Abstract

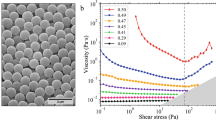

Although liquids typically flow around intruding objects, a counterintuitive phenomenon occurs in dense suspensions of micrometre-sized particles: they become liquid-like when perturbed lightly, but harden when driven strongly1,2,3,4,5. Rheological experiments have investigated how such thickening arises under shear, and linked it to hydrodynamic interactions1,3 or granular dilation2,4. However, neither of these mechanisms alone can explain the ability of suspensions to generate very large, positive normal stresses under impact. To illustrate the phenomenon, such stresses can be large enough to allow a person to run across a suspension without sinking, and far exceed the upper limit observed under shear or extension2,4,6,7. Here we show that these stresses originate from an impact-generated solidification front that transforms an initially compressible particle matrix into a rapidly growing jammed region, ultimately leading to extraordinary amounts of momentum absorption. Using high-speed videography, embedded force sensing and X-ray imaging, we capture the detailed dynamics of this process as it decelerates a metal rod hitting a suspension of cornflour (cornstarch) in water. We develop a model for the dynamic solidification and its effect on the surrounding suspension that reproduces the observed behaviour quantitatively. Our findings suggest that prior interpretations of the impact resistance as dominated by shear thickening need to be revisited.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Cheng, X., McCoy, J. H., Israelachvili, J. N. & Cohen, I. Imaging the microscopic structure of shear thinning and thickening colloidal suspensions. Science 333, 1276–1279 (2011)

Brown, E. et al. Generality of shear thickening in dense suspensions. Nature Mater. 9, 220–224 (2010)

Wagner, N. J. & Brady, J. F. Shear thickening in colloidal dispersions. Phys. Today 62, 27–32 (2009)

Fall, A., Huang, N., Bertrand, F., Ovarlez, G. & Bonn, D. Shear thickening of cornstarch suspensions as a reentrant jamming transition. Phys. Rev. Lett. 100, 018301 (2008)

Merkt, F. S., Deegan, R. D., Goldman, D. I., Rericha, E. C. & Swinney, H. L. Persistent holes in a fluid. Phys. Rev. Lett. 92, 184501 (2004)

Bischoff White, E. E., Chellamuthu, M. & Rothstein, J. P. Extensional rheology of a shear-thickening cornstarch and water suspension. Rheol. Acta 49, 119–129 (2010)

Smith, M. I., Besseling, R., Cates, M. E. & Bertola, V. Dilatancy in the flow and fracture of stretched colloidal suspensions. Nature Commun. 1, 114–115 (2010)

Brady, J. F. & Bossis, G. Stokesian dynamics. Annu. Rev. Fluid Mech. 20, 111–157 (1988)

Maranzano, B. J. & Wagner, N. J. The effects of particle-size on reversible shear thickening of concentrated colloidal dispersions. J. Chem. Phys. 114, 10514–10527 (2001)

Brown, E. et al. Shear thickening and jamming in densely packed suspensions of different particle shapes. Phys. Rev. E 84, 031408 (2011)

Brown, E. & Jaeger, H. M. Dynamic jamming point for shear thickening suspensions. Phys. Rev. Lett. 103, 086001 (2009)

Bi, D., Zhang, J., Chakraborty, B. & Behringer, R. P. Jamming by shear. Nature 480, 355–358 (2011)

Cates, M. E., Haw, M. D. & Holmes, C. B. Dilatancy, jamming, and the physics of granulation. J. Phys. Condens. Matter 17, S2517–S2531 (2005)

Brown, E. & Jaeger, H. M. The role of dilation and confining stresses in shear thickening of dense suspensions. J. Rheol. 56, 875–923 (2012)

von Kann, S., Snoeijer, J. H., Lohse, D. & van der Meer, D. Nonmonotonic settling of a sphere in a cornstarch suspension. Phys. Rev. E 84, 060401 (2011)

Liu, B., Shelley, M. & Zhang, J. Focused force transmission through an aqueous suspension of granules. Phys. Rev. Lett. 105, (2010)

Royer, J. R. et al. Formation of granular jets observed by high-speed X-ray radiography. Nature Phys. 1, 164–167 (2005)

Fedorchenko, A. I. & Wang, A. B. On some common features of drop impact on liquid surfaces. Phys. Fluids 16, 1349–1365 (2004)

Moghisi, M. & Squire, P. T. An experimental investigation of the initial force of impact on a sphere striking a liquid surface. J. Fluid Mech. 108, 133–146 (1981)

Gómez, L. R., Turner, A. M., van Hecke, M. & Vitelli, V. Shocks near jamming. Phys. Rev. Lett. 108, 058001 (2012)

Debenedetti, P. G. & Stillinger, F. H. Supercooled liquids and the glass transition. Nature 410, 259–267 (2001)

Papoular, M. Dense suspensions and supercooled liquids: dynamic similarities. Phys. Rev. E 60, 2408–2410 (1999)

Ediger, M. D., Angell, C. A. & Nagel, S. R. Supercooled liquids and glasses. J. Phys. Chem. 100, 13200–13212 (1996)

Graham, D. J., Magdolinos, P. & Tosi, M. Investigation of the solidification of benzophenone in the supercooled liquid state. J. Phys. Chem. 99, 4757–4762 (1995)

Hocking, L. M. The effect of slip on the motion of a sphere close to a wall and of two adjacent spheres. J. Eng. Math. 7, 207–221 (1973)

Davis, R. H. & Serayssol, J.-M. The elastohydrodynamic collision of two spheres. J. Fluid Mech. 163, 479–497 (1986)

Glasheen, J. W. & McMahon, T. A. Vertical water entry of disks at low Froude numbers. Phys. Fluids 8, 2078–2083 (1996)

Richardson, E. G. The impact of a solid on a liquid surface. Proc. Phys. Soc. 61, 352–367 (1948)

Brennen, C. E. A Review of Added Mass and Fluid Inertial Forces Report CR 82.010 (Naval Civil Engineering Laboratory, 1982)

Liu, A. J. & Nagel, S. R. Jamming is not just cool any more. Nature 396, 21–22 (1998)

Acknowledgements

We thank E. Brown, J. Burton, J. Ellowitz, Q. Guo, W. Irvine, M. Miskin, S. Nagel, C. Orellana, V. Vitelli, T. Witten and W. Zhang for discussions and J. Burton for his PIV code. This work was supported by NSF through its MRSEC programme (DMR-0820054) and by the US Army Research Office through grant number W911NF-12-1-0182. S.R.W. acknowledges support from a Millikan fellowship.

Author information

Authors and Affiliations

Contributions

S.R.W. and H.M.J. conceived the study and wrote the paper. S.R.W. performed the experimental work, analysed results and created the model.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

This file contains Supplementary Discussions I-III, Supplementary Figures 1-4 and an additional reference. (PDF 811 kb)

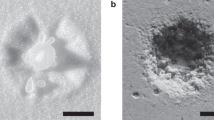

Supplementary Movie 1

This file contains a high-speed video of rod (mrod = 0.368 kg, rrod = 0.93 cm) impact into a cornstarch and water suspension (Φ = 0.49, μ = 1.0 cP) at v = 0~0.5 m-1. Video covers ~10 ms before to 50 ms after impact. Rather than penetrating and creating a splash, the rod pushes the surface downward, causing a growing depression around the impact site. (MOV 975 kb)

Supplementary Movie 2

This file contains a high-speed video of depression evolution via laser-line projection. The rod (centred on left edge of field of view) and suspension are black, while the laser on the suspension surface creates the bright line. Video covers ~10 ms before to 50 ms after impact. The maximum radial extent of the depression grows with the distance travelled by the rod. (MOV 517 kb)

Supplementary Movie 3

This file contains an X-ray video of suspension interior during impact. Duration is ~0.67 s. Tracer particles loaded into the central plane below the rod are displaced by the dynamic solidification, while outside this the suspension responds in a fluid-like manner to ensure global volume conservation. (MOV 942 kb)

Rights and permissions

About this article

Cite this article

Waitukaitis, S., Jaeger, H. Impact-activated solidification of dense suspensions via dynamic jamming fronts. Nature 487, 205–209 (2012). https://doi.org/10.1038/nature11187

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature11187

This article is cited by

-

A novel shear-stiffening supramolecular material derived from diboron structure

Science China Materials (2023)

-

Development of cornstarch-based shear thickening fluid and characterization of the effects of the addition of halloysite nanotubes-silica hybrid reinforcements

Journal of Polymer Research (2023)

-

Investigating projectile penetration into immersed granular beds via CFD-DEM coupling

Granular Matter (2023)

-

Numerical simulation of shear jamming in a shear thickening fluid under impact

Rheologica Acta (2023)

-

High-strain-rate Response of GFRP Composites Impregnated with Multiwalled Carbon Nanotube Reinforced Shear Thickening Fluid

Applied Composite Materials (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.