Abstract

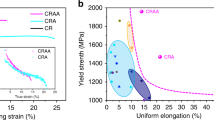

The high-temperature stability and mechanical properties of refractory molybdenum alloys are highly desirable for a wide range of critical applications. However, a long-standing problem for these alloys is that they suffer from low ductility and limited formability. Here we report a nanostructuring strategy that achieves Mo alloys with yield strength over 800 MPa and tensile elongation as large as ~ 40% at room temperature. The processing route involves a molecular-level liquid–liquid mixing/doping technique that leads to an optimal microstructure of submicrometre grains with nanometric oxide particles uniformly distributed in the grain interior. Our approach can be readily adapted to large-scale industrial production of ductile Mo alloys that can be extensively processed and shaped at low temperatures. The architecture engineered into such multicomponent alloys offers a general pathway for manufacturing dispersion-strengthened materials with both high strength and ductility.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Perepezko, J. H. The hotter the engine, the better. Science 326, 1068–1069 (2009).

Dimiduk, D. M. & Perepezko, J. H. Mo-Si-B alloys: Developing a revolutionary turbine-engine material. Mater. Res. Soc. Bull. 9, 639–645 (2003).

El-Genk, M. S. & Tournier, J. M. A review of refractory metal alloys and mechanically alloyed-oxide dispersion strengthened steels for space nuclear power systems. J. Nucl. Mater. 340, 93–112 (2005).

Sturm, D. et al. The influence of silicon on the strength and fracture toughness of molybdenum. Mater. Sci. Eng. 463, 107–114 (2007).

Wadsworth, J., Nieh, T. G. & Stephens, J. J. Recent advances in aerospace refractory-metal alloys. Int. Mater. Rev. 33, 131–150 (1988).

Cockeram, B. V. The fracture toughness and toughening mechanism of commercially available unalloyed molybdenum and oxide dispersion strengthened molybdenum with an equiaxed, large grain structure. Metall. Mater. Trans. 40A, 2843–2860 (2009).

Schneibel, J. H., Brady, M. P., Kruzic, J. J. & Ritchie, R. O. On the improvement of the ductility of molybdenum by spinel (MgAl2O4) particles. Z. für Metall. 96, 632–637 (2005).

Cockeram, B. V., Smith, R. W., Hashimoto, N. & Snead, L. L. The swelling, microstructure, and hardening of wrought LCAC, TZM, and ODS molybdenum following neutron irradiation. J. Nucl. Mater. 418, 121–136 (2011).

Byun, T. S., Li, M., Cockeram, B. V. & Snead, L. L. Deformation and fracture properties in neutron irradiated pure Mo and Mo alloys. J. Nucl. Mater. 376, 240–246 (2008).

Trinkle, D. R. & Woodward, C. The chemistry of deformation: How solutes soften pure metals. Science 310, 1665–1667 (2005).

Medvedeva, N. I., Gornostyrev, Y. N. & Freeman, A. J. Solid solution softening and hardening in the group-V and group-VI bcc transition metals alloys: First principles calculations and atomistic modelling. Phys. Rev. B 76, 212104 (2007).

Brosse, J. B., Fillet, R. & Biscondi, M. Intrinsic intergranular brittleness of molybdenum. Scr. Metall. 15, 619–623 (1981).

Miller, M. K., Kenik, E. A., Mousa, M. S., Russell, K. F. & Bryhan, A. J. Improvement in the ductility of molybdenum alloys due to grain boundary segregation. Scr. Metall. 46, 299–303 (2002).

Majumdar, S., Raveendra, S., Samajdar, I., Bhargava, P. & Sharma, I. G. Densification and grain growth during isothermal sintering of Mo and mechanically alloyed Mo-TZM. Acta Mater. 57, 4158–4168 (2009).

Mueller, A. J., Bianco, R. & Buckman, R. W. Evaluation of oxide dispersion strengthened (ODS) molybdenum and molybdenum-rhenium alloys. Inter. J. Ref. Met. Hard Mater. 18, 205–211 (2000).

Zhang, G. J. et al. Microstructure and strengthening mechanism of oxide lanthanum dispersion strengthened molybdenum alloy. Adv. Eng. Mater. 6, 943–948 (2004).

Cockeram, B. V. The mechanical properties and fracture mechanisms of wrought low carbon arc cast (LCAC), molybdenum-0.5pct titanium-0.1pct zirconium (TZM), and oxide dispersion strengthened (ODS) molybdenum flat products. Mater. Sci. Eng. A 418, 120–136 (2006).

Bianco, R. & Buckman, R. W. Jr et al. in Molybdenum and Molybdenum Alloys (ed. Crowson, A.) 125–44 (TMS, 1998).

Klopp, W. D. & Witzke, W. R. Mechanical properties of electron-beam-melted molybdenum and dilute Mo–Re alloys. Metall. Trans. 4, 2006–2008 (1973).

Takida, T. et al. Mechanical properties of fine-grained, sintered molybdenum alloys with dispersed particles developed by mechanical alloying. Mater. Trans. JIM 45, 143–148 (2004).

Cockeram, B. V. Measuring the fracture toughness of molybdenum-0.5 pct titanium-0.1 pct zirconium and oxide dispersion-strengthened molybdenum alloys using standard and subsized bend specimens. Metall. Mater. Trans. A 33A, 3685–3707 (2002).

Wang, Y. M., Chen, M. W., Zhou, F. H. & Ma, E. High tensile ductility in a nanostructured metal. Nature 419, 912–915 (2002).

Zhao, Y. H., Liao, X. Z., Cheng, S., Ma, E. & Zhu, Y. T. Simultaneously increasing the ductility and strength of nanostructured alloys. Adv. Mater. 18, 2280–2283 (2006).

Ma, E. Eight routes to improve the tensile ductility of bulk nanostructured metals and alloys. JOM 58, 49–53 (2006).

Kumar, K. S., Van Swygenhoven, H. & Suresh, S. Mechanical behaviour of nanocrystalline metals and alloys. Acta Mater. 51, 5743–5774 (2003).

Sabirov, I., Murashkin, M. Yu. & Valiev, R. Z. Nanostructured aluminium alloys produced by severe plastic deformation: New horizons in development. Mater. Sci. Eng. A 560, 1–24 (2013).

Sha, G., Wang, Y. B., Liao, X. Z., Duan, Z. C., Ringer, S. P. & Langdon, T. G. Influence of equal-channel angular pressing on precipitation in an Al–Zn–Mg–Cu alloy. Acta Mater. 57, 3123–3132 (2009).

Wadsworth, J., Packer, C. M., Chewey, P. M. & Coons, W. C. A microstructural investigation of the origin of brittle behaviour in the transverse direction in Mo-based alloy bars. Metall. Trans. 15A, 1741–1752 (1984).

Gurland, J. & Plateau, J. The mechanism of ductile rupture of metals containing inclusions. Trans. Am. Soc. Metals 56, 442–454 (1963).

Cockeram, B. V. The role of stress state on the fracture toughness and toughening mechanisms of wrought molybdenum and molybdenum alloys. Mater. Sci. Eng. A528, 288–308 (2010).

Sun, J., Zhang, G. J., Sun, Y. J., Liu, G., Jiang, F. & Ding, X. D. A Preparing Method of Mo Alloys Doped with Nanosized Rare-earth Oxides Particles, Chinese Patent ZL 200810150463.0 (2010).

Liu, G., Sun, J., Nan, C. W. & Chen, K. H.. Experimental and multiscale modelling of the coupled influence of constituents and precipitates on the ductile fracture of heat-treatable aluminium alloys. Acta Mater. 53, 3453–3468 (2005).

Liu, G., Zhang, G. J., Wang, R. H., Hu, W., Sun, J. & Chen, K. H. Heat treatment-modulated coupling effect of multi-scale second-phase particles on the ductile fracture of aged aluminium alloys. Acta Mater. 55, 273–284 (2007).

Pauly, S., Liu, G., Gorantla, S., Wang, G., Kuhn, U., Kim, D. H. & Eckert, J. Criteria for tensile plasticity in Cu–Zr–Al bulk metallic glasses. Acta Mater. 58, 4883–4890 (2010).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51171149, 51171142, 50831004), the 973 Program of China (No. 2010CB631003), the 863 Key Project of China (No. 2008AA031000), the National Science Technology Supporting Program of China (No. 2012BAE06B02), and the 111 Project of China (B06025). We thank L. Wang and J. H. Luo, from JinDuiCheng Molybdenum, China, for their assistance in the production and application of the NS-Mo alloys. E.M. was supported in part by an adjunct professorship at XJTU.

Author information

Authors and Affiliations

Contributions

J.S. designed and supervised the project, G.J.Z., G.L., F.J. and Y.J.S. carried out the experiments, G.L., X.D.D. and J.S. performed the calculations, E.M., G.L. and J.S. wrote the paper. All the co-authors contributed to discussions.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 1182 kb)

Rights and permissions

About this article

Cite this article

Liu, G., Zhang, G., Jiang, F. et al. Nanostructured high-strength molybdenum alloys with unprecedented tensile ductility. Nature Mater 12, 344–350 (2013). https://doi.org/10.1038/nmat3544

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat3544

This article is cited by

-

Heterostructured metal matrix composites for structural applications: a review

Journal of Materials Science (2024)

-

Revealing the room temperature superplasticity in bulk recrystallized molybdenum

Nature Communications (2023)

-

Grain refinement in titanium prevents low temperature oxygen embrittlement

Nature Communications (2023)

-

Effects of In Situ TiB2 Particles and (Ce + Yb) on the Microstructure and Mechanical Properties of Al–Si Matrix Composites

Transactions of the Indian Institute of Metals (2023)

-

Research and development of nanocrystalline W/W-based materials: novel preparation approaches, formation mechanisms, and unprecedented excellent properties

Frontiers of Materials Science (2023)