Abstract

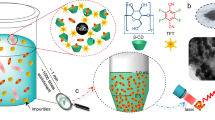

Heterogeneous solid sensors are regarded as promising next-generation sensor due to their excellent chemical stability, low contamination and excellent recyclability, despite their low sensitivity and weak signal. The dispersity and signals specifically from the exterior of solid sensors are critical aspects which define the sensing sensitivity and selectivity. A novel strategy for the preparation of ideal heterogeneous sensors based upon luminescent lanthanide coordination polymers (LnCP) has been demonstrated. Ideal heterogeneous sensors are systematically achieved by producing the sensors in small, uniform and thin core-shell particles (silica@LnCP, Ln = Eu, Tb). Eventually, we found that the extremely small amount of well-structured silica@LnCP microsphere, less than ca. 1/400 compared to the amount of several known coordination polymer-based sensors, was sufficient to achieve a reliable Cu2+ sensing with even much greater sensitivity (ca. 550% improvement).

Similar content being viewed by others

Introduction

The effective detection of small amounts of metal ions is important in many environmental and biological systems. In special, the detection of Cu2+ is essential in biological systems, as Cu2+ plays vital roles for living organisms. Wilson's disease and Alzheimer's disease are two known examples related to alterations in Cu2+ cellular homeostasis1,2. Recent developments in Cu2+ sensing methodology include discrete molecular chemosensor systems and heterogeneous solid sensing materials3,4,5,6. In general, homogeneous sensors based upon discrete molecules show more effective sensing events than heterogeneous solid sensors, which exhibit low sensitivity and weak signals. However, there is great demand for heterogeneous solid sensors due to their excellent chemical stability, low contamination and excellent recyclability. Therefore, the development of effective solid sensor materials remains an important and challenging area. Coordination polymers (CPs) or metal-organic frameworks (MOFs) are fascinating materials for use in heterogeneous solid sensors because their compositions and properties can be easily tuned by altering their components, metal ions or organic building blocks6,7,8,9,10,11,12,13,14,15,16. Lanthanide-based MOFs (LnMOFs) or lanthanide-based CPs (LnCPs), including EuMOFs and TbMOFs, have been extensively investigated as luminescent sensor materials. They showed great ability in the sensing process due to their sharp and strong emissions and long luminescent lifetimes originating from characteristic f-f transitions8,9,10,11,12,13,14,15,16. It should be noted that CPs and MOFs are widely used in a variety of applications in addition to sensing, such as gas storage, gas separation and catalysis17,18,19,20,21,22,23,24.

The luminescent intensity of LnMOFs (including LnCPs) is typically altered depending upon the identity of analytes through analyte-metal or analyte-ligand interactions. Though several LnMOFs have been developed as luminescent sensor materials to detect metal ions, anions, or small molecules8,9,10,11,12,13,14,15,16, the majority of these were prepared in the form of bulk macro-scaled materials. During sensing events of heterogeneous solid sensors, signals from exterior of the sensor materials rather than those from interior of materials should be more critical to define the sensing sensitivity and selectivity. Therefore, the systematic decrease in the size of sensor materials will be a critical factor in sensing enhancement and reducing material cost. On the other hands, several research groups, including our group, have recently developed nano- and micro-sized coordination polymer particles (CPPs) or MOFs25,26,27,28,29,30. The development of CPPs or nano-MOFs enhanced their original properties and extended their application range27,28,29,30. Herein, we report highly effective heterogeneous sensor materials made from luminescent lanthanide(III) coordination polymers (LnCP) in the form of simple microspheres or core-shell microspheres. We found that the inside of solid sensor materials was not important for the effective sensing process. Sensor materials were lightened through making those in the form of small core-shells with thin sensing shell. Eventually, only less than ~ 1/400 of core-shell typed LnCP microspheres, compared to typical LnMOF-based or LnCP-based sensor materials, was required to achieve a reliable sensing process and this exceptionally small amount of LnCP even showed a higher sensitivity on metal ion detection. The excellent recycling capability of the resulting micro-sized core-shell type sensor was also demonstrated.

Results

Synthesis of luminescent EuCP microspheres

Luminescent spherical particles made from europium(III) coordination polymer (EuCP) were rapidly and conveniently synthesized via the simple solvothermal reaction of coordination polymer precursors containing Eu(NO3)3 and isophthalic acid (H2IPA) at 140°C for 20 min (Fig. 1). It should be noted that a considerable process time (1 ~ 3 days) is typically required for the preparation of LnMOF-based sensor materials8,9,10,11,12,13. The isolated EuCP microspheres were characterized using scanning electron microscopy (SEM), scanning transmission electron microscopy (STEM), confocal microscopy, powder X-ray diffraction (PXRD), energy dispersive X-ray (EDX), infrared (IR) and emission spectroscopy. The formation of spherical particles with an average size of 0.70 ± 0.06 µm was first identified from SEM and STEM images (Fig. 2a). The chemical composition of EuCP microspheres was determined via EDX spectrum, where carbon, oxygen and europium atoms were detected (Fig. 2b). The shift of the CO stretching frequency to 1606 cm−1 in the IR spectrum of EuCP microspheres from 1692 cm−1 for uncoordinated H2IPA revealed the coordination of the carboxylate groups of IPA to Eu3+ ions (Supplementary Fig. S1). Featureless PXRD pattern of EuCP microspheres revealed that they are amorphous and not crystalline materials and so the structural details on those materials cannot be obtained (Supplementary Fig. S2a). Finally, the emission spectrum of EuCP microspheres showed the characteristic transitions of Eu3+ ions (Fig. 2d). The strong emission bands at 592 and 615 nm are related to the 5D0 → 7F1 and 5D0 → 7F2 transitions of Eu3+ ions, respectively8,9,10. These intense transitions resulted in the red emission of particles. The confocal microscopy image (Fig. 2c) and the photograph in the presence of UV irradiation (inset in Fig. 2d) of EuCP microspheres visually showed the luminescence in red regions of the spectrum. The weak emission bands at 651 and 698 nm originating from the 5D0 → 7F3 and 5D0 → 7F4 transitions were also observed in the emission spectrum.

Morphology, optical property and sensing property of EuCP microspheres.

(a) SEM and STEM (inset) images of europium(III) coordination polymer (EuCP) microspheres (0.70 ± 0.06 µm, s.d., n = 100). (b) EDX spectrum and (c) confocal microscopy and OM (top inset) images of EuCP microspheres. Bottom inset in (c) shows EuCP microspheres dispersed in MeCN. (d) Luminescent titration spectra of EuCP microspheres with the addition of various concentrations of Cu(NO3)2 in MeCN with an excitation wavelength of 280 nm. Inset in (d) shows the EuCP microspheres suspension before and after immersion in a Cu2+ solution with UV irradiation. (e) Luminescent intensity changes of EuCP microspheres after immersion in various metal ion solutions (5 mM). (f) Photograph of a series of EuCP microspheres suspensions before and after immersion in various metal ion solutions in the presence of UV irradiation.

Selective Cu2+ sensing of luminescent EuCP microspheres

The utilization of EuCP microspheres as a luminescent sensor for metal ion detection was then investigated. The excellent dispersity of heterogeneous solid sensor materials in solution is a vital prerequisite for the sensitive and reliable detection of analytes. Within this point, the resulting EuCP microspheres, which exhibit an excellent dispersity in the solution (see insets in Fig. 2c,d), should be an excellent candidate for the heterogeneous solid sensor and should exhibit superior properties when compared to typical bulk-scaled MOF-based sensor materials. Note that an extra grind process of bulk MOFs was generally required for their utilization as a sensor in solution; this process may not be sufficient to achieve an excellent dispersity13,14. The titration of well-dispersed MeCN suspensions of EuCP microspheres with various concentrations of Cu2+ revealed a decrease in the luminescent intensity of EuCP microspheres with increasing amounts of added-Cu2+ (Fig. 2d). Interestingly, we found that quite a small amount of sensor materials (EuCP, 0.1 mg) was required during the sensing process, compared to the archetypal quantities of bulk MOF-based sensing materials at ca. 1 ~ 10 mg (Table 1)8,9,10,11,12,13. This reduction in the amount of sensor materials required during a sensing event is possibly due to the small size and excellent dispersity of the EuCP microspheres. Luminescent turn-off sensing on Cu2+ of EuCP microspheres was also easily recognized by the naked eye, as shown in inset of Fig. 2d. The initial strong red emission of the EuCP microspheres almost disappeared after interaction with Cu2+. The decrease in emission bands could stem from the quenching effect attributed to the interaction of Cu2+ with coordination polymers. Specifically, the interaction of Cu2+ with a Lewis base within materials is a well-established quenching process10,11,12,13 and the oxygen atom of the carboxylate group is known as one example of a Cu2+ ion interacting site8,9. In addition, the Cu2+-detecting sensitivity of EuCP microspheres was significantly higher than the many known LnMOF-based sensor materials (Table 1)8,9,10,11,12,13. The quantified value of the quenching effect of Cu2+ was obtained using the Stern-Volmer equation (I0/I = 1 + Ksv[M])9,10,11. The quenching effect coefficient Ksv value (12,485 M−1) of EuCP microspheres for Cu2+ ions exhibited more than ~ 200% improvement over many known LnMOF-based sensor materials (Table 1)8,9,10,11,12,13.

The selectivity of EuCP microspheres on Cu2+ sensing was certified through observation of parallel reactions using various other metal ions instead of Cu2+. Luminescent EuCP microspheres were immersed in various MeCN solutions (5 mM) containing different kinds of metal ions, such as Mn2+, Co2+, Ni2+, Zn2+, Cd2+, Mg2+, Ca2+ and Ag+. Changes in the luminescent intensity of the initial EuCP microspheres were quite different depending upon the specific type of metal ions. As shown in Fig. 2e,f, significant change in luminescent intensity was only observed when EuCP microspheres were immersed in Cu2+ solution. Alkaline-earth metal ions (Mg2+ and Ca2+) and other transition metal ions (Mn2+, Co2+, Ni2+, Zn2+, Cd2+ and Ag+) showed no significant or little effect on the luminescent intensity of the initial EuCP microspheres. The quantified values of the quenching effect of various metal ions were obtained using the Stern-Volmer equation. The quenching effect coefficient Ksv value for Cu2+ ions at 12,485 M−1 was the largest and most distinguishable among those of other metal ions (Supplementary Table S1).

Reducing the amount of sensing-active EuCP materials

The small size of EuCP microspheres in comparison to that of typical macro-scaled MOF-based sensing materials is an excellent advantage in terms of the effective sensing event, because the luminescent signal of sensing materials is significantly contributed from the exterior of the materials, with only an insignificant contribution coming from the interior of the materials. The internal portion of the sensor materials is not seriously necessary for the sensing event and so core-shell type sensing materials with the sensing-active shell will be still good enough for the effective sensing event. Core-shell type sensor materials will result in reducing the amount of required sensor materials and decrease waste. Luminescent silica@EuCP core-shell microspheres31 were prepared according to the reported solvothermal method31,32 (Fig. 1). The reaction of carboxylic acid-terminated silica particles with coordination polymer precursors of Eu(NO3)3 and H2IPA at 140°C for 20 min resulted in the formation of uniform silica@EuCP microspheres. The resulting monodisperse silica@EuCP was first identified by SEM and STEM, as shown in Fig. 3a,b. Microscopy images clearly showed the formation of uniform microspheres and a size increase from 0.87 ± 0.02 μm for bare silica particles to 1.10 ± 0.03 μm after the formation of silica@EuCP. The thickness of the coordination polymer shell (EuCP) was 115 nm. Specially, the STEM image clearly showed the formation of well-organized core-shell structure. The relative weight percentages of both EuCP shell and silica core within silica@EuCP were calculated at ca. 6:4 (w/w, EuCP:silica). The relative weight percentages of EuCP shell and silica core were obtained by measuring the weight of the samples before and after removing the EuCP shell from the silica@EuCP using acetic acid. The formation of silica@EuCP core-shell structures was further verified using energy dispersive X-ray (EDX) spectroscopy, EDX spectrum profile scanning, IR spectroscopy and PXRD (Fig. 3c,d, Supplementary Fig. S1 and Supplementary Fig. S2). Especially, EDX spectrum profile scanning of silica@EuCP revealed the characteristic features for core-shell structure, where silica atoms were dominant at the center of the particles and europium atoms were abundant at the edge of the particles as a component of the shell (Fig. 3d). Confocal microscopy image (Fig. 3e) and photograph with UV irradiation (shown on the left side of Fig. 3h) of silica@EuCP microspheres visually showed luminescence in red regions of the spectrum due to the luminescent EuCP shell.

Morphology, optical property and sensing property of silica@EuCP microspheres.

(a) SEM and (b) STEM images of silica@EuCP microspheres (1.10 ± 0.03 µm). SEM image of initial silica (0.87 ± 0.02 µm) are shown in insets of (a) (s.d., n = 100). (c) EDX spectrum, (d) EDX spectrum profile scanning and (e) confocal microscopy and OM (inset) images of silica@EuCP microspheres. (f) Luminescent titration spectra of silica@EuCP microspheres with the addition of various concentrations of Cu(NO3)2 in MeCN with an excitation wavelength of 280 nm. (g) Luminescent intensity changes of silica@EuCP microspheres after immersion in various metal ion solutions (5 mM). (h) Photograph of a series of silica@EuCP microspheres suspensions before and after immersion in various metal ion solutions in the presence of UV irradiation.

Selective Cu2+ sensing of luminescent silica@EuCP microspheres

A study was conducted on the utilization of core-shell type silica@EuCP microspheres as a luminescent sensor along with the EuCP microspheres. The sensitivity of silica@EuCP core-shell in Cu2+ sensing was nearly identical with that of the pure EuCP microspheres, as shown in the titration of an MeCN suspension of silica@EuCP microspheres with various concentrations of Cu2+ (Fig. 3f). The turn-off signal of the silica@EuCP microspheres upon the Cu2+ addition was easily identified by the naked eye, as shown in Fig. 3h. The sensing selectivity of silica@EuCP microspheres was also essentially identical to that of pure EuCP microspheres, as shown in the series of the luminescent intensity changes after immersion in various kinds of metal ion solutions (Fig. 3g,h and Supplementary Table S2). The Ksv value (15,200 M−1) for Cu2+ ions of silica@EuCP is ca. 20% higher than that of pure EuCP microspheres (12,485 M−1). As demonstrated here, though the amount of EuCP within silica@EuCP microspheres was reduced to ca. 60% in comparison to pure EuCP microspheres, the sensitivity and selectivity of silica@EuCP core-shell for metal ion sensing does not decrease.

Silica@TbCP microspheres as highly effective solid sensor

Analogue silica@TbCP core-shell microspheres were also synthesized from a similar solvothermal reaction of carboxylic acid-terminated silica particles with Tb(NO3)3 and H2IPA at 140°C for 20 min. The formation of uniform silica@TbCP microspheres was first identified by SEM and STEM images. Microscopy images (Fig. 4a,b) revealed the formation of uniform core-shell structure with an average size of 1.14 ± 0.02 μm and TbCP shell thickness of 135 nm. The EDX spectrum and EDX spectrum profile scanning confirmed its chemical compositions (Fig. 4c,d). The emission spectrum of silica@TbCP microspheres showed the characteristic transitions of Tb3+ ions (Fig. 4f). The strong emission bands at 491 and 546 nm are attributed to the 5D4 → 7F6 and 5D4 → 7F5 transitions of Tb3+ ions, respectively11,14. These intense transitions resulted in the green emission of particles. Confocal microscopy image (Fig. 4e) and photograph (far left in Fig. 4h) in the presence of UV irradiation of silica@TbCP microspheres visually showed luminescence in green regions of the spectrum. Weak emission bands at 585 and 621 nm originating from the 5D4 → 7F4 and 5D4 → 7F3 transitions were also observed in the emission spectrum of the silica@TbCP microspheres.

Morphology, optical property and sensing property of silica@TbCP microspheres.

(a) SEM and (b) STEM images of silica@TbCP microspheres (1.14 ± 0.02 µm, s.d., n = 100). (c) EDX spectrum, (d) EDX spectrum profile scanning and (e) confocal microscopy and OM (inset) images of silica@TbCP microspheres. (f) Luminescent titration spectra of silica@TbCP microspheres with the addition of various concentrations of Cu(NO3)2 in MeCN with an excitation wavelength of 280 nm. (g) Luminescent intensity changes of silica@TbCP microspheres after immersion in various metal ions solutions (5 mM). (h) Photograph of a series of silica@TbCP microspheres suspensions before and after immersion in various metal ion solutions in the presence of UV irradiation.

The initial luminescent intensity of silica@TbCP microspheres was much stronger than that of silica@EuCP microspheres (Fig. 4f). In addition, the silica@TbCP exhibited superior sensing sensitivity in Cu2+ detection over silica@EuCP, as shown in the titration of the MeCN suspension of silica@TbCP microspheres with various concentrations of Cu2+ (Fig. 4f). The Ksv value for Cu2+ ions of silica@TbCP microspheres was 30,763 M−1. The sensitivity of silica@TbCP on Cu2+ detecting was 2 times higher than that of silica@EuCP. Turn-off sensing of silica@TbCP on Cu2+ was also easily identified by the clear disappearance of the green emission of silica@TbCP after immersion in Cu2+ solution (Fig. 4h). The sensing selectivity of silica@TbCP microspheres was also similar to that of silica@EuCP microspheres, as shown in the luminescent intensity changes attributed to various metal ions (Fig. 4g,h, Supplementary Fig. S5a and Supplementary Table S3).

Reducing sensing-active TbCP shell thickness

The portion of the coordination polymers responsible for signalling within the core-shell sensor materials can be additionally reduced by decreasing the coordination polymer shell thickness. Thin silica@TbCP microspheres with an average thickness of 40 nm were prepared from a similar solvothermal reaction, but with a decreased amount of coordination polymer precursors to that used during core-shell formation while maintaining the same amount of silica cores (Fig. 5a,b and Supplementary Fig. S6). In this case, the weight ratio between the luminescent TbCP shell and silica core was only ca. 1:3 (w/w, TbCP:silica). The sensitivity (Fig. 5c) and selectivity (Fig. 5d and Supplementary Table S4) on Cu2+ sensing of thin silica@TbCP microspheres was unchanged, even after reducing the shell thickness of the luminescent TbCP. The Ksv value for Cu2+ ions of thin silica@TbCP microspheres (36,432 M−1) was slightly higher than thick silica@TbCP microspheres. The sensitivity of thin silica@TbCP microspheres showed an improvement in excess of 550% in comparison to several known LnMOF-based sensor materials (Table 1). Finally, when we used only 0.01 mg of thin silca@TbCP microspheres instead of 0.1 mg, we still achieved a reliable response for the sensing events, as shown in Fig. 5e,f. Only 0.0026 mg of TbCP was presenting within 0.01 mg of thin silica@TbCP and this miniscule amount of TbCP was sufficient for exceptionally sensitive (more than 550% improvement) and selective sensing of Cu2+. Note that this tiny amount of TbCP (0.0026 mg) is only ca. 1/400 ~ 1/4000 of the quantity of other known MOF-based sensors, where 1 ~ 10 mg of MOF-based sensors were used during the sensing events.

Ideal heterogeneous solid sensor with small size and thin sensing-active layer.

(a) SEM and (b) STEM images of thin silica@TbCP microspheres (0.95 ± 0.02 µm, s.d., n = 100). (c) Luminescent titration spectra of thin silica@TbCP microspheres (0.1 mg) with the addition of various concentrations of Cu(NO3)2 in MeCN. Excitation wavelength was 280 nm. (d) Luminescent intensity changes of thin silica@TbCP microspheres (0.1 mg) after immersion in various metal ions solutions (5 mM). (e) Luminescent titration spectra in the presence of small amount of thin silica@TbCP microspheres (0.01 mg) with the addition of various concentrations of Cu(NO3)2 in MeCN. (f) Luminescent intensity changes of small amount of thin silica@TbCP microspheres (0.01 mg) after immersion in various metal ions solutions (5 mM). (g) Schematic representation outlining the strategy for design of ideal heterogeneous sensor particles (reducing the amount of required sensor material).

Recyclability of silica@TbCP micro-sensors

In last, we have demonstrated the recyclability of thin silica@TbCP microspheres for sensing processes. Silica@TbCP microspheres can be reused several times by simply washing the micro-sensors with fresh MeCN after the sensing process (Fig. 6a). SEM image of thin silica@TbCP microspheres measured after 3 successive usages was shown in Fig. 6b.

Discussion

In summary, we have developed highly effective heterogeneous sensor materials based upon luminescent coordination polymers. The small size and excellent dispersity of micro-sized EuCP spheres make it possible for extremely sensitive and selective sensing on Cu2+ ions. Interestingly, small amounts of EuCP microspheres were sufficient for a reliable sensing process. The amount of sensor materials (EuCP) can be further reduced by making sensor in the form of core-shell and so cutting off the waste. Core-shell type silica@LnCP microspheres showed the enhanced sensing sensitivity. The amount of sensor materials (LnCP) was additionally reduced by decreasing the shell thickness of the luminescent LnCP within silica@LnCP microspheres. The sensitivity of thin silica@TbCP microspheres, which contain tiny amount of sensing active materials, exhibited an improvement more than 550% in comparison to known LnMOF-based sensor materials. Finally, we found that only 0.0026 mg of luminescent LnCP, which is ca. 1/400 ~1/4000 of amount of MOF-based sensors typically required in sensing events, was sufficient for a reliable sensing event. Reducing the size of solid sensor and producing well-structured core-shells from solid sensing materials are an ideal direction for the future heterogeneous sensor development (Fig. 5g). In addition, the resulting micro-sized core-shell sensor exhibited the excellent recyclability.

Methods

General Methods

Solvents and all other chemicals were obtained from commercial sources and were used as received unless otherwise noted. Carboxylic acid-terminated silica particles were purchased from Polysciences, Inc. (USA). All scanning electron microscopy (SEM) images were obtained using a JEOL JSM-7001F field-emission SEM and energy dispersive X-ray (EDX) spectra were obtained using a Hitachi SU 1510 SEM equipped with a Horiba EMAX Energy E-250 EDS system. All scanning transmission electron microscopy (STEM) images were obtained using an FEI Tecnai G2 F30 ST and were carried out using dark-field imaging in STEM mode at 300 kV and EDX spectrum profile scanning data were obtained using an STEM attachment at Korea Basic Science Institute Seoul Center. Luminescent properties were measured on a Jasco FP-8500 fluorometer using quartz cells (10 × 4 mm light path). All confocal microscopy images were obtained using a Multiphoton CLSM (LSM 780 NLO, GaAsP detector, Carl-Zeiss) with a Ti:Sappuire laser (Maitai eHP deepsee, Spectra Physics) at Korea Basic Science Institute Chuncheon Center. The infrared spectra of solid samples were obtained on a Jasco FT/IR-4200 spectrometer. X-ray diffraction patterns were conducted using a Rigaku Ultima IV equipped with a graphite-monochromated Cukα radiation source (40 kV, 40 mA). Thermogravimetric analysis (TGA) measurements were carried out using a Shimadzu TGA-50 in a nitrogen atmosphere at a heating rate of 10°C min−1.

Preparation of luminescent EuCP microspheres

A coordination polymer precursor solution was prepared by mixing isophthalic acid (H2IPA, 10.0 mg, 0.060 mmol) and Eu(NO3)3·5H2O (28.4 mg, 0.066 mmol) in 15 mL of DMF/THF cosolvent (2:1, v/v). The resulting precursor solution was placed in an oil bath (140 °C). After 20 minutes, resulting spherical particles were isolated and subsequently washed with DMF and MeCN via centrifugation-redispersion cycles. Each successive supernatant was decanted and replaced with fresh solvent. IR for EuCP microspheres (KBr): 1606s, 1540s, 1481m, 1446m, 1402s, 1316w, 1280w, 1165w, 1106w, 1078w, 1003w, 927w, 874w, 833w, 811w, 747m, 717m, 681w, 658w, 636w, 626w, 610w, 579w, 534w, 472w.

Preparation of luminescent silica@LnCP (Ln = Eu or Tb) microspheres

A coordination polymer precursor solution was prepared by mixing isophthalic acid (H2IPA, 8.0 mg, 0.048 mmol) and Eu(NO3)3·5H2O (22.7 mg, 0.053 mmol) in 12 mL of DMF/THF cosolvent (2:1, v/v). The precursor solution was then mixed with carboxylic acid-terminated silica (12.0 mg). The resulting mixture was placed in an oil bath at 140 °C for 20 min. Luminescent silica@EuCP core-shell microspheres generated during this time were isolated by cooling the reaction mixture to room temperature, collecting the precipitate through centrifugation and washing the precipitate several times with DMF and MeCN. Each successive supernatant was decanted and replaced with fresh solvent. Luminescent silica@TbCP microspheres were also prepared using Tb(NO3)3·5H2O, under otherwise identical reaction conditions to those described above. IR for silica@EuCP microspheres (KBr): 1607s, 1543s, 1481m, 1447m, 1399s, 1316w, 1277w, 1104s, 943w, 875w, 801w, 747m, 716m, 657w, 635w, 472s. IR for silica@TbCP microspheres (KBr): 1607s, 1543s, 1481m, 1449m, 1400s, 1315w, 1277w, 1104s, 949w, 874w, 810w, 747m, 717m, 658w, 628w, 472s.

Preparation of thin silica@TbCP microspheres

Silica@TbCP microspheres with thin TbCP shell thickness was prepared by using small amounts of coordination polymer precursors (H2IPA; 2.0 mg, Tb(NO3)3·5H2O; 5.76 mg) and same amount of carboxylic acid-terminated silica particles (12.0 mg), under otherwise identical reaction conditions to those described above.

Measurements of luminescent properties

The luminescent properties of samples (spherical and core-shell microspheres) were measured in MeCN suspensions at room temperature. The luminescent titration spectra were measured by immersing EuCP microspheres or silica@LnCP microspheres (0.1 mg or 0.01 mg) into MeCN solutions (1.0 mL) of various concentrations of Cu(NO3)2 (0.1 mM ~ 5 mM). For the sensing selectivity experiments, EuCP microspheres or silica@LnCP microspheres (0.1 mg or 0.01 mg) were immersed in MeCN solutions (1.0 mL) containing M(NO3)2 (M = Mg2+, Ca2+, Mn2+, Co2+, Ni2+, Cu2+, Zn2+, Cd2+) or AgNO3 with a concentration of 5 mM. For recycling, the used silica@TbCP microspheres were washed several times with fresh MeCN.

References

Gaggelli, E., Kozlowski, H., Valensin, D. & Valensin, G. Copper homeostasis and neurodegenerative disorders (Alzheimer's, Prion and Parkinson's diseases and amyotrophic lateral sclerosis). Chem. Rev. 106, 1995–2044 (2006).

Barnham, K. J., Masters, C. L. & Bush, A. I. Neurodegenerative diseases and oxidative stress. Nat. Rev. Drug Discov. 3, 205–214 (2004).

Brunner, J. & Kraemer, R. Copper(II)-quenched oligonucleotide probes for fluorescent DNA sensing. J. Am. Chem. Soc. 126, 13626–13627 (2004).

Choi, J. K. et al. A PCT-based, pyrene-armed calix[4]crown fluoroionophore. J. Org. Chem. 71, 8011–8015 (2006).

Mu, L., Shi, W., Chang, J. C. & Lee, S.-T. Silicon nanowires-based fluorescence sensor for Cu(II). Nano Lett. 8, 104–109 (2008).

Jayaramulu, K., Narayanan, R. P., George, S. J. & Maji, T. K. Luminescent microporous metal-organic framework with functional Lewis basic sites on the pore surface: specific sensing and removal of metal ions. Inorg. Chem. 51, 10089–10091 (2012).

Kreno, L. E. et al. Metal-organic framework materials as chemical sensors. Chem. Rev. 112, 1105–1125 (2012).

Hao, Z. et al. A europium(III) based metal-organic framework: bifunctional properties related to sensing and electronic conductivity. J. Mater. Chem. A 2, 237–244 (2014).

Xiao, Y. et al. A microporous luminescent metal-organic framework for highly selective and sensitive sensing of Cu2+ in aqueous solution. Chem. Commun. 46, 5503–5505 (2010).

Chen, B. et al. A luminescent metal-organic framework with Lewis basic pyridyl sites for the sensing of metal ions. Angew. Chem. Int. Ed. 48, 500–503 (2009).

Zhou, J.-M., Shi, W., Li, H.-M., Li, H. & Cheng, P. Experimental studies and mechanism analysis of high-sensitivity luminescent sensing of pollutional small molecules and ions in Ln4O4 cluster based microporous metal-organic frameworks. J. Phys. Chem. C 118, 416–426 (2014).

Hao, Z. et al. One-dimensional channel-structured Eu-MOF for sensing small organic molecules and Cu2+ ion. J. Mater. Chem. A 1, 11043–11050 (2013).

Song, X.-Z. et al. Single-crystal-to-single-crystal transformation of a europium(III) metal-organic framework producing a multi-responsive luminescent sensor. Adv. Funct. Mater. 24, 4034–4041 (2014).

Yang, W. et al. MOF-76: from a luminescent probe to highly efficient UVI sorption material. Chem. Commun. 49, 10415–10417 (2013).

Chen, B., Wang, L., Zapata, F., Qian, G. & Lobkovsky, E. B. A luminescent microporous metal-organic framework for the recognition and sensing of anions. J. Am. Chem. Soc. 130, 6718–6719 (2008).

Chen, B. et al. Luminescent open metal sites within a metal-organic framework for sensing small molecules. Adv. Mater. 19, 1693–1696 (2007).

Dincă, M. et al. Observation of Cu2+-H2 interactions in a fully desolvated sodalite-type metal-organic framework. Angew. Chem. Int. Ed. 46, 1419–1422 (2007).

Wang, B., Côté, A. P., Furukawa, H., O'Keeffe, M. & Yaghi, O. M. Colossal cages in zeolitic imidazolate frameworks as selective carbon dioxide reservoirs. Nature 453, 207–211 (2008).

Huang, A. & Caro, J. Covalent post-functionalization of zeolitic imidazolate framework ZIF-90 membrane for enhanced hydrogen selectivity. Angew. Chem. Int. Ed. 50, 4979–4982 (2011).

Yanai, N. et al. Gas detection by structural variations of fluorescent guest molecules in a flexible porous coordination polymer. Nat. Mater. 10, 787–793 (2011).

Bohnsack, A. M., Ibarra, I. A., Bakhmutov, V. I., Lynch, V. M. & Humphrey, S. M. Rational design of porous coordination polymers based on bis(phosphine)MCl2 complexes that exhibit high-temperature H2 sorption and chemical reactivity. J. Am. Chem. Soc. 135, 16038–16041 (2013).

Tanabe, K. K. & Cohen, S. M. Engineering a metal-organic framework catalyst by using postsynthetic modification. Angew. Chem. Int. Ed. 48, 7424–7427 (2009).

Zhu, Q.-L. & Xu, Q. Metal-organic framework composites. Chem. Soc. Rev. 43, 5468–5512 (2014).

Aijaz, A., Akita, T., Tsumori, N. & Xu, Q. Metal-organic framework-immobilized polyhedral metal nanocrystals: reduction at solid-gas interface, metal segregation, core-shell structure and high catalytic activity. J. Am. Chem. Soc. 135, 16356–16359 (2013).

Oh, M. & Mirkin, C. A. Chemically tailorable colloidal particles from infinite coordination polymers. Nature 438, 651–654 (2005).

Lee, H. J., Cho, Y. J., Cho, W. & Oh, M. Controlled isotropic or anisotropic nanoscale growth of coordination polymers: formation of hybrid coordination polymer particles. ACS Nano 7, 491–499 (2013).

Cho, W., Lee, H. J. & Oh, M. Growth-controlled formation of porous coordination polymer particles. J. Am. Chem. Soc. 130, 16943–16946 (2008).

Li, T., Sullivan, J. E. & Rosi, N. L. Design and preparation of a core-shell metal-organic framework for selective CO2 capture. J. Am. Chem. Soc. 135, 9984–9987 (2013).

Liu, D., Huxford, R. C. & Lin, W. Phosphorescent nanoscale coordination polymers as contrast agents for optical imaging. Angew. Chem. Int. Ed. 50, 3696–3700 (2011).

Horcajada, P. et al. Porous metal-organic-framework nanoscale carriers as a potential platform for drug delivery and imaging. Nat. Mater. 9, 172–178 (2010).

Lee, H. J., Park, J.-U., Choi, S., Son, J. & Oh, M. Synthesis and photoluminescence properties of Eu3+-doped silica@coordination polymer core-shell structures and their calcinated silica@Gd2O3:Eu and hollow Gd2O3:Eu microsphere products. Small 9, 561–569 (2013).

Jo, C., Lee, H. J. & Oh, M. One-pot synthesis of silica@coordination polymer core-shell microspheres with controlled shell thickness. Adv. Mater. 23, 1716–1719 (2011).

Acknowledgements

This work was supported by the National Leading Research Lab Program (no. NRF-2012R1A2A1A03670409) through NRF grant funded by the Ministry of Science, ICT and Future Planning.

Author information

Authors and Affiliations

Contributions

M.O. planned and organized the project and wrote the paper; W.C., H.J.L., S.C. and Y.K. performed the experiments and collected data; M.O., W.C., H.J.L., S.C. and Y.K. discussed and analyzed the results.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary Information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/4.0/

About this article

Cite this article

Cho, W., Lee, H., Choi, S. et al. Highly effective heterogeneous chemosensors of luminescent silica@coordination polymer core-shell micro-structures for metal ion sensing. Sci Rep 4, 6518 (2014). https://doi.org/10.1038/srep06518

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep06518

This article is cited by

-

Classification, Synthesis, and Application of Luminescent Silica Nanoparticles: a Review

Nanoscale Research Letters (2019)

-

Fabrication and characterization of dual-functional ultrafine composite fibers with phase-change energy storage and luminescence properties

Scientific Reports (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.