Abstract

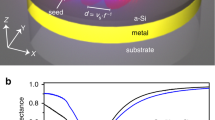

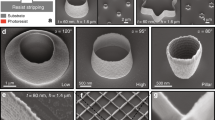

The fabrication of micrometre- and nanometre-scale devices in silicon typically involves lithography and etching. These processes are costly and tend to be either limited in their resolution or slow in their throughput1. Recent work has demonstrated the possibility of patterning substrates on the nanometre scale by ‘imprinting’2,3 or directed self-assembly4, although an etching step is still required to generate the final structures. We have devised and here demonstrate a rapid technique for patterning nanostructures in silicon that does not require etching. In our technique—which we call ‘laser-assisted direct imprint’ (LADI)—a single excimer laser pulse melts a thin surface layer of silicon, and a mould is embossed into the resulting liquid layer. A variety of structures with resolution better than 10 nm have been imprinted into silicon using LADI, and the embossing time is less than 250 ns. The high resolution and speed of LADI, which we attribute to molten silicon's low viscosity (one-third that of water), could open up a variety of applications and be extended to other materials and processing techniques.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Ito, T. & Okazaki, S. Pushing the limits of lithography. Nature 406, 1027–1031 (2000)

Rogers, J. A. & Mirkin, C. Emerging methods for micro- and nanofabrication. Mater. Res. Bull. 26, (2001)

Chou, S. Y., Krauss, P. R. & Renstrom, P. J. Imprint lithography with 25-nanometer resolution. Science 272, 85–87 (1996)

Chou, S. Y. & Zhuang, L. Lithographically induced self-assembly of periodic polymer micropillar arrays. J. Vac. Sci. Technol. B 17, 3197–3202 (1999)

Silvesrelli, P. L., Alavi, A., Parrinello, M. & Frenkel, D. Ab initio molecular dynamics simulation of laser melting of silicon. Phys. Rev. Lett. 77, 3149–3152 (1996)

Ivlev, G. D. & Gatskevich, E. I. Liquid phase reflectivity under conditions of laser induced melting. Semiconductors 34, 759–762 (2000)

Poute, J. M. & Mayer, J. Laser Annealing of Semiconductors (Academic, New York, 1982)

Carey, P. G. & Sigmon, T. W. In-situ doping of silicon using gas immersion laser doping (GILD). Appl. Surf. Sci. 43, 325–332 (1989)

Weiner, K. H. & Sigmon, T. W. Thin-base bipolar transistor fabrication using gas immersion laser doping. IEEE Electr. Device Lett. 10, 260–263 (1989)

Glazov, V. M., Chizhevskaya, S. N. & Glagoleva, N. N. Liquid Semiconductors (Plenum, New York, 1969)

Langen, M., Hibiya, T., Eguchi, M. & Egry, I. Measurement of the density and the thermal expansion coefficient of molten silicon using electromagnetic levitation. J. Cryst. Growth 186, 550–556 (1998)

Acknowledgements

We thank Y. Zhan for his contributions in the initial phase of the work, Z. Suo for help with the discussion of the Reynolds number, and the US Defense Advanced Research Program Agency (DARPA), the Office of Naval Research (ONR) and the Army Research Office (ARO, through an equipment grant) for their partial financial support of the project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing financial interests.

Rights and permissions

About this article

Cite this article

Chou, S., Keimel, C. & Gu, J. Ultrafast and direct imprint of nanostructures in silicon. Nature 417, 835–837 (2002). https://doi.org/10.1038/nature00792

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1038/nature00792

This article is cited by

-

Laser-assisted direct roller imprinting of large-area microstructured optical surfaces

Microsystems & Nanoengineering (2024)

-

Revised mathematical model for assessment of thermal characteristics developed in ultrafast pulse laser assisted nanoimprinting lithography on silicon based substrate surface

Optical and Quantum Electronics (2024)

-

Spatially-separated and photo-enhanced semiconductor corrosion processes for high-efficient and contamination-free electrochemical nanoimprint lithography

Science China Chemistry (2022)

-

Friction-Induced Nanofabrication: A Review

Chinese Journal of Mechanical Engineering (2021)

-

Extending the resolution limits of nanoshape imprint lithography using molecular dynamics of polymer crosslinking

Microsystems & Nanoengineering (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.