Abstract

Granular matter does not flow homogeneously like a fluid when submitted to external stress, but usually forms rigid regions that are separated by narrow shear bands where the material yields and flows1,2,3,4,5,6,7,8,9,10,11,12,13 (examples include geological faults9,10,11, avalanches12 and silo discharges2,13). Shear bands are narrow (five to ten grains in diameter1,2,3,4,5,6,7,8,9,10,11,12,13) and dependent on the particle shape5, and often localize near a boundary4,5,6,7,8,12,13; they hinder mixing and make grain flows difficult to predict or describe1,2,3. Here we show that the shear zones created in the bulk of the material are wider than those near the walls, and that their bulk velocity profiles lie on a universal curve. This finding challenges the accepted picture of shear banding in granular media.

Similar content being viewed by others

Main

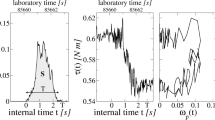

To create tunable shear zones away from lateral boundaries, we modified a Couette cell by splitting its bottom at radius Rs and attaching the two resulting concentric rings to the inner and outer cylinder (Fig. 1a, b). The cell was filled with grains up to a height h, the outer cylinder and its co-moving ring were rotated, and the resulting flow was monitored from above by a fast CCD (charge-coupled-device) camera. We investigated the behaviour of many different types of grain, but only show results for spherical glass beads (diameter, 0.3 ± 0.1 mm).

a, Sketch of our split-bottomed Couette cell; stationary parts are shown in green. Ri = 65 mm, R0 = 105 mm; Rs can be varied. b, Extension of the shear zone (circled in a), where the angular velocity, ω(r), ranges from 0.1 to 0.9 as a function of the level-height of the grains in the cell, h, for Rs = 85 mm. c, Velocity profiles showing the evolution of the ratio of the average angular velocity, ω(r), with h; values of h from left (in mm) are: 50, 40, 30, 20, 10. d, Universal bulk angular-velocity profiles obtained for different heights and plotted as a function of the rescaled radial coordinate λ = (r = Rc)/W. Red curve is an error function.

The flow rapidly relaxed to a steady state, was purely azimuthal and was proportional to the driving rate, Ω (refs 4–8). We fixed Ω at 0.16 rad s−1 and measured ω(r), the dimensionless ratio of the average angular velocity, and Ω as a function of the radial coordinate. For shallow layers, a narrow shear zone developed above the split at Rs. When h was increased, this shear zone shifted away from Rs and broadened continuously and without any apparent boundary (Fig. 1b, c) — the widest zones exceeded 50 grain-diameters. The shear zone reached the inner cylinder and eventually localized there5,7 when the height was sufficiently large. There was, however, a substantial range of layer heights where there were wide, symmetric bulk shear zones.

After appropriate rescaling, all of these bulk velocities collapse onto a universal curve, which is extremely well described by an error function ('erf'; Fig. 1d)

The strain rate is therefore gaussian, and the shear zones are completely determined by their centres, Rc, and widths, W. The fit to equation (1) is just as good for particles of different size and shape. Unlike shear bands localized at walls5, bulk shear zones are universal — that is, they are not qualitatively influenced by the granular 'microstructure'. Removal of the inner cylinder while retaining the stationary bottom disc (dark green in Fig. 1a, b) does not affect the bulk profiles.

The evolution of the velocity profile from a step function at the bottom to an error function at the surface is reminiscent of a diffusive process along the vertical axis. However, W grows faster than √(√h), as diffusion would suggest, but slower than h. The shear zone's width is independent of Rs, but varies with particle size and type, hinting at a non-trivial internal length scale. By contrast, the location of the shear zone's centre, Rc, is particle-independent. Therefore, the only relevant length scales for Rc are h and Rs, and we find that the dimensionless displacement of the shear zone is well fitted by (Rs − Rc)/Rs = (h/Rs)(5/2).

Our results suggest that, for large Rs and h, the shear zones become arbitrarily broad. This raises the question of whether shear banding is intrinsic to granular matter or only occurs for particular flow geometries. Continuum theories, which should be able to describe granular shear zones, are severely constrained by the universality of the velocity profiles and the shear-zone positions, and should also incorporate the strong influence of the boundary. Our simple experimental protocol can be used to investigate unexpected regimes of granular flow, not least with a view to answering the basic question of how sand flows.

References

Duran, J. Sand, Powders and Grains (Eyrolles, Paris, 1997).

Nedderman, R. Statics and Kinematics of Granular Materials (Cambridge Univ. Press, Cambridge, 1992).

Jaeger, H. M., Nagel, S. R. & Behringer, R. P. Rev. Mod. Phys. 68, 1259–1272 (1996).

Hartley, R. R. & Behringer, R. P. Nature 421, 928–930 (2003).

Mueth, D. M. et al. Nature 406, 385–389 (2000).

Howell, D. W., Behringer, R. P. & Veje, C. T. Phys. Rev. Lett. 82, 5241–5244 (1999).

Losert, W., Bocquet, L., Lubensky, T. C. & Gollub, J. P. Phys. Rev. Lett. 85, 1428–1431 (2000).

Lätzel, M., Luding, S., Herrmann, H. J., Howell, D. W. & Behringer, R. P. Preprint http://arxiv.org/abs/cond-mat/0211274

Scott, D. R. Nature 381, 592–595 (1996).

Oda, M. & Kazama, H. Géotechnique 48, 465–481 (1998).

Muhlhaus, H. B. & Vardoulakis, I. Géotechnique 37, 271–283 (1987).

Daerr, A. & Douady, S. Nature 399, 241–243 (1999).

Pouliquen, O. & Gutfraind, R. Phys. Rev. E 53, 552–560 (1996).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Fenistein, D., van Hecke, M. Wide shear zones in granular bulk flow. Nature 425, 256 (2003). https://doi.org/10.1038/425256a

Issue Date:

DOI: https://doi.org/10.1038/425256a

This article is cited by

-

3D implementation and validation of VOF-coupled non-local granular rheology

Granular Matter (2022)

-

Characterization of shear zones in soft granular beds by means of a novel magnetic resonance imaging technique

Granular Matter (2022)

-

Torsional shear flow of granular materials: shear localization and minimum energy principle

Computational Particle Mechanics (2018)

-

Similarities between GSH, hypoplasticity and KCR

Acta Geotechnica (2016)

-

Experimental measurements of orientation and rotation of dense 3D packings of spheres

Granular Matter (2014)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.