Abstract

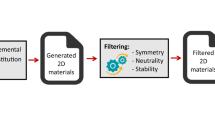

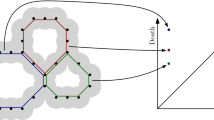

There is currently a push towards big data and data mining in materials research to accelerate discovery. Zeolites, metal–organic frameworks and other related crystalline porous materials are not immune to this phenomenon, as evidenced by the proliferation of porous structure databases and computational gas-adsorption screening studies over the past decade. The endeavour to identify the best materials for various gas separation and storage applications has led not only to thousands of synthesized structures, but also to the development of algorithms for building hypothetical materials. The materials databases assembled with these algorithms contain a much wider range of complex pore structures than have been synthesized, with the reasoning being that we have discovered only a small fraction of realizable structures and expanding upon these will accelerate rational design. In this Review, we highlight the methods developed to build these databases, and some of the important outcomes from large-scale computational screening studies.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Flanigen, E. M., Broach, R. W. & Wilson, S. T. in Zeolites in Industrial Separation and Catalysis 1–26 (Wiley, 2010).

Zimmermann, N. E. R. & Haranczyk, M. History and utility of zeolite framework-type discovery from a data-science perspective. Cryst. Growth Des. 16, 3043–3048 (2016).

Hoskin, B. F. & Robson, R. Design and construction of a new class of scaffolding-like materials comprising infinite polymeric frameworks of 3D-linked molecular rods. A reappraisal of the Zn(CN)2 and Cd(CN)2 structures and the synthesis and structure of the diamond-related frameworks [N(CH3)4][CuIZnII(CN)4] and CuI[4,4′,4″,4‴-tetracyanotetraphenylmethane]BF4∙x C6H5NO2 . J. Am. Chem. Soc. 112, 1546–1554 (1990).

Chui, S. S.-Y., Lo, S. M.-F., Charmant, J. P. H., Orpen, A. G. & Williams, I. D. A. Chemically functionalizable nanoporous material [Cu3(TMA)2(H2O)3]n . Science 283, 1148–1150 (1999).

Li, H., Eddaoudi, M., O’Keeffe, M. & Yaghi, O. M. Design and synthesis of an exceptionally stable and highly porous metal–organic framework. Nature 402, 276–279 (1999).

Yaghi, O. M. & Li, H. Hydrothermal synthesis of a metal–organic framework containing large rectangular channels. J. Am. Chem. Soc. 117, 10401–10402 (1995).

Batten, S. R. et al. Terminology of metal–organic frameworks and coordination polymers (IUPAC Recommendations 2013). Pure Appl. Chem. 85, 1715–1724 (2013).

Côté, A. P. et al. Porous, crystalline, covalent organic frameworks. Science 310, 1166–1170 (2005).

El-Kaderi, H. M. et al. Designed synthesis of 3D covalent organic frameworks. Science 316, 268–272 (2007).

Banerjee, R. et al. High-throughput synthesis of zeolitic imidazolate frameworks and application to CO2 capture. Science 319, 939–943 (2008).

Lu, W. et al. Porous polymer networks: synthesis, porosity, and applications in gas storage/separation. Chem. Mater. 22, 5964–5972 (2010).

Yaghi, O. M. et al. Reticular synthesis and the design of new materials. Nature 423, 705–714 (2003).

Ockwig, N. W., Delgado-Friedrichs, O., O’Keeffe, M. & Yaghi, O. M. Reticular chemistry: occurrence and taxonomy of nets and grammar for the design of frameworks. Acc. Chem. Res. 38, 176–182 (2005).

Delgado-Friedrichs, O., O’Keeffe, M. & Yaghi, O. M. Taxonomy of periodic nets and the design of materials. Phys. Chem. Chem. Phys. 9, 1035–1043 (2007).

Bonneau, C., Delgado-Friedrichs, O., O’Keeffe, M. & Yaghi, O. M. Three-periodic nets and tilings: minimal nets. Acta Crystallogr. A. 60, 517–520 (2004).

Delgado-Friedrichs, O. & O’Keeffe, M. Crystal nets as graphs: terminology and definitions. J. Solid State Chem. 178, 2480–2485 (2005).

Li, M., Li, D., O’Keeffe, M. & Yaghi, O. M. Topological analysis of metal–organic frameworks with polytopic linkers and/or multiple building units and the minimal transitivity principle. Chem. Rev. 114, 1343–1370 (2014).

O’Keeffe, M. & Yaghi, O. M. Deconstructing the crystal structures of metal–organic frameworks and related materials into their underlying nets. Chem. Rev. 112, 675–702 (2012).

Schoedel, A., Li, M., Li, D., O’Keeffe, M. & Yaghi, O. M. Structures of metal–organic frameworks with rod secondary building units. Chem. Rev. 116, 12466–12535 (2016).

Blatov, V. A., Carlucci, L., Ciani, G. & Proserpio, D. M. Interpenetrating metal–organic and inorganic 3D networks: a computer-aided systematic investigation. Part I. Analysis of the Cambridge Structural Database. CrystEngComm 6, 377–395 (2004).

Alexandrov, E. V., Blatov, V. A., Kochetkov, A. V. & Proserpio, D. M. Underlying nets in three-periodic coordination polymers: topology, taxonomy and prediction from a computer-aided analysis of the Cambridge Structural Database. CrystEngComm 13, 3947–3958 (2011).

Farha, O. K. et al. De novo synthesis of a metal–organic framework material featuring ultrahigh surface area and gas storage capacities. Nat. Chem. 2, 944–948 (2010).

Vaidhyanathan, R. et al. Direct observation and quantification of CO2 binding within an amine-functionalized nanoporous solid. Science 330, 650–653 (2010).

McDonald, T. M. et al. Cooperative insertion of CO2 in diamine-appended metal–organic frameworks. Nature 519, 303–308 (2015).

Lyne, P. D. Structure-based virtual screening: an overview. Drug Discov. Today 7, 1047–1055 (2002).

Colón, Y. J. & Snurr, R. Q. High-throughput computational screening of metal–organic frameworks. Chem. Soc. Rev. 43, 5735–5749 (2014).

Martin, R. L. et al. In silico design of three-dimensional porous covalent organic frameworks via known synthesis routes and commercially available species. J. Phys. Chem. C 118, 23790–23802 (2014).

Simon, C. M. et al. Optimizing nanoporous materials for gas storage. Phys. Chem. Chem. Phys. 16, 5499–5513 (2014).

Simon, C. M. et al. The materials genome in action: identifying the performance limits for methane storage. Energy Environ. Sci. 8, 1190–1199 (2015).

Martin, R. L., Simon, C. M., Smit, B. & Haranczyk, M. In silico design of porous polymer networks: high-throughput screening for methane storage materials. J. Am. Chem. Soc. 136, 5006–5022 (2014).

Ohno, H. & Mukae, Y. Machine learning approach for prediction and search: application to methane storage in a metal–organic framework. J. Phys. Chem. C 120, 23963–23968 (2016).

Martin, R. L., Lin, L.-C., Jariwala, K., Smit, B. & Haranczyk, M. Mail-order metal–organic frameworks (MOFs): designing isoreticular MOF-5 analogues comprising commercially available organic molecules. J. Phys. Chem. C 117, 12159–12167 (2013).

Kim, J. et al. New materials for methane capture from dilute and medium-concentration sources. Nat. Commun. 4, 1694 (2013).

Gómez-Gualdrón, D. A. et al. Impact of the strength and spatial distribution of adsorption sites on methane deliverable capacity in nanoporous materials. Chem. Eng. Sci. 159, 18–30 (2017).

Gómez-Gualdrón, D. A., Wilmer, C. E., Farha, O. K., Hupp, J. T. & Snurr, R. Q. Exploring the limits of methane storage and delivery in nanoporous materials. J. Phys. Chem. C 118, 6941–6951 (2014).

Fu, J., Tian, Y. & Wu, J. Seeking metal–organic frameworks for methane storage in natural gas vehicles. Adsorption 21, 499–507 (2015).

Keskin, S. & Sholl, D. S. Efficient methods for screening of metal organic framework membranes for gas separations using atomically detailed models. Langmuir 25, 11786–11795 (2009).

Wu, D. et al. Large-scale computational screening of metal–organic frameworks for CH4/H2 separation. AIChE J. 58, 2078–2084 (2012).

Yazaydın, A. O. et al. Screening of metal–organic frameworks for carbon dioxide capture from flue gas using a combined experimental and modeling approach. J. Am. Chem. Soc. 131, 18198–18199 (2009).

Koh, H. S., Rana, M. K., Hwang, J. & Siegel, D. J. Thermodynamic screening of metal-substituted MOFs for carbon capture. Phys. Chem. Chem. Phys. 15, 4573 (2013).

Krishna, R. & van Baten, J. M. In silico screening of metal–organic frameworks in separation applications. Phys. Chem. Chem. Phys. 13, 10593–10616 (2011).

Chung, Y. G. et al. Computation-ready, experimental metal–organic frameworks: a tool to enable high-throughput screening of nanoporous crystals. Chem. Mater. 26, 6185–6192 (2014).

Allen, F. H. The Cambridge Structural Database: a quarter of a million crystal structures and rising. Acta Crystallogr. Sect. B Struct. Sci. 58, 380–388 (2002).

Pophale, R., Cheeseman, P. A. & Deem, M. W. A database of new zeolite-like materials. Phys. Chem. Chem. Phys. 13, 12407–12412 (2011).

Deem, M. W., Pophale, R., Cheeseman, P. A. & Earl, D. J. Computational discovery of new zeolite-like materials. J. Phys. Chem. C 113, 21353–21360 (2009).

Lin, L.-C. et al. In silico screening of carbon-capture materials. Nat. Mater. 11, 633–641 (2012).

Kim, J., Lin, L., Swisher, J. A., Haranczyk, M. & Smit, B. Predicting large CO2 adsorption in aluminosilicate zeolites for postcombustion carbon dioxide capture. J. Am. Chem. Soc. 134, 18940–18943 (2012).

Kim, J., Abouelnasr, M., Lin, L.-C. & Smit, B. Large-scale screening of zeolite structures for CO2 membrane separations. J. Am. Chem. Soc. 135, 7545–7552 (2013).

Kim, J. et al. Large-scale computational screening of zeolites for ethane/ethene separation. Langmuir 28, 11914–11919 (2012).

Bai, P. et al. Discovery of optimal zeolites for challenging separations and chemical transformations using predictive materials modeling. Nat. Commun. 6, 5912 (2015).

Mellot Draznieks, C., Newsam, J. M., Gorman, A. M., Freeman, C. M. & Férey, G. De novo prediction of inorganic structures developed through Automated Assembly of Secondary Building Units (AASBU method). Angew. Chem. Int. Ed. 39, 2270–2275 (2000).

Kirkpatrick, S., Gelatt, C. D. & Vecchi, M. P. Optimization by simulated annealing. Science 220, 671–680 (1983).

Falcioni, M. & Deem, M. W. A biased Monte Carlo scheme for zeolite structure solution. J. Chem. Phys. 110, 1754–1766 (1999).

Deem, M. W. & Newsam, J. M. Determination of 4-connected framework crystal structures by simulated annealing. Nature 342, 260–262 (1989).

Mellot-Draznieks, C., Dutour, J. & Férey, G. Hybrid organic–inorganic frameworks: routes for computational design and structure prediction. Angew. Chem. Int. Ed. 43, 6290–6296 (2004).

Mellot-Draznieks, C. et al. Computational design and prediction of interesting not-yet-synthesized structures of inorganic materials by using building unit concepts. Chem. Eur. J. 8, 4102–4113 (2002).

Wilmer, C. E. et al. Large-scale screening of hypothetical metal–organic frameworks. Nat. Chem. 4, 83–89 (2012).

Chen, B., Eddaoudi, M., Hyde, S. T., O’Keeffe, M. & Yaghi, O. M. Interwoven metal–organic framework on a periodic minimal surface with extra-large pores. Science 291, 1021–1023 (2001).

Skiena, S. S. in The Algorithm Design Manual Ch. 2 31–65 (Springer, 2009).

Sikora, B. J., Winnegar, R., Proserpio, D. M. & Snurr, R. Q. Textural properties of a large collection of computationally constructed MOFs and zeolites. Micropor. Mesopor. Mater. 186, 207–213 (2014).

Martin, R. L. & Haranczyk, M. Exploring frontiers of high surface area metal–organic frameworks. Chem. Sci. 4, 1781–1785 (2013).

Martin, R. L. & Haranczyk, M. Optimization-based design of metal–organic framework materials. J. Chem. Theory Comput. 9, 2816–2825 (2013).

Bao, Y., Martin, R. L., Haranczyk, M. & Deem, M. W. In silico prediction of MOFs with high deliverable capacity or internal surface area. Phys. Chem. Chem. Phys. 17, 11962–11973 (2015).

Gómez-Gualdrón, D. A. et al. Evaluating topologically diverse metal–organic frameworks for cryo-adsorbed hydrogen storage. Energy Environ. Sci. 9, 3279–3289 (2016).

Wang, T. C. et al. Ultrahigh surface area zirconium MOFs and insights into the applicability of the BET theory. J. Am. Chem. Soc. 137, 3585–3591 (2015).

Coudert, F.-X. & Fuchs, A. H. Computational characterization and prediction of metal–organic framework properties. Coord. Chem. Rev. 307, 211–236 (2016).

Martin, R. L. & Haranczyk, M. Construction and characterization of structure models of crystalline porous polymers. Cryst. Growth Des. 14, 2431–2440 (2014).

Willems, T. F., Rycroft, C. H., Kazi, M., Meza, J. C. & Haranczyk, M. Algorithms and tools for high-throughput geometry-based analysis of crystalline porous materials. Micropor. Mesopor. Mater. 149, 134–141 (2012).

Pinheiro, M. et al. Characterization and comparison of pore landscapes in crystalline porous materials. J. Mol. Graph. Model. 44, 208–219 (2013).

O’Keeffe, M., Peskov, M. A., Ramsden, S. J. & Yaghi, O. M. The reticular chemistry structure resource (RCSR) database of, and symbols for, crystal nets. Acc. Chem. Res. 41, 1782–1789 (2008).

Xiang, Z. et al. Systematic tuning and multifunctionalization of covalent organic polymers for enhanced carbon capture. J. Am. Chem. Soc. 137, 13301–13307 (2015).

Bao, Y. et al. In silico discovery of high deliverable capacity metal–organic frameworks. J. Phys. Chem. C 119, 186–195 (2015).

Addicoat, M. A., Coupry, D. E. & Heine, T. AuToGraFS: automatic topological generator for framework structures. J. Phys. Chem. A 118, 9607–9614 (2014).

Gale, J. GULP: a computer program for the symmetry-adapted simulation of solids. J. Chem. Soc. Faraday Trans. 93, 629–637 (1997).

Coupry, D. E., Addicoat, M. A. & Heine, T. Extension of the universal force field for metal–organic frameworks. J. Chem. Theory Comput. 12, 5215–5225 (2016).

Addicoat, M. A., Vankova, N., Akter, I. F. & Heine, T. Extension of the universal force field to metal–organic frameworks. J. Chem. Theory Comput. 10, 880–891 (2014).

Boyd, P. G. & Woo, T. K. A generalized method for constructing hypothetical nanoporous materials of any net topology from graph theory. CrystEngComm 18, 3777–3792 (2016).

US Department of Energy. ARPA-E methane opportunities for vehicular energy (MOVE) (DE-FOA-000672). ARPAhttp://arpa-e-foa.energy.gov (2012).

Hulvey, Z. et al. Critical factors driving the high volumetric uptake of methane in Cu3(btc)2 . J. Am. Chem. Soc. 137, 10816–10825 (2015).

Kim, J., Lin, L.-C., Lee, K., Neaton, J. B. & Smit, B. Efficient determination of accurate force fields for porous materials using ab initio total energy calculations. J. Phys. Chem. C 118, 2693–2701 (2014).

Becker, T. M., Heinen, J., Dubbeldam, D., Lin, L.-C. & Vlugt, T. J. H. Polarizable force fields for CO2 and CH4 adsorption in M-MOF-74. J. Phys. Chem. C 121, 4659–4673 (2017).

Mason, J. a. et al. Methane storage in flexible metal–organic frameworks with intrinsic thermal management. Nature 527, 357–361 (2015).

Wilmer, C. E., Farha, O. K., Bae, Y.-S., Hupp, J. T. & Snurr, R. Q. Structure–property relationships of porous materials for carbon dioxide separation and capture. Energy Environ. Sci. 5, 9849 (2012).

Chung, Y. G. et al. In silico discovery of metal–organic frameworks for precombustion CO2 capture using a genetic algorithm. Sci. Adv. 2, e1600909 (2016).

Braun, E. et al. High-throughput computational screening of nanoporous adsorbents for CO2 capture from natural gas. Mol. Syst. Des. Eng. 1, 175–188 (2016).

Qiao, Z., Zhang, K. & Jiang, J. In silico screening of 4764 computation-ready, experimental metal–organic frameworks for CO2 separation. J. Mater. Chem. A 4, 2105–2114 (2016).

Rufford, T. E. et al. The removal of CO2 and N2 from natural gas: a review of conventional and emerging process technologies. J. Pet. Sci. Eng. 94–95, 123–154 (2012).

Lee, Z. H., Lee, K. T., Bhatia, S. & Mohamed, A. R. Post-combustion carbon dioxide capture: evolution towards utilization of nanomaterials. Renew. Sustain. Energy Rev. 16, 2599–2609 (2012).

IEA Statistics. CO2 emissions from fuel combustion — highlights. IEAhttp://www.pbl.nl/en/publications/2012/co2-emissions-from-fuel-combustion-2012-edition (2012).

Abu-Zahra, M. R. M., Schneiders, L. H. J., Niederer, J. P. M., Feron, P. H. M. & Versteeg, G. F. CO2 capture from power plants. Int. J. Greenh. Gas Control 1, 37–46 (2007).

Bae, Y.-S. & Snurr, R. Q. Development and evaluation of porous materials for carbon dioxide separation and capture. Angew. Chem. Int. Ed. 50, 11586–11596 (2011).

Chen, T.-H. et al. Mesoporous fluorinated metal–organic frameworks with exceptional adsorption of fluorocarbons and CFCs. Angew. Chem. Int. Ed. 54, 13902–13906 (2015).

Pachfule, P., Chen, Y., Sahoo, S. C., Jiang, J. & Banerjee, R. Structural isomerism and effect of fluorination on gas adsorption in copper-tetrazolate based metal organic frameworks. Chem. Mater. 23, 2908–2916 (2011).

Makal, T. A., Wang, X. & Zhou, H.-C. Tuning the moisture and thermal stability of metal–organic frameworks through incorporation of pendant hydrophobic groups. Cryst. Growth Des. 13, 4760–4768 (2013).

Li, Z., Xiao, G., Yang, Q., Xiao, Y. & Zhong, C. Computational exploration of metal–organic frameworks for CO2/CH4 separation via temperature swing adsorption. Chem. Eng. Sci. 120, 59–66 (2014).

Tong, M., Yang, Q., Xiao, Y. & Zhong, C. Revealing the structure–property relationship of covalent organic frameworks for CO2 capture from postcombustion gas: a multi-scale computational study. Phys. Chem. Chem. Phys. 16, 15189 (2014).

Simon, C. M., Mercado, R., Schnell, S. K., Smit, B. & Haranczyk, M. What are the best materials to separate a xenon/krypton mixture? Chem. Mater. 27, 4459–4475 (2015).

Banerjee, D. et al. Metal–organic framework with optimally selective xenon adsorption and separation. Nat. Commun. 7, 11831 (2016).

Sikora, B. J., Wilmer, C. E., Greenfield, M. L. & Snurr, R. Q. Thermodynamic analysis of Xe/Kr selectivity in over 137 000 hypothetical metal–organic frameworks. Chem. Sci. 3, 2217 (2012).

Sumer, Z. & Keskin, S. Molecular simulations of MOF adsorbents and membranes for noble gas separations. Chem. Eng. Sci. 164, 108–121 (2017).

Gee, J. A. et al. Computational identification and experimental evaluation of metal–organic frameworks for xylene enrichment. J. Phys. Chem. C 120, 12075–12082 (2016).

Thornton, A. W. et al. Materials genome in action: identifying the performance limits of physical hydrogen storage. Chem. Mater. 29, 2844–2854 (2017).

Bobbitt, N. S., Chen, J. & Snurr, R. Q. High-throughput screening of metal–organic frameworks for hydrogen storage at cryogenic temperature. J. Phys. Chem. C 120, 27328–27341 (2016).

Colón, Y. J., Fairen-Jimenez, D., Wilmer, C. E. & Snurr, R. Q. High-throughput screening of porous crystalline materials for hydrogen storage capacity near room temperature. J. Phys. Chem. C 118, 5383–5389 (2014).

U.S. Department of Energy. Targets for onboard hydrogen storage systems for light-duty vehicles. Energy.govhttps://energy.gov/sites/prod/files/2015/05/f22/fcto_targets_onboard_hydro_storage_explanation.pdf (2015).

McDaniel, J. G., Li, S., Tylianakis, E., Snurr, R. Q. & Schmidt, J. R. Evaluation of force field performance for high-throughput screening of gas uptake in metal–organic frameworks. J. Phys. Chem. C 119, 3143–3152 (2015).

McDaniel, J. G. & Schmidt, J. R. Robust, transferable, and physically motivated force fields for gas adsorption in functionalized zeolitic imidazolate frameworks. J. Phys. Chem. C 116, 14031–14039 (2012).

Mercado, R. et al. Force field development from periodic density functional theory calculations for gas separation applications using metal–organic frameworks. J. Phys. Chem. C 120, 12590–12604 (2016).

Rappe, A. K. & Goddard, W. A. Charge equilibration for molecular dynamics simulations. J. Phys. Chem. 95, 3358–3363 (1991).

Wilmer, C. E. & Snurr, R. Q. Towards rapid computational screening of metal–organic frameworks for carbon dioxide capture: calculation of framework charges via charge equilibration. Chem. Eng. J. 171, 775–781 (2011).

Wilmer, C. E., Kim, K. C. & Snurr, R. Q. An extended charge equilibration method. J. Phys. Chem. Lett. 3, 2506–2511 (2012).

Haldoupis, E., Nair, S. & Sholl, D. S. Finding MOFs for highly selective CO2/N2 adsorption using materials screening based on efficient assignment of atomic point charges. J. Am. Chem. Soc. 134, 4313–4323 (2012).

Wells, B. A., De Bruin-Dickason, C. & Chaffee, A. L. Charge equilibration based on atomic ionization in metal–organic frameworks. J. Phys. Chem. C 119, 456–466 (2015).

Moghadam, P. Z., Fairen-Jimenez, D. & Snurr, R. Q. Efficient identification of hydrophobic MOFs: application in the capture of toxic industrial chemicals. J. Mater. Chem. A 4, 529–536 (2016).

Kadantsev, E. S., Boyd, P. G., Daff, T. D. & Woo, T. K. Fast and accurate electrostatics in metal organic frameworks with a robust charge equilibration parameterization for high-throughput virtual screening of gas adsorption. J. Phys. Chem. Lett. 4, 3056–3061 (2013).

Campanñá, C., Mussard, B. & Woo, T. K. Electrostatic potential derived atomic charges for periodic systems using a modified error functional. J. Chem. Theory Comput. 5, 2866–2878 (2009).

Manz, T. A. & Sholl, D. S. Chemically meaningful atomic charges that reproduce the electrostatic potential in periodic and nonperiodic materials. J. Chem. Theory Comput. 6, 2455–2468 (2010).

Manz, T. A. & Sholl, D. S. Improved atoms-in-molecule charge partitioning functional for simultaneously reproducing the electrostatic potential and chemical states in periodic and nonperiodic materials. J. Chem. Theory Comput. 8, 2844–2867 (2012).

Nazarian, D., Camp, J. S. & Sholl, D. S. A. Comprehensive set of high-quality point charges for simulations of metal–organic frameworks. Chem. Mater. 28, 785–793 (2016).

First, E. L., Gounaris, C. E., Wei, J. & Floudas, C. A. Computational characterization of zeolite porous networks: an automated approach. Phys. Chem. Chem. Phys. 13, 17339–17358 (2011).

Sarkisov, L. & Harrison, A. Computational structure characterisation tools in application to ordered and disordered porous materials. Mol. Simul. 37, 1248–1257 (2011).

Aghaji, M. Z., Fernandez, M., Boyd, P. G., Daff, T. D. & Woo, T. K. Quantitative structure–property relationship models for recognizing metal organic frameworks (MOFs) with high CO2 working capacity and CO2/CH4 selectivity for methane purification. Eur. J. Inorg. Chem. 2016, 4505–4511 (2016).

Fernandez, M., Boyd, P. G., Daff, T. D., Aghaji, M. Z. & Woo, T. K. Rapid and accurate machine learning recognition of high performing metal organic frameworks for CO2 capture. J. Phys. Chem. Lett. 5, 3056–3060 (2014).

Fernandez, M. & Barnard, A. S. Geometrical properties can predict CO2 and N2 adsorption performance of metal–organic frameworks (MOFs) at low pressure. ACS Comb. Sci. 18, 243–252 (2016).

Fernandez, M., Trefiak, N. R. & Woo, T. K. Atomic property weighted radial distribution functions descriptors of metal–organic frameworks for the prediction of gas uptake capacity. J. Phys. Chem. C 117, 14095–14105 (2013).

Thornton, A. W., Winkler, D. A., Liu, M. S., Haranczyk, M. & Kennedy, D. F. Towards computational design of zeolite catalysts for CO2 reduction. RSC Adv. 5, 44361–44370 (2015).

Raccuglia, P. et al. Machine-learning-assisted materials discovery using failed experiments. Nature 533, 73–76 (2016).

Evans, J. D. et al. Computational identification of organic porous molecular crystals. CrystEngComm 18, 4133–4141 (2016).

Fernandez, M., Woo, T. K., Wilmer, C. E. & Snurr, R. Q. Large-scale quantitative structure–property relationship (QSPR) analysis of methane storage in metal–organic frameworks. J. Phys. Chem. C 117, 7681–7689 (2013).

Lee, Y. et al. Quantifying similarity of pore-geometry in nanoporous materials. Nat. Commun. 8, 15396 (2017).

Boyd, P. G., Moosavi, S. M., Witman, M. & Smit, B. Force-field prediction of materials properties in metal–organic frameworks. J. Phys. Chem. Lett. 8, 357–363 (2017).

Springer, S. et al. A zeolitic imidazolate framework with conformational variety: conformational polymorphs versus frameworks with static conformational disorder. CrystEngComm 18, 2477–2489 (2016).

Sarkisov, L., Martin, R. L., Haranczyk, M. & Smit, B. On the flexibility of metal–organic frameworks. J. Am. Chem. Soc. 136, 2228–2231 (2014).

Watanabe, T. & Sholl, D. S. Accelerating applications of metal–organic frameworks for gas adsorption and separation by computational screening of materials. Langmuir 28, 14114–14128 (2012).

Nazarian, D., Camp, J. S., Chung, Y. G., Snurr, R. Q. & Sholl, D. S. Large-scale refinement of metal–organic framework structures using density functional theory. Chem. Mater. 29, 2521–2528 (2017).

Witman, M. et al. The influence of intrinsic framework flexibility on adsorption in nanoporous materials. J. Am. Chem. Soc. 139, 5547–5557 (2017).

Krause, S. et al. A pressure-amplifying framework material with negative gas adsorption transitions. Nature 532, 348–352 (2016).

Serre, C., Bourrelly, S., Ramsahye, N. A. & Maurin, G. An explanation for the very large breathing effect of a metal–organic framework during CO2 adsorption. Adv. Mater. 19, 2246–2251 (2007).

Barthelet, K., Marrot, J. J., Riou, D. & Férey, G. A breathing hybrid organic–inorganic solid with very large pores and high magnetic characteristics. Angew. Chem. Int. Ed. 41, 281–284 (2002).

Serre, C. et al. Very large breathing effect in the first nanoporous chromium(III)-based solids: MIL-53 or CrIII(OH)·{O2C–C6H4–CO2}·{HO2C–C6H4–CO2H}x·H2Oy. J. Am. Chem. Soc. 124, 13519–13526 (2002).

Barthelet, K., Marrot, J., Ferey, G. & Riou, D. VIII(OH){O2C–C6H4–CO2}·(HO2C–C6H4–CO2H)x (DMF)y(H2O)z (or MIL-68), a new vanadocarboxylate with a large pore hybrid topology: reticular synthesis with infinite inorganic building blocks? Chem. Commun. 2004, 520–521 (2004).

Tan, J. C. & Cheetham, A. K. Mechanical properties of hybrid inorganic–organic framework materials: establishing fundamental structure–property relationships. Chem. Soc. Rev. 40, 1059–1080 (2011).

Li, S., Chung, Y. G. & Snurr, R. Q. High-throughput screening of metal–organic frameworks for CO2 capture in the presence of water. Langmuir 32, 10368–10376 (2016).

Greathouse, J. A. & Allendorf, M. D. The interaction of water with MOF-5 simulated by molecular dynamics. J. Am. Chem. Soc. 128, 10678–10679 (2006).

Haigis, V., Coudert, F.-X., Vuilleumier, R., Boutin, A. & Fuchs, A. H. Hydrothermal breakdown of flexible metal–organic frameworks: a study by first-principles molecular dynamics. J. Phys. Chem. Lett. 6, 4365–4370 (2015).

Chanut, N. et al. Screening the effect of water vapour on gas adsorption performance: application to CO2 capture from flue gas in metal–organic frameworks. ChemSusChem 10, 1543–1553 (2017).

Bellarosa, L., Gutiérrez-Sevillano, J. J., Calero, S. & López, N. How ligands improve the hydrothermal stability and affect the adsorption in the IRMOF family. Phys. Chem. Chem. Phys. 15, 17696–17704 (2013).

Vanduyfhuys, L. et al. QuickFF: a program for a quick and easy derivation of force fields for metal–organic frameworks from ab initio input. J. Comput. Chem. 36, 1015–1027 (2015).

Wieme, J., Vanduyfhuys, L., Rogge, S. M. J., Waroquier, M. & Van Speybroeck, V. Exploring the flexibility of MIL-47(V)-type materials using force field molecular dynamics simulations. J. Phys. Chem. C 120, 14934–14947 (2016).

Bureekaew, S. et al. MOF-FF — a flexible first-principles derived force field for metal–organic frameworks. Phys. Status Solidi 250, 1128–1141 (2013).

Bristow, J. K., Tiana, D. & Walsh, A. Transferable force field for metal–organic frameworks from first-principles: BTW-FF. J. Chem. Theory Comput. 10, 4644–4652 (2014).

Bristow, J. K., Skelton, J. M., Svane, K. L., Walsh, A. & Gale, J. D. A general forcefield for accurate phonon properties of metal–organic frameworks. Phys. Chem. Chem. Phys. 18, 29316–29329 (2016).

Jeong, W. & Kim, J. Understanding the mechanisms of CO2 adsorption enhancement in pure silica zeolites under humid conditions. J. Phys. Chem. C 120, 23500–23510 (2016).

Poloni, R. & Kim, J. Predicting low-k zeolite materials. J. Mater. Chem. C 2, 2298 (2014).

Gomez, D. A., Toda, J. & Sastre, G. Screening of hypothetical metal–organic frameworks for H2 storage. Phys. Chem. Chem. Phys. 16, 19001–19010 (2014).

Qiao, Z., Peng, C., Zhou, J. & Jiang, J. High-throughput computational screening of 137953 metal–organic frameworks for membrane separation of a CO2/N2/CH4 mixture. J. Mater. Chem. A 4, 15904–15912 (2016).

First, E. L., Gounaris, C. E. & Floudas, C. A. Predictive framework for shape-selective separations in three-dimensional zeolites and metal–organic frameworks. Langmuir 29, 5599–5608 (2013).

Witman, M. et al. In silico design and screening of hypothetical MOF-74 analogs and their experimental synthesis. Chem. Sci. 7, 6263–6272 (2016).

Yeo, B. C., Kim, D., Kim, H. & Han, S. S. High-throughput screening to investigate the relationship between the selectivity and working capacity of porous materials for propylene/propane adsorptive separation. J. Phys. Chem. C 120, 24224–24230 (2016).

Van Heest, T., Teich-McGoldrick, S. L., Greathouse, J. A., Allendorf, M. D. & Sholl, D. S. Identification of metal–organic framework materials for adsorption separation of rare gases: applicability of ideal adsorbed solution theory (IAST) and effects of inaccessible framework regions. J. Phys. Chem. C 116, 13183–13195 (2012).

Acknowledgements

The intial stage of this work was supported by the Center for Gas Separations Relevant to Clean Energy Technologies, an Energy Frontier Research Center funded by the US Department of Energy, Office of Science, Basic Energy Sciences (DE-SC0001015). This work was further supported by the Swiss National Science Foundation through the National Center of Competence in Research (NCCR) Materials’ Revolution: Computational Design and Discovery of Novel Materials (MARVEL). In addition, Y.L. is supported by the Korean–Swiss Science and Technology Programme (KSSTP, Grant No. 162130), and P.G.B. and B.S. are supported by the European Research Council under the European Union's Horizon 2020 research and innovation programme (Grant Agreement No. 666983, MaGic).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Rights and permissions

About this article

Cite this article

Boyd, P., Lee, Y. & Smit, B. Computational development of the nanoporous materials genome. Nat Rev Mater 2, 17037 (2017). https://doi.org/10.1038/natrevmats.2017.37

Published:

DOI: https://doi.org/10.1038/natrevmats.2017.37

This article is cited by

-

Design of electromagnetic metasurface using two dimensional crystal nets

Scientific Reports (2023)

-

Rapid design of top-performing metal-organic frameworks with qualitative representations of building blocks

npj Computational Materials (2023)

-

End-to-end differentiability and tensor processing unit computing to accelerate materials’ inverse design

npj Computational Materials (2023)

-

Metal–Organic Frameworks: Challenges Addressed via Magnetic Resonance Spectroscopy

Applied Magnetic Resonance (2023)

-

Carbon neutrality orientates the reform of the steel industry

Nature Materials (2022)