- RESEARCH HIGHLIGHT

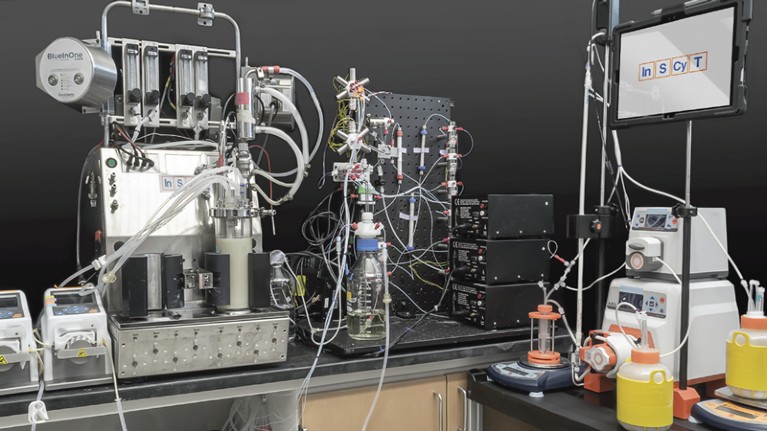

This miniature drug factory fits on a few lab benches

A protein-based drug is made in a reaction vessel (silver box, left) before passing over columns of purifying chemicals (slender white cylinders, middle). Credit: L. E. Crowell et al./Nat. Biotechnol.

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Rent or buy this article

Prices vary by article type

from$1.95

to$39.95

Prices may be subject to local taxes which are calculated during checkout

Nature 562, 166-167 (2018)

doi: https://doi.org/10.1038/d41586-018-06929-6