Abstract

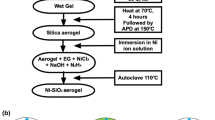

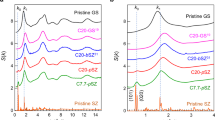

The carbothermal reduction of silica into silicon requires the use of temperatures well above the silicon melting point (≥2,000 °C)1. Solid silicon has recently been generated directly from silica at much lower temperatures (≤850 °C) via electrochemical reduction in molten salts2,3. However, the silicon products of such electrochemical reduction did not retain the microscale morphology of the starting silica reactants2,3. Here we demonstrate a low-temperature (650 °C) magnesiothermic reduction process for converting three-dimensional nanostructured silica micro-assemblies into microporous nanocrystalline silicon replicas. The intricate nanostructured silica microshells (frustules) of diatoms (unicellular algae) were converted into co-continuous, nanocrystalline mixtures of silicon and magnesia by reaction with magnesium gas. Selective magnesia dissolution then yielded an interconnected network of silicon nanocrystals that retained the starting three-dimensional frustule morphology. The silicon replicas possessed a high specific surface area (>500 m2 g-1), and contained a significant population of micropores (≤20 Å). The silicon replicas were photoluminescent, and exhibited rapid changes in impedance upon exposure to gaseous nitric oxide (suggesting a possible application in microscale gas sensing). This process enables the syntheses of microporous nanocrystalline silicon micro-assemblies with multifarious three-dimensional shapes inherited from biological4,5,6 or synthetic silica templates7,8,9 for sensor, electronic, optical or biomedical applications10,11,12,13.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Nagamori, M., Malinsky, I. & Claveau, A. Thermodynamics of the silicon-carbon-oxygen system for the production of silicon carbide and metallic silicon. Metall. Trans. B 17, 503–514 (1986)

Nohira, T., Yasuda, K. & Ito, Y. Pinpoint and bulk electrochemical reduction of insulating silicon dioxide to silicon. Nature Mater. 2, 397–401 (2003)

Yasuda, K., Nohira, T., Takahashi, K., Hagiwara, R. & Ogata, Y. H. Electrolytic reduction of a powder-molded SiO2 pellet in molten CaCl2 and acceleration of reduction by Si addition to the pellet. J. Electrochem. Soc. 152, D232–D237 (2005)

Round, F. E., Crawford, R. M. & Mann, D. G. The Diatoms: Biology and Morphology of the Genera (Cambridge Univ. Press, New York, 2000)

Aizenberg, J. et al. Skeleton of Euplectella sp.: structural hierarchy from the nanoscale to the macroscale. Science 309, 275–278 (2005)

Hall, S. R., Bolger, H. & Mann, S. Morphosynthesis of complex inorganic forms using pollen grain templates. Chem. Commun. 2784–2785 (2003)

Blaaderen, A., Ruel, R. & Wiltzius, P. Template-directed colloidal crystallization. Nature 385, 321–324 (1997)

Cha, J. N., Stucky, G. D., Morse, D. E. & Deming, T. J. Biomimetic synthesis of ordered silica structures mediated by block copolypeptides. Nature 403, 289–292 (2000)

Fan, H. et al. Rapid prototyping of patterned functional nanostructures. Nature 405, 56–60 (2000)

Cullis, A. G. & Canham, L. T. Visible light emission due to quantum size effects in highly porous crystalline silicon. Nature 353, 335–338 (1991)

Baratto, C. et al. Front-side micromachined porous silicon nitrogen dioxide gas sensor. Thin Solid Films 391, 261–264 (2001)

Shin, H.-C., Corno, J. A., Gole, J. L. & Liu, M. Porous silicon negative electrodes for rechargeable lithium batteries. J. Power Sources 139, 314–320 (2005)

Bengtsson, M. et al. Applications of microstructured porous silicon as a biocatalytic surface. Phys. Status Solidi A 182, 495–504 (2000)

Powder Diffraction File Card No. 27–1402 for Si, Card No. 45–946 for MgO, Card No. 35–0773 for Mg2Si (International Center on Diffraction Data, Newtown Square, Pennsylvania); 〈www.icdd.com〉.

Bouvard, D. & Lange, F. F. Relation between percolation and particle coordination in binary powder mixtures. Acta Metall. Mater. 39, 3083–3090 (1991)

Barrett, E. P., Joyner, L. G. & Halenda, P. P. The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms. J. Am. Chem. Soc. 73, 373–380 (1951)

Barin, I. Thermochemical Data of Pure Substances 3rd edn, pages 994, 1012, 1014, 1481, 1504, 1505 (VCH, Weinheim, 1995)

Wynnyckyj, J. R. & Rao, D. B. The mechanism of reduction of silica by magnesium vapor. High Temp. Sci. 8, 203–217 (1976)

Banerjee, H. D., Sen, S. & Acharya, H. N. Investigations on the production of silicon from rice husks by the magnesium method. Mater. Sci. Eng. 52, 173–179 (1982)

Sandhage, K. H. et al. Novel, bioclastic route to self-assembled, 3D, chemically tailored meso/nanostructures: shape-preserving reactive conversion of biosilica (diatom) microshells. Adv. Mater. 14, 429–433 (2002)

Cullity, B. D. Elements of X-ray Diffraction 101–102 (Addison-Wesley, Reading, Massachusetts, 1978)

Watanabe, K., Okada, T., Choe, I. & Sato, Y. Organic vapor sensitivity in a porous silicon device. Sensors Actuators B 33, 194–197 (1996)

Boarino, L. et al. NO2 monitoring at room temperature by a porous silicon gas sensor. Mater. Sci. Eng. B 69–70, 210–214 (2000)

Seals, L., Gole, J. L., Tse, L. A. & Hesketh, P. J. Rapid, reversible, sensitive porous silicon gas sensor. J. Appl. Phys. 91, 2519–2523 (2002)

Balagurov, L. A., Leiferov, B. M., Petrova, E. A., Orlov, A. F. & Panasenko, E. M. Influence of water and alcohols on photoluminescence of porous silicon. J. Appl. Phys. 79, 7143–7147 (1996)

Gelloz, B., Kojima, A. & Koshida, N. Highly efficient and stable luminescence of nanocrystalline porous silicon treated by high-pressure water vapour annealing. Appl. Phys. Lett. 87, 031107 (2005)

Miron, A. S., Gomez, A. C., Camacho, F. G., Grima, E. M. & Chisti, Y. Comparative evaluation of compact photobioreactors for large-scale monoculture of microalgae. J. Biotechnol. 70, 249–270 (1999)

Schmid, A.-M. M., Borowitzka, M. A. & Volcani, B. E. in Cytomorphogenesis in Plants (ed. Kiermayer, O.) Cell Biology Monographs 8 63–97 (Springer, Vienna, 1981)

Li, X., He, Y., Talukdar, S. S. & Swihart, M. T. Process for preparing macroscopic quantities of brightly photoluminescent silicon nanoparticles with emission spanning the visible spectrum. Langmuir 19, 8490–8496 (2003)

Acknowledgements

This work was supported by the US Air Force Office of Scientific Research (H. C. DeLong and J. Fuller) and the US Office of Naval Research (M. Spector). We thank M. Bestor for assistance with XPS analysis and S. Yoo for help with focused ion beam milling.

Author Contributions Z.B., M.R.W., S.M.A., P.D.G., M.B.D. and K.H.S. conceived, developed and demonstrated the low-temperature magnesiothermic reduction and selective dissolution process. S.S. prepared and tested silicon replica gas sensors. G.A. cultured diatoms for conversion. Transmission electron microscope and BET analyses were conducted by Y.C. and B.C.C., respectively. H.W.A. and M.L. conducted and analysed FTIR measurements. Z.K. and C.J.S. conducted and analysed photoluminescence measurements. M.B.D. conducted fluorescence microscopy. Overall data analyses, project planning and paper preparation were largely conducted by Z.B. and K.H.S.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

Reprints and permissions information is available at www.nature.com/reprints. The authors declare no competing financial interests.

Supplementary information

Supplementary Figures and Methods

This file contains Supplementary Figures S1-S5 with Legends and Supplementary Methods. Figure S1 reveals silicon-converted Melosira nummoloides frustule replicas. Figures S2 and S3 provide XPS and FTIR confirmation of silicon in Aulacoseira frustule replicas. Figure S4 reveals the significant micropore population in silicon replicas of Aulacoseira frustules. Figure S5 demonstrates the photoluminescence of silicon Aulacoseira frustule replicas after immersion in water. The equipment and conditions used to obtain the secondary electron, transmission electron, and fluorescence microscope images of silica and silicon-converted diatom frustules are described in Supplementary Methods. (PDF 1127 kb)

Rights and permissions

About this article

Cite this article

Bao, Z., Weatherspoon, M., Shian, S. et al. Chemical reduction of three-dimensional silica micro-assemblies into microporous silicon replicas. Nature 446, 172–175 (2007). https://doi.org/10.1038/nature05570

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1038/nature05570

This article is cited by

-

Silicon nanoparticles: fabrication, characterization, application and perspectives

Micro and Nano Systems Letters (2023)

-

Green utilization of silicon slime: recovery of Si and synergetic preparation of porous silicon as lithium-ion battery anode materials

Ionics (2023)

-

A Study on the Heat Effect during Magnesiothermic Reduction of Porous SiO2

Silicon (2022)

-

Magnesiothermic Reduction of Natural Quartz

Metallurgical and Materials Transactions B (2022)

-

Metallothermic Reduction of Silica–Carbon Composites: Revealing the Relationship Between Silicon-Based Products and the Reactivity of Reductants

Metallurgical and Materials Transactions B (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.