Abstract

Sodium-ion batteries are being considered as a promising system for stationary energy storage and conversion, owing to the natural abundance of sodium. It is important to develop new cathode and anode materials with high capacities for sodium-ion batteries. Herein, we report the synthesis of β-MnO2 nanorods with exposed tunnel structures by a hydrothermal method. The as-prepared β-MnO2 nanorods have exposed {111} crystal planes with a high density of (1 × 1) tunnels, which leads to facile sodium ion (Na-ion) insertion and extraction. When applied as cathode materials in sodium-ion batteries, β-MnO2 nanorods exhibited good electrochemical performance with a high initial Na-ion storage capacity of 350 mAh g−1. β-MnO2 nanorods also demonstrated a satisfactory high-rate capability as cathode materials for sodium-ion batteries.

Similar content being viewed by others

Introduction

Sodium-ion (Na-ion) batteries have recently been considered as an alternative battery system for large-scale energy storage and conversion due to the availability of low-cost and widespread terrestrial reserves of sodium mineral salts.1 Na-ion batteries share many similarities with lithium-ion batteries (Li-ion batteries), such as an intercalating cathode and anode, a nonaqueous electrolyte and an ion shuttle mechanism. Computational studies on the voltage, stability and diffusion barrier of Na-ion and Li-ion materials indicate that Na-ion systems are competitive with Li-ion systems.2 However, the large ionic size of sodium (1.02 Å versus lithium (0.76 Å)) limits the choice of electrode materials for Na-ion batteries. Many cathode materials have been investigated for Na-ion batteries, including phosphate polyanion materials (NaFePO4),3, 4 Na4Mn9O18,5, 6, 7 fluoride-based cathode materials—NaMF3 (M=Fe, Mn, V and Ni),8, 9 fluorophosphates,10, 11 fluorosulfates,12, 13, 14 and layered transition metal oxides, such as P2-NaxCoO2,15, 16 P2-Na2/3(Fe1/2Mn1/2)O2,17 Na2/3(Ni1/3Fe1/3Mn2/3)O2,18 NaCrO2,19, 20 NaxMnO2,21, 22 and NaxVO2.23 However, none of the above cathode materials showed satisfactory electrochemical performance in terms of specific capacity, cyclability and high-rate capability. Therefore, the discovery of appropriate electrode materials is crucial for the development of high-performance Na-ion batteries.

Manganese dioxide has large open tunnels, which can provide interstitial spaces for Na-ion storage and transport. Herein, we report the synthesis of single-crystalline β-MnO2 nanorods with dominantly exposed {111} crystal planes. The {111} crystal plane consists of high-density (1 × 1) tunnels that can facilitate fast Na-ion insertion and extraction during the charge and discharge process. The as-prepared β-MnO2 nanorods exhibited a high Na-ion storage capacity, a good high-rate capability and a satisfactory cyclability. Furthermore, we also explored the effects of Na-ion intercalation and extraction on cycling using ex situ X-ray diffraction (XRD) and transmission electron microscopy (TEM) measurements.

Materials and methods

Synthesis of β-MnO2 nanorods

β-MnO2 nanorods were synthesized by a hydrothermal method. In a typical process, 1 mmol (NH4)2S2O8 (Sigma-Aldrich, Castle Hill, NSW, Australia, ⩾99%) and 1 mmol MnSO4·H2O (Sigma-Aldrich, ⩾99%) were dissolved in 20 ml of deionized water. A soft template consisting of 0.2 g of cationic surfactant cetyltrimethylammonium bromide (CTAB) (Sigma-Aldrich, ⩾98%) was added. After stirring for at least 30 min, the precursor solution was treated at 90 °C in a teflon-lined autoclave (25 ml in capacity) for 36 h. The precipitate was cooled down to room temperature naturally, collected and washed with distilled water and ethanol several times. After drying at 60 °C in a vacuum oven overnight, the final products were obtained.

Structural and physical characterization

The crystal structure and phase of the as-prepared materials were characterized by XRD, Siemens D5000 (Bruker Axs. Inc., Madison, WI, USA) using Cu Kα radiation at a very slow scanning step of 0.0025° s−1 (8.9 h from 10° to 90°). Rietveld refinement was implemented using the GSAS software suite. The morphology was analyzed by a field emission scanning electron microscope (FESEM, Zeiss Supra 55VP, Carl Zeiss Group, Oberkochen, Germany). The structure details were further characterized by TEM and high-resolution transmission electron microscopy (HRTEM, JEOL JEM-2011). Selected area electron diffraction (SAED) patterns were recorded by a Gatan CCD camera in a digital format. Fourier transform infrared spectroscopy (FT-IR) spectra of the samples were recorded on a Nicolet 6700 Spectrometer (Thermo Fisher Scientific Inc., Waltham, MA, USA) by using potassium bromide (KBr) as the dispersant. The surface area information was collected by N2 adsorption isotherm using a Micromeritics 3Flex analyzer (Micromeritics Instrument Corporation, Norcross, GA, USA) at 77 K. Brunauer–Emmett–Teller (BET) surface areas were calculated using experimental points at a relative pressure of P/P0=0.05–0.25. The pore size distribution was calculated by the Barret–Joyner–Halenda (BJH) method.

Electrochemical testing

The electrodes were prepared by dispersing the as-prepared β-MnO2 nanorods (70 wt%), acetylene carbon black (20 wt%) and poly(vinylidene fluoride) binder (PVDF, 10 wt%) in N-methyl-2-pyrrolidone (NMP) to form a slurry. The resultant slurry was pasted onto an aluminum foil using a doctor blade and dried in a vacuum oven for 12 h, followed by pressing at 200 kg cm−2. The loading of each electrode is 1.2 mg. The electrochemical measurements were carried out using the two-electrode coin cells (CR2032-type) with Na metal as the reference and counter electrode, and glass microfiber (Whatman) as the separator. The CR2032-type coin cells were assembled in an argon-filled glove box (UniLab, Mbraun, Germany). The electrolyte solution was 1 M NaClO4 dissolved in a mixture of ethylene carbonate (EC) and propylene carbonate (PC) with a volume ratio of 1:1. Cyclic voltammetry (CV) was carried out on a CHI 660C electrochemistry workstation with a scan rate of 0.1 mV s−1 from 1–4.3 V. The charge-discharge measurements were performed at an ambient temperature, and at different current densities in the voltage range from 1 to 4.3 V. To investigate the sodium driven structural and morphological changes of the as-prepared β-MnO2 nanorods during the sodium insertion and extraction processes, Swagelok-type cells were assembled. The cells were discharged or charged to the required voltages and then opened in the glove box. The active materials were removed from the electrodes and washed with PC before being used for ex situ XRD and TEM analyses. The samples were covered and sealed with parafilm in the glove box to avoid exposure to air. Next, the samples were transferred to the XRD instrument for measurement of the XRD patterns.

Results

Structural characterization of β-MnO2 nanorods

The crystal phase of the as-prepared β-MnO2 nanorods was identified by XRD. As shown in Figure 1a, all the diffraction peaks can be indexed to the tetragonal phase with the space group of P42/mnm (JCPDS no. 24-0735). The lattice parameters were refined to be a=b=4.388 Å, c=2.873 Å. No impurity phases were observed. The refined crystal structure projected along the [001] direction is shown in Figure 1b, from which the (1 × 1) tunnels are presented with a tunnel density of 0.104 Å−2 (two tunnels per formula unit). We confirmed that the CTAB was completely removed from β-MnO2 by the measurement of FTIR spectra of CTAB and β-MnO2 nanorods (Supplementary Figure S1). The as-prepared β-MnO2 nanorods have a specific surface area of 14.99 m2 g−1 (as shown in Supplementary Figure S2).

(a) Rietveld refinement pattern from the X-ray diffraction data for the β-MnO2 nanorods; the observed and calculated intensity are represented by red pulses and a blue solid line, respectively. The bottom line shows the fitting residual difference. The Bragg positions are represented as light green ticks (χ2=2.2, Rwp=6.34%, Rp=5.08%). (b) Refined β-MnO2 crystal structure seen from the [001] orientation. (c) Low-magnification field emission scanning electron microscope (FESEM) image of β-MnO2 nanorods. (d) High-magnification FESEM image of β-MnO2 nanorods, which have a square cross section.

The morphology of β-MnO2 nanorods were investigated by field emission scanning electron microscope. As shown in Figure 1c, the product consists of 100% one-dimensional (1D) nanorods. The lengths of the β-MnO2 nanorods extend to a few micrometers. Figure 1d shows a high-magnification view of the cross section of a β-MnO2 nanorod, which has a square shape with a side length of approximate 20 nm.

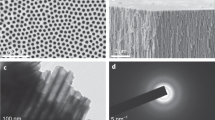

The detailed crystal structures of β-MnO2 nanorods were further analyzed by TEM, SAED and HRTEM analyses (Figure 2). Figure 2a shows a typical low-magnification TEM image of the freestanding β-MnO2 nanorods, from which it is evident that the individual β-MnO2 nanorods are well separated. The growth directions of β-MnO2 nanorods were determined by HRTEM and SAED. As shown in Figure 2b1, the individual β-MnO2 nanorods grow along the  direction, as deduced from the SAED patterns (Figure 2b2). The spot SAED patterns verify the single-crystalline feature of the as-prepared β-MnO2 nanorods. The rhombic SAED spot patterns can be well indexed along the [111] zone axis of tetragonal β-MnO2, which indicates that the facet vertical to the electron beam is the (111) crystal plane, and that the two side facets are exposed with

direction, as deduced from the SAED patterns (Figure 2b2). The spot SAED patterns verify the single-crystalline feature of the as-prepared β-MnO2 nanorods. The rhombic SAED spot patterns can be well indexed along the [111] zone axis of tetragonal β-MnO2, which indicates that the facet vertical to the electron beam is the (111) crystal plane, and that the two side facets are exposed with  and

and  crystal planes. If this β-MnO2 nanorod is tilted 34° around the

crystal planes. If this β-MnO2 nanorod is tilted 34° around the  axis (Figure 2c), the contrast of different facets can be observed. Its corresponding SAED spot patterns (Figure 2c2) can be indexed along the [201] zone axis of the tetragonal β-MnO2. The SAED pattern reflects the combination of the (111) crystal plane and the

axis (Figure 2c), the contrast of different facets can be observed. Its corresponding SAED spot patterns (Figure 2c2) can be indexed along the [201] zone axis of the tetragonal β-MnO2. The SAED pattern reflects the combination of the (111) crystal plane and the  crystal plane. This further confirms that the enclosed facets of the β-MnO2 nanorods are {111} and {110} crystal planes, as demonstrated by the geometrical model shown in Figure 2e. From the lattice-resolved HRTEM image (Figure 2d), we can directly observe the regular lattice arrangement of the exposed (111) crystal plane. The crystal structure of the tetragonal β-MnO2 nanorods is simulated along the [111] direction (the middle inset in Figure 2d). The corresponding Fast-Fourier-Transform (FFT) pattern is shown as the inset in Figure 2d (left-bottom). Figure 2d also shows the

crystal plane. This further confirms that the enclosed facets of the β-MnO2 nanorods are {111} and {110} crystal planes, as demonstrated by the geometrical model shown in Figure 2e. From the lattice-resolved HRTEM image (Figure 2d), we can directly observe the regular lattice arrangement of the exposed (111) crystal plane. The crystal structure of the tetragonal β-MnO2 nanorods is simulated along the [111] direction (the middle inset in Figure 2d). The corresponding Fast-Fourier-Transform (FFT) pattern is shown as the inset in Figure 2d (left-bottom). Figure 2d also shows the  and

and  crystal planes with lattice spacings of 0.24 and 0.31 nm and a 67° interfacial angle. As illustrated in Figure 2e, the as-prepared β-MnO2 nanorods are enclosed with {111} and {110} facets. More TEM images and crystal structural information are shown in Supplementary Figure S3.

crystal planes with lattice spacings of 0.24 and 0.31 nm and a 67° interfacial angle. As illustrated in Figure 2e, the as-prepared β-MnO2 nanorods are enclosed with {111} and {110} facets. More TEM images and crystal structural information are shown in Supplementary Figure S3.

(a) Low-magnification TEM images of typical freestanding β-MnO2 nanorods. (b 1) High-magnification TEM image of an individual β-MnO2 nanorod. (c 1) is the same area imaged in the high-magnification TEM image from b1 but with a tilt of 34° around the  axis. (b 2) and (c 2) are the selected area electron diffraction spot patterns (SAED) of (b 1) and (c 1), respectively. (d) Lattice resolution HRTEM image of β-MnO2 nanorods. The left bottom inset of d is its corresponding fast-Fourier-transform (FFT) patterns, and the middle inset of d is the simulated [111] projection of the tetragonal β-MnO2 crystal structure with several formula units presenting the regular arrangement of atoms (Mn and O marked in purple and red, respectively). (e) Geometrical model of β-MnO2 nanorods, in which different colors represent different crystal planes.

axis. (b 2) and (c 2) are the selected area electron diffraction spot patterns (SAED) of (b 1) and (c 1), respectively. (d) Lattice resolution HRTEM image of β-MnO2 nanorods. The left bottom inset of d is its corresponding fast-Fourier-transform (FFT) patterns, and the middle inset of d is the simulated [111] projection of the tetragonal β-MnO2 crystal structure with several formula units presenting the regular arrangement of atoms (Mn and O marked in purple and red, respectively). (e) Geometrical model of β-MnO2 nanorods, in which different colors represent different crystal planes.

Electrochemical properties of β-MnO2 nanorods for Na-ion storage in Na-ion batteries

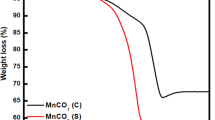

β-MnO2 nanorods were used as cathodes for Na-ion storage in Na-ion batteries. Figure 3a shows the galvanostatic charge–discharge profiles of the β-MnO2 nanorod electrode in the 1st, 2nd and 100th cycles at a low current density of 20 mA g−1. The galvanostatic charge-discharge profiles are similar to the β-MnO2 as cathode materials in Li-ion batteries.24 β-MnO2 nanorods delivered a high initial discharge capacity of 350 mAh g−1. Although the discharge capacity decreased gradually upon cycling, it still maintained a high value after 100 cycles. The electrochemical reactions during the charge and discharge process were further studied by cyclic voltammetry (as shown in Supplementary Figure S4), from which a pair of redox peaks at 2.4 V and 2.5 V, respectively, were observed.

The cycling performance of the β-MnO2 nanorods is shown in Figure 3b. The discharge capacity decreases during the initial 20 cycles and then remains stable. A discharge capacity of 192 mAh g−1 was achieved after 100 cycles. Figure 4a shows the cycling performance of a β-MnO2 nanorod electrode charged/discharged at different current densities. The β-MnO2 nanorod electrode exhibited initial discharge capacities of 280 and 264 mAh g−1 at current densities of 50 and 100 mA g−1, respectively. We also examined the high-rate performance of β-MnO2 nanorods as cathodes in Na-ion batteries. The electrode still delivered a capacity of 118 mAh g−1 even when the current density was increased to 1600 mA g−1. The β-MnO2 nanorod electrodes maintained stable cycling performances over 100 cycles at high current densities (166 mAh g−1 at 50 mA g−1, 135 mAh g−1 at 100 mA g−1, 105 mAh g−1 at 200 mA g−1 and 71 mAh g−1 at 400 mA g−1, respectively). This high-rate performance is superior than that of previously reported β-MnO2, used as cathode Li-ion storage in Li-ion batteries.24, 25, 26 Furthermore, the cycling performances of β-MnO2 nanorod electrodes were also tested under varied current densities: 20, 50, 200 and 400 mA g−1 (Figure 4b). It should be noted that as long as the current density reversed back to the low current density, the cell capacity recovered to the original values, indicating that the integrity of β-MnO2 nanorods had been preserved, even after the high-rate cycling.

Discussion

The good electrochemical performance of β-MnO2 nanorods as cathodes in the Na-ion batteries can be ascribed to its unique crystal structure with high-density (1 × 1) tunnels presented on the exposed (111) facets. β-MnO2 consists of a 1D channel (1 × 1) tunnel structure and has 2 × (1 × 1) tunnels per formula unit with a tunnel density of 0.104 Å−2. The (1 × 1) tunnel has a size of 2.3 Å × 2.3 Å, which can not only provide facile transport for Na-ion insertion and extraction but also accommodate Na-ions. Figure 5 shows the illustration of the tunnel structure of the as-prepared β-MnO2 nanorods. It can be observed that when the as-prepared β-MnO2 nanorod was turned 42.7° along its  axis, the (001) crystal plane of β-MnO2, with the visible 1D (1 × 1) tunnels, is presented (Figures 5a→b). These open tunnels can facilitate Na-ion insertion and extraction (as illustrated in Figures 5c and d and Supplementary Figure S5). Furthermore, the (1 × 1) tunnels can also accommodate the inserted Na-ions. Therefore, the (1 × 1) tunnel structure can effectively prevent structural collapse and local volumetric variation during the charge/discharge process, which enhances the structural stability and cycling performance.27, 28 Consequently, the as-prepared β-MnO2 nanorods with exposed (1 × 1) tunnel structures can achieve a high-rate performance and durable cyclability as cathodes in Na-ion batteries.

axis, the (001) crystal plane of β-MnO2, with the visible 1D (1 × 1) tunnels, is presented (Figures 5a→b). These open tunnels can facilitate Na-ion insertion and extraction (as illustrated in Figures 5c and d and Supplementary Figure S5). Furthermore, the (1 × 1) tunnels can also accommodate the inserted Na-ions. Therefore, the (1 × 1) tunnel structure can effectively prevent structural collapse and local volumetric variation during the charge/discharge process, which enhances the structural stability and cycling performance.27, 28 Consequently, the as-prepared β-MnO2 nanorods with exposed (1 × 1) tunnel structures can achieve a high-rate performance and durable cyclability as cathodes in Na-ion batteries.

Illustrations of the crystal structure of the as-prepared β-MnO2 nanorods along the [111] (a), [001] (b) and  (c) projected directions. (c) is a schematic of the Na-ion insertion and extraction in the (1 × 1) tunnels, from which we can see the orientational relationship between the [111] and [001] with a 42.7° interfacial angle. (d) is a schematic of a β-MnO2 nanorod with inserted Na-ions. The Mn, O and Na are colored in purple, red and blue, respectively.

(c) projected directions. (c) is a schematic of the Na-ion insertion and extraction in the (1 × 1) tunnels, from which we can see the orientational relationship between the [111] and [001] with a 42.7° interfacial angle. (d) is a schematic of a β-MnO2 nanorod with inserted Na-ions. The Mn, O and Na are colored in purple, red and blue, respectively.

As shown in Figures 3 and 4, the capacities of the β-MnO2 nanorod electrodes gradually decrease during long-term cycling. It should also be noted that the discharge profiles become sloped upon cycling, which suggests the slow deterioration of the crystallinity of β-MnO2 nanorods. To explore the mechanism of Na-ion insertion and extraction in β-MnO2 nanorods, we conducted ex situ XRD and TEM measurements. Figure 6 shows the ex situ XRD patterns of the β-MnO2 nanorod electrodes in the fully discharged state (Na-ion insertion) and fully charged state (Na-ion extraction) in the 1st cycle and the 100th cycle. For comparison, the simulated XRD patterns of β-MnO2, 1 Na inserted β-MnO2 and NaMn2O4 are also presented in Figure 6. From the simulated XRD patterns, we can see that the (200), (220) and (002) reflections become more intense, and that the intensity of the (110) reflection decreased with an Na insertion (see the details in Supplementary Figure S6). When analyzing the ex situ XRD patterns (Figure 6), it can be observed that the intensities of all (110), (200) and (220) peaks slightly decreased at the 1st and 100th discharged states.

XRD patterns of simulated tetragonal β-MnO2, 1 Na–inserted β-MnO2, the orthorhombic NaMn2O4 phase, and β-MnO2 nanorod electrodes in the fully discharged state in the 1st cycle (Na-ion insertion), fully charged state in the 1st cycle (Na-ion extraction), fully discharged state in the 100th cycle, and fully charged state in the 100th cycle. The peaks belonging to the β-MnO2 and 1 Na–inserted β-MnO2 are marked by red lines, whereas the peaks belonging to the orthorhombic NaMn2O4 phase are marked by blue lines.

There are differences between the theoretical calculation and the experimental measurements. The reason could be that the theoretical calculation is based on bulk materials, and the preferred orientation of the β-MnO2 nanorods could affect the change in the relative intensity of diffraction peaks upon Na insertion. We have used the GSAS software suite to calculate the lattice parameters of β-MnO2 nanorods at the 1st and 100th discharged states (1 Na insertion) based on the diffraction lines of (110), (101) and (111). The results are summarized as follows:

At the 1st discharged state, a=b=4.3916 Å, c=2.8740 Å.

At the 100th discharged state, a=b=4.4109 Å, c=2.8756 Å.

Compared with the lattice parameters of the pristine β-MnO2 nanorods, a=b=4.3880 Å, c=2.8730 Å, the lattice of β-MnO2 nanorods slightly expanded after the insertion of 1 Na per formula.

Furthermore, to identify the impurity phase of the by-product generated during the cycling process, we calculated the XRD patterns of all possible NaxMnyOz compounds, including NaMn7O12 (space group: Im3), Na2Mn3O7 (space group: P1), NaMnO2 (space group: Pmnmz), Na4Mn2O5 (space group: Fdddz), Na2MnO4 (space group: P63mc), Na14Mn2O9 (space group: P3) and NaMn2O4 (space group: Pnam). The calculated XRD patterns of all the NaxMnyOz compounds and their crystal structures are shown in Supplementary Figures S7a and b , respectively. It was found that the peaks, which do not belong to the β-MnO2 or Na-inserted β-MnO2, match the NaMn2O4 phase (space group: Pnam).

The peaks at 12.8°, 15.8°, 25.5°, 26.1°, 32.3°, 36.8°, 50.25° and 52° correspond to the (110), (020), (220), (130), (040), (121), (241) and (401) crystal planes of NaMn2O4, respectively. In particular, the high intensity peak at 34.1° in all ex situ XRD patterns (Figure 6) should be the (320) plane of NaMn2O4, which is one of its primary reflection peaks. Moreover, some other peaks overlap with the diffraction peaks of β-MnO2 or Na-inserted β-MnO2 (as marked by the blue lines in Figure 6). Therefore, the NaMn2O4 phase was generated during the discharge and charge process. Although, a small amount of impurity phase NaMn2O4 was formed, β-MnO2 nanorods maintained the tetragonal phase during the extended cycling process. This indicates that the β-MnO2 nanorods are tolerant of the repeated Na ion insertion and extraction.

Ex situ TEM and SAED analyses were also performed on the β-MnO2 nanorods at the fully discharged and charged states in the 1st and 100th cycles (as shown in Figure 7). It can be observed that the nanorod shape and morphology were preserved for all discharge and charge states (Figures 7a0). At the fully discharged state in the 1st cycle, the SAED pattern taken from an individual β-MnO2 nanorod can be indexed along the [001] zone axis of one Na-ion–inserted β-MnO2 (Figure 7a1), in which the  ,

,  , (110),

, (110),  and (200) crystal planes can be indexed accurately, whereas the other spot patterns can be indexed as the (020), (040) and (241) crystal planes (with 5.54, 2.77 and 1.81 Å d-spacing, respectively) of the orthorhombic NaMn2O4 phase.

and (200) crystal planes can be indexed accurately, whereas the other spot patterns can be indexed as the (020), (040) and (241) crystal planes (with 5.54, 2.77 and 1.81 Å d-spacing, respectively) of the orthorhombic NaMn2O4 phase.

TEM images and SAED patterns of β-MnO2 nanorods electrodes taken in the fully discharged states (a 0,a 2) and fully charged states (b 0 –b 1) in the first cycle and the fully discharged (c 0,c 1) and fully charged (d0,d1) states after 100 cycles. a 0, b 0, c 0 and d 0 show bright-field TEM images of individual β-MnO2 nanorods at different stages of the charge and discharge processes. a 1, b 1, c 1 and d 1 are the corresponding SAED patterns. a 2, b 2, c 2 and d 2 are the lattice-resolved HRTEM images at various stages of the charge and discharge processes. The insets in a 2, b 2, c 2 and d 2 are the corresponding fast-Fourier-transform (FFT) patterns.

By further analyzing the lattice-resolved HRTEM image (Figure 7a2) and its corresponding Fast-Fourier-Transform spot patterns, we can directly identify the (110) crystal plane (with approximately 3.1 Å d-spacing) of the Na-ion–inserted β-MnO2 and the (121) crystal plane (with approximately 2.5 Å d-spacing) of the impurity NaMn2O4 phase, which confirmed that the formation of impurity NaMn2O4 occurred in the initial discharge process. After being fully charged, the obtained SAED pattern in Figure 7b1 can be indexed as two sets of diffraction patterns along the  zone axis of β-MnO2, where the (210),

zone axis of β-MnO2, where the (210),  and (212) crystal planes with 1.96, 1.62 and 1.16 Å d-spacing, respectively, can be indexed, indicating the reversible structural recovery of β-MnO2 after the extraction of Na-ions. From the HRTEM image in Figure 7b2, we observed the

and (212) crystal planes with 1.96, 1.62 and 1.16 Å d-spacing, respectively, can be indexed, indicating the reversible structural recovery of β-MnO2 after the extraction of Na-ions. From the HRTEM image in Figure 7b2, we observed the  crystal plane of β-MnO2 with a 0.31 nm lattice spacing. The rest of the spot patterns can be indexed as the crystal planes of the NaMn2O4 phase, including the (220), (101) and (241) with 3.4, 2.7 and 1.81 Å d-spacings, respectively.

crystal plane of β-MnO2 with a 0.31 nm lattice spacing. The rest of the spot patterns can be indexed as the crystal planes of the NaMn2O4 phase, including the (220), (101) and (241) with 3.4, 2.7 and 1.81 Å d-spacings, respectively.

These results reveal the irreversible property of the NaMn2O4 phase, which is the reason for the capacity deterioration of the β-MnO2 electrode upon cycling. After 100 cycles, the discharged and charged electrodes still preserved their crystalline features, as revealed by the SAED spot patterns (Figures 7c1 and d1). The  ,

,  and (110) diffraction spots of Na-ion–inserted β-MnO2 can be well indexed along the [001] zone axis (Figure 7c1). The

and (110) diffraction spots of Na-ion–inserted β-MnO2 can be well indexed along the [001] zone axis (Figure 7c1). The  ,

,  and (020) diffraction spots of Na-ion extracted β-MnO2 in the charged state can be clearly indexed along the [101] zone axis. This proved that the crystalline structure of the β-MnO2 nanorods was retained upon cycling, which is a benefit for the long-term cycling of β-MnO2 nanorod electrodes. Nevertheless, the impurity phase NaMn2O4 has been identified in both the SAED patterns (in Figures 7c1 and d1) and the lattice-resolved HRTEM images (Figures 7c2 and d2). This verified that the inactive NaMn2O4 phase was generated during the cycling process, which is the main cause of the gradual capacity deterioration of the β-MnO2 electrodes.

and (020) diffraction spots of Na-ion extracted β-MnO2 in the charged state can be clearly indexed along the [101] zone axis. This proved that the crystalline structure of the β-MnO2 nanorods was retained upon cycling, which is a benefit for the long-term cycling of β-MnO2 nanorod electrodes. Nevertheless, the impurity phase NaMn2O4 has been identified in both the SAED patterns (in Figures 7c1 and d1) and the lattice-resolved HRTEM images (Figures 7c2 and d2). This verified that the inactive NaMn2O4 phase was generated during the cycling process, which is the main cause of the gradual capacity deterioration of the β-MnO2 electrodes.

In summary, β-MnO2 nanorods with exposed tunnel structures have been synthesized by a hydrothermal method. TEM, SAED and HRTEM characterization identified that the β-MnO2 nanorods grow along the  direction and have exposed (111) facets. When applied as cathodes in the Na-ion batteries, the β-MnO2 nanorods delivered a high initial specific capacity of 350 mAh g−1 and achieved a good high-rate performance, which could be attributed to the unique crystal structure of β-MnO2 nanorods with exposed (1 × 1) tunnels that provide facile transport for Na-ion insertion, accommodation and extraction. The mechanisms of Na-ion intercalation and de-intercalation in β-MnO2 nanorods were studied with ex situ XRD and TEM analyses. It was found that the formation of an inactive NaMn2O4 phase is the main cause of the gradual capacity decrease upon cycling for β-MnO2 nanorod electrodes.

direction and have exposed (111) facets. When applied as cathodes in the Na-ion batteries, the β-MnO2 nanorods delivered a high initial specific capacity of 350 mAh g−1 and achieved a good high-rate performance, which could be attributed to the unique crystal structure of β-MnO2 nanorods with exposed (1 × 1) tunnels that provide facile transport for Na-ion insertion, accommodation and extraction. The mechanisms of Na-ion intercalation and de-intercalation in β-MnO2 nanorods were studied with ex situ XRD and TEM analyses. It was found that the formation of an inactive NaMn2O4 phase is the main cause of the gradual capacity decrease upon cycling for β-MnO2 nanorod electrodes.

References

Palomares, V., Serras, P., Villaluenga, I., Hueso, K. B., Carretero-Gonzalez, J. & Rojo, T. Na-ion batteries, recent advances and present challenges to become low cost energy storage systems. Energy Environ. Sci. 5, 5884–5901 (2012).

Ong, S. P., Chevrier, V. L., Hautier, G., Jain, A., Moore, C., Kim, S., Ma, X. H. & Ceder, G. Voltage, stability and diffusion barrier differences between sodium-ion and lithium-ion intercalation materials. Energy Environ. Sci. 4, 3680–3688 (2011).

Zaghib, K., Trottier, J., Hovington, P., Brochu, F., Guerfi, A., Mauger, A. & Julien, C. M. Characterization of Na-based phosphate as electrode materials for electrochemical cells. J. Power Sources 196, 9612–9617 (2011).

Tepavcevic, S., Xiong, H., Stamenkovic, V. R., Zuo, X., Balasubramanian, M., Prakapenka, V. B., Johnson, C. S. & Rajh, T. Nanostructured bilayered vanadium oxide electrodes for rechargeable sodium-ion batteries. Acs Nano. 6, 530–538 (2012).

Cao, Y. L., Xiao, L. F., Wang, W., Choi, D. W., Nie, Z. M., Yu, J. G., Saraf, L. V., Yang, Z. G. & Liu, J. Reversible sodium ion insertion in single crystalline manganese oxide nanowires with long cycle life. Adv. Mater. 23, 3155–3160 (2011).

Tevar, A. D., De Graef, M. & Whitacre, J. Cycling-Induced crystallographic and morphological changes in Na4Mn9O18 . Electrochem. Soc. 7, 642–642 (2008).

Doeff, M. M., Peng, M. Y., Ma, Y. P. & Jonghe, L. C. D. Orthorhombic NaxMnO2 as a cathode material for secondary sodium and lithium polymer batteries. J. Electrochem. Soc. 141, L145–L147 (1994).

Gocheva, I. D., Nishijima, M., Doi, T., Okada, S., Yamaki, J. I. & Nishida, T. Mechanochemical synthesis of NaMF3 (M=Fe, Mn, Ni) and their electrochemical properties as positive electrode materials for sodium batteries. J. Power Sources 187, 247–252 (2009).

Yamada, Y., Doi, T., Tanaka, I., Okada, S. & Yamaki, J. Liquid-phase synthesis of highly dispersed NaFeF3 particles and their electrochemical properties for sodium-ion batteries. J. Power Sources 196, 4837–4841 (2011).

Recham, N., Chotard, J. N., Dupont, L., Djellab, K., Armand, M. & Tarascon, J. M. Ionothermal synthesis of sodium-based fluorophosphate cathode materials. J. Electrochem. Soc. 156, A993–A999 (2009).

Tripathi, R., Wood, S., Islam, M. S. & Nazar, L. Na-ion mobility in layered Na2FePO4F and olivine Na[Fe, Mn]PO4 . Energy Environ. Sci. 6, 2257–2264 (2013).

Ati, M., Dupont, L., Recham, N., Chotard, J. N., Walker, W. T., Davoisne, C., Barpanda, P., Sarou-Kanian, V., Armand, M. & Tarascon, J. M. Synthesis, structural and transport properties of novel bihydrated fluorosulphates NaMSO4F center dot 2H2O (M=Fe, Co, and Ni). Chem. Mater. 22, 4062–4068 (2010).

Barpanda, P., Chotard, J. N., Recham, N., Delacourt, C., Ati, M., Dupont, L., Armand, M. & Tarascon, J. M. Structural, transport, and electrochemical investigation of novel AMSO4F (A=Na, Li; M=Fe, Co, Ni, Mn) metal fluorosulphates prepared using low temperature synthesis routes. Inorg. Chem. 49, 7401–7413 (2010).

Reynaud, M., Barpanda, P., Rousse, G., Chotard, J. N., Melot, B. C., Recham, N. & Tarascon, J. M. Synthesis and crystal chemistry of the NaMSO4F family (M=Mg, Fe, Co, Cu, Zn). Solid State Sci. 14, 15–20 (2012).

Berthelot, R., Carlier, D. & Delmas, C. Electrochemical investigation of the P2-NaxCoO2 phase diagram. Nat. Mater. 10, 74–80 (2011).

Doeff, M. M., Ma, Y. P., Peng, M. Y., Visco, S. J. & Dejonghe, L. C. in Energy Environment Economics: 28th Intersociety Energy Conversion Engineering Conference: Papers Ch. 1 1111–1116 American Chemical Society: Washington, DC, (1993).

Yabuuchi, N., Kajiyama, M., Iwatate, J., Nishikawa, H., Hitomi, S., Okuyama, R., Usui, R., Yamada, Y. & Komaba, S. P2-type Nax[Fe1/2Mn1/2]O2 made from earth-abundant elements for rechargeable Na batteries. Nat. Mater. 11, 512–517 (2012).

Kim, D., Lee, E., Slater, M., Lu, W., Rood, S. & Johnson, C. S. Layered Na[Ni1/3Fe1/3Mn1/3]O2 cathodes for Na-ion battery application. Electrochem. Commun. 18, 66–69 (2012).

Komaba, S., Takei, C., Nakayama, T., Ogata, A. & Yabuuchi, N. Electrochemical intercalation activity of layered NaCrO2 vs LiCrO2 . Electrochem. Commun. 12, 355–358 (2010).

Xia, X. & Dahn, J. R. NaCrO2 is a fundamentally safe positive electrode material for sodium-ion batteries with liquid electrolytes. Electrochem. Solid-State Lett. 15, A1–A4 (2012).

Mendiboure, A., Delmas, C. & Hagenmuller, P. Electrochemical intercalation and deintercalation of NaxMnO2 bronzes. J. Solid State Chem. 57, 323–331 (1985).

Stoyanova, R., Carlier, D., Sendova-Vassileva, M., Yoncheva, M., Zhecheva, E., Nihtianova, D. & Delmas, C. Stabilization of over-stoichiometric Mn4+ in layered Na2/3MnO2 . J. Solid State Chem. 183, 1372–1379 (2010).

Hamani, D., Ati, M., Tarascon, J.-M. & Rozier, P. NaxVO2 as possible electrode for Na-ion batteries. Electrochem. Commun. 13, 938–941 (2011).

Lee, J., Lee, J. M., Yoon, S., Kim, S. O., Sohn, J. S., Rhee, K. I. & Sohn, H. J. Electrochemical characteristics of manganese oxide/carbon composite as a cathode material for Li/MnO2 secondary batteries. J. Power Sources 183, 325–329 (2008).

Chen, W.-M., Qie, L., Shao, Q. G., Yuan, L. X., Zhang, W. X. & Huang, Y. H. Controllable Synthesis of hollow bipyramid beta-MnO2 and its high electrochemical performance for lithium storage. ACS Appl. Mater. Int. 4, 3047–3053 (2012).

Jiao, F. & Bruce, P. G. Mesoporous crystalline beta-MnO2: a reversible positive electrode for rechargeable lithium batteries. Adv. Mater. 19, 657–660 (2007).

Su, D., Ahn, H.-J. & Wang, G. Hydrothermal synthesis of α-MnO2 and β-MnO2 nanorods as high capacity cathode materials for sodium ion batteries. J. Mater. Chem. A 1, 4845–4850 (2013).

Devaraj, S. & Munichandraiah, N. Effect of crystallographic structure of MnO2 on its electrochemical capacitance properties. J. Phys. Chem. C 112, 4406–4417 (2008).

Acknowledgements

This work was financially supported by the Australian Research Council (ARC) through the ARC FT project (FT110100800). We also acknowledge the support from the National Research Foundation of Korea through the 2013R1A2A1A01015911 project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies the paper on the NPG Asia Materials website

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/3.0/

About this article

Cite this article

Su, D., Ahn, HJ. & Wang, G. β-MnO2 nanorods with exposed tunnel structures as high-performance cathode materials for sodium-ion batteries. NPG Asia Mater 5, e70 (2013). https://doi.org/10.1038/am.2013.56

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/am.2013.56

Keywords

This article is cited by

-

Enhanced electrochemical energy storage devices utilizing a one-dimensional (1D) α-MnO2 nanocomposite encased in onion-like carbon

Journal of Materials Science (2024)

-

Ternary metal oxide nanocomposite for room temperature H2S and SO2 gas removal in wet conditions

Scientific Reports (2022)

-

In situ micro-current collector of amorphous manganese dioxide as cathode material for sodium-ion batteries

Ionics (2022)

-

Electrode Materials for Sodium-Ion Batteries: Considerations on Crystal Structures and Sodium Storage Mechanisms

Electrochemical Energy Reviews (2018)

-

Energy-driven surface evolution in beta-MnO2 structures

Nano Research (2018)