Abstract

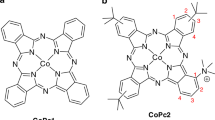

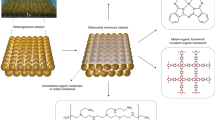

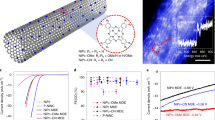

Electrochemical carbon dioxide (CO2) reduction can in principle convert carbon emissions to fuels and value-added chemicals, such as hydrocarbons and alcohols, using renewable energy, but the efficiency of the process is limited by its sluggish kinetics1,2. Molecular catalysts have well defined active sites and accurately tailorable structures that allow mechanism-based performance optimization, and transition-metal complexes have been extensively explored in this regard. However, these catalysts generally lack the ability to promote CO2 reduction beyond the two-electron process to generate more valuable products1,3. Here we show that when immobilized on carbon nanotubes, cobalt phthalocyanine—used previously to reduce CO2 to primarily CO—catalyses the six-electron reduction of CO2 to methanol with appreciable activity and selectivity. We find that the conversion, which proceeds via a distinct domino process with CO as an intermediate, generates methanol with a Faradaic efficiency higher than 40 per cent and a partial current density greater than 10 milliamperes per square centimetre at −0.94 volts with respect to the reversible hydrogen electrode in a near-neutral electrolyte. The catalytic activity decreases over time owing to the detrimental reduction of the phthalocyanine ligand, which can be suppressed by appending electron-donating amino substituents to the phthalocyanine ring. The improved molecule-based electrocatalyst converts CO2 to methanol with considerable activity and selectivity and with stable performance over at least 12 hours.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Data supporting the findings of this study are available from the corresponding authors upon reasonable request. Source data for Figs. 2, 4 are provided with the paper.

References

Costentin, C., Robert, M. & Savéant, J.-M. Catalysis of the electrochemical reduction of carbon dioxide. Chem. Soc. Rev. 42, 2423–2436 (2013).

Schiffer, Z. J. & Manthiram, K. Electrification and decarbonization of the chemical industry. Joule 1, 10–14 (2017).

Francke, R., Schille, B. & Roemelt, M. Homogeneously catalyzed electroreduction of carbon dioxide—methods, mechanisms, and catalysts. Chem. Rev. 118, 4631–4701 (2018).

Hori, Y., Wakebe, H., Tsukamoto, T. & Koga, O. Electrocatalytic process of CO selectivity in electrochemical reduction of CO2 at metal electrodes in aqueous media. Electrochim. Acta 39, 1833–1839 (1994).

Hori, Y. in Modern Aspects of Electrochemistry Vol. 42 (eds Vayenas, C. G. et al.) 89–189 (Springer, 2008).

Peterson, A. A., Abild-Pedersen, F., Studt, F., Rossmeisl, J. & Nørskov, J. K. How copper catalyzes the electroreduction of carbon dioxide into hydrocarbon fuels. Energy Environ. Sci. 3, 1311–1315 (2010).

Peterson, A. A. & Nørskov, J. K. Activity descriptors for CO2 electroreduction to methane on transition-metal catalysts. J. Phys. Chem. Lett. 3, 251–258 (2012).

Zhang, X. et al. Highly selective and active CO2 reduction electrocatalysts based on cobalt phthalocyanine/carbon nanotube hybrid structures. Nat. Commun. 8, 14675 (2017).

Varela, A. S. et al. Metal-doped nitrogenated carbon as an efficient catalyst for direct CO2 electroreduction to CO and hydrocarbons. Angew. Chem. Int. Ed. 54, 10758–10762 (2015).

Shen, J. et al. Electrocatalytic reduction of carbon dioxide to carbon monoxide and methane at an immobilized cobalt protoporphyrin. Nat. Commun. 6, 8177 (2015).

Wu, Y., et al. Electroreduction of CO2 catalyzed by a heterogenized Zn–porphyrin complex with a redox-innocent metal center. ACS Cent. Sci. 3, 847–852 (2017).

Pan, Y. et al. Design of single-atom Co–N5 catalytic site: a robust electrocatalyst for CO2 reduction with nearly 100% CO selectivity and remarkable stability. J. Am. Chem. Soc. 140, 4218–4221 (2018).

Tripkovic, V. et al. Electrochemical CO2 and CO reduction on metal-functionalized porphyrin-like graphene. J. Phys. Chem. C 117, 9187–9195 (2013).

Ju, W. et al. Understanding activity and selectivity of metal-nitrogen-doped carbon catalysts for electrochemical reduction of CO2. Nat. Commun. 8, 944 (2017).

Dhanasekaran, T., Grodkowski, J., Neta, P., Hambright, P. & Fujita, E. p-Terphenyl-sensitized photoreduction of CO2 with cobalt and iron porphyrins. Interaction between CO and reduced metalloporphyrins. J. Phys. Chem. A 103, 7742–7748 (1999).

Fujita, E., Creutz, C., Sutin, N. & Szalda, D. J. Carbon dioxide activation by cobalt(I) macrocycles: factors affecting carbon dioxide and carbon monoxide binding. J. Am. Chem. Soc. 113, 343–353 (1991).

Rao, H., Schmidt, L. C., Bonin, J. & Robert, M. Visible-light-driven methane formation from CO2 with a molecular iron catalyst. Nature 548, 74 (2017).

Leonard, N. et al. The chemical identity, state and structure of catalytically active centers during the electrochemical CO2 reduction on porous Fe–nitrogen–carbon (Fe–N–C) materials. Chem. Sci. 9, 5064–5073 (2018).

Zhang, H., Li, J., Cheng, M.-J. & Lu, Q. CO Electroreduction: current development and understanding of Cu-based catalysts. ACS Catal. 9, 49–65 (2018).

Solis, B. H., Maher, A. G., Dogutan, D. K., Nocera, D. G. & Hammes-Schiffer, S. Nickel phlorin intermediate formed by proton-coupled electron transfer in hydrogen evolution mechanism. Proc. Natl Acad. Sci. USA 113, 485–492 (2016).

Jiang, J. et al. Unusual stability of a bacteriochlorin electrocatalyst under reductive conditions. A case study on CO2 conversion to CO. ACS Catal. 8, 10131–10136 (2018).

Grodkowski, J. et al. Reduction of cobalt and iron phthalocyanines and the role of the reduced species in catalyzed photoreduction of CO2. J. Phys. Chem. A 104, 11332–11339 (2000).

Lieber, C. M. & Lewis, N. S. Catalytic reduction of carbon dioxide at carbon electrodes modified with cobalt phthalocyanine. J. Am. Chem. Soc. 106, 5033–5034 (1984).

Zhang, Z. et al. Reaction mechanisms of well-defined metal–N4 sites in electrocatalytic CO2 reduction. Angew. Chem. Int. Ed. 57, 16339–16342 (2018).

Kapusta, S. & Hackerman, N. Carbon dioxide reduction at a metal phthalocyanine catalyzed carbon electrode. J. Electrochem. Soc. 131, 1511–1514 (1984).

Boutin, E. et al. Aqueous electrochemical reduction of carbon dioxide and carbon monoxide into methanol with cobalt phthalocyanine. Angew. Chem. Int. Ed. 58, 16172 (2019).

Aoi, S., Mase, K., Ohkubo, K. & Fukuzumi, S. Selective electrochemical reduction of CO2 to CO with a cobalt chlorin complex adsorbed on multi-walled carbon nanotubes in water. Chem. Commun. 51, 10226–10228 (2015).

Hu, X.-M., Rønne, M. H., Pedersen, S. U., Skrydstrup, T. & Daasbjerg, K. Enhanced catalytic activity of cobalt porphyrin in CO2 electroreduction upon immobilization on carbon materials. Angew. Chem. Int. Ed. 56, 6468–6472 (2017).

Achar, B. N. & Lokesh, K. S. Studies on tetra-amine phthalocyanines. J. Organomet. Chem. 689, 3357–3361 (2004).

Ding, X. & Han, B.-H. Metallophthalocyanine-based conjugated microporous polymers as highly efficient photosensitizers for singlet oxygen generation. Angew. Chem. Int. Ed. 54, 6536–6539 (2015).

Acknowledgements

This work was supported by the US National Science Foundation (grant CHE-1651717). X.L. acknowledges a Croucher Fellowship for Postdoctoral Research. Z.J. and Y.L. acknowledge financial support by Shenzhen fundamental research funding (JCYJ20160608140827794) and the Guangdong Provincial Key Laboratory (2018B030322001). The authors thank Q. Wang and M. Gu (Southern University of Science and Technology) for assistance with STEM imaging.

Author information

Authors and Affiliations

Contributions

Y.W. and H.W. conceived the project and designed the experiments. Z.J. and Y.L. synthesized the catalyst materials and performed the structural characterizations. Y.W. and X.L. performed the electrocatalytic studies. Y.W., Y.L. and H.W. analysed the data. Y.W. and H.W. wrote the manuscript. Y.L. and H.W. supervised the project.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Peer review information Nature thanks Robert Francke and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Extended data figures and tables

Extended Data Fig. 1 Catalytic properties of FePc/CNT and NiPc/CNT.

a–d, Potential-dependent catalytic performance of CO2 electroreduction by FePc/CNT (a, b) and NiPc/CNT (c, d).

Extended Data Fig. 2 Product identification and quantification.

a, b, Typical gas chromatography diagrams from the flame ionization detector (a) and the thermal conductivity detector (b),showing the presence of CO and H2 (marked in red) and the absence of other common gas products (marked in grey). c, d, Typical 1H NMR (c) and 13C NMR (d) spectra of a liquid sample after CO2 electroreduction electrolysis (green traces) versus a blank 0.1 M KHCO3 solution (red traces). e, f, Representative 1H NMR spectra of liquid samples after 1 h of CO2 reduction electrolysis catalysed by CoPc/CNT at −0.94 V versus RHE (e) and 1 h of CO reduction electrolysis catalysed by CoPc–NH2/CNT at −0.95 V versus RHE (f). The detailed information used to determine the FE of MeOH production is given in the diagrams.

Extended Data Fig. 3 Catalytic performance of CoPc/CNT under N2.

a, b, Potential-dependent product selectivity (a) and partial current density (b) for CO2 electroreduction catalysed by CoPc/CNT under N2.

Extended Data Fig. 4 Effects of carbon support on CO2-to-MeOH conversion.

a, b, Potential-dependent product selectivity (a) and partial current density (b) for the electroreduction of CO2 by bare CoPc aggregates on carbon paper. c, Nyquist plots of bare CoPc, a physical mixture of CoPc and CNTs and the CoPc/CNT hybrid, measured at −0.94 V versus RHE in a 0.1 M aqueous KHCO3 solution saturated with CO2 with a scanning frequency range from 200 kHz to 100 Hz and an a.c. amplitude of 5 mV. Z′ and Z″ refer to the real and imaginary parts of impedance, respectively. The inset shows the enlarged area where the traces for the CoPc/CNT hybrid and the mixture of CoPc and CNTs are clearer. d, Selectivity (FEMeOH) and partial current density (jMeOH) for CO2 reduction to MeOH catalysed by bare CoPc (‘Bare’), the CoPc/CNT physical mixture (‘CNT Mix’), the CoPc/Vulcan XC72 mixture (‘VXC72 Mix’), the CoPc/Ketjenblack mixture (‘KB Mix’) and the CoPc/CNT hybrid (‘CNT Hybrid’) at −0.94 V versus RHE.

Extended Data Fig. 5 Long-term electrocatalytic performance of CoPc/CNT.

a, Gas product selectivity and total current density in a 12-h electrolysis of CO2 reduction catalysed by CoPc/CNT at −0.94 V versus RHE. b, c, SEM images of an as-deposited CoPc/CNT electrode before (b) and after (c) catalysing CO2 reduction electrolysis at −0.94 V versus RHE for 12 h.

Extended Data Fig. 6

UV-Vis spectra of post-electrolysis CoPc and free-base phthalocyanine (H2Pc) in DMF.

Extended Data Fig. 7 Cyclic voltammograms of CoPc/CNT and CoPc–NH2/CNT.

a, b, The curves were recorded at a scan rate of 400 mV s−1 in a 0.1 M aqueous KHCO3 solution under N2 (a) and CO2 (b). The most prominent cathodic (ic) and anodic (ia) features of the molecules are labelled. The redox potential of CoPc–NH2/CNT is more negative than that of CoPc/CNT.

Extended Data Fig. 8

Catalytic performance of CoPc–NH2/CNT for electroreduction of CO to MeOH.

Extended Data Fig. 9 Spectroscopic characterization of CoPc–NH2.

a, High-resolution mass spectrometry results for CoPc–NH2. Calculated for CoC32H20N12: 631.12604; found: 631.12435. b, UV-Vis spectrum of CoPc–NH2 in 15 M H2SO4. λmax = 210 nm, 299 nm, 380 nm and 739 nm.

Source data

Rights and permissions

About this article

Cite this article

Wu, Y., Jiang, Z., Lu, X. et al. Domino electroreduction of CO2 to methanol on a molecular catalyst. Nature 575, 639–642 (2019). https://doi.org/10.1038/s41586-019-1760-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-019-1760-8

This article is cited by

-

Spatial engineering of single-atom Fe adjacent to Cu-assisted nanozymes for biomimetic O2 activation

Nature Communications (2024)

-

The origins of catalytic selectivity for the electrochemical conversion of carbon dioxide to methanol

Nano Research (2024)

-

Tuning electronic properties of cobalt phthalocyanines for oxygen reduction and evolution reactions

Science China Chemistry (2024)

-

Efficient Fixation of CO2 to Cyclic Carbonates Under Mild Conditions Catalyzed by Deep Eutectic Solvent

Catalysis Letters (2024)

-

Efficient multicarbon formation in acidic CO2 reduction via tandem electrocatalysis

Nature Nanotechnology (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.