Abstract

Several metal surfaces, such as titanium, aluminum and copper, were exposed to highfluxes (in the range of 1023m−2s−1) of low energy(<100 eV) Helium (He) ions. The surfaces were analyzed by scanningelectron microscopy and to get a better understanding on morphology changes both topview and cross sectional images were taken. Different surface modifications, such asvoids and nano pillars, are observed on these metals. The differences andsimilarities in the development of surface morphologies are discussed in terms ofthe material properties and compared with the results of similar experimentalstudies. The results show that He ions induced void growth and physical sputteringplay a significant role in surface modification using high fluxes of low energy Heions.

Similar content being viewed by others

Introduction

Surface structuring by energetic ion bombardment has been widely studied and consideredas an efficient surface processing technique, since it is fast, cost effective andvarious types of material can be processed by this technique. This so-called ion beamsputtering technique is attributed to the removal of atoms from the surface due to theimpact of energetic ions.1 Both experimental and theoretical studies havebeen conducted for a wide range of conditions, such as ion species, ion energy, surfacetemperature and angle of ion bombardment.1,2,3 As a particular case,the interaction of helium ions with metal surfaces, especially with tungsten, has longbeen studied extensively because of helium production in fusion reactors.4,5,6,7 More recently, significant surface modifications were observedon tungsten under low-energy He ion irradiation, with ion energies below the thresholdfor damage creation and investigated as a function of surface temperature, ion flux andexposure time.8,9,10,11 These studies revealed the formation of a finenanostructure exhibiting a high porosity of up to 90% and high light absorption.12,13,14 The size of those nanostructures and thickness of thenanostructured layer could be controlled by surface temperature and plasma exposuretime, respectively.15 After these results on tungsten, investigationswere extended to other metals. Similar nanostructure formation has been observed formolybdenum, nickel and iron surfaces under low energy He ion irradiation.15,16,17 Although a clear explanation of why some metals can be modifiedmore easily than others is still missing, one could categorize these metals with respectto their crystal structure; except nickel, all of these metals have body centered cubic(bcc) type crystal structure.

Due to their controllable growth and porous structure, helium induced nanostructuredsurfaces appear to have a great potential to be used for various applications requiringhigh surface area and high light absorption, such as photo electrochemical watersplitting for example.18,19,20 Indeed, an enhancement in thephotocatalytic activity has been reported for nanostructured WO3, prepared bylow-energy helium ion exposure and followed by annealing.21

In this study, we explore the effect of low-energy helium ion exposure of several metalsurfaces, such as titanium (Ti), aluminum (Al) and copper (Cu). The choice of thosemetals was driven by the aforementioned application of photocatalytic properties ofthese metals in oxidized form. The influence of the different crystal structures onhelium-plasma irradiation induced surface modification is studied and results arecompared with both theoretical and experimental studies in literature.

Effect of low energy He ions on surface modification of metals

Helium is a chemically inert gas and has almost zero solubility in metals, butcan diffuse rapidly through the metal surface because of its relatively smallsize. These features of helium lead to bubble formation underneath the surfaceat crystallographic defects. Experimental and theoretical studies have shownthat helium irradiation induced damages could be obtained even in the absence ofdisplacement damage and native defects.9,13,22

Theoretical works conducted on tungsten and iron agree on a qualitativedescription of the formation and growth of clusters (or bubbles).23,24 Interstitial helium atoms are very mobile and tend tocoalesce to form interstitial clusters. Both the interstitial He atoms andclusters can act as traps for incoming He atoms, which indicates a self-trappingability of He. Once an interstitial He cluster reaches a sufficient size, itpunches out a metal self-interstitial and forms a relatively immobilehelium-vacancy cluster. Helium diffusion is required for nucleation of bubblesand their growth.24 In the case of negligible ion radiationdamages, helium diffusion is dominated by interstitial migration and for highertemperatures (>0.5 Tm, where Tmis the melting temperature) the interstitially diffusing He atoms are mainlytrapped by thermal vacancies, since the concentration of thermal vacancies tendsto increase with temperature.24 There are 12 tetrahedral and 6octahedral, 8 tetrahedral and 4 octahedral, 4 tetrahedral and 2 octahedralinterstitial sites existing in metals with bcc, face centered cubic (fcc) andhexagonal close packed (hcp) type crystal structure, respectively.25 Since the interstitial sites could assist the He diffusion inthe metal lattice, one could expect that helium trapping would be easiest in bcctype metals and less likely in closely packed metals. In addition to theseself-interstitials in the metal, He ions could induce extra interstitials asmentioned above, which assist He diffusion and consequently nucleation, in themetal even if their energies are well below the knock-on energy for displacementdamage. Besides, detrapping has to be taken into account during the discussionof helium trapping in the metals. The substitutional detrapping energies for bcctype metals listed in table 1 indicate that release ofHe atoms in a metal lattice is hardly expected from these metals. The formationand migration energies of He interstitials for different metals are compared intable 1.26,27,28,29,30,31,32Although the values do not seem to differ much from each other, slightly higherformation and migration energies of hcp metal from the ones for fcc metals couldindicate that He diffusion and clustering processes could be slower for hcpmetals. Hence, one might expect that hcp-type metals will be less prone to Heion-induced morphology changes.

The experimental results have showed that nanobubble formation near the surfaceis necessary but not sufficient to give rise to nanostructure formation.33 The nanostructuring on tungsten surface is achieved for asurface temperature range of ~0.25<T/Tm<0.55.8The upper boundary of the temperature range for nanostructure formation isdefined by rapid surface diffusion, which could lead to surface smoothing andeventually disappearance of the nanostructure.8,34 The slowbubble growth rate is considered as the limiting factor at low temperature.Similar nanostructuring has been observed in the experimental studies conductedon Mo and Fe for intermediate temperatures (0.3 - 0.5Tm).15,17 The relation between swellingrate of helium bubbles and T/Tm has already beenreported.34 Relying on both experimental and theoreticalstudies, the temperature ranges worth to study for surface modification ofdifferent metals could be determined in advance.

Methods

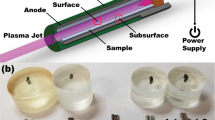

Polycrystalline titanium (99.99% purity, Goodfellow), copper (≥ 99.95%purity, Salomon’s Metalen) and aluminum (95.90% purity,Salomon’s Metalen) samples were exposed to pure helium plasma inPilot-PSI, a high-flux linear plasma generator.35 The plasma isgenerated by a thermal plasma (cascaded arc) source and confined by an axialmagnetic field. More detailed information about the experimental setup can be foundelsewhere.35 The magnetic field was set to 0.2 T during ourexperiments. The plasma density profile has a Gaussian shape and the maximum ionflux to the surface was in the range of 2-7x1023m−2s−1. The samples wereclamped on a water cooled target holder by a ring made from molybdenum. In order tohave a better thermal contact, a Grafoil® layer was inserted between thesample and the target holder. The samples are negatively biased to control the ionenergy, which is calculated with respect to plasma potential and sheath entrancevoltage. Further details about ion energy calculation can be found in Ref 36.

Polycrystalline samples, which are 20 mm in diameter and 1 mm in thickness, weremechanically polished with SiC grinding papers and followed by 3 and 1 µmdiamond and 0.05 µm alumina suspensions. The metals that we worked withhave different levels of hardness, so that different polishing recipes have beenfollowed. For Ti and Cu samples we used 320 to 2400 grit SiC papers and for Alsamples 500 to 2400 grit SiC papers. The mirror finish polished samples were cleanedwith a basic procedure, acetone, ethanol, de-ionized water in ultrasonic bath andfor easy rinsing a further bath with ethanol repeated at the end.

During plasma exposure, the peak temperature was measured by a multiwavelengthpyrometer (FMPI SpectroPyrometer, FAR Associates), which measures in the wavelengthrange of 900–1600 nm. In addition, an infrared camera (FLIR A645 SC) wasused to measure the 2D surface temperature profile and was also used in case oftemperatures lower than the detection limit of the pyrometer.

The surfaces were analyzed by high resolution scanning electron microscopy (SEM,Hitachi S-4800 field emission at 5 kV) and atomic force microscopy (Bruker DimensionEdge AFM ) in order to investigate the modifications after plasma exposures. Forcross sectional imaging, the samples were prepared by focused ion beam (Dual BeamFIB/SEM) milling method.

Results

Titanium

All experimental conditions are listed in table2.Titanium surfaces were irradiated by low energy (~45 eV) He ions withflux of 2-3x1023m−2s−1 atsurface temperatures of 400, 600 and 750°C for 10 minutes (samples(i), (ii), (iii)). Until around 450°C no clear surface modificationwas observed. Above that temperature voids start to appear on the surface. Asseen in SEM images in (Figure 1.), the areal density ofthese voids increased with the surface temperature. SEM images were analyzed bythe Gwyddion software to specify the mean void size.37 There isalso a slight increase in the mean diameter of these voids, from 20 nm (88 voidswere taken into analysis) to 25 nm (104 voids were taken into analysis) with anincrease in surface temperature from 600°C to 750°C. Thesample exposed with surface temperature of 750°C was prepared by FIBmilling method to get a cross section view. At the beginning of the FIBanalysis, a region with an area of 2 µm x 6 µm was coatedby Pt to protect that region from the Ga ions. Hence, the etched side givesinformation about the cross section view of these structures. Voids, which aresmaller than 100 nm in diameter, are detected with a wide size distributionunderneath the surface (Figure 2.). When these surfacesare compared with other studies in literature, they show a resemblance to thoseobserved after exposures of W and Mo to low energy (~20 eV) He ions.15 In that study, an increase of the ion energy to 45 eV led tonanostructure growth. Although the ion energy is around 45 eV in our study, nonanostructure growth is observed.

The surface temperature was increased above 850°C (sample (iv)-(vii),Figure 3a-d). Beyond that temperature, the surfaceseems to be roughened and reformed. Nanosized structures start to be observedbeyond 1000°C at an ion energy of 45 eV, whereas similar nanosizedstructures are observed at surface temperatures starting from 850°Cif the ion energy is increased up to 70 eV. The number of the nanosizedstructures on a given area tends to decrease by a factor of around 2.5 and themean diameter is shifted from 36 nm to 53 nm with increase in surfacetemperature from 850°C to 1000°C (Figure3c,d.).

Aluminum

Aluminum surfaces were exposed to He plasma with an ion flux in the range of3-4x1023m−2s−1 and an ionenergy of 25 eV at a surface temperature of 250°C. On these surfaces,randomly located structures besides some voids are detected. (Figure 4a,b) show that for longer exposures the spatial distributionof the structures becomes more homogenous and the average size of voids tends toincrease with time.

SEM images of Al samples, which are irradiated by He ions with an energy of25 eV at a surface temperature of 250°C (0.56 Tm) for 10minutes and 30 minutes (samples (viii) and (ix)) and with ion energy of 35 eVfor 10 minutes (sample (x)), taken under low (a), (b), (c) and high (d), (e),(f) magnification, respectively.

Since the melting temperature of Al is relatively low (around 660°C)compared to the other metals investigated here, the surface temperature was keptconstant at 250°C. Besides the exposure time, the effect of ionenergy on surface modification was studied. A significant change in both sizeand shape of structures is observed with a slight increase in average ionenergy, of only 10 eV (see Figure 4c,d). The mean diameterof the structures formed become around 1.4 µm and the voids around150 nm.

The tilted SEM image (Figure 5a) shows that surface iscovered by individual structures with different heights. Although it is hard tojudge from a top view image, the structures seem to be formed of several layers.To gain more insight, AFM measurement has been done on sample (viii). AFMmeasurement of one of these structures shows that these structures are formed bylayers with thickness of around 50 nm (Figure 5b).

In order to clarify the surface modification mechanism, cross sectional imageswere taken from the sample prepared by FIB milling method. (Figure 6) exhibits the effect of He ions on surface modificationwith the presence of voids underneath the surface of the sample (x).

Copper

Copper surfaces were irradiated by He ions with flux of 5-7x1023m−2s−1 and at an ionenergy of 25 eV. The surface temperature during these exposures was kept in theintermediate temperature range (0.3 Tm<T < 0.5 Tm) and exposures were repeatedfor two different durations, 10 and 30 minutes. As seen in (Figure 7), no significant change in the form of nanostructures canbe observed for different exposure times. With the increase in surfacetemperature, individual structures tend to enlarge and then connect to eachother for both exposure times.

Similarly to the Al surfaces, sample (xii) was prepared by FIB milling and across sectional image was taken. As seen in (Figure 8), ananostructured layer with a thickness of around 100 nm is observed without anytrace of He-induced voids.

Copper surfaces were exposed at higher temperatures, above 0.5Tm resulting in significant changes in morphology. Thestructures observed at the highest temperature for our range resemble the oneson Al, but in this case they are homogenously distributed and almost in the samesize, around 240 nm in diameter (Figure 9). (Figure 10) shows the cross sectional views of samples (xv)and (xvi). In contrast with the samples exposed with lower surface temperature(<400°C), voids are clearly detected underneath thesurface. The homogenously distributed structures, which are formed afterexposure at 650°C, are clearly visible on the cross sectional imagesin (Figure 10b) and seem to have pillar-like shape.

Discussion

In order to observe the variation in efficacy of He ion induced surface modificationof metals with different crystal structures, we investigated Ti, which has hcp typecrystal structure and Al and Cu, which have fcc type crystal structure, undersimilar irradiation conditions. Our results show that He ions could penetrate andform voids underneath the surface in all metals that we worked with. However, interms of the resulting surface modifications different metals behave differently. Tiexposures do not show any nanostructure growth on the surface, which seemsconsistent with the expectations considering its densely packed crystal structure orlow population of interstitials which mostly mediate effective He diffusion in themetal. Kajita et al. recently published an extensive study on the surfacemodification of titanium after He plasma exposure.38 Significantchanges in surface morphology have been observed with slight differences inirradiation conditions, such as ion energy. Most of their exposures are conducted athigher ion energy (>70 eV) than in our experiments. For that ion energyrange, cone like structures are observed on the surface due to the enhanced effectof physical sputtering. For slightly lower ion energies (~50 eV),38void formation has been reported on the surface, which is quite similar to what isobserved in our experiments at similar surface temperatures and ion energy value(~45 eV). Besides that, the morphology obtained at 927°C (Figure 2 in Ref. 38.) is similar to thesurfaces obtained at 850°C in our experiments. In that temperature range,the surface seems to be roughened and nanosized structures are formed.

Once the survey shifted to metals with lower mass compared to tungsten andmolybdenum, other effects have to be invoked in the explanation of surfacemodifications under low energy He ion irradiations. Our previous work and also otherstudies suggested physical sputtering as an additional mechanism which contributesto the surface modification.16,17,39 In studies conducted ontungsten and molybdenum the sputtering yield is considered as negligible, since theion energy in those studies is typically well below the threshold energy forphysical sputtering. In our study, the mass loss is measured by weighing the samplesbefore and after the plasma exposure. The sputtering yield is then determined byusing the following expression:

whereΔm is mass loss, M2 - atomic mass of metalof interest, n1 - number of He ions reaching the surface andNo - Avogadro's number.

The sputtering yields measured here (taken on samples (i)-(xix)) are compared withthe fit to several calculated values.40 (Figure11) shows that our values are around one order of magnitude below theexpected sputtering yields of the metals that we worked with. It is worth to notethat the calculations are usually done by assuming a nearly flat surface, i.e. theeffect of surface morphology on the sputtering yield is not taken into account. Thecurvature dependent sputtering has already been proposed in Sigmund’stheory.41 Based on that theory, an analytical formula for themorphology dependent sputtering yield is developed and accordingly a decrease insputtering yield is predicted with the development of surface morphology.42 The morphological change induced here by He ion irradiation is morecomplex than a symmetrical structure, hence one would expect to have enhanceddeviation between calculated and experimental data. The variation in the sputteringyield of flat and modified surface has been reported after a similar experimentalstudy as well. Nishijima et al. have shown that the sputtering yield ofnanostructured tungsten derived from mass loss measurements are around one order ofmagnitude lower than the values calculated by TRIM code.43 Thedeviation in the calculated and experimental results is in agreement with ourresults. Different from the other metals, the sputtering yield for Al that weobtained from our experiments is around two orders of magnitude lower than theliterature values. Since Al is quite reactive and native aluminum oxide (mostlikely, Al2O3) has higher binding energy than Al, we wouldexpect a decrease in sputtering yield for samples (viii)-(x).

Sputtering yield of Ti, Al and Cu regarding to our mass loss measurements andliterature values41.

The structures on Al and Cu surfaces show similarity with the self-organizednanopatterns and nanodots obtained by ion beam sputtering.44,45 Theformation of these patterns is explained as a result of interplay between ionsputtering, which induces surface roughening and surface diffusion, which inducessmoothing.44 To investigate the role of physical sputtering onthe observed morphology changes, several studies have been conducted on W and Tisurfaces exposed to both Ar and Ne plasma for W and Ne plasma for Ti. In neither ofthose cases, nanostructure formation or bubble growth beneath the surface weredetected.38,46 Similarly, Al surfaces were exposed to Ar ionsand (Figure 12) shows that Ar ions induce no surfacemodification except for some sparse structures whose layered structure resembles thenanostructures formed under He plasma. However, there is no significant similaritybetween surfaces after He and Ar plasma exposures, namely neither homogenouslylocated nanostructures nor voids are detected. Hence, the surface modifications thatwe observe on Al and Cu cannot be only attributed to physical sputtering caused byany ion species. The effect of He clustering and consequently void formation onsurface modification is clearly seen on Al and Cu surfaces. Both He ion irradiationand physical sputtering would be considered as effective factors in the morphologychanges of Cu and Al.

Titanium, aluminum and copper surfaces were exposed to pure He plasmas to study theassociated morphology changes. Different surface modifications were observed amongthese metals. The experimental studies show that it is rather hard to rely on asingle material property in order to predict the behavior of metals after heliumplasma exposures. The effect of physical sputtering on surface modification isclearly seen for Al and Cu surfaces. Homogenously distributed nano pillars areobserved on these metals. Any significant surface modification could not be observedfor Ti, which might be resulted because of its closely packed structure and lowsputtering yield. Once the nano pillars formed on Cu surfaces are oxidized, theycould be of interest for further energy applications, such as electrochemicalreductions of CO2 and photoelectrochemical water splitting, because oftheir homogenous distribution and high aspect ratios.47

References

Frost, F., Ziberi, B., Schinler, A. & Rauschenbach, B. Surface engineering with ion beams: from self-organized nanostructures to ultra-smooth surfaces. Appl. Phys. A 91, 551–559 (2008).

Ziberi, B., Frost, F., Tartz, M., Neumann, H. & Rauschenbach, B. Importance of ion beam parameters on self-organized pattern formation on semiconductor surfaces by ion beam erosion. Thin Solid Films 459, 106–110 (2004).

Yewande, E. O., Hartmann, A. K. & Kree, R. Propagation of ripples in Monte Carlo models of sputter-induced surface morphology. Phys. Rev. B: Condensed Matter 71, 195405–8 (2005).

Iwakiri, H., Yasunaga, K., Morishita, K. & Yoshida, N. Microstructure evolution in tungsten during low-energy helium ion irradiation. J. Nucl. Mater. 283-287, 1134–1138 (2000).

Ullmaier, H. The influence of helium on the bulk properties of fusion reactor structural materials. Nucl. Fusion 24, 1039–1083 (1984).

Trinkaus, H. Energetics and formation kinetics of helium bubbles in metals, Radiation Effects. Radiation Effects 78, 189–211 (1983).

Kornelsen, E. V. & Van Gorkum, A. A. A study of bubble nucleation in tungsten using thermal desorption spectrometry: Clusters of 2 to 100 helium atoms. J. Nucl. Mater. 92, 79–88 (1980).

Kajita, S., Sakaguchi, W., Ohno, N., Yoshida, N. & Saeki, T. Formation process of tungsten nanostructure by the exposure to helium plasma under fusion relevant plasma conditions. Nucl. Fusion 49, 095005–6 (2009).

Nishijima, D., Ye, M. Y., Ohno, N. & Takamura, S. Incident ion energy dependence of bubble formation on tungsten surface with low energy and high flux helium plasma irradiation. J. Nucl. Mater. 313-316, 97–101 (2003) .

Baldwin, M. J., Doerner, R. P., Nishijima, D., Tokunaga, K. & Ueda, Y. The effect of high fluence mixed-species (deuterium, helium, beryllium) plasma interactions with tungsten. J. Nucl. Mater. 390–391, 886–890 (2009).

Iyyakkunnel, S. et al. Morphological Changes of Tungsten Surfaces by Low-Flux Helium Plasma Treatment and Helium Incorporation via Magnetron Sputtering. ACS Appl. Mater. Interfaces 6, 11609–11616 (2014).

Takamura, S., Ohno, N., Nishijima, D. & Kajita, S. Formation of nanostructured tungsten with arborescent shape due to helium plasma irradiation. Plasma Fusion Res. 1, 051 (2006).

Baldwin, M. & Doerner, R. Helium induced nanoscopic morphologhy on tungsten under fusion relevant plasma conditions. Nucl. Fusion 48, 035001–5 (2008).

Kajita, S., Saeki, T., Yoshida, N., Ohno, N. & Iwamae, A. Nanostructured Black Metal: Novel Fabrication Method by Use of Self-Growing Helium Bubbles. Appl. Phys. Express 3, 085204 (2010).

De Temmerman, G. et al. Nanostructuring of molybdenum and tungsten surfaces by low-energy helium ions. J. Vac. Sci. Technol. A. 30, 041306–6 (2012).

Kajita, S. et al. Helium plasma implantation on metals: Nanostructure formation and visible-light photocatalytic response. J. Appl. Phys. 113, 134301–7 (2013).

Tanyeli, I., Marot, L., van de Sanden, M. C. M., & De Temmerman, G. Nanostructuring of Iron Surfaces by Low-Energy Helium Ions. ACS Appl. Mater. Interfaces 6, 3462–3468 (2014).

Sivula, K., Le Formal, F. & Grätzel, M. Solar Water Splitting: Progress Using Hematite (α-Fe2O3) Photoelectrodes. ChemSusChem. 4, 432–449 (2011).

Berger, S., Tsuchiya, H., Ghicov, A. & Schmuki, P. High photocurrent conversion efficiency in self-organized porous WO3 . Appl. Phys. Lett. 88, 203119 (2006).

Brillet, J., Grätzel, M. & Sivula, K. Decoupling feature size and functionality in solution-processed, porous hematite electrodes for solar water splitting. Nano Lett. 10, 4155–4160 (2010).

de Respinis, M. et al. Efficient Plasma Route to Nanostructure Materials: Case Study on the Use of m-WO3 for Solar Water Splitting. ACS Appl. Mater. Interfaces 5, 7621–7625 (2013).

Henriksson, K. O. E., Nordlund, K. & Keinonen,. Molecular dynamics simulations of helium cluster formation in tungsten. J. . Nucl. Instr. Meth. Phys. Res. B 244, 377–391 (2006).

Stewart, D., Osetskiy, Y. & Stoller, R. Atomistic studies of formation and diffusion of helium clusters and bubbles in BCC iron. J. Nucl. Mater. 417, 1110–1114 (2011).

Trinkaus, H. & Singh, B. N. Helium accumulation in metals during irradiation – where do we stand? J. Nucl. Mater. 323, 229–242 (2003).

Fahlman, B. D. Materials Chemistry [2nd edition] (Springer, Dordrecht, HeidelbergLondon, New York, 2011).

Wilson, W. D. & Johnson, R. A. [Rare Gases in Metals], Interatomic Potentials and Simulation of Lattice Defects [Gehlen, P. C., Beeler, J. R. & Jaffee, R. I. (eds.)] (Plenum Press, New York, 1972).

van Veen, A. & Caspers, L. M. Proc. Consultants Symp. on Inert gases in metals (Harwell, U.K., 1979).

Wang, Y., Liu, S., Rong, L. & Wang, Y. Atomistic properties of helium in hcp titanium: A first-principles study. J. Nucl. Mater. 402, 55–59 (2010).

Ao, B. Y., Yang, J. Y., Wang, X. L., & Hu, W. Y. Atomistic behavior of helium-vacancy clusters in aluminum. J. Nucl. Mater. 350, 83–88 (2006).

Baskes, M. I., & Melius, C. F. Pair potentials for fcc metals. Phys. Rev. B 20, 3197–3204 (1979).

Jing, P., Khraishi, T., Young, J. A. & Wirth, B. D. Multi-scale simulations of the effects of irradiation-induced voids and helium bubbles on the mechanical properties of aluminum. Philos. Mag. 85, 757–767 (2005).

Yang, L., Zu, X. T. & Gao, F. Ab initio study of formation, migration and binding properties of helium-vacancy clusters in aluminum. Physica B: Condensed Matter 403, 2719–2724 (2008).

Baldwin, M. J. & Doerner, R. P. Formation of helium induced nanostructure ‘fuzz’ on various tungsten grades. J. Nucl. Mater. 404, 165–173 (2010).

Evans, J. H. Breakaway bubble growth during the annealing of helium bubbles in metals. J. Nucl. Mater. 334, 40–46 (2004).

De Temmerman, G., Zielinski, J. J., van Diepen, S., Marot, L. & Price, M. ELM simulation experiments on Pilot-PSI using simultaneous high flux plasma and transient heat/particle source. J. Nucl. Mater. 51, 073008–8 (2011).

Bystrov, K., van der Vegt, L., De Temmerman, G., Arnas, C. & Marot, L. Reorganization of graphite surfaces into carbon micro- and nanoparticles under high flux hydrogen plasma bombardment. J. Vac. Sci. Technol. A 31, 011303 (2013).

Klapetek, P. & Necas, D. Gwyddion, Czech Metrology Institut, Brno, Czech Republic, (2007).

Kajita, S. et al. Surface modification of titanium using He plasma. Appl. Surf. Sci. 303, 438–445 (2014).

Doerner, R. P., Baldwin, M. J. & Stangeby, P. C. An equilibrium model for tungsten fuzz in an eroding plasma environment. Nucl. Fusion 51, 043001–6 (2011).

Carter, G., Navinsek, B. & Whitton, J. L. Sputtering by Ion Bombardment II [Behrisch, R. (ed.)] (Springer, Berlin, 1983).

Sigmund, P. Theory of Sputtering. I. Sputtering Yield of Amorphous and Polycrystalline Targets. Phys. Rev. 184, 383–416 (1969).

Wei, Q., Eddy, M., Li, K. D. & Wang, L. Influence of surface morphology on sputtering yields. J. Phys. D:Appl. Phys. 42, 165304–6 (2009).

Nishijima, D., Baldwin, M. J., Doerner, R. P. & Yu, J. H. Sputtering properties of tungsten ‘fuzzy’ surfaces. J. Nucl. Mater. 415, S96-S99 (2011).

Facsko, S. et al. Formation of Ordered Nanoscale Semiconductor Dots by Ion Sputtering. Science 285, 1551–1553 (1999).

Munoz-Garcia, J. et al. [Self-Organized Surface Nanopatterning by Ion Beam Sputtering] Toward Functional Nanomaterials, Lecture Notes in Nanoscale Science and Technology 5 [Wang, Z. M. (ed.)] (Springer Science+Business Media, LLC 2009).

Yajima, M. et al. Comparison of Damages on Tungsten Surface Exposed to Noble Gas Plasmas. Plasma Sci. Technol. 15, 282 (2013).

Sen, S., Liu, D. & Palmore, G. T. R. Electrochemical Reduction of CO2 at Copper Nanofoams. ACS Catal. 4, 3091–3095 (2014).

Acknowledgements

This work is part of the research program of the Stichting voor Fundamental Onderzoekder Materie (FOM), which is financially supported by the Nederlandse Organisatievoor Wetenschappelijk Onderzoek (NWO). It is supported by the European Communitiesunder the contract of Association between EUROTAM and FOM and was conducted withinthe framework of the European Fusion Programme.

Author information

Authors and Affiliations

Contributions

The experiments were planned by I.T. and G.d.T. and conducted by I.T. SEMmeasurements and FIB milling were performed by D.M. The results were discussed byI.T., M.C.M.v.d.S. and G.d.T. Manuscript was written by I.T. with improvements fromG.d.T., M.C.M.v.d.S. and L.M.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0International License. The images or other third party material in this article areincluded in the article's Creative Commons license, unless indicatedotherwise in the credit line; if the material is not included under the CreativeCommons license, users will need to obtain permission from the license holder inorder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Tanyeli, İ., Marot, L., Mathys, D. et al. Surface Modifications Induced by High Fluxes of Low Energy Helium Ions. Sci Rep 5, 9779 (2015). https://doi.org/10.1038/srep09779

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep09779

This article is cited by

-

Theoretical Model of Helium Bubble Growth and Density in Plasma-Facing Metals

Scientific Reports (2020)

-

A review of surface damage/microstructures and their effects on hydrogen/helium retention in tungsten

Tungsten (2020)

-

Morphology and crystalline evolution of tungsten induced by low-energy helium ions irradiation

Journal of Radioanalytical and Nuclear Chemistry (2019)

-

Synthesis of advanced aluminide intermetallic coatings by low-energy Al-ion radiation

Scientific Reports (2016)

-

Fuzzy nanostructure growth on Ta/Fe by He plasma irradiation

Scientific Reports (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.