The Japan Advanced Institute of Science and Technology (JAIST) has been producing research to address societal challenges since it was established in 1990 as Japan’s first independent national graduate school. One of Japan’s premiere research centres, JAIST hosts researchers who focus on advancing basic science to promote the United Nations’ Sustainable Development Goals (SDGs), including responsible consumption and production, as well as good health and wellbeing.

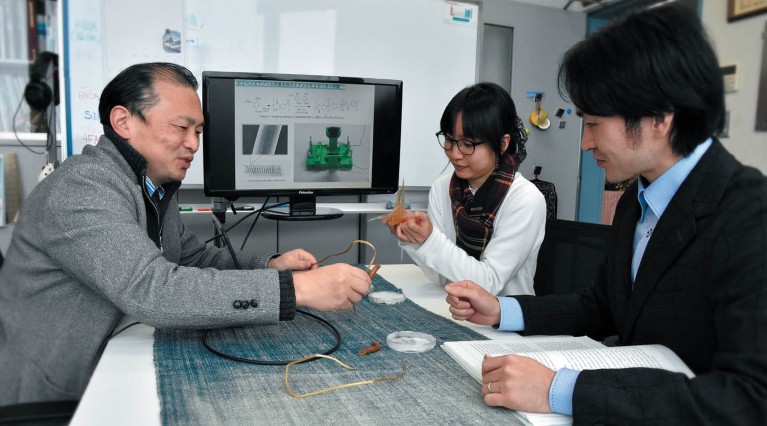

Professor Tatsuo Kaneko and colleagues are developing bioplastics from engineered bacteria and pulp.

Making plastic sustainable

Plastic pollution is one of the leading environmental challenges. Some 6.3 billion tonnes of plastic waste had been generated by 2015, with 79% ending up in landfills or the natural environment, where, a 2017 Science Advances paper suggests, it threatens ecosystems as well as food production. Plastics molecules derived from renewable sources, or bioplastics, have gained attention in recent years as an alternative to petroleum-based plastics. However, their widespread adoption is hindered by their relatively low melting point, which means they cannot be a substitute for all conventional plastics that cause pollution. Less than 1% of the annual global plastics market of 360 million tonnes is produced from renewable resources such as biomass, according to a 2019 European Bioplastics report.

Polymer scientist, Tatsuo Kaneko, is a professor in the Energy and Environment Area at JAIST who has spent decades researching this problem. On his desk sits a transparent, light-coloured origami crane made of bioplastic film derived from amino acids generated by genetically modified microorganisms. These amino acids, are biodegradable and nontoxic. Kaneko uses many techniques to knit them into long chains in a process called macromolecule design.

Professor Tatsuo Kaneko (left) and colleagues discuss new molecular design of bio-derived materials.

Kaneko and colleagues have been trying to increase the melting point of bioplastics. In a 2020 paper published in Advanced Sustainable Systems, they report the development of a bioplastic film from engineered bacteria and pulp. The paper reports the film has no melting point below a degradation temperature of 740 degrees Celsius, the highest on record. It is one of many bioplastics that Kaneko and colleagues want to commercialize to increase the share of sustainable plastics.

“We want plastics to be durable when we use them but then degradable after we discard them,” says Kaneko, who at JAIST oversees a lab of researchers from Japan and abroad. “Therefore, we want to develop a bioplastic that can switch between these functions. Both plastic production and waste control are very important for the economy.”

Forging new tools for diagnosis and health

Yuzuru Takamura, professor in bioscience and biotechnology at JAIST, is also pursuing SDGs, but in the field of public health. One focus of his work is enzyme-linked immunosorbent assays (ELISAs). First described in 1971, ELISAs have become vital tools to determine the presence of substances such as allergens or proteins; a common example is a pregnancy test, a form of sandwich ELISA that uses capillary action to detect human chorionic gonadotropin (hCG).

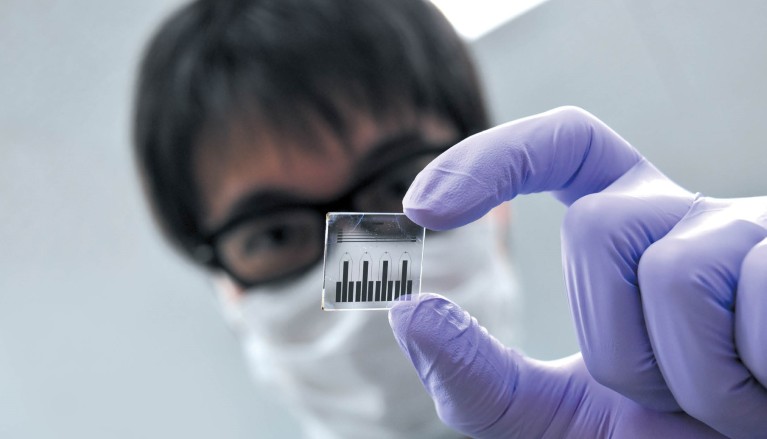

Professor Yuzuru Takamura aims to reduce natural resources used to produce printable microchips to make them cheaper and more sustainable.

Takamura aims to make ELISAs more sustainable by reducing the natural resources needed to produce them, thereby also cutting their cost. In a 2013 Lab on a Chip paper, Takamura and colleagues describe how they created the first paper-based ELISA with a single-step sample application.

Based on a piece of nitrocellulose membrane, the device incorporates low-cost inkjet printing technology to form the barriers and flow channel and was used to detect hCG in urine samples. But it is really intended for tests that require greater sensitivity, such as antigen-antibody reactions like in influenza or potentially COVID-19, or for toxins such as heavy metals and dioxins. The researchers intend to make a simple, very low-cost device that has the capacity to diagnose many kinds of infectious diseases.

Takamura is also collaborating with Takashi Masuda, a senior lecturer of electronics at JAIST, to produce printable microelectromechanical systems (MEMS), which are used in accelerometers, sensors, displays and other applications. For such devices, printing would dramatically reduce the amount of waste material generated.

The researchers are also developing solution-process-based biochips containing printable actuators, transistors, sensors and microfluidics structure. Takamura and colleagues envisage centimetre-scale, flexible microfluidics devices, embedded with solar cells and displays.

Such biochips could be used for everything from basic health check-ups to complex tasks for medical research and drug discovery. One potential application of this technique, using a piezoelectric actuator array electrically driven by an active-matrix oxide-thin film transistor, would be high-yield analysis of messenger RNA profiles in living cells.

“This could be a new tool to study nerve cells and potentially the mechanism of diseases such as Alzheimer’s,” says Takamura. “We want to use this technique to develop microfluidic devices to improve human health so we can create new process methods with fewer resources.”

Collection: Nature Index 2021 Asia Pacific

Collection: Nature Index 2021 Asia Pacific