Abstract

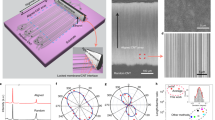

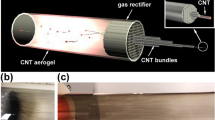

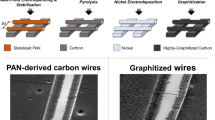

Carbon nanotubes1,2 might be usefully employed in nanometre-scale engineering and electronics. Electrical conductivity measurements on the bulk material3,4, on individual multi-walled5,6 and single-walled7 nanotubes and on bundles of single-walled nanotubes8,9 have revealed that they may behave as metallic, insulating or semiconducting nanowires, depending on the method of production—which controls the degree of graphitization, the helicity and the diameter. Measurements of Young's modulus show10 that single nanotubes are stiffer than commercial carbon fibres. Methods commonly used to generate nanotubes—carbon-arc discharge techniques1,2,4, catalytic pyrolysis of hydrocarbons11,12 and condensed-phase electrolysis13,14—generally suffer from the drawbacks that polyhedral particles are also formed and that the dimensions of the nanotubes are highly variable. Here we describe a method for generating aligned carbon nanotubes by pyrolysis of 2-amino-4,6-dichloro-s-triazine over thin films of a cobalt catalyst patterned on a silica substrate by laser etching. The use of a patterned catalyst apparently encourages the formation of aligned nanotubes. The method offers control over length (up to about 50 μm) and fairly uniform diameters (30–50 nm), as well as producing nanotubes in high yield, uncontaminated by polyhedral particles.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Iijima, S. Helical microtubules of graphitic carbon. Nature 354, 56–58 (1991).

Ebbesen, T. W. & Ajayan, P. M. Large scale synthesis of carbon nanotubes. Nature 358, 220–222 (1992).

De Heer, W. A., Chatelain, A. & Ugarte, D. Acarbon nanotube field-emission electron source. Science 270, 1179–1180 (1995).

Terrones, M. et al. Recent Advances in the Chemistry and Physics of Fullerenes and Related Materials Vol. 2(eds Kadish, K. M. & Ruoff, R. S.) 599–620 (Electrochem. Soc., Pennington, NJ, (1995)).

Dai, H. J., Wong, E. W. & Lieber, C. M. Probing electrical transport in nanomaterials: conductivity of individual carbon nanotubes. Science 272, 523–526 (1996).

Ebbesen, T. W. et al. Electrical conductivity of individual carbon nanotubes. Nature 382, 54–56 (1996).

Tans, S. J. et al. Individual single-wall carbon nanotubes as quantum wires. Nature 386, 474–477 (1997).

Bockrath, M. et al. Single-electron transport in ropes of carbon nanotubes. Science 275, 1922–1925 (1997).

Thess, A. et al. Crystalline ropes of metallic carbon nanotubes. Science 273, 483–487 (1996).

Treacy, M. M. J., Ebbesen, T. W. & Gibson, J. M. Exceptionally high Young's modulus observed for individual nanotubes. Nature 381, 678–680 (1996).

Amelinckx, S. et al. Aformation mechanism for catalytically grown helix-shaped graphite nanotubes. Science 265, 635–639 (1994).

Endo, M. et al. Pyrolytic carbon nanotubes from vapor-grown carbon fibres. Carbon 33, 873–881 (1995).

Hsu, W. K. et al. Condensed-phase nanotubes. Nature 377, 687 (1995).

Hsu, W. K. et al. Electrolytic formation of carbon nanostructures. Chem. Phys. Lett. 261, 161–166 (1996).

Thurston, J. T. et al. Cyanuric chloride derivatives I. Aminochloro-s-triazines. J. Am. Chem. Soc. 73, 2981–2983 (1951).

Chrisey, D. B. & Hubler, G. K. (eds) Pulsed Laser Deposition of Thin Films(Wiley, New York, (1994)).

Terrones, M. et al. Pyrolytically grown BxCyNznanomaterials: nanofibres and nanotubes. Chem. Phys. Lett. 257, 576–582 (1996).

Li, W. Z. et al. Large synthesis of aligned carbon nanotubes. Science 274, 1701–1703 (1996).

Tennent, H. G., Barber, J. J. & Hoch, R. US Patent No. 5578543((1996)).

Hausslein, R. W. Commercial manufacture and uses of carbon nanotubules. 187th Mtg of the Electrochem. Soc. (Abstr.) 175 (Electrochem. Soc., Pennington, NJ, (1995)).

Niu, C., Sichel, E. K., Hoch, R., Moy, D. & Tennent, H. High power electrochemical capacitors based on carbon nanotube electrodes. Appl. Phys. Lett. 70, 1480–1482 (1997).

Acknowledgements

We thank J. Thorpe, D. P. Randall, S. Tehuacanero, R. Hernández, P. Mexía, R. Guardián and L. Rendón for providing electron microscope facilities, and D. Bernaerts for discussions. We thank CONACYT-México (M.T. and H.T.), the ORS scheme for scholarships (M.T. and W.K.H.), DGAPA-UNAM IN 107-296 (H.T.), EU-TMR grant (J.O.), the Royal Society (London) and the EPSRC for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Terrones, M., Grobert, N., Olivares, J. et al. Controlled production of aligned-nanotube bundles. Nature 388, 52–55 (1997). https://doi.org/10.1038/40369

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1038/40369

This article is cited by

-

Properties, assembly and characterization of carbon nanotubes: their application in water purification, environmental pollution control and biomedicines—a comprehensive review

Carbon Letters (2023)

-

A nitrogen-doped nanotube molecule with atom vacancy defects

Nature Communications (2020)

-

3D hierarchical porous hybrid nanostructure of carbon nanotubes and N-doped activated carbon

Scientific Reports (2020)

-

Carbon nanotubes: synthesis, properties and engineering applications

Carbon Letters (2019)

-

Effect of Interwall Interaction on Phonon Oscillations of Growing Multi-Walled Carbon Nanotube

Iranian Journal of Science and Technology, Transactions A: Science (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.