Abstract

VO2 (M) STF through reduction of V2O5 STF was prepared. The results illustrate that V2O5 STF can be successfully obtained by oblique angle thermal evaporation technique. After annealing at 550°C/3 min, the V2O5 STF deposited at 85° can be easily transformed into VO2 STF with slanted columnar structure and superior thermochromic properties. After deposition SiO2 antireflective layer, Tlum of VO2 STF is enhanced 26% and ΔTsol increases 60% compared with that of normal VO2 thin films. Due to the anisotropic microstructure of VO2 STF, angular selectivity transmission of VO2 STF is observed and the solar modulation ability is further improved from 7.2% to 8.7% when light is along columnar direction. Moreover, the phase transition temperature of VO2 STF can be depressed into 54.5°C without doping. Considering the oblique incidence of sunlight on windows, VO2 STF is more beneficial for practical application as smart windows compared with normal homogenous VO2 thin films.

Similar content being viewed by others

Introduction

Monoclinic/rutile (M/R)-phase VO2, due to its reversible metal-insulator (MIT) phase transitions, has attracted great attention in many fields, such as resistive switching elements1, smart windows2, light modulators3 and optical storage devices4, etc. With the energy supply tension and the rise of energy-saving technology, VO2-based smart window becomes the focus due to its optical modulation ability in infrared spectra region. However, a low luminous transmittance (Tlum) and solar modulating ability (ΔTsol) are the two major drawbacks for the practical application of VO2-base smart windows5. The Tlum and Tsol values were obtained from Tlum,sol(τ) = ∫φlum,sol(λ)T(λ,τ)dλ/∫φlum,sol(λ)dλ, where φlum is the spectral sensitivity of the light-adapted eye and φsol is the solar irradiance spectrum for an air mass 1.5 (corresponding to the sun standing 37° above the horizon). ΔTsol is obtained from ΔTsol = Tsol,l − Tsol,h, where l and h denote low- and high-temperature, respectively.

Different strategies are investigated to improve Tlum and ΔTsol, including Mg- or F-doping6,7, multilayer-stack design8,9, composite film construction10,11, nanoporous incorporation12. Mg- or F-doping causes both the depression of transition temperature and a blue shift in the absorption edge of VO2 films (from around 445 to 415 nm6). A blue shift of absorption edge results in a significant increase of luminous transmittance with the expense of infrared modulating ability7. The competitive relation between luminous transmittance and solar modulation ability has also been observed in VO2 based multilayer films8. A VO2-SiO2 composite films show a high luminous transmittance but weak infrared modulating ability10. Optical calculations suggest that VO2 nanoparticles distributed in a transparent dielectric matrix can show higher Tlum and ΔTsol13. Gao et al.11 have proved that VO2-based composite thin films show superior luminous transmittance and solar modulation ability. However, compared with other dielectric matrix, porosity shows much more advantages, such as low refractive index, good compatibility and flexible adjustability. Kang et al.12 have proved that nanoporous VO2 thin films prepared by spinning method can enhance the luminous transmittance and solar modulation ability. However, investigation on nanoporous VO2 thin films prepared by physical vapor deposition is seldom.

Oblique angle deposition (OAD) technique is a common technique to adjust the porosity and microstructure of thin films, which is named sculptured thin films (STF)14. Sculptured thin films with controllable porosity and microstructure can show gradual optical constants and special physical properties, which can be used in many fields, such as rugate filters15, sensors16, phase retarder17, etc. The adjustable optical constants of STF are beneficial for the optical design of multilayer thin films and the dielectric layer is more optional. The anisotropic microstructure of STF can show angular selectivity transmission. Combination with VO2 thin films and OAD technique, it is supposed that VO2 STF can show superior luminous transmittance and solar modulation ability. In present paper, the optical properties and phase transition process of VO2 STF were investigated. The results illustrated that VO2 STF with slanted columnar structure can show superior thermochromic properties and angular selectivity transmission, which can be improved by antireflective layer design. The phase transition temperature of VO2 STF can be depressed into 54.5°C without doping, which is superior to normal VO2 film without doping. Due to the porosity, the refractive index of antireflective layer can be smaller than 2. Combination of SiO2 antireflective layer and angular selectivity transmittance, ΔTsol can be enhanced from 4.5% to 8.7%. Considering the oblique incidence of sunlight on windows, VO2 STF is supposed as the most suitable candidate as smart windows.

Results

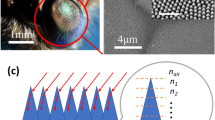

V2O5 sculptured thin films

SEM images of as-deposited V2O5 STF deposited at different angles are shown in Fig. 1 . It can be found that the thin films are porous with OAD technique (see Fig. 1(a, b) ). With the increase of deposition angle, films are with slanted columnar structure. The columns incline towards the direction of the incoming flux. The higher the deposition angle is, the greater the column inclination is. The highly orientated nanostructure of the slanted columns indicates that V2O5 films are anisotropy19, with the long axis parallel to the columnar growth direction. The anisotropic structure will introduce the anisotropic dependence into the thermal, electrical, magnetic and optical properties of thin films20.

Column angle β, defined as the angle between substrate surface normal and the long axis of slanted columns, is a significant structural parameter. As can be seen, the column angle increases with the increase of deposition angle. There are two empirical formulae developed to estimate column angle at oblique incidence: (1) tangent rule (tanβ = 0.5 tanα, α < 70°)21; (2) cosine rule (2sin(α − β) = 1 − cosα, α > 70°)22. However, the experimental column angle measured from SEM images is about 25°, 42°, 47° for α = 60, 80, 85°, respectively, which are rather lower than the value estimated by the tangent rule (β = 40.9° at α = 60) and cosine rule (β = 55.6° at α = 80° and β = 57.8° at α = 85°). The origin of the deviation may be due to the great surface curvature of nanostructure films grown by OAD. This will distinctly change the direction of column angle compared to that of micro-sized thin films. Additionally, the column angle also depends on the deposited material. Hodgkinson and Wu proposed the modified tangent rule (tanβ = E1tanα) and the parameter E1 is variable with different materials23. As to V2O5 STF, the relationship between β and α obeys exponential function fitted by the results of SEM measurements (see the insert of Fig. 1 (a) ).

The effect of annealing temperature

It is well-known that deposition angle is an important factor to sculpture films structure by OAD technique. However, in our experiment, VO2 (M) STF is indirectly obtained through V2O5 STF. It can be deduced that annealing conditions can play a great effect on the microstructure of VO2 (M).

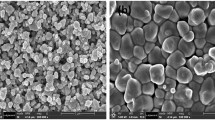

To obtain VO2 STF, V2O5 STF was reduced in hydrogen atmosphere. After annealing, the morphology and structure of STF were greatly changed just as shown in Fig. 2 . According to the SEM images of V2O5 STF annealed at different temperature, it can be found that the columnar structure become aggregation. The gap between columns in the same row is decreasing after annealing at 500°C. When the annealing temperature is up to 550°C, the intact columnar structure can not be observed and conglutination appears between columns. When the annealing temperature reaches 600°C, distinct particles on columns are observed and the single column becomes thick. When annealing temperature is up to 700°C, no column and porosity is observed and only polygonal particles disperse on the film surface. It means the sculptured thin films are completely destroyed at 700°C.

The XRD patterns of V2O5 STF annealed at different temperature are shown in Fig. 3 . It can be found that as-deposited thin film is polycrystalline with apparent peaks in XRD pattern, which is different from other oxide STF by evaporation method18. The peaks are ascribed to V2O5 (JCPDS 89-0611). After annealing at hydrogen atmosphere, peaks ascribed to V2O5 disappear and some peaks ascribed to VO2 (B) (JCPDS 81-2392) are observed. With the increase of annealing temperature, the peaks of VO2 (B) are firstly enhanced at 500°C and then disappear at 550°C. When annealing temperature is higher than 550°C, no peaks of VO2 (B) is observed and peaks ascribed to VO2 (M) (JCPDS 43-1051) appear. It is known that VO2 (B) can be transformed into VO2 (M) at high temperature24. However, the transformation temperature is higher than that observed in VO2 (B) powder at inert atmosphere25. According to our previous results on VO2 (B) prepared by hydrothermal method, lower crystallinity of VO2 (B) needs low transformation temperature25. In present paper, the higher transformation temperature of VO2 (B) may be resulted from the different structure of thin film and preparation process. With the increase of annealing temperature, the peaks ascribed to VO2 (M) are enhanced. When V2O5 STF is annealed at 700°C, two peaks at 12.2° and 29.2° appear, which can be ascribed to NaV6O15 (JCPDS 77-0146). It is inferred that sodium is from the glass substrate and high temperature is beneficial for the diffusion of Na+ ions, which finally result in the formation of NaV6O15.

Transmission spectra of V2O5 STF after annealing are shown in Fig. 4 . It can be found that as-deposited V2O5 STF show high transmission. After annealing, the transmission is reduced and the UV cut-off edge shifts to longer wavelength, which is resulted from the transformation of V2O5 to VO2. According to the high (H) and low (L) temperature transmission spectra of VO2 STF, the MIT transition is clearly observed as a dramatic infrared-transmittance change with temperature. The change of transmittance value is compiled in Table I .

It can be found that STF annealing at 400°C shows high Tlum and weak ΔTsol. With the increase of annealing temperature, the Tlum is gradually decreasing while the ΔTsol is firstly increasing and then decreasing. It is known that the VO2 (B) with broad band gap can show relatively high visible transmittance and Tlum, while it cannot produce reversible phase transition below 100°C. Thus, V2O5 STF annealing at 400°C mainly containing VO2 (B) does not show apparent infrared-transmission change (see Fig. 2). The decreasing of Tlum and increasing of ΔTsol is resulted from the increasing content of VO2 (M). Theoretically, the improved crystallinity and content of VO2 (M) can result in the increase of ΔTsol. However, the ΔTsol is decreasing for V2O5 STF annealing at 600°C and 700°C. For V2O5 STF annealing at 600°C, the aggregation of columns augment the distance of columns and minify the columnar angle, which result in the decreasing of columnar density and effective content of VO2(M) in fixed light spot size of transmittance testing. Thus, the ΔTsol is still decreasing for thin films with superior crystallinity. For STF annealed at 700°C, VO2 (M) particles are much more dispersive and the existence of NaV6O15 reduces the content of VO2 (M). Therefore, STF annealed at 700°C show weak ΔTsol. Conventionally, the transmittance change at wavelength of 2000nm is another factor to evaluate the spectral modulation ability. According to the transmittance spectra, ΔT2000 is also shown in Table I . The change of ΔT2000 is consistent with the change of ΔTsol, which is further proved our above mentioned analysis. According to the optical properties and microstructure of thin films, it can be deduced that the optimum annealing temperature is about 550°C.

The effect of annealing time

SEM images of V2O5 STF after annealing at 550°C for different time are shown in Fig. 5 . It can be found that short time heat treatment does no effect on the morphology of thin films, which are still porous with slanted columns. With the elongation of annealing time, the particles grow up and some columns begin aggregation. When annealing time is up to 5 min, some columns begin to melt and become coarse. The pores between columns are enlarging. When annealing time reaches 8 min, no columns can be observed. Only abnormal bulk-like structures with big pores are existent on the film surface, which means that the regular porous columnar structure is completely destroyed after long time heat treatment.

The XRD patterns of V2O5 STF annealing at 550°C for different time are shown in Fig. 6 . It can be found that only several weak peaks appear in the XRD pattern of V2O5 STF annealing for 1 min, which are ascribed to VO2 (B). When the annealing time reaches 3 min, thin films completely transform into VO2 (M).

The transmission spectra of V2O5 STF annealing at 550°C for different time are shown in Fig. 7 . It can be found that the transmission is decreasing with the increase of annealing time and the UV cut-off edge shifts to longer wavelength, which means that the content of VO2 (M) is increasing with annealing time. According to transmission spectra, the Tlum and ΔTsol are compiled in Table II . The Tlum is decreasing with the increasing annealing time and ΔTsol is increasing with annealing time, which is consistent with the result in XRD patterns (see Fig. 6 ). It means that long annealing time is beneficial for high crystallinity of VO2 (M) and superior solar modulation ability. However, the columnar structure can be destroyed when annealing time is longer than 5 min. Therefore, in the following works, we choose a moderate annealing time of 3 min to investigate the microstructure and optical properties of thin films.

The effect of deposition angle

The morphology of V2O5 STF deposited at different oblique angles after annealing at 550°C/3 min are shown in Fig. 8 . It can be found that the morphology was greatly changed after annealing. For V2O5 thin films deposited at 0°, the film is compact (see Fig. 1 ). After annealing, the films become porous with abnormal structure on the surface. While for V2O5 thin films deposited at 60°, the columnar structure is completely destroyed after annealing and only some belt like particles are existent on the surface. For V2O5 thin films deposited at 80°, the surface is like melted after annealing and the columns aggregates which make the column more inclined with higher column angle. The column angle is about 60°, but the arrangement of columns is not regular compared with as-deposited V2O5 STF at 80°. For V2O5 thin films deposited at 85°, the morphology and column structure is almost constant after annealing except for the increased column angle. It is known that large column angle can result in large anisotropy and high porosity, which can resulted in low refractive index and high visible transmission.

Transmittance spectra of V2O5 STF deposited at different oblique angles after annealing at 550°C/3 min are shown in Fig. 9 . It can be found that the transmittance is remarkably enhancing with the increase of deposition angle. It is proposed that the increase of deposition angle can increase the porosity in films and reduce the refractive index of films, which can result in the increase of transmission18. For film deposited at 85°, the ultraviolet cut-off edge of VO2 (M) STF is even smaller than 400 nm, which means that optical band gap is increased and the refractive index is sharply reduced by deposition angle adjustment18. The optical properties of Tlum and ΔTsol are compiled in Table III.

Discussion

It can be found that Tlum is increasing with deposition angle while the variation of ΔTsol is not consistent with Tlum in Table III. Generally, the visible transmittance at 30°C is lower than that at 100°C (see Table I and II). However, the visible transmittance at 30°C of 0° deposited film exceeds that at 100°C (see Table III). Xu et al.26 and Kang et al.12 proposed that film thickness dependent interference effects can result in the reversion of ΔTlum. In view of the fact that solar energy is mainly in the visible region with a peak at 550 nm, the ΔTlum reversion across the MIT greatly influences ΔTsol. Thus, film deposited at 0° shows larger ΔTsol than that of films deposited at other deposition angle. However, the absolute value of ΔTlum reversion is decreasing with the increase of deposition angle and the ΔTsol rises up after a fall. Factually, the solar modulation ability (ΔTsol) is related with both ΔTlum and infrared modulation (ΔT2000). The variation of ΔT2000 is resulted from the crystallinity, content and film structure of VO2 (M). The increase of deposition angle can result in the high porosity and relative low content of VO2 (M) as well as low infrared modulation. Thus, films deposited at 85° show high visible transmittance and relative low solar ability.

To determine the phase-transition temperature of the VO2 STF, hysteresis loops of pure and tungsten-doped VO2 STF were measured by recording transmittances and temperatures of STF at a fixed optical wavelength (2000 nm). As seen in Fig. 10 , pure VO2 film shows hysteresis loop width of 6°C at mean transmittance, which is consistent with that of pure VO2 film on glass10. The mean phase transition temperature (Tt) is about 54.5°C, which is much lower than that of pure VO2 films (68°C) deposited by other methods10,27. It is known that phase transition temperature can be depressed by doping, finite size and inhomogeneous strain28,29. For VO2 STF without doping, films are porous with tilted columnar structure and the residual stress is huge30. It can be deduced that the depressed phase transition temperature may be resulted form inhomogeneous strain in film. After tungsten doping, VO2 films exhibited a hysteresis loop centered at 35.8°C with a width of 9.7°C, implying a decrease in the phase transition temperature of about 17.7°C. This decreasing efficiency is less than that described in other reports31,32, likely because the tungsten ions were not completely incorporated into the final VO2 films. The width widening of the hysteresis loop can be attributed to the states of grain boundaries and defects introduced by tungsten doping. It is known that tungsten doping can result in both the decrease of temperature and infrared modulation ability. The VO2 STF without doping can show superior infrared modulation ability and equal transition temperature compared with VO2 thin films with doping.

Deposition antireflective layer is an important factor to improve luminous transmittance. Generally, antireflective layer with refractive index about 2 ~ 2.5 is proposed as the superior material for common VO2 film9. Considering VO2 STF deposited by OAD technique with gradient refractive index, refractive index of antireflective layer can be lower than 2. Though the real refractive index of VO2 STF was not tested due to the limit of instrument, silicon dioxide with refractive index about 1.46 (λ = 550 nm) was used as antireflective layer to prove our supposition. The transmission spectra of V2O5 STF deposited at 0° and 85° after annealing at 550°C/3 min before and after SiO2 antireflective layer deposition are shown in Fig. 11 . It can be found that the transmission spectra are greatly changed after antireflective layer deposition with the same thickness. For films deposited at 0°, besides the increase of transmission, the position of interference peaks was not changed after SiO2 layer deposition. While for films deposited at 85°, the position of interference peak shifts to shorter wavelength accompanying with the enhanced transmittance. The reason may be that relatively smaller equivalent thickness and the low refractive index of VO2 films deposited at 85° show strong interferences with SiO2 antireflective layer, which results in the blue shift of interferences peaks. The Tlum and ΔTsol are compiled in Table IV. After SiO2 deposition, Tlum of VO2 film deposited at 0° increases 20% (32.7% to 39.5%) and ΔTsol increases 15% (6.6% to 7.6%), while Tlum of VO2 film deposited at 85° is enhanced 26% (36.9% to 46.6%) and ΔTsol increases of 60% (4.5% to 7.2%), which means that SiO2 antireflective layer is much more effective to improve luminous transmission and solar modulation ability of VO2 STF than normal VO2 films.

It is known that VO2 STF with slanted columnar structure can show anisotropy optical properties. The transmission of STF along and perpendicular to column direction is obviously different. For convenience to prove, transmission spectra of 0° and ±30° incidence are shown in Fig. 12 . Tlum and ΔTsol according to transmission spectra are compiled in Table V . For VO2 deposited at 0°, Tlum and ΔTsol of +30° light incidence are almost the same with that of −30° light incidence, but it is much smaller than that of 0° incidence. For the homogeneous film, transmission of light oblique incidence is smaller than that of normal incidence according to interference optics. However, the result is absolutely different for anisotropic VO2 STF. For VO2 deposited at 85°, Tlum of +30° light incidence is smaller than that of −30° and 0° light incidence, but ΔTsol is higher than that of −30° and 0° incidence. The reason may be that +30° light incidence is along columnar direction and the effective thickness of VO2 (M) is larger than that of −30° and 0° light incidence. Thus, Tlum is relatively smaller than that of −30° and 0° light incidence and ΔTsol is higher than that of −30° and 0° light incidence. For VO2 deposited at 85° with SiO2 antireflective layer, ΔTsol of +30° light incidence is enhanced 20% with only 4% decrease of Tlum compared with normal incidence. Factually, sunlight is oblique incidence onto windows, the angle selective transmission of VO2 STF is more beneficial for practical application.

Considering the polarization effect and anisotropy of STF films, the polarization transmittance spectra are shown in Fig. 13 . For VO2 films deposited at 0°, films are homogenous. There is no polarization effect observed when polarization light is 0° incidence just as see in Fig. 13 (a) . While the transmission spectra of P-light and S-light are divided and polarization effect happens when incidence angel is 30°. For VO2 deposited at 85°, films are anisotropy with slanted columns. The P and S lights are separated and the transmission spectra cannot be overlapped when polarization incidence is 0° (see Fig. 13 (d) ), which means the optical anisotropy is observed in VO2 STF and is consistent with the results in other oxides films18,23. When incident light is oblique, the polarization effect is amplified just as see in Fig. 13 (e, f) . Simultaneously, the polarization effect is more distinct when light is along the direction of columns. For VO2 deposited at 85° with a layer of SiO2, the structure of films is changed and the anisotropy is reduced. Thus, the polarization effect and optical anisotropy is not apparent (see Fig. 13 (i, g, h) ). Due to phase transition of VO2 films at high and low temperature, the polarization effects need further study in future.

In conclusion, V2O5 STF with slanted column structure was prepared by oblique angle thermal evaporation technique. After annealing, V2O5 STF can be transformed into VO2 STF with the melting and aggregation of columnar structure. VO2 STF with slanted columnar structure can be obtained at 550°C/3 min for V2O5 STF deposited at 85°. Due to the porous structure and low refractive index, SiO2 can be used as effective antireflective layer to improve luminous transmittance and solar modulation ability. After SiO2 deposition, Tlum of VO2 films deposited at 85° is enhanced 26% (36.9% to 46.6%) and ΔTsol increases 60% (4.5% to 7.2%). Due to the anisotropic column structure, angle selective transmittance is observed for VO2 (M) STF. The solar modulation ability is further improved for light along the columnar direction especially for VO2 (M) STF with SiO2 antireflective layer (7.2% to 8.7%). Moreover, the phase transition temperature of VO2 STF is greatly depressed into 54.5°C without doping. Considering the oblique incidence of sunlight on windows, VO2 (M) STF is more suitable as smart window compared with normal homogeneous VO2 (M) films.

Methods

Preparation

V2O5 sculptured thin films were deposited by thermal evaporation at base pressure of 5 × 10−3 Pa with OAD technique. BK7 glass was ultrasonically cleaned in acetone and ethanol before introducing into the vacuum system. V2O5 powder (purity: 99.5%) were evaporated from a tungsten boat located 20 cm from the substrate. The deposition equipment was similar to our previous work18. The substrate tilted angle α was measured as the direction of the incident flux with respect to the substrate normal. In our experiment, the deposition angle α was fixed to be 0°, 60°, 80°, 85° without substrate rotation. During deposition, substrate was kept at room temperature. After deposition, V2O5 STF was annealed in an infrared lamp heating system (Mila-5000, ULVAC) with heating rate about 50°C/s in hydrogen atmosphere. For antireflective layer deposition, SiO2 sol was spinning on the surface of VO2 films at speed of 2000 rpm.

Characterization

The X-ray diffraction (XRD) patterns were obtained on X'Pert Pro MPD diffractometer, using Cu Kα radiation at a scan rate of 0.02° 2θ·S−1. A Hitachi S-4800 scanning electron microscope (SEM) equipped with energy dispersive spectrum (EDS, HORIBA EX-250) was used to acquire SEM images. The thermochromic property was monitored on a PerkinElmer Lambda 750 spectrophotometer equipped with a film heating unit in the wavelength range of 300–2500 nm. Temperature was measured by a temperature sensor in contact with the films and was controlled by a temperature controlling unit. The temperature errors were less than ±2°C. Transmittance spectra before and after phase transition were recorded at low (L) temperature of 30°C and high (H) temperature of 100°C. For the polarization measurement, the polarizer was introduced into the light path. The incident light was two-orthogonal polarization light named as P-light and S-light. The incident light was parallel to the deposition plane.

References

Corr, S. A. et al. Controlled reduction of vanadium oxide nanoscrolls: crystal structure, morphology and electrical properties. Chem. Mater. 20, 6396–6404 (2008).

Chen, Z. et al. VO2-based double-layered films for smart windows: optical design, all-solution preparation and improved properties. Sol. Energ. Mat. Sol. C. 95, 2677–2681 (2011).

Benkahoul, M. et al. Thermochromic VO2 film deposited on Al with tunable thermal emissivity for space applications. Sol. Energ. Mat. Sol. C. 95, 3504–3510 (2011).

Lu, S. W., Hou, L. S. & Gan, F. X. Structure and optical property changes of sol-gel derived VO2 thin films. Adv. Mater. 9, 244–247 (1997).

Mlyuka, N. R., Niklasson, G. A. & Granqvist, C. G. Thermochromic VO2-based multilayer films with enhanced luminous transmittance and solar modulation. Phys. Status Solidi A 206, 2155–2160 (2009).

Mlyuka, N. R., Niklasson, G. A. & Granqvist, C. G. Mg doping of thermochromic VO2 films enhances the optical transmittance and decreases the metal-insulator transition temperature. Appl. Phys. Lett. 95, 171909–11 (2009).

Burkhardt, W. et al. Tungsten and fluorine co-doping of VO2 films. Thin Solid Films 402, 226–230 (2002).

Jin, P., Xu, G., Tazawa, M. & Yoshimura, K. Design, formation and characterization of a novel multifunctional window with VO2 and TiO2 coatings. Appl. Phys. A: Mater, Sci. Process 77, 455–460 (2003).

Xu, G., Jin, P., Tazawa, M. & Yoshimura, K. Optimization of antireflection coating for VO2-based energy efficient window. Sol. Energ. Mat. Sol. C. 83, 29–32 (2004).

Lee, M. H. & Cho, J. S. Better thermochromic glazing of windows with antireflection coating. Thin Solid Films 365, 5–9 (2000).

Gao, Y. F. et al. Enhanced chemical stability of VO2 nanoparticles by the formation of SiO2/VO2 core/shell structures and the application to transparent and flexible VO2-based composite foils with excellent thermochromic properties for solar heat control. Energ. Environ. Sci. 5, 6104–61010 (2012).

Kang, L. T. et al. Nanoporous thermochromic VO2 films with low optical constants, enhanced luminous transmittance and thermochromic properties. ACS Appl. Mater. Inter. 3, 135–138 (2011).

Li, S. Y., Niklasson, G. A. & Granqvist, C. G. Nanothermochromics: calculations for VO2 nanoparticles in dielectric hosts show much improved luminous transmittance and solar energy transmittance modulation. J. Appl. Phys. 108, 063525–8 (2010).

Robbie, K. et al. Ultrahigh vacuum glancing angle deposition system for thin films with controlled three-dimensional nanoscale structure. Rev. Sci. Instrum. 75, 1089–1093 (2004).

Popta, A., Hawkeye, M., Sit, J. & Brett, M. J. Gradient-index narrow-bandpass filter fabricated with glancing-angle deposition. Opt. Lett. 29, 2545–2547 (2004).

Ertekin, E. & Lakhtakia, A. Sculptured thin film solc for optical sensing of gas concentration. Eur. Phys. J. Appl. Phys. 5, 45–50 (1999).

Motohiro, T. & Taga, Y. Thin film retardation plate by oblique deposition. Appl. Opt. 28, 2466–2469 (1989).

Xiao, X. D. et al. Structure and optical properties of Nb2O5 sculptured thin films by glancing angle deposition. Appl. Surf. Sci. 255, 20192–20197 (2008).

Kranenburg, V. H. & Lodder, C. Oblique-incidence deposition: a review and new experiment data. Mater. Sci. Eng. R 11, 295–354 (1994).

Brian, D. & Michael, B. J. Nanofabrication by glancing angle deposition. Encyclopedia Nanosci. Nanotechnol. 6, 703–726 (2004).

Nieuwenhizen, J. M. & Haanstra, H. B. Microfractography of thin films. Philips Tech. Rev. 27, 87–90 (1996).

Tait, R. N., Smy, T. & Brett, M. J. Modelling and characterization of columnar growth in evaporated films. Thin Solid Films 226, 196–201 (1993).

Hodgkinson, I. & Wu, Q. H. Empirical equations for the principal refractive indices and column angle of obliquely deposited films of tantalum oxide, titanium oxide and zirconium oxide. Appl. Opt. 37, 2653–2659 (1998).

Leroux, Ch., Nihoul, G. & Van Tendeloo, G. From VO2 (B) to VO2 (R): theoretical structures of VO2 polymorphs and in situ electron microscopy. Phys. Rev. B 57, 5111–5121 (1998).

Xiao, X. D. et al. A facile process to prepare one dimension VO2 nanostructures with superior metal-semiconductor transition. CrystEngComm 15, 1095–1106 (2013).

Xu, G., Jin, P., Tazawa, M. & Yoshimura, K. Thickness dependence of optical properties of VO2 thin films epitaxially grown on sapphire (0001). Appl. Surf. Sci. 244, 449–452 (2005).

Kang, L. T., Gao, Y. F. & Luo, H. J. A novel solution process for the synthesis of VO2 thin films with excellent thermochromic properties. ACS Appl. Mater. Inter. 1, 2211–2218 (2009).

Patridge, C. J., Whittaker, L., Ravel, B. & Banerjee, S. Elucidating the influence of local structure perturbations on the metal-insulator transitions of V1−xMoxO2 nanowires: mechanistic insights from an X-ray absorption spectroscopy study. J. Phys. Chem. C 116, 3728–3736 (2012).

Jin, P., Nakao, S. & Tanemura, S. Tungsten doping into vanadium dioxide thermochromic films by high-energy ion implantation and thermal annealing. Thin Solid Films 324, 151–158 (1998).

Xiao, X. D. et al. Anisotropic laser-induced damage threshold and residual stress of TiO2 sculptured thin films. J. Nanosci. Nanotechnol. 13, 824–828 (2013).

Binions, R., Hyett, G., Piccirillo, C. & Parkin, I. P. Doped and un-doped vanadium dioxide thin films prepared by atmospheric pressure chemical vapour deposition from vanadyl acetylacetonate and tungsten hexachloride: the effects of thickness and crystallographic orientation on thermochromic properties. J. Mater. Chem. 17, 4652–4660 (2007).

Manning, T. D. & Parkin, I. P. Vanadium oxide thin films on glass and silicon from the atmospheric pressure chemical vapour deposition. J. Mater. Chem. 14, 2554–2559 (2004).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 51102235 and 51102096) and Strategic New Industry Core Technology Research Project of Guangdong Province (No. 2011A032304003) and CAS Key Laboratory of Inorganic Coating Materials (No. KLICM-2010-05) and Director Innovation fund of GIEC (No. y007r21001) and State Key Laboratory of Silicate Materials for Architectures (Wuhan University of Technology) (No. SYSJJ2013-04).

Author information

Authors and Affiliations

Contributions

X.D.X. proposed and guided the overall project. Y.M.S., G.X., G.P.D., G.Q.C., H.Z., P.Y.L., H.M.Z. and Y.J.Z. performed all the experiments and analyzed the results. All the authors discussed the results. X.D.X. and Y.M.S. wrote the manuscript, with discussion from G.X.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Sun, Y., Xiao, X., Xu, G. et al. Anisotropic vanadium dioxide sculptured thin films with superior thermochromic properties. Sci Rep 3, 2756 (2013). https://doi.org/10.1038/srep02756

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep02756

This article is cited by

-

Moderating oxygen deficiency induced better thermochromic properties of monoclinic vanadium dioxide thin films

Applied Physics A (2020)

-

Impact of Annealing Temperature on Spin Coated V2O5 Thin Films as Interfacial Layer in Cu/V2O5/n-Si Structured Schottky Barrier Diodes

Journal of Inorganic and Organometallic Polymers and Materials (2019)

-

Insulator–metal transition in substrate-independent VO2 thin film for phase-change devices

Scientific Reports (2017)

-

Fabrication of smart wood with reversible thermoresponsive performance

Journal of Materials Science (2017)

-

Porous W-doped VO2 films with simultaneously enhanced visible transparency and thermochromic properties

Journal of Sol-Gel Science and Technology (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.