Abstract

The electrochemical conversion of CO2 and H2O into liquid fuel is ideal for high-density renewable energy storage and could provide an incentive for CO2 capture. However, efficient electrocatalysts for reducing CO2 and its derivatives into a desirable fuel1,2,3 are not available at present. Although many catalysts4,5,6,7,8,9,10,11 can reduce CO2 to carbon monoxide (CO), liquid fuel synthesis requires that CO is reduced further, using H2O as a H+ source. Copper (Cu) is the only known material with an appreciable CO electroreduction activity, but in bulk form its efficiency and selectivity for liquid fuel are far too low for practical use. In particular, H2O reduction to H2 outcompetes CO reduction on Cu electrodes unless extreme overpotentials are applied, at which point gaseous hydrocarbons are the major CO reduction products12,13. Here we show that nanocrystalline Cu prepared from Cu2O (‘oxide-derived Cu’) produces multi-carbon oxygenates (ethanol, acetate and n-propanol) with up to 57% Faraday efficiency at modest potentials (–0.25 volts to –0.5 volts versus the reversible hydrogen electrode) in CO-saturated alkaline H2O. By comparison, when prepared by traditional vapour condensation, Cu nanoparticles with an average crystallite size similar to that of oxide-derived copper produce nearly exclusive H2 (96% Faraday efficiency) under identical conditions. Our results demonstrate the ability to change the intrinsic catalytic properties of Cu for this notoriously difficult reaction by growing interconnected nanocrystallites from the constrained environment of an oxide lattice. The selectivity for oxygenates, with ethanol as the major product, demonstrates the feasibility of a two-step conversion of CO2 to liquid fuel that could be powered by renewable electricity.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Appel, A. M. et al. Frontiers, opportunities, and challenges in biochemical and chemical catalysis of CO2 fixation. Chem. Rev. 113, 6621–6658 (2013)

Jhong, H. R., Ma, S. & Kenis, P. J. A. Electrochemical conversion of CO2 to useful chemicals: current status, remaining challenges, and future opportunities. Curr. Opin. Chem. Eng. 2, 191–199 (2013)

Cole, E. B. & Bocarsly, A. B. in Carbon Dioxide as Chemical Feedstock (ed. Aresta, M.) 291–316 (Wiley, 2010)

Costentin, C., Robert, M. & Saveant, J. M. Catalysis of the electrochemical reduction of carbon dioxide. Chem. Soc. Rev. 42, 2423–2436 (2013)

Benson, E. E., Kubiak, C. P., Sathrum, A. J. & Smieja, J. M. Electrocatalytic and homogeneous approaches to conversion of CO2 to liquid fuels. Chem. Soc. Rev. 38, 89–99 (2009)

Costentin, C., Drouet, S., Robert, M. & Saveant, J. M. A local proton source enhances CO2 electroreduction to CO by a molecular Fe catalyst. Science 338, 90–94 (2012)

Hori, Y. in Modern Aspects of Electrochemistry Vol. 42 (eds Vayenas, C. G., White, R. E. & Gamboa-Aldeco, M. E.) 89–189 (Springer, 2008)

Chen, Y., Li, C. W. & Kanan, M. W. Aqueous CO2 reduction at very low overpotential on oxide-derived Au nanoparticles. J. Am. Chem. Soc. 134, 19969–19972 (2012)

Tornow, C. E., Thorson, M. R., Ma, S., Gewirth, A. A. & Kenis, P. J. A. Nitrogen-based catalysts for the electrochemical reduction of CO2 to CO. J. Am. Chem. Soc. 134, 19520–19523 (2012)

DiMeglio, J. L. & Rosenthal, J. Selective conversion of CO2 to CO with high efficiency using an inexpensive bismuth-based electrocatalyst. J. Am. Chem. Soc. 135, 8798–8801 (2013)

Ebbesen, S. D. & Mogensen, M. Electrolysis of carbon dioxide in solid oxide electrolysis cells. J. Power Sources 193, 349–358 (2009)

Hori, Y., Takahashi, R., Yoshinami, Y. & Murata, A. Electrochemical reduction of CO at a copper electrode. J. Phys. Chem. B 101, 7075–7081 (1997)

Hori, Y., Murata, A., Takahashi, R. & Suzuki, S. Electroreduction of CO to CH4 and C2H4 at a copper electrode in aqueous solutions at ambient temperature and pressure. J. Am. Chem. Soc. 109, 5022–5023 (1987)

Gattrell, M., Gupta, N. & Co, A. A review of the aqueous electrochemical reduction of CO2 to hydrocarbons at copper. J. Electroanal. Chem. 594, 1–19 (2006)

Hori, Y., Takahashi, I., Koga, O. & Hoshi, N. Selective formation of C2 compounds from electrochemical reduction of CO2 at a series of copper single crystal electrodes. J. Phys. Chem. B 106, 15–17 (2002)

Calle-Vallejo, F. & Koper, M. T. M. Theoretical considerations on the electroreduction of CO to C2 species on Cu(100) electrodes. Angew. Chem. Int. Ed. 52, 7282–7285 (2013)

Schouten, K. J. P., Qin, Z. S., Gallent, E. P. & Koper, M. T. M. Two pathways for the formation of ethylene in CO reduction on single-crystal copper electrodes. J. Am. Chem. Soc. 134, 9864–9867 (2012)

Kuhl, K. P., Cave, E. R., Abram, D. N. & Jaramillo, T. F. New insights into the electrochemical reduction of carbon dioxide on metallic copper surfaces. Energy Environ. Sci. 5, 7050–7059 (2012)

Hori, Y., Murata, A. & Takahashi, R. Formation of hydrocarbons in the electrochemical reduction of carbon dioxide at a copper electrode in aqueous solution. J. Chem. Soc. Faraday Trans. I 85, 2309–2326 (1989)

Li, C. W. & Kanan, M. W. CO2 reduction at low overpotential on Cu electrodes resulting from the reduction of thick Cu2O films. J. Am. Chem. Soc. 134, 7231–7234 (2012)

Gileadi, E. Electrode Kinetics for Chemists, Engineers, and Materials Scientists Ch. 1 1–8 (Wiley, 1993)

Hori, Y., Murata, A. & Yoshinami, Y. Adsorption of CO, intermediately formed in electrochemical reduction of CO2, at a copper electrode. J. Chem. Soc. Faraday Trans. 87, 125–128 (1991)

Montoya, J. H., Peterson, A. A. & Nørskov, J. K. Insights into C–C coupling in CO2 electroreduction on copper electrodes. ChemCatChem 5, 737–742 (2013)

Koga, O. et al. Infrared spectroscopic and voltammetric study of adsorbed CO on stepped surfaces of copper monocrystalline electrodes. Electrochim. Acta 50, 2475–2485 (2005)

Shaw, S. K. et al. Role of axially coordinated surface sites for electrochemically controlled carbon monoxide adsorption on single crystal copper electrodes. Phys. Chem. Chem. Phys. 13, 5242–5251 (2011)

Radetic, T., Lancon, F. & Dahmen, U. Chevron defect at the intersection of grain boundaries with free surfaces in Au. Phys. Rev. Lett. 89, 085502 (2002)

Wang, S. Y., Jiang, S. P., White, T. J., Guo, J. & Wang, X. Electrocatalytic activity and interconnectivity of Pt nanoparticles on multiwalled carbon nanotubes for fuel cells. J. Phys. Chem. C 113, 18935–18945 (2009)

Gavrilov, A. N. et al. On the influence of the metal loading on the structure of carbon-supported PtRu catalysts and their electrocatalytic activities in CO and methanol electrooxidation. Phys. Chem. Chem. Phys. 9, 5476–5489 (2007)

Mills, G. A. Status and future opportunities for conversion of synthesis gas to liquid fuels. Fuel 73, 1243–1279 (1994)

Gupta, M., Smith, M. L. & Spivey, J. J. Heterogeneous catalytic conversion of dry syngas to ethanol and higher alcohols on Cu-based catalysts. ACS Catal. 1, 641–656 (2011)

Waszczuk, P., Zelenay, P. & Sobkowski, J. Surface interaction of benzoic-acid with a copper electrode. Electrochim. Acta 40, 1717–1721 (1995)

CRC. Handbook of Chemistry and Physics 9th edn, section 5 (CRC, 2013).

Acknowledgements

We thank Stanford University and the NSF (CHE-1266401) for support of this work. C.W.L. gratefully acknowledges an NSF Predoctoral Fellowship. A portion of this work was performed at NCEM, which is supported by the Office of Science, Office of Basic Energy Sciences of the US Department of Energy under contract number DE-AC02-05CH11231. We thank M. Toney and B. Shyam for assistance with grazing incidence X-ray diffraction performed at SSRL, a national user facility operated by Stanford University on behalf of the Office of Basic Energy Sciences of the US Department of Energy.

Author information

Authors and Affiliations

Contributions

C.W.L. and M.W.K. designed the experiments. C.W.L. prepared and characterized all electrodes and performed all electrochemical experiments; J.C. obtained all TEM images; C.W.L. and M.W.K. wrote the manuscript. All authors contributed to the overall scientific interpretation and edited the manuscript.

Corresponding author

Ethics declarations

Competing interests

C.W.L. and M.W.K. have filed a patent application (WO 2013-US25791, US) covering oxide-derived Cu and other oxide-derived catalysts for electrochemical fuel synthesis.

Extended data figures and tables

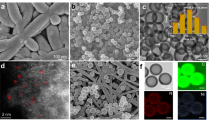

Extended Data Figure 1 Additional physical characterization of OD-Cu 1.

a, X-ray photoelectron spectroscopy survey spectrum. b, High-resolution X-ray photoelectron spectrum of the Cu LMM region. c, High-resolution X-ray photoelectron spectrum of the Cu 2p peaks. d, Low-resolution SEM image.

Extended Data Figure 2 Additional physical characterization of OD-Cu 2.

a, X-ray photoelectron spectroscopy survey spectrum. b, High-resolution X-ray photoelectron spectrum of the Cu LMM region. c, High-resolution X-ray photoelectron spectrum of the Cu 2p peaks. d, Low-resolution SEM image.

Extended Data Figure 3 Additional physical characterization of Cu nanoparticle electrodes.

a, X-ray photoelectron spectroscopy survey spectrum. b, High-resolution X-ray photoelectron spectrum of the Cu LMM region. c, High-resolution X-ray photoelectron spectrum of the Cu 2p peaks. d, Low-resolution SEM image.

Extended Data Figure 4 Additional grazing-incidence X-ray diffraction pattern data, collected using synchrotron X-rays at 11.5 keV.

a, X-ray diffraction patterns for OD-Cu 1 and OD-Cu 2. b, c, Williamson–Hall plots for OD-Cu 1 (b) and for OD-Cu 2 (c), where B = integral breadth of the peak, and the points highlighted in red have been excluded. To calculate crystallite size and strain, the following relationships were used: B = Kλ/<D>cosθ + 4εtanθ, where <D> is the average crystallite size, λ is the wavelength, ε is the non-uniform strain (microstrain), and the Scherrer constant K ≈ 1.

Extended Data Figure 5 Electrochemical surface area measurement.

a, b, Determination of double-layer capacitance over a range of scan rates for an OD-Cu 1 electrode after 1 h bulk electrolysis. c, d, Determination of double-layer capacitance over a range of scan rates for an OD-Cu 2 electrode after 12 h bulk electrolysis at –0.3 V versus RHE in 0.1 M KOH. a, c, Cyclic voltammagrams taken over a range of scan rates. b, d, Current due to double-layer charging plotted against cyclic voltammetry scan rate.

Extended Data Figure 6 Representative bulk-electrolysis data for CO reduction on OD-Cu 1.

a, Current density over time for the reduction of Cu2O to form active OD-Cu. b, Current density over time (left) for OD-Cu 1 at –0.4 V versus RHE in 0.1 M KOH, saturated with 1 atm CO and Faraday efficiency over time (right) for H2 (green), C2H4 (red), and C2H6 (blue). Efficiencies for EtOH and AcO– were obtained at the end of the electrolysis.

Extended Data Figure 7 Representative NMR spectrum for an OD-Cu 1 bulk electrolysis at –0.5 V versus RHE in 0.1 M KOH, saturated with 2.4 atm CO.

DMSO, dimethyl sulphoxide.

Extended Data Figure 8 Additional Tafel data collected in 0.1 M KOH, saturated with 1 atm CO.

a, Geometric current density for CO reduction versus potential for OD-Cu 2 and Cu nanoparticles. b, Surface-area-normalized current density for H2 evolution versus potential for OD-Cu 1, OD-Cu 2, Cu nanoparticles and polycrystalline Cu foil.

Extended Data Figure 9 CO reduction bulk electrolysis data for OD-Cu 1 in 1 M KOH, saturated with 1 atm CO.

a, Faraday efficiency for various products versus potential. b, Total current density and partial current density for CO reduction versus potential. c, d, SEM images of OD-Cu 1 after electrolysis in 1 M KOH.

Rights and permissions

About this article

Cite this article

Li, C., Ciston, J. & Kanan, M. Electroreduction of carbon monoxide to liquid fuel on oxide-derived nanocrystalline copper. Nature 508, 504–507 (2014). https://doi.org/10.1038/nature13249

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature13249

This article is cited by

-

Dual-site catalysts featuring platinum-group-metal atoms on copper shapes boost hydrocarbon formations in electrocatalytic CO2 reduction

Nature Communications (2023)

-

In-situ spectroscopic probe of the intrinsic structure feature of single-atom center in electrochemical CO/CO2 reduction to methanol

Nature Communications (2023)

-

A silver–copper oxide catalyst for acetate electrosynthesis from carbon monoxide

Nature Synthesis (2023)

-

Energy- and carbon-efficient CO2/CO electrolysis to multicarbon products via asymmetric ion migration–adsorption

Nature Energy (2023)

-

Pb-rich Cu grain boundary sites for selective CO-to-n-propanol electroconversion

Nature Communications (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.