Abstract

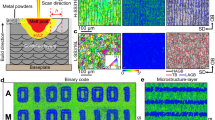

Metal-based additive manufacturing, or three-dimensional (3D) printing, is a potentially disruptive technology across multiple industries, including the aerospace, biomedical and automotive industries. Building up metal components layer by layer increases design freedom and manufacturing flexibility, thereby enabling complex geometries, increased product customization and shorter time to market, while eliminating traditional economy-of-scale constraints. However, currently only a few alloys, the most relevant being AlSi10Mg, TiAl6V4, CoCr and Inconel 718, can be reliably printed1,2; the vast majority of the more than 5,500 alloys in use today cannot be additively manufactured because the melting and solidification dynamics during the printing process lead to intolerable microstructures with large columnar grains and periodic cracks3,4,5. Here we demonstrate that these issues can be resolved by introducing nanoparticles of nucleants that control solidification during additive manufacturing. We selected the nucleants on the basis of crystallographic information and assembled them onto 7075 and 6061 series aluminium alloy powders. After functionalization with the nucleants, we found that these high-strength aluminium alloys, which were previously incompatible with additive manufacturing, could be processed successfully using selective laser melting. Crack-free, equiaxed (that is, with grains roughly equal in length, width and height), fine-grained microstructures were achieved, resulting in material strengths comparable to that of wrought material. Our approach to metal-based additive manufacturing is applicable to a wide range of alloys and can be implemented using a range of additive machines. It thus provides a foundation for broad industrial applicability, including where electron-beam melting or directed-energy-deposition techniques are used instead of selective laser melting, and will enable additive manufacturing of other alloy systems, such as non-weldable nickel superalloys and intermetallics. Furthermore, this technology could be used in conventional processing such as in joining, casting and injection moulding, in which solidification cracking and hot tearing are also common issues.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Lewandowski, J. J. & Seifi, M. Metal additive manufacturing: a review of mechanical properties. Annu. Rev. Mater. Res. 46, 151–186 (2016)

Frazier, W. E. Metal additive manufacturing: a review. J. Mater. Eng. Perform. 23, 1917–1928 (2014)

Collins, F. R. & Dudas, J. H. Preventing weld cracks in high-strength aluminum alloys. Weld. J. 45, 241 (1966)

Kaufmann, N. et al. Influence of process parameters on the quality of aluminium alloy EN AW 7075 using selective laser melting (SLM). Phys. Procedia 83, 918–926 (2016)

Zhang, H., Zhu, H., Qi, T., Hu, Z. & Zeng, X. Selective laser melting of high strength Al-Cu-Mg alloys: processing, microstructure and mechanical properties. Mater. Sci. Eng. A 656, 47–54 (2016)

Kurz, W . & Fisher, D. J. Fundamentals of Solidification (Trans Tech Publications, 1998)

Coniglio, N. & Cross, C. E. Initiation and growth mechanisms for weld solidification cracking. Int. Mater. Rev. 58, 375–397 (2013)

Rappaz, M., Drezet, J. & Gremaud, M. A new hot-tearing criterion. Metall. Mater. Trans. A 30, 449–455 (1999)

Yuan, L., O’Sullivan, C. & Gourlay, C. M. Exploring dendrite coherency with the discrete element method. Acta Mater. 60, 1334–1345 (2012)

Collins, P. C., Brice, D. A., Samimi, P., Ghamarian, I. & Fraser, H. L. Microstructural control of additively manufactured metallic materials. Annu. Rev. Mater. Res. 46, 63–91 (2016)

Easton, M. A. & Stjohn, D. Grain refinement of aluminum alloys : part I. The nucleant and solute paradigms — a review of the literature. Metall. Mater. Trans. A 30, 1613–1623 (1999)

Ding, Y. et al. Microstructure and mechanical property considerations in additive manufacturing of aluminum alloys. MRS Bull. 41, 745–751 (2016)

Schmidtke, K., Palm, F., Hawkins, A. & Emmelmann, C. Process and mechanical properties: applicability of a scandium modified Al-alloy for laser additive manufacturing. Phys. Procedia 12, 369–374 (2011)

Material Data Sheet — Scalmalloy (APWorks, 2016)

Starke, E. A. & Staley, J. T. Application of modern aluminum alloys to aircraft. Prog. Aerosp. Sci. 32, 131–172 (1996)

Immarigeon, J. P. et al. Lightweight materials for aircraft applications. Mater. Charact. 35, 41–67 (1995)

Miller, W. et al. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 280, 37–49 (2000)

Society of Automotive Engineers & American Society for Testing and Materials. Metals and Alloys in the Unified Numbering System (ASTM International, 2012)

Nelson, W. Duralumin Welding. Report No. 399 (National Advisory Committee for Aeronautics, 1927)

Pumphrey, W. I. & Lyons, J. V. Cracking during the casting and welding of the more common binary aluminum alloys. J. Inst. Met. 74, 439–455 (1948)

Gourlay, C. M. & Dahle, A. K. Dilatant shear bands in solidifying metals. Nature 445, 70–73 (2007)

Murray, J., Peruzzi, A. & Abriata, J. P. The Al-Zr (aluminum-zirconium) system. J. Phase Equilibria 13, 277–291 (1992)

Murty, B. S., Kori, S. A. & Chakraborty, M. Grain refinement of aluminium and its alloys by heterogeneous nucleation and alloying. Int. Mater. Rev. 47, 3–29 (2002)

Dehoff, R. R. et al. Site specific control of crystallographic grain orientation through electron beam additive manufacturing. Mater. Sci. Technol. 31, 931–938 (2015)

Martorano, M. A., Beckermann, C. & Gandin, C.-A. A solutal interaction mechanism for the columnar-to-equiaxed transition in alloy solidification. Metall. Mater. Trans. A 34, 1657–1674 (2003)

Hunt, J. D. Steady state columnar and equiaxed growth of dendrites and eutectic. Mater. Sci. Eng. 65, 75–83 (1984)

Eskin, D. G., Suyitno & Katgerman, L. Mechanical properties in the semi-solid state and hot tearing of aluminium alloys. Prog. Mater. Sci. 49, 629–711 (2004)

TCAL4: TCS Al-based Alloy Databasehttp://www.thermocalc.com/media/19881/tcal4.pdf (Thermo-Calc, 2016)

Aziz, M. J. Model for solute redistribution during rapid solidification. J. Appl. Phys. 53, 1158–1168 (1982)

Yu, C. Y., Kao, P. W. & Chang, C. P. Transition of tensile deformation behaviors in ultrafine-grained aluminum. Acta Mater. 53, 4019–4028 (2005)

CL 30AL/CL 31AL Aluminium Alloy (Concept Laser, Hofmann Innovation Group, 2012)

Boyer, H. E. & Gail, T. L. Materials Handbook Desk Edition (American Society for Metals, 1985)

Acknowledgements

We acknowledge financial support by HRL Laboratories, LLC, and thank D. Martin for her artistic contribution to the figures, as well as B. Carter of HRL Laboratories, LLC, X. Li of the University of California, Los Angeles, and K. Hemker of John Hopkins University for discussions.

Author information

Authors and Affiliations

Contributions

J.H.M., B.D.Y., J.M.H., T.A.S. and T.M.P. analysed the results and wrote the manuscript. J.H.M., B.D.Y. and T.A.S. designed the experiments. B.D.Y. and J.A.M. functionalized the feedstock material and operated the Concept Laser M2. J.H.M., B.D.Y. and J.A.M. prepared the metallurgical specimens and performed the optical and electron microscopy and the mechanical testing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Reviewer Information Nature thanks P. Collins, I. Todd and the other anonymous reviewer(s) for their contribution to the peer review of this work.

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Figure 2 As-printed Al7075 parts for tensile testing and microstructure evaluation.

a, Stock Al7075. b, Al7075 + Zr.

Extended Data Figure 4 Stress–strain curves for the materials tested in this study, indicating high repeatability in the Al7075 + Zr material.

The colour indicates the material type, with curves of the same colour indicating replicate samples.

Extended Data Figure 5 Scheil solidification curves for aluminium alloys AlSi10Mg, Al7075 and Al6061.

The curve for Al6061 is from ref. 28.

Extended Data Figure 6 Micrographs of etched Al6061, processed as received.

Large cracks are observed in the absence of Zr (left). With the addition of Zr nanoparticles, no cracking is observed, but there is some residual porosity (right). Rows indicate increasing magnification.

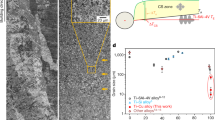

Extended Data Figure 7 Micrographs of etched Al7075, processed as received.

Large networks of cracks are observed in the absence of Zr (left). With the addition of Zr nanoparticles, no cracking is observed, but there is some residual porosity (right). Rows indicate increasing magnification.

Extended Data Figure 8 EBSD inverse pole figure of 3D-printed stock 7075 indicating large networks of columnar cracking.

Build direction is vertical to the page.

Rights and permissions

About this article

Cite this article

Martin, J., Yahata, B., Hundley, J. et al. 3D printing of high-strength aluminium alloys. Nature 549, 365–369 (2017). https://doi.org/10.1038/nature23894

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature23894

This article is cited by

-

High-strength and crack-free welding of 2024 aluminium alloy via Zr-core-Al-shell wire

Nature Communications (2024)

-

Manufacturing of high strength and high conductivity copper with laser powder bed fusion

Nature Communications (2024)

-

Powder-size driven facile microstructure control in powder-fusion metal additive manufacturing processes

Nature Communications (2024)

-

Probabilistic and Fuzzy Nonlinear Discontinuous Aeroelastic Analysis of In-plane FG Panels in Supersonic Flow with Mechanical and Thermal In-plane Loadings

Arabian Journal for Science and Engineering (2024)

-

Investigation on keyhole stability and surface quality in laser welding of TC4 titanium alloy with adjustable ring-mode (ARM) laser

The International Journal of Advanced Manufacturing Technology (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.