Abstract

Solid oxide cells (SOCs) can operate with high efficiency in two ways—as fuel cells, oxidizing a fuel to produce electricity, and as electrolysis cells, electrolysing water to produce hydrogen and oxygen gases. Ideally, SOCs should perform well, be durable and be inexpensive, but there are often competitive tensions, meaning that, for example, performance is achieved at the expense of durability. SOCs consist of porous electrodes—the fuel and air electrodes—separated by a dense electrolyte. In terms of the electrodes, the greatest challenge is to deliver high, long-lasting electrocatalytic activity while ensuring cost- and time-efficient manufacture1. This has typically been achieved through lengthy and intricate ex situ procedures. These often require dedicated precursors and equipment1,2,3; moreover, although the degradation of such electrodes associated with their reversible operation can be mitigated4, they are susceptible to many other forms of degradation5. An alternative is to grow appropriate electrode nanoarchitectures under operationally relevant conditions, for example, via redox exsolution6,7,8,9,10. Here we describe the growth of a finely dispersed array of anchored metal nanoparticles on an oxide electrode through electrochemical poling of a SOC at 2 volts for a few seconds. These electrode structures perform well as both fuel cells and electrolysis cells (for example, at 900 °C they deliver 2 watts per square centimetre of power in humidified hydrogen gas, and a current of 2.75 amps per square centimetre at 1.3 volts in 50% water/nitrogen gas). The nanostructures and corresponding electrochemical activity do not degrade in 150 hours of testing. These results not only prove that in operando methods can yield emergent nanomaterials, which in turn deliver exceptional performance, but also offer proof of concept that electrolysis and fuel cells can be unified in a single, high-performance, versatile and easily manufactured device. This opens up the possibility of simple, almost instantaneous production of highly active nanostructures for reinvigorating SOCs during operation.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Change history

21 September 2016

In Fig. 2a, ‘H2O/H2’ was replaced with ‘H2O/N2’.

References

Irvine, J. T. S. et al. Evolution of the electrochemical interface in high-temperature fuel cells and electrolysers. Nature Energy 1, 15014 (2016)

Jiang, S. P. A review of wet impregnation—an alternative method for the fabrication of high performance and nano-structured electrodes of solid oxide fuel cells. Mater. Sci. Eng. A 418, 199–210 (2006)

Jung, W., Gu, K. L., Choi, Y. & Haile, S. M. Robust nanostructures with exceptionally high electrochemical reaction activity for high temperature fuel cell electrodes. Energy Environ. Sci. 7, 1685–1692 (2014)

Graves, C., Ebbesen, S. D., Jensen, S. H., Simonsen, S. B. & Mogensen, M. B. Eliminating degradation in solid oxide electrochemical cells by reversible operation. Nature Mater. 14, 239–244 (2015)

Irvine, J. T. S. & Connor, P. in Solid Oxide Fuels Cells: Facts and Figures (eds Irvine, J. T. S. & Connor, P. ) 163–180 (Springer London, 2013)

Nishihata, Y. et al. Self-regeneration of a Pd-perovskite catalyst for automotive emissions control. Nature 418, 164–167 (2002)

Kobsiriphat, W. et al. Nickel- and ruthenium-doped lanthanum chromite anodes: effects of nanoscale metal precipitation on solid oxide fuel cell performance. J. Electrochem. Soc. 157, B279–B284 (2010)

Neagu, D., Tsekouras, G., Miller, D. N., Ménard, H. & Irvine, J. T. S. In situ growth of nanoparticles through control of non-stoichiometry. Nature Chem. 5, 916–923 (2013)

Neagu, D. et al. Nano-socketed nickel particles with enhanced coking resistance grown in situ by redox exsolution. Nature Commun. 6, 8120 (2015)

Tsekouras, G., Neagu, D. & Irvine, J. T. S. Step-change in high temperature steam electrolysis performance of perovskite oxide cathodes with exsolution of B-site dopants. Energy Environ. Sci. 6, 256–266 (2013)

Nenning, A. et al. Ambient pressure XPS study of mixed conducting perovskite-type SOFC cathode and anode materials under well-defined electrochemical polarization. J. Phys. Chem. C 120, 1461–1471 (2015)

Sengodan, S. et al. Layered oxygen-deficient double perovskite as an efficient and stable anode for direct hydrocarbon solid oxide fuel cells. Nature Mater. 14, 205–209 (2014)

Neagu, D. & Irvine, J. T. S. Structure and properties of La0.4Sr0.4TiO3 ceramics for use as anode materials in solid oxide fuel cells. Chem. Mater. 22, 5042–5053 (2010)

Tsekouras, G. & Irvine, J. T. S. The role of defect chemistry in strontium titanates utilised for high temperature steam electrolysis. J. Mater. Chem. 21, 9367–9376 (2011)

Acknowledgements

We acknowledge support from the Engineering and Physical Sciences Research Council (EPSRC) Platform (grant EP/K015540/1), the EPSRC Material World Network (EP/J018414/1), EPSRC SUPERGEN Projects (EP/K021036/1 and EP/G01244X/1), EPSRC Capital for Great Technologies grant (EP/L017008/1) and a Royal Society Wolfson Merit Award (WRMA 2012/R2).

Author information

Authors and Affiliations

Contributions

J.M. fabricated and optimized the cells, and carried out electrochemical testing and analysis. D.N. designed the study with help from J.M., and collected and analysed thermogravimetric analysis (TGA) and scanning electron microscope (SEM) data. D.N.M. collected transmission electron microscope (TEM) data. J.T.S.I. oversaw the study. D.N. wrote the manuscript with assistance from J.M. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Reviewer Information

Nature thanks J.-L. Luo and M. Mogensen for their contribution to the peer review of this work.

Extended data figures and tables

Extended Data Figure 1 Microstructures of as-prepared electrode.

a, b, SEM micrographs of the electrodes before any gas reduction/electrochemical switching by potential.

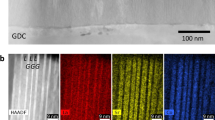

Extended Data Figure 2 TEM analysis of a nickel-exsolved electrode.

a, TEM micrograph of a nickel exsolution particle from an LCNT electrode after ‘electrochemical switching’. b, Composition analysis by EDS.

Extended Data Figure 3 Polarization resistance after electrochemical switching.

The plot of imaginary (Z″) versus real (Z′) complex impedance compares the polarization resistance of the whole cell at OCV after electrochemical switching, with the contribution from the air electrode as measured in an impedance half-cell measurement in air. Both spectra were obtained at 900 °C and the series resistances were subtracted for easier comparison.

Extended Data Figure 4 Comparison of perovskite electrodes, produced by electrochemical switching, that either contain or do not contain nickel.

a, Current–voltage curves and b, impedance spectra at OCV. Cells were based on 140-μm-thick electrolytes, with La0.4Ca0.4TiO3 (LCT) and La0.43Ca0.37Ni0.06Ti0.94O3-δ (LCNT) electrodes; data were collected at 900 °C in 3% H2O/H2.

Extended Data Figure 5 Effects of electrolyte thickness on performance.

a, Current–voltage curves from SOCs that are supported by electrolytes of thickness 140 μm, operated between 900 °C and 700 °C in 3% H2O/H2. b, Impedance spectra at 900 °C, at OCV or 0.7 V, and for supporting electrolytes of 80 μm or 140 μm.

Extended Data Figure 6 Long-term stability.

The evolution of power density, polarization resistance (Rp), series resistance (Rs) and voltage over time, for a cell supported by a 140-μm-thick electrolyte (Fig. 1g and Extended Data Fig. 5a) at 750 °C in 3% H2O/H2. Rs and Rp were measured at 0.7 V. Galvanostatic measurements in fuel-cell mode were made under an applied current of 0.6 A cm−2 (0–54 h) and then 0.5 A cm−2 (54–100 h).

Extended Data Figure 7 Extended dataset for Fig. 3.

The sample that had been operated in EC, FC and RC modes (Fig. 2) was subjected to a long-term test at 700 °C, including EC/RC cycling and an extra 40 hours of EC mode. a, Electrochemical data. b, SEM micrograph of the fuel electrode after testing. The data (especially the polarization resistance, Rp, and the microstructure) indicate that the electrode performance and nanostructure are stable throughout ~40 hours of electrolysis in very harsh conditions (50% H2O/N2), possibly indicating that little additional exsolution occurred. This conclusion is also supported by a slight increase in the fuel-cell power density. However, a snapshot of the starting microstructure (that is, after electrochemical switching but before any long-term test) is not available for a direct, quantitative comparison. As illustrated by the microstructure in b, particles are on average smaller than 25 nm and there is negligible growth owing to additional exsolution or coalescence. Note that exsolution will probably self-regulate owing to the formation of a core–shell structure of perovskite grains (suggested in Fig. 1a), the surface having ‘depleted’ Ni ions (and lower A-site deficiency, for example, A0.8B0.94Ni0.06O3 → A0.8B0.94O3 (= A0.85BO3) + 0.06 Ni + 0.03 O2) and the core probably having ‘unaltered’ stoichiometry (A0.8B0.94Ni0.06O3). Because of the lower A-site deficiency of the outer perovskite shell, cation diffusion from the core to the surface and subsequent exsolution will be decelerated and controlled, providing the slow-release mechanism suggested in the text. We also note that, during the 40-hour EC test, the electrode performance was stable, while the series resistance (Rs) increased slightly. After the experiment we found that this was probably due to the cell wiring (Pt), which was severely oxidized because of the harsh conditions. Overall, the results suggest that these nanostructures are very stable in the harsh EC and FC environments.

Extended Data Figure 8 Performance improvement after stability tests.

a, b, Using the sample that was used for the long-term stability test and 20-cyclic test (Fig. 3 and Extended Data Fig. 7), we measured a, current–voltage curves at 700 °C and 900 °C in 3% H2O/H2, and b, impedance spectra at 700 °C and 900 °C at 0.7 V, both before (‘initial’) and after the stability test.

Extended Data Figure 9 SEM image of the microstructure of a full cell.

The cell configuration is: LCNT (fuel electrode) | ScSZ (electrolyte) | LSM–ScSZ (air electrode) (see Methods).

Extended Data Figure 10 Particle analysis from SEM images.

a, Original SEM image. b, Individual particles have been highlighted on the basis of pixel contrast. c, Distribution of particle sizes, based on b. d, Other exsolution characteristics that can be calculated on the basis of b, c.

Rights and permissions

About this article

Cite this article

Myung, Jh., Neagu, D., Miller, D. et al. Switching on electrocatalytic activity in solid oxide cells. Nature 537, 528–531 (2016). https://doi.org/10.1038/nature19090

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature19090

This article is cited by

-

Nanoparticle Exsolution on Perovskite Oxides: Insights into Mechanism, Characteristics and Novel Strategies

Nano-Micro Letters (2024)

-

Real-time insight into the multistage mechanism of nanoparticle exsolution from a perovskite host surface

Nature Communications (2023)

-

Palladium exsolution and dissolution with lanthanum ferrite perovskite oxides

Journal of Materials Science (2023)

-

Anti-phase boundary accelerated exsolution of nanoparticles in non-stoichiometric perovskite thin films

Nature Communications (2022)

-

Boosting the stability of perovskites with exsolved nanoparticles by B-site supplement mechanism

Nature Communications (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.