Abstract

Understanding and predicting crystal growth is fundamental to the control of functionality in modern materials. Despite investigations for more than one hundred years1,2,3,4,5, it is only recently that the molecular intricacies of these processes have been revealed by scanning probe microscopy6,7,8. To organize and understand this large amount of new information, new rules for crystal growth need to be developed and tested. However, because of the complexity and variety of different crystal systems, attempts to understand crystal growth in detail have so far relied on developing models that are usually applicable to only one system9,10,11. Such models cannot be used to achieve the wide scope of understanding that is required to create a unified model across crystal types and crystal structures. Here we describe a general approach to understanding and, in theory, predicting the growth of a wide range of crystal types, including the incorporation of defect structures, by simultaneous molecular-scale simulation of crystal habit and surface topology using a unified kinetic three-dimensional partition model. This entails dividing the structure into ‘natural tiles’ or Voronoi polyhedra that are metastable and, consequently, temporally persistent. As such, these units are then suitable for re-construction of the crystal via a Monte Carlo algorithm. We demonstrate our approach by predicting the crystal growth of a diverse set of crystal types, including zeolites, metal–organic frameworks, calcite, urea and l-cystine.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Ostwald, W. Studien über die Bildung und Umwandlung fester Körper. Z. Phys. Chem. 22, 289–330 (1897)

Volmer, M. Kinetics of Phase Formation (Kinetik der Phasenbildung) http://www.dtic.mil/cgi-bin/GetTRDoc?Location=U2&doc=GetTRDoc.pdf&AD=ADA800534 (Theodor Steinkopf, 1939)

Stranski, I. N. Zur Theorie des Kristallwachstums. Z. Phys. Chem. 136, 259–278 (1928)

Kossel, W. Zur Theorie des Kristallwachstums. Nachrichten der Gesselschaft der Wissenschaften Göttingen, Mathematisch-Physikalische Klasse 1927, 135–143, (1927)

Burton, W. K., Cabrera, N. & Frank, F. C. The growth of crystals and the equilibrium structure of their surfaces. Phil. Trans. R. Soc. Lond. A 243, 299–358 (1951)

Hillner, P. E., Gratz, A. J., Manne, S. & Hansma, P. K. Atomic-scale imaging of calcite growth in real-time. Geology 20, 359–362 (1992)

Land, T. A., DeYoreo, J. J. & Lee, J. D. An in-situ AFM investigation of canavalin crystallization kinetics. Surf. Sci. 384, 136–155 (1997)

Agger, J. R., Pervaiz, N., Cheetham, A. K. & Anderson, M. W. Crystallization in zeolite A studied by atomic force microscopy. J. Am. Chem. Soc. 120, 10754–10759 (1998)

Cuppen, H. M., van Veenendaal, E., van Suchtelen, J., van Enckevort, W.J.P. & Vlieg, E. A Monte Carlo study of dislocation growth and etching of crystals. J. Cryst. Growth 219, 165–175 (2000)

De Yoreo, J. J. et al. Rethinking classical crystal growth models through molecular scale insights: consequences of kink-limited kinetics. Cryst. Growth Des. 9, 5135–5144 (2009)

Brent, R. et al. Unstitching the nanoscopic mystery of zeolite crystal formation. J. Am. Chem. Soc. 132, 13858–13868 (2010)

Davis, M. E. Ordered porous materials for emerging applications. Nature 417, 813–821 (2002)

Kinrade, S. D. & Swaddle, T. W. 29Si NMR studies of aqueous silicate solutions 2: transverse 29Si relaxation and the kinetics and mechanism of silicate polymerisation. Inorg. Chem. 27, 4259–4264 (1988)

Knight, C. T. G. & Harris, R. K. Silicon-29 nuclear magnetic resonance studies of aqueous silicate solutions 8: spin-lattice relaxation times and mechanisms. Magn. Reson. Chem. 24, 872–874 (1986)

Harris, R. K. & Kimber, B. J. Si NMR as a tool for studying silicones. Appl. Spectrosc. Rev. 10, 117–137 (1975)

Petry, D. P. et al. Connectivity analysis of the clear sol precursor of silicalite: are nanoparticles aggregated oligomers or silica particles? J. Phys. Chem. C 113, 20827–20836 (2009)

Yaghi, O. M. et al. Reticular synthesis and the design of new materials. Nature 423, 705–714 (2003)

Férey, G. Hybrid porous solids: past, present, future. Chem. Soc. Rev. 37, 191–214 (2008)

Kitagawa, S., Kitaura, R. & Noro, S. Functional porous coordination polymers. Angew. Chem. Int. Ed. 43, 2334–2375 (2004)

Boerrigter, S. X. M. et al. MONTY: Monte Carlo crystal growth on any crystal structure in any crystallographic orientation; application to fats. J. Phys. Chem. A 108, 5894–5902 (2004)

Blatov, V. A., Delgado-Friedrichs, O., O’Keeffe, M. & Proserpio, D. M. Three-periodic nets and tilings: natural tilings for nets. Acta Crystallogr. A 63, 418–425 (2007)

Blatov, V. A., Shevchenko, A. P. & Proserpio, D. M. Applied topological analysis of crystal structures with the program package ToposPro. Cryst. Growth Des. 14, 3576–3586 (2014)

Roeffaers, M. B. J. et al. Morphology of large ZSM-5 crystals unraveled by fluorescence microscopy. J. Am. Chem. Soc. 130, 5763–5772 (2008)

Jeong, N. C., Lim, H., Cheong, H. & Yoon, K. B. Distribution pattern of length, length uniformity, and density of TiO32− quantum wires in an ETS-10 crystal revealed by laser-scanning confocal polarized micro-Raman spectroscopy. Angew. Chem. Int. Ed. 50, 8697–8701 (2011)

Shtukenberg, A. G. et al. Dislocation-actuated growth and inhibition of hexagonal l-cystine crystallization at the molecular level. Cryst. Growth Des. 15, 921–934 (2015)

Rimer, J. D. et al. Crystal growth inhibitors for the prevention of l-cystine kidney stones through molecular design. Science 330, 337–341 (2010)

Teng, H. H., Dove, P. M. & DeYoreo, J. J. Reversed calcite morphologies induced by microscopic growth kinetics: insight into biomineralisation. Geochim. Cosmochim. Acta 63, 2507–2512 (1999)

Pokrovski, G. S., Schott, J., Salvi, S., Gout, R. & Kubicki, J. D. Structure and stability of aluminum-silica complexes in neutral to basic solutions. Experimental study and molecular orbital calculations. Min. Mag. 62A, 1194–1195 (1998)

Tagirov, B., Schott, J., Harrichoury, J.-C. & Escalier, J. Experimental study of the stability of aluminate-borate complexes in hydrothermal solutions. Geochim. Cosmochim. Acta 68, 1333–1345 (2004)

Walker, A. M., Slater, B., Gale, J. D. & Wright, K. Predicting the structure of screw dislocations in nanoporous materials. Nat. Mater. 3, 715–720 (2004)

Carta, R. & Tola, G. Solubilities of l-cystine, l-tyrosine, l-leucine, and glycine in aqueous solutions at various pHs and NaCl concentrations. J. Chem. Eng. Data 41, 414–417 (1996)

Klamt, A. & Schüürmann, G. COSMO — a new approach to dielectric screening in solvents with explicit expressions for the screening energy and its gradient. J. Chem. Soc., Perkin Trans. 2 799–805 (1993)

Raiteri, P., Demichelis, R. & Gale, J. D. A thermodynamically consistent force field for molecular dynamics simulations of alkaline-earth carbonates and their aqueous speciation. J. Phys. Chem. C 119, 24447–24458 (2015)

Acknowledgements

V.A.B. is grateful to the Russian Science Foundation (Grant No. 16-13-10158) for support. The Research Council of Norway, through the project Catlife, ‘Catalyst transformation and lifetimes by in-situ techniques and modelling’, P#233848, is acknowledged for financial support. A.R.H. and J.T.G.-R. are grateful for part funding from EPSRC through CASE awards. J.D.G. thanks the Australian Research Council for support through the Discovery Programme, and the Pawsey Supercomputing Centre and National Computational Infrastructure for provision of computing resources. We also acknowledge the Leverhulme Trust and the Royal Society for financial support.

Author information

Authors and Affiliations

Contributions

M.W.A. conceived ideas, wrote the CrystalGrower growth code and performed simulations, J.T.G.-R. wrote an early version of the growth and visualization code and performed simulations, A.R.H. wrote the CrystalGrower visualization code and performed simulations, N.F. and P.C. recorded AFM images, M.P.A. coordinated MOF work, V.A.B. modified the ToposPro code to interface with CrystalGrower, D.M.P. developed ideas to integrate tiling methodology, D.A. and B.A. funded A.R.H. and contributed to discussions about the mechanism of crystal growth, and J.D.G. computed energetics for the calcite and l-cystine systems. All authors contributed to writing the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Reviewer Information Nature thanks M. Deem, M. Tuckerman and the other anonymous reviewer(s) for their contribution to the peer review of this work.

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Figure 1 Experimental and simulated data for the LTA framework with energy level diagram.

a, A schematic of energy ladders for the LTA structure. Double 4-rings (D4Rs) are shown in yellow, sodalite (β) cages are shown in magenta and α cages are shown in cyan. Each level on the energy ladders, moving from bulk to the top, corresponds to the loss of coordination (or gain in hydration) of one Q4 site to a Q3 site. In the case of a double 4-ring, the bottom level corresponds to a cage with zero Q3 sites and eight Q4 sites, whereas the top level corresponds to a fully solvated double 4-ring with zero Q4 sites and eight Q3 sites. The driving force Δμ, which is the chemical potential of the solution, can be considered as a single value for a zeolite in which the nutrient is interconverting. However, for a system with species that do not interconvert, such as a co-crystal, more than one driving force would be required—although these driving forces would be interrelated by the stoichiometry of solution species and their relative rates of consumption. b–f, The LTA structure consists of three tiles (b) connected in a cubic lattice (c). Typical crystals exhibit three facets, each with a unique terrace shape (d), all of which can be reproduced along with the crystal habit in a simulation that treats the crystallization energy of each tile separately (e, top); a prediction of the surface termination on (100) can also be made (e, bottom). Screw dislocations along [100] in the LTA structure are ubiquitous and the same set of parameters also reproduces the nature of this defect (f). Supplementary Video 1 shows the screw dislocation growing through the simulation. The simulated crystals shown in e and f are approximately 0.15 μm × 0.15 μm × 0.15 μm and 0.20 μm × 0.15 μm × 0.15 μm in size, respectively; ΔUs(α) = 1 kcal mol−1, ΔUs(β) = 5.4 kcal mol−1, ΔUs(D4R) = 8 kcal mol−1. g, A ternary plot consisting of 1,176 simulation data points, corresponding to exploring the energy space at 2% intervals. All images are recorded at equilibrium driving force. The highest destabilization for each cage is at the corner at which its name appears, and the corresponding axes are colour coded. The directions of the grid lines for each axis can be seen in the small diagram top right. Examples of interesting morphologies for particular energy combinations are highlighted.

Extended Data Figure 2 Experimental and simulated data for the FAU framework.

a, b, The FAU structure consists of three tiles (a) connected in a face-centred-cubic lattice (b). c–e, A simulation in which the supersaturation is decreased from high (50 kcal mol−1) to low (1 kcal mol−1) at the halfway point, with ΔUs = 2 kcal mol−1 (c), matches scanning electron microscopy (SEM; d) and AFM (e) data on a zinc phosphate structure, in terms of both the octahedral habit and the triangular terraces on the (111) face with correct orientation. f, Simulations with the same parameters as for c with varying zoom distances show the surface structure predicted for this simulation. Supplementary Video 2 shows an example of how a FAU crystal grows at both high and low supersaturation. The simulated crystal shown in c and f has an approximate size of 0.20 μm × 0.20 μm × 0.20 μm.

Extended Data Figure 3 Experimental and simulated data for the UOV framework.

a, b, The UOV structure represents one of the most complex framework systems, with a particularly large unit cell with dimensions of 1.27 nm × 2.20 nm × 3.88 nm, and consists of 16 different tile types (a) connected in an orthorhombic lattice (b). c, The germanosilicate crystallites that adopt this framework structure, although intergrown, show very well defined shape bounded by six faces. d, e, Simulation confirms the two large faces to be {100} (d) and the four side faces to be {013} (e, left). Simulations also reveal the structure at the crystal surface on the side wall (e, left) and top face (e, right), with differing colouring methods; ΔUs = 2 kcal mol−1. Supplementary Video 3 shows an example of how a UOV crystal grows at both high and low supersaturation values. The simulated crystal shown in all of these examples is approximately 0.050 μm × 0.75 μm × 1.40 μm in size.

Extended Data Figure 4 Experimental and simulated data for the NES framework.

a, b, The NES framework can usually be expressed with four different tile types. The tile with the largest number of vertices, ‘t-nes’, can be split into three smaller tiles (green, cyan and blue) to give a total of six tiles of similar size (a) that combine to form an orthorhombic lattice (b). These three tiles can no longer be referred to as natural tiles, but they were still generated using the ToposPro software. These tiles play the part of units of growth and are required because CrystalGrower utilizes connections through faces, making frameworks that share only corners and edges between small tiles, such as NES, difficult to grow over reasonable timescales. c, d, AFM and SEM micrographs show the morphology of aluminosilicate crystals that adopt this framework structure to be long and wafer-like with rounded terraces (c), which can be reproduced with simulations using the six smaller tiles chosen (d); ΔUs = 2 kcal mol−1. e, Lowering the energy penalty for the largest cage, ΔUs = 1 kcal mol−1 compared to other cages at 3 kcal mol−1, changes the morphology of the crystal markedly, thickening the crystal considerably (left and top right). This is an observable example of a structure being constrained in its propagation in a particular direction owing to the difficulty in growing such large cages. Investigating the surface structure (bottom right) shows that the surface is almost entirely terminated by the largest tile (blue) in the framework, again highlighting this observation. The simulated crystal shown in d is approximately 0.05 μm × 0.40 μm × 0.15 μm, whereas the example in e is estimated to be 0.10 μm × 0.20 μm × 0.15 μm in size.

Extended Data Figure 5 Experimental and simulated data for the MFI framework.

a, b, The MFI structure consists of ten tile types (a) connected in an orthorhombic lattice (b). c, A consistent feature in MFI crystals is the optical hourglass effect seen in crystals of silicalite. There has been much conjecture about the origin of this hourglass effect. However, the fact that the optical birefringence, seen in these 300-μm-long crystals, is located in sectors bounded by the crystal faces is a good indication that the origin is a result of the mechanism for crystal growth being different on different faces of the crystal. d, Our simulations reflect well the crystal habit and surface topology and allow investigation of the surface termination; ΔUs = 2 kcal mol−1 for small tiles and ΔUs = 4 kcal mol−1 for large tiles. e, The internal structure shows that the density of silanol groups mirrors very closely the sectoring of the crystal, because only tiles with incomplete coordination are shown. Such a change in crystal chemistry would, almost certainly, be associated with a change in the refractive index of the crystal and hence the observed optical effect. Supplementary Video 4 demonstrates growth of the hourglass feature as the simulation progresses and shows how different tiles express this feature to differing degrees. The simulated crystal shown in d is approximately 0.10 μm × 0.05 μm × 0.40 μm in size, whereas the crystal shown in e is approximately 0.10 μm × 0.05 μm × 0.20 μm.

Extended Data Figure 6 Experimental and simulated data for the titanosilicate material ETS-10.

a, b, ETS-10 is a nanoporous titanosilicate with a structure consisting of five tiles (a) connected in a monoclinic lattice (b). c, The structure has a very similar symmetry to zeolite β; however, the titanium is incorporated into titania rods surrounded by silica. High-resolution electron microscopy courtesy of O. Terasaki. d, e, These rods run alternately in orthogonal [110] and  directions and are found to be the dominant components for the crystal growth. f, Because the rods do not always connect and heal inside the crystal structure, there is a high concentration of internal silianol groups in a sector from the (001) faces to the centre of the crystal. Such sectoring in ETS-10 has been observed in Raman microscopy24. Supplementary Video 5 demonstrates how the rods in the ETS-10 framework grow in alternating orthogonal directions. The simulated crystals shown in d and f are approximately 0.25 μm × 0.25 μm × 0.05 μm and 0.10 μm × 0.10 μm × 0.10 μm in size, respectively; ΔUs = 2 kcal mol−1.

directions and are found to be the dominant components for the crystal growth. f, Because the rods do not always connect and heal inside the crystal structure, there is a high concentration of internal silianol groups in a sector from the (001) faces to the centre of the crystal. Such sectoring in ETS-10 has been observed in Raman microscopy24. Supplementary Video 5 demonstrates how the rods in the ETS-10 framework grow in alternating orthogonal directions. The simulated crystals shown in d and f are approximately 0.25 μm × 0.25 μm × 0.05 μm and 0.10 μm × 0.10 μm × 0.10 μm in size, respectively; ΔUs = 2 kcal mol−1.

Extended Data Figure 7 Experimental and simulated data for the CHA framework.

a, b, The CHA structure consists of two tiles (a) connected in a monoclinic lattice (b). c, Typical silicoaluminophosphate (SAPO-34) crystals show distorted cube morphology when viewed using SEM, exhibiting {100} faces with isotropic growth of terraces. d, e, Many screw dislocations can be observed in this system (e) and one such dislocation with a screw core running along [100] is reproduced by simulations (d); ΔUs = 2 kcal mol−1. f, Simulations predict that the surface terminates at the double 6-rings. The simulated crystal shown in d has an approximate size of 1.50 μm × 0.10 μm × 0.10 μm due to elongation caused by the screw dislocation.

Extended Data Figure 8 Experimental and simulated data for the AEI framework.

a, b, The AEI structure consists of two tiles (a) connected in an orthorhombic lattice (b). c, The structure is related to CHA in that it can be built by connecting double 6-rings. However, because of the alternating orientation of these units along the c direction, the fast and slow growth rates switch along the a and b directions (shown on AFM of aluminophosphate (AlPO-18). d–f, The result is complex, interleaved spiral growth that is faithfully simulated using our space partitioning methodology; ΔUs = 2 kcal mol−1. The simulated crystal shown in d–f is approximately 1.70 μm × 0.05 μm × 0.05 μm in size due to elongation caused by the screw dislocation.

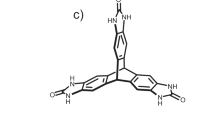

Extended Data Figure 9 Experimental and simulated data for two metal–organic frameworks, HKUST-1 and MOF-5.

a–d, HKUST-1, a porous MOF of copper trimesate, Cu3[(O2C)3C6H3]2(H2O)3. By partitioning the structure with nodes at metal clusters and tile edges along linkers, the HKUST-1 structure consists of three tiles (a) connected in a face-centred cubic lattice (b). Such a partitioning produces simulation results (d) that are in excellent agreement with experiments in terms of both the crystal habit and the terrace topology of the prevalent screw dislocations (c). The simulation predicts that the screw core runs along [110], not perpendicular to the {111} faces because such a screw core would result in multiple spirals (d); ΔUs = 2 kcal mol−1 for small tiles and ΔUs = 5 kcal mol−1 for large tiles. Simulations also allow investigation of the surface termination for this framework (d). Supplementary Video 6 shows the screw dislocation growing and migrating across the surface of the crystal. The approximate size of the crystal shown in d is 0.35 μm × 0.35 μm × 0.35 μm. e–i, MOF-5 (Zn4O(bdc)3, where bdc is 1,4-benzenedicarboxylate), a porous MOF with a simple cubic arrangement of metal centres (red) and linkers (grey), along with a solvent molecule occupying the centre of each cube (purple) (e, left). Treating the structure as a multicomponent molecular crystal in lieu of a standard tile-partition as used in other cases, the framework can also be partitioned into Voronoi polyhedra to demonstrate the interactions between each of the linkers, metal centres and solvent molecules (e, right). Square terracing on the (100) face (f) can be in one of two orientations, depending on the synthesis conditions. The crystal morphology can also be changed to exhibit {111} faces as an octahedral crystal, again depending on synthesis conditions (g, left), as opposed to only {100} faces (g, right) in a cubic crystal. {111} faces exhibited by the crystal are much more isotropic (h) compared to the {100} faces (f) and do not adopt the different orientations demonstrated by the {100} faces. The simple cubic network alone will not permit the development of {111} faces and is immediately an indication of the importance of the solvent N,N′-diethylformamide (DEF) in the preparation. By varying the driving forces for binding of the linker, metal centre and solvent in the final crystal, all crystal habits and surface topologies may be generated (f–h). Double spirals through growth at screw dislocations on the (100) face can also be simulated (i). The estimated sizes of the crystals shown are: f, 0.76 μm × 0.75 μm × 0.75 μm and 0.70 μm × 0.80 μm × 0.80 μm; g, 0.50 μm × 0.50 μm × 0.50 μm and 0.75 μm × 0.75 μm × 0.75 μm; h, 0.50 μm × 0.50 μm × 0.50 μm; and i, 0.75 μm × 0.75 μm × 0.75 μm.

Extended Data Figure 10 Collection of simulated data for l-cystine along with a single simulation of d-cystine.

a, A suite of calculations of the crystal growth of l-cystine at a supersaturation of 0.6 kcal mol−1 viewed down the [001] direction, showing characteristic pin-wheel surface topology and hexagonal step bunching. Simulations are based on four characteristic free energies of crystallization: (i) in the strong binding direction where l-cystine molecules are bound by two hydrogen bonds and S….S contacts; (ii) and (iii) in the weak, slow growth directions, labelled A+ and A− in refs 25 and 26, with one hydrogen bond; and (iv) in the c direction with two hydrogen bonds. Interaction types (ii) and (iii) are maintained at half the strength of (iv), with a minimal difference between (ii) and (iii). These interactions can be combined into 491 growth sites that are computed in the simulation. The grid explores the effect of changing the relative magnitude of interaction (i) (number on the x axis), relative to the sum of the other interactions (number on the y axis); all values given in kcal mol−1. When all of these interactions are too weak, isotropic sticky growth is observed; when they are too high, the growth is too geometrical. The optimum balance is highlighted (black outline), for which the sum of the free energies of crystallization is 7.0 kcal mol−1, compared to the value of 4.3 kcal mol−1 derived from the solubility of l-cystine at pH 7 directly31. Similar to the results of ref. 25, the step bunching is closer than observed experimentally because lattice strain at the screw core weakens interactions and prevents the core region, which is advancing by attachment to the slow step alone, from forming a closed hexagonal step bunch as quickly as predicted. b, A set of simulations demonstrating the effect of small differences in the energy of slow growth directions A+ and A−; energies given in kcal mol−1. If there were no difference in energy, then the pin-wheel structure would have a step bunch height of only half a unit cell, owing to the symmetry that is produced every 180° turn around the screw core. A difference of 0.1 kcal mol−1 is sufficient to eradicate this symmetry and make the step bunches one unit cell high. c, Reversal of the handedness of the screw core is not immediately apparent because the pin-wheel structure and handedness remain the same whatever the handedness of the screw core as this is driven by the symmetry of the crystal structure at the molecular level. However, differences can be observed in the surface topology close to the screw core, depending on whether the handedness of the crystal structure is the same or the reverse of the handedness of the screw core. d, l-cystine and d-cystine present identical surface structures with opposite handedness, as expected.

Supplementary information

LTA – Growth via Screw Dislocation

An LTA crystal grown with a screw dislocation running in the [100] direction through the crystal. Similar to the FAU simulation, the crystal is first grown under high supersaturation conditions (90 kcal/mol) for 5 million iterations, followed by a drop in supersaturation to slightly above equilibrium (1.5 kcal/mol) to allow a more detailed study of the growing process. During the slow growth, the propagation of the spiral from the screw dislocation is clear. The crystal is then rotated to the opposing face, demonstrating the elongation of the morphology in the [100] as expected as the screw dislocation creates a low energy surface for the growth units to attach to. After arriving at the opposing face, the slow growth process is reversed then replayed to again demonstrate the spiral-growth of the crystal. (MP4 28314 kb)

FAU – Layer Growth

A FAU crystal is grown under high supersaturation conditions (50 kcal/mol) for 5 million iterations, showing rapid growth and the adoption of an octahedral crystal morphology. The second 5 million iterations occur after the supersaturation is lowered to slightly above equilibrium (1 kcal/mol), allowing the growth process to continue slowly. At this point the triangular shape of the terraces can be observed, growing in the opposing direction to the facet where the growth is occurring. The final portion of the video shows the surface structure viewed from the top, followed by the side of a grown terrace. (MP4 27983 kb)

UOV – Layer Growth

Growth of a UOV crystal is demonstrated using similar conditions to the previous videos: 5 million iterations at high supersaturation (70 kcal/mol) followed by 5 million iterations at a supersaturation value slightly above equilibrium (1 kcal/mol). The diamond-like morphology of the UOV crystal can clearly be seen during panning and rotation. Rounded / isotropic layer growth can be observed during the growth process, along with the fusion of terraces once the growth process is slowed. Close-up shots are then shown of the surface structure on the (100) face, followed by the side-wall of the crystal: the (013) face. (MP4 25660 kb)

MFI – Hourglass Growth and Tile Type Relation

To begin, the t-mfi-1 tiles are shown during the growth process of an MFI crystal to allow a view into the internal structure of the crystal as it grows, showing the formation of the hourglass structure mentioned previously. Following this growth, a series of frames are shown where the tile type shown is cycled on the (001), (100) and (001) faces respectively, demonstrating how different tile types contribute to this internal feature in varying degrees. (MP4 27622 kb)

ETS-10 – Orthogonal Rod Growth

Demonstration of the growth mechanism of ETS-10 via titanate rods in alternating directions, orthogonal to each other. Each alternating layer is represented by different colours to draw attention to the orthogonal directions. The conditions for this growth process are changed slightly compared to the previous videos. The crystal is first grown at high supersaturation (140 kcal/mol) to ensure the growth process begins, however no frames are recorded. The supersaturation is then lowered to 1 kcal/mol, and frames are taken every 200,000 iterations for the first 20 frames, followed by 40 frames recorded at every 10,000 iterations. During these slowed down frames, a closer view of the surface is shown, with arrows overlaid following the direction of rod growth that can be observed. A final 20 frames with a spacing of 20000 iterations are shown, along with close-ups of the surface structures adopted by the vertical and horizontal rods that express the structure. (MP4 26376 kb)

HKUST-1 – Growth via Screw Dislocation

The growth of an HKUST-1 crystal. The first 5 million iterations are run at high supersaturation conditions (100 kcal/mol) followed by a drop to a lower supersaturation (1 kcal/mol). Slowing down the growth clearly demonstrates how the screw dislocation running along the [110] direction completely alters the final morphology of the crystal. The growth is then reversed, and the screw dislocation is followed to the point where it migrates back onto the (111) that it originally appeared from. Rotating the crystal then allows the viewer to observe the elongation of the crystal shape caused by the spiral growth on both sides. Rotating the crystal to view the opposite side of the screw dislocation, the location of the core is again followed whilst re-growing the crystal at low supersaturation (1 kcal/mol) ending with the final growth frame, and a panned out view of the entire crystal. (MP4 24692 kb)

L-cystine – Growth via Screw Dislocation

The growth of l-cystine at a supersaturation of 0.6 kcal mol-1. The optimal binding free energies where: (i) strong binding 3.5 kcal mol-1; (ii) and (iii) weak binding 0.78 kcal mol-1 and 0.98 kcal mol-1; (iv) binding in the c-direction 1.75 kcal mol-1. Advancement of the step bunches is through birth-and-spread growth on the <100> side faces, which is encouraged through the strong binding direction. This birth-and-spread growth precipitates growth at the single slow growth edges. Growth is further complicated by a small amount of birth-and-spread growth on the <001> face. (MP4 25562 kb)

Rights and permissions

About this article

Cite this article

Anderson, M., Gebbie-Rayet, J., Hill, A. et al. Predicting crystal growth via a unified kinetic three-dimensional partition model. Nature 544, 456–459 (2017). https://doi.org/10.1038/nature21684

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature21684

This article is cited by

-

Crystallization of molecular layers produced under confinement onto a surface

Nature Communications (2024)

-

Growth strategy for solution-phase growth of two-dimensional nanomaterials via a unified model

Nature Synthesis (2023)

-

Direct synthesis of hierarchical zeolites through mesoporous 3D wormhole framework using single-head quaternary ammonium salt as structure-directing agent

Journal of Materials Science (2021)

-

Graph similarity drives zeolite diffusionless transformations and intergrowth

Nature Materials (2019)

-

Linking synthesis and structure descriptors from a large collection of synthetic records of zeolite materials

Nature Communications (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.