- NEWS AND VIEWS

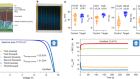

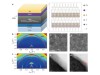

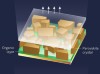

Solar cells boosted by an improved charge-carrying material

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Rent or buy this article

Prices vary by article type

from$1.95

to$39.95

Prices may be subject to local taxes which are calculated during checkout

Nature 567, 465-467 (2019)

doi: https://doi.org/10.1038/d41586-019-00936-x

References

Yang, W. S. et al. Science 356, 1376–1379 (2017).

Zhang, M. et al. Chem. Eur. J. 21, 434–439 (2015).

Wang, Y., Yue, Y., Yang, X. & Han, L. Adv. Energy Mater. 8, 1800249 (2018).

Jung, E. H. et al. Nature 567, 511–515 (2019).

Liu, J. et al. Energy Environ. Sci. 7, 2963–2967 (2014).

Jiang, X. et al. J. Mater. Chem. A 5, 17862–17866 (2017).

Zhang, J. et al. Adv. Energy Mater. 8, 1701209 (2018).

Yue, Y. et al. Adv. Mater. 28, 10738–10743 (2016).

Brauer, J. C., Lee, Y. H., Nazeeruddin, M. K. & Banerji, N. J. Phys. Chem. Lett. 6, 3675–3681 (2015).

Stolterfoht, M. et al. Preprint at https://arxiv.org/abs/1810.01333 (2018).

Sirringhaus, H. et al. Nature 401, 685–688 (1999).

Kim, Y. et al. Nature Mater. 5, 197–203 (2006).

Read the paper: Efficient, stable and scalable perovskite solar cells using poly(3-hexylthiophene)

Read the paper: Efficient, stable and scalable perovskite solar cells using poly(3-hexylthiophene)

LED technology breaks performance barrier

LED technology breaks performance barrier

Twenty-five years of low-cost solar cells

Twenty-five years of low-cost solar cells