. J. Colloid Interface Sci. 298, 663–671 (2006)

Acknowledgements

This work was supported by the NSF CAREER award DMR-1653465. The Zeiss Merlin FESEM was acquired through the support of the NSF under award number DMR-0923251. G.-R.Y. acknowledges support from the NRF (Korea) under award numbers 2010-0029409 and 2014S1A2A2028608. We thank S. Phua for comments on the manuscript and discussions.

Author information

Authors and Affiliations

Contributions

Z.G. and T.H. synthesized all of the colloidal systems, designed and performed the colloidal fusion experiments and analysed data; G.-R.Y. performed Surface Evolver simulations; S.S. conceived the study and supervised the research with the help of G.-R.Y.; S.S., G.-R.Y., Z.G. and T.H. wrote the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Reviewer Information Nature thanks N. Kotov, N. Vogel and the other anonymous reviewer(s) for their contribution to the peer review of this work.

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Figure 1 Synthesis of the constituent building blocks of the LCCs.

a, Schematic representation of the spontaneous emulsification and subsequent polymerization of 3-(trimethoxysilyl)propyl methacrylate. b, Bright-field microscopy image showing monodispersed emulsion droplets prepared from 3-(trimethoxysilyl)propyl methacrylate oil precursor. c, Fluorescence microscopy image showing emulsion droplets labelled with rhodamine B. d, SEM image of a polymerized emulsion. e–g, SEM images documenting the growth of positively charged PS particles during the three steps of seeded emulsion polymerization. h, PVP–PS particles prepared by dispersion polymerization. Scale bars are 1 μm.

Extended Data Figure 2 Self-assembly on a LCC.

a, Schematics showing the assembly of an LCC via electrostatic attraction. Rapid parking of PS spheres on droplets followed by slower wetting dynamics ensures high yields of regular tetrahedral clusters. b, Bright-field microscopy image showing tetrahedral LCCs isolated by density splitting. c, SEM image showing a micrometre-sized cluster next to a nanometre-sized cluster. Scale bars are 1 μm.

Extended Data Figure 3 Tuning of the oil–PS contact angle.

a, Zeta potential of oil droplets (3-(trimethoxysilyl)propyl methacrylate, TPM) and amidinated PS particles as a function of pH (Malvern Zetasizer Nano Series). b, Wetting behaviour of a fluorescent oil droplet on an amidinated PS sphere at different pH. c, d, Left, schematics of the recovery of solid cores (green) from LCCs. Right, SEM images of recovered cores (polymerized), imprinted by PS shells at low (c) and neutral (d) pH. Scale bars are 1 μm.

Extended Data Figure 4 Design and realization of faceted tetrahedra.

Simulated fusion of a tetrahedral LCC into a spherical core–shell particle is shown for γPSl/o = 40 mN m−1. The snapshot sequence reveals the morphological transformation of the liquid core (red) in great detail. During the intermediate stages of the transformation, the core is gradually reshaped into a faceted tetrahedron. This intermediate deformation stage can be targeted experimentally to fabricate the colloidal tetrahedra shown in the SEM images. Scale bar is 1 μm.

Extended Data Figure 5 Simulated fusion of tetrahedral LCCs.

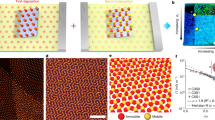

a, Surface Evolver simulations probing the effect of γPSl/o (red surface) on the evolution pathway of the cluster. The values of γPSl/w = 50 mN m−1 (green surface), γo/w = 36 mN m−1 (yellow surface) and Vo/VPS = 0.125 are chosen to match the corresponding experimental values. We can follow the morphological evolution of the liquid cores experimentally by fixing intermediate states by radical polymerization. The hardened cores are isolated by dissolving the PS matrix and analysed using SEM (right). Scale bar is 1 μm. b, A comparison between simulations and experiments suggest a two-step evolution process in which γPSl/o increases during the deformation. Experimentally, this could be rationalized by considering the change in the THF concentration during the evaporation process or the ageing of the oil phase. c, Phase diagram showing how γPSl/o and Vo/VPS can predictably change the evolutionary fate of a tetrahedral LCC undergoing colloidal fusion.

Extended Data Figure 6 Simulated fusion of octahedral LCCs.

The simulated evolution proceeds in two consecutive steps (see also Extended Data Fig. 5b). The first step, with γPSl/o = 2 mN m−1, correctly evolves the cluster into an eight-patch particle; the second step, with γPSl/o = 20 mN m−1, further refines the patch morphology to a nearly perfect match with the experimental results. On the right is a fluorescence microscopy image of eight-patch particles and SEM images showing the patchy particle before and after coordination with PS singlets. Scale bars are 1 μm.

Extended Data Figure 7 Supracolloidal assembly via liquid bonds.

False-colour SEM images of patchy particles (red) mixed with PVP–PS singlets (green). The images (at increasing magnification) show supracolloidal architectures assembled via liquid bonds. Scale bar is 5 μm.

Extended Data Figure 8 Patch-swelling and formation of patch-to-patch liquid bridges.

Bright-field and fluorescence microscopy images are shown. The patchy particles are first exposed to Pluronic L61, which selectively swells the patches, which tend to coalesce and thus form liquid bonds under acidic conditions. Scale bar is 5 μm.

Supplementary information

Colloidal fusion visualised by microscopy

Tetrahedral liquid-core colloidal clusters transform into spherical patchy particles when plasticized by THF. (MP4 25816 kb)

Rights and permissions

About this article

Cite this article

Gong, Z., Hueckel, T., Yi, GR. et al. Patchy particles made by colloidal fusion. Nature 550, 234–238 (2017). https://doi.org/10.1038/nature23901

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature23901

This article is cited by

-

A colloidal viewpoint on the sausage catastrophe and the finite sphere packing problem

Nature Communications (2023)

-

Visualizing defect dynamics by assembling the colloidal graphene lattice

Nature Communications (2023)

-

Colloidal robotics

Nature Materials (2023)

-

Topological nature of the liquid–liquid phase transition in tetrahedral liquids

Nature Physics (2022)

-

Comprehensive view of microscopic interactions between DNA-coated colloids

Nature Communications (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.