Abstract

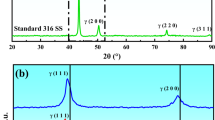

IT is sometimes assumed that the oxide film formed on iron at room temperatures is uniform in thickness across a specimen, and that where several oxides exist together they are present as layers stacked neatly one above the other. In an electron microscope investigation of the oxidation of mild steel using oxide films stripped by the iodine/methanol technique1 the only oxide that consistently conforms with this idea is magnetite, Fe3O4. Fig. 1 shows magnetite with its diffraction pattern on a film stripped from mild steel. The metal specimen was electropolished in a 5 per cent perchloric acid/95 per cent acetic acid mixture, washed in methanol and given no additional air exposure before the surface layer was stripped. It is interesting to note that these stripped oxide films remain quite stable if kept in a desiccator for a year and still give the same diffraction results after this length of time. Magnetite typically appears as an almost featureless layer, though with experience its presence may be recognized without examination of the very characteristic orientated arced diffraction patterns it produces. The (001) projection, as in Fig. 1, occurs most frequently although other orientations have been observed on the surface layers produced on thin foil corrosion specimens and there is evidence that the orientation changes from grain to grain. The usual difficulty in distinguishing between Fe3O4 and γ Fe2O3 was experienced in this work2 since these oxides have the same crystal structure and lattice parameters. It is noticeable that the (200) reflexions are absent and that no mixed index reflexions appear–these facts point to Fe3O4. There are, however, eight (311)3 reflexions that would not be expected and these consistently appear with this type of pattern on foils as well as on stripped oxide films. They suggest that the film is of the order of one unit cell in thickness, approximately 10 Å, and that the reflexions could arise by streaking4.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Vernon, W. H. J., Wormwell, F., and Nurse, T. J., J. Chem. Soc., 621 (1939).

Luborsky, F. E., Kock, E. F., and Morlock, C. R., J. App. Phys., 34, No. 9, 2905 (1963).

Bernal, J. D., Dasgupta, D. R., and Mackay, A. L., Clay. Min. Bull., 4, No. 21 (1959).

Vainshtein, B. K., Structure Analysis by Electron Diffraction, 36 (Pergamon Press).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

FURSEY, A. Oxide Films on Mild Steel. Nature 207, 747–748 (1965). https://doi.org/10.1038/207747a0

Issue Date:

DOI: https://doi.org/10.1038/207747a0

This article is cited by

-

Dependence of Tribological Performance and Tribopolymerization on the Surface Binding Strength of Selected Cycloalkane-Carboxylic Acid Additives

Tribology Letters (2020)

-

Relating Tribological Performance and Tribofilm Formation to the Adsorption Strength of Surface-Active Precursors

Tribology Letters (2020)

-

Detection of Magnetite as a Surface Impurity on Thin Foils of Ferrous Materials

Nature (1966)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.