Abstract

The advance of nanomaterials has opened new opportunities to develop ever more sensitive sensors owing to their high surface-to-volume ratio. However, it is challenging to achieve intrinsic sensitivities of nanomaterials for ultra-low level detections due to their vulnerability against contaminations. Here we show that despite considerable achievements in the last decade, continuous in situ cleaning of carbon nanotubes with ultraviolet light during gas sensing can still dramatically enhance their performance. For instance in nitric oxide detection, while sensitivity in air is improved two orders of magnitude, under controlled environment it reaches a detection limit of 590 parts-per-quadrillion (ppq) at room temperature. Furthermore, aiming for practical applications we illustrate how to address gas selectivity by introducing a gate bias. The concept of continuous in situ cleaning not only reveals the tremendous sensing potential of pristine carbon nanotubes but also more importantly it can be applied to other nanostructures.

Similar content being viewed by others

Introduction

Nanomaterials are known to be extremely sensitive to their surrounding environment1,2,3. Accordingly intense research is underway to develop new sensing materials and devices for a wide range of areas including environmental pollution, space exploration, homeland security, biology and medicine. Single-walled carbon nanotubes (SWNTs) have been regarded as one of the most exciting materials due to their high surface-to-volume ratio and unique electronic structure4,5,6. Ironically the ultrahigh sensitivity of SWNTs is easily compromised by various unintentional contaminants from the device fabrication process as well as the ambient environment. Indeed, here we show that despite the significant progress that has been made in the last decade, we are still far from what a pristine SWNT based sensor can truly offer for detection of gases such as NO, NO2 and NH3. It is well known that nitrogen oxides including NO and NO2 play an important role in the chemistry of our atmosphere. NH3 is another toxic gas for proper safety monitoring. Since gases of interest even at very low concentrations can have significant impact on the environment, therefore, the capability to detect extremely low levels of these species becomes important. Among various explored nanotube sensors1,2,3,7,8, response based on conductance change is one of the easiest to implement. Because pristine SWNTs are speculated to be relatively limited in sensor performance, much effort has been focused on functionalized nanotubes9,10,11,12,13,14. The detection limit (DL) reported for each of these gases using carbon nanotubes as the electrical sensing material spreads over several orders of magnitude. Multiple factors have been discussed in the literature that includes the quality of tubes, multi-walled versus single-walled, the sensor catchment area, metal contacts, method of device fabrication as well as the detection environment. There is another commonly overlooked factor that we will examine in the present study, which is the surface condition of the sensing material, although the performance volatility of SWNT based devices due to interactions with ambient species is well recognized. The extreme sensitivity of the electronic properties of SWNTs to oxygen was reported in the literature15. Our previous study showed that the variation of oxygen in the ambient could lead to reversible continuous transformations of a SWNT from p-type to n-type, accompanied with significant changes of conductance16. Furthermore, water vapor could also interact with carbon nanotubes17. Fortunately, these contaminants can be removed by methods such as Ultraviolet (UV) light illumination. UV light induced molecular desorption from SWNTs had been reported previously where the desorption mechanism was attributed to plasmon excitation of nanotubes18. Plasmon induced photodesorption had also been observed before on metal surfaces19. In this study we will unveil the ultrasensitivity of pristine carbon nanotubes and show that applying continuous in situ UV light illumination during gas detection can enhance a SWNT-sensor’s performance by orders of magnitude under otherwise identical sensing conditions.

Results

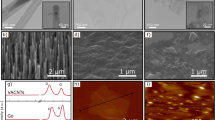

All SWNTs used in this study were obtained from direct growth by chemical vapor deposition (CVD) using iron nanocatalysts supported on a SiO2/Si substrate. Scanning electron microscopy (SEM) image shows that the nanotube film has a uniformly distributed thin layer of tubes of a few microns in length (Fig. 1). Typical Raman spectrum of our SWNT films taken with 532 nm laser excitation and averaged from 50 micron-size spots through an automatic mapping stage is shown in Fig. 1b. The radial breathing mode (RBM) peak frequencies (ωRBM) indicate that the tubes are single-walled with diameters (D) mostly in the range of 1–2 nm (D ~ 234 cm−1nm/ωRBM)20. More details of sample synthesis and characterization were published previously21 (see Methods section for device fabrication details).

First we investigated the effect of UV light illumination on a SWNT sensor’s performance in dry air (Fig. 2). The sensor’s response was recorded as the change of conductance normalized by the initial conductance commonly defined as the sensitivity. After the electrical conductance of the sample had been stabilized, we exposed the device to 200 parts-per-million (ppm) of NO. Without UV light, the sensor had very big (~0.6 or 60%) and fast response (~10 seconds) to the first NO exposure, while subsequent exposures had much smaller (~7%) but quite reproducible response. We attribute the smaller response at later cycles to partial device recovery which appears to have many active sites still occupied by pre-adsorbed NO molecules. The assumption has been justified in Fig. 2b where the application of UV light illumination during air flushing not only dramatically reduced the recovery time down to a few seconds but also enhanced the signal 5 times, i.e., from ~7% to ~36%. This observation prompted us to investigate the idea of in situ device cleaning during the process of gas detection. As expected, NO sensing with continuous in situ UV light illumination shows much improved sensitivity, where estimated DL improves about 2 orders of magnitude from 27.1 ppm down to 229 ppb (Fig. 2c). Although this sensitivity enhancement is astonishing considering that the experiment was carried out in a practical setting suitable for many sensor applications, unfortunately we found that the sensor would eventually lose its performance. The life time of the sensor was observed to depend on the thickness of the SWNT film, e.g., thicker SWNT films appeared to last longer. Electrical study shows that the SWNT sensor continuously loses conductance under UV light illumination. SEM images taken after ~1 hour of illumination indicates that the center of the film has no SWNTs left while the edge of the sample which is further away from the light has much lowered density of SWNTs than before the UV light was applied (Fig. 2d). Since the center of the film receives the strongest intensity because of its closer distance to the light source, this observation suggests that SWNTs are probably gradually removed by the UV light irradiation. This result is not very surprising considering UV light induced ozone formation in an oxygen rich environment and a potential ozone-SWNT chemical reaction22, yet the detailed mechanism of nanotube removal under UV light requires further investigation and is outside the scope of the current study.

Comparison of NO gas sensing in air.

(a) Relative change of conductance (ΔG/G0) versus time recorded with repeated 200 ppm of NO exposures. The inset shows the amplitude of signal at each cycle. DL is estimated to be 27.1 ppm. (b) Same experiment but with UV light illumination added during air flushing. (c) Same experiment but at 2 ppm of NO exposures under continuous in situ UV light illumination. The experiment was done after the conductance had been stabilized under UV light. The inset shows the sensor response at each cycle. DL is estimated to be 229 ppb. (d) Current versus time recorded before and after UV light was shed on the SWNT film. The device gradually loses conductance after ~1 hour of UV light illumination, where SEM images taken from the edge and center regions of the film are shown in the lower left and upper right panels, respectively.

In order to prevent damage to the active sensing material, i.e., SWNTs, next we studied the effect of UV light illumination in an inert environment. The effect is clearly illustrated by a drastic 10 fold current change on a pre-cleaned SWNT film with UV light placed in flowing N2, while it is ~200 fold compared to when the sample was initially in air (Fig. 3). The linear I-V relationship points to good ohmic contact between nanotubes and their metal contacts. Independent of the presence of gas analytes, no hysteresis had been observed on the device throughout the current study. In addition, the SWNT sensor was found to have very stable baseline conductance even after multiple cycles of UV light illumination, which suggests that there is no noticeable damage done to nanotubes by the UV light in a controlled inert environment. Because the decrease of conductance clearly excludes the possibility of UV light induced photoelectrical effect, the apparent explanation is that SWNTs are so sensitive to their environment that any minor imperfection of the sample sealing system or very low level of interactive impurities present in a 99.9999% pure inert carrier gas (N2 or Ar) will be enough to dope nanotubes and make their conductance increase after the UV light is turned off. These results further point to the intrinsic ultrasensitivity of pristine SWNTs and the crucial role of surface cleanness prior to molecular sensing. The effect of continuous in situ UV light illumination on a SWNT sensor’s performance is further demonstrated below for the detections of NO, NO2 and NH3 in an inert carrier gas of atmospheric pressure at room temperature. Due to ultra-low level gas detections in the present work, extra caution had been paid regarding all aspects of experiments (see Methods).

Effect of UV light on the electrical characteristics of the SWNT film.

(a) Device response to UV light under flowing N2. (b) I–V characteristics before and after UV light illumination. The data before UV light illumination was taken in air, while that after UV light was recorded under UV light illumination in an inert atmosphere after thorough cleaning of the nanotubes. The inset shows the curve plotted on an enlarged scale.

The electrical response of a SWNT film to NO molecules in flowing N2 is shown in Fig. 4. Before gas sensing, the sensor was continuously pumped for 1 day with a mechanical pump (the vacuum level was in the millitorr range), then annealed at 100°C while pumping for another day and finally the device was put under continuous UV light illumination in flowing N2 until the sensor had reached a flat baseline conductance of less than 1% drift over a 5-minute period. This step was found to be critical in order to obtain the best gas sensitivity. The NO detection was then done with in situ UV light kept on throughout the experiment. We have observed a ~30% conductance increase at 10 parts-per-trillion (ppt) of NO exposure. A linear response is observed with concentrations up to 50 ppt. Further increase of NO level leads to a non-linear behavior, presumably indicating that a different mechanism of gas adsorption has occurred23. DL can be derived from the noise of the baseline and the slope of Δ(ΔG/G0) versus concentration24. A noise value of 3.54×10−3 and a slope of 0.018 thus render DL = 590 ppq (see Methods). For comparison, tin oxide coated multi-walled carbon nanotubes (MWNTs) detected NO down to 2 parts-per-million (ppm) in air25. SWNTs wrapped with a 3,4-diaminophenyl-functionalized dextran exhibited selectivity for in vivo detection of NO10, while polymer coated SWNTs showed DL of 5 parts-per-billion (ppb) compared to 300 ppb for bare SWNTs in an inert atmosphere11. Compared to those results and other reports that we are aware of for NO detection under comparable detection environment, the sensitivity of pristine SWNTs as shown here is at least 4 orders of magnitude better. This ultrasensitivity is a strong support of the great potential of SWNTs in sensor applications which has been speculated for many years now. To further verify the reliability and reproducibility of the obtained results we recorded the sensor response by alternating between pure N2 and 10 ppt of NO in N2 (Fig. 4b). Very consistent result with a signal around 30% is observed. Furthermore, the sensor shows fast response and significant recovery in the scale of minutes. Note that the baselines in both panels of Fig. 4 are flat before NO exposures, which indicates that a stable dynamic balance has been established between adsorption and UV light induced molecular desorption. However, the baselines exhibit up drift with NO exposures which we attribute to incomplete device recovery since we have restricted both exposure time and recovery time to 5 minutes for all of our gas sensing experiments (unless otherwise marked) in order to have fair comparison of DLs. Moreover, we consider 5 minutes of sensing or recovery to be reasonable for a practical sensor, a number which is also in line with other published works. Remarkably, the sensor shows very repeatable response even at such a partially recovered state (Fig. 4b), a feature certainly desirable for a sensor.

Sensor response to NO molecules under in situ UV light illumination.

(a) Conductance change recorded with NO exposures ranging from 10 to 200 ppt. The inset shows sensor response with concentration. Squares are experimental data and dashed line is a guide to the eye. In the linear-fit equation, Y and X denote Δ(ΔG/G0) and NO concentration, respectively. DL is estimated to be 590 ppq. (b) Reproducibility of sensor response at 10 ppt of NO exposure. The inset shows the amplitude of response at each cycle. The experiment was done after device recovery.

Next we used the same device to investigate the sensing performance of NO2 molecules under analogical sensor preparation and detection conditions (Fig. 5). Similar to NO detection, a linear response is observed at low NO2 concentrations. The conductance is observed to increase 25% with 40 ppt of NO2 exposure in 5 min. The DL is estimated to be 1.51 ppt. As a comparison, an individual semiconducting-SWNT (S-SWNT) demonstrated remarkable sensitivity to 2 ppm of NO2 in Ar or air1 and a DL of 44 ppb was achieved using SWNT-based chemiresistor in ultrapure N224. DLs down to ppb level had been reported on pristine carbon nanotubes26,27 as well as gold functionalized SWNTs12. NO2 detection as low as 100 ppt was reported on polyethileneimine coated SWNTs13. PPB level detection of NO2 was also reported on other nanomaterials under an inert atmosphere28,29. Compared with those results, about 2 orders of magnitude better NO2 detection limit has been obtained in the current work due to dynamic surface cleaning induced by the application of continuous in situ UV light illumination. In analogy to the detection of NO molecules, repeated sensings at 40 ppt of NO2 exposure also show good reversibility (Fig. 5b). It is noticeable that the best detection levels of NO2 and NO that we have achieved under analogous sensing conditions but without in situ UV light illumination are also in the ppb range similar to those lower limits presented in the literature, where the gas sensitivities are about 3 and 4 orders of magnitude worse than what are reported here for the detections of NO2 and NO, respectively. This comparative study of UV light application clearly illustrates the significant impact of continuous in situ cleaning on sensor performance.

NO2 sensing under in situ UV light illumination.

(a) Conductance change versus time recorded with NO2 exposures ranging from 40 to 1000 ppt. The inset shows sensor response with concentration. Squares are experimental data and dashed line is a guide to the eye. In the linear-fit equation, Y and X denote Δ(ΔG/G0) and NO2 concentration, respectively. DL is estimated to be 1.51 ppt. (b) Reproducibility of sensor response at 40 ppt of NO2 exposure. The experiment was done after device recovery.

Interestingly, the change of conductance to NH3 exposures reverses its direction, i.e., from decrease of conductance to eventually increase of conductance upon applying in situ UV light illumination on the sensor (Fig. 6). This change of sign is attributed to the initial conducting state of the sensor. Carbon nanotubes were found to be p-type in air1,15. In contrast to NO and NO2 which are electron acceptors, NH3 is an electron donor. Because of a lone electron pair that can be donated, negative charge transfer from NH3 adsorption will cancel the existing p-type carriers of an air doped nanotube and thus make its conductance to decrease. After applying UV light illumination, Fig. 6b indicates that the UV light has efficiently removed the p-type dopants so as to shift the Fermi level of a nanotube closer to the carrier neutrality point. Therefore, any charge transfer from subsequent NH3 adsorption will only increase its conductance by adding free electrons. It is remarkable that simply applying in situ UV light illumination improves the DL of NH3 under otherwise identical sensing conditions from 5.67 ppm to 27.8 ppt, i.e., 5 orders of magnitude sensitivity improvement in this case. There have been significant progresses on ultra-low level detection of NH3 with both SWNTs and MWNTs1,7,8,9,14,24,27. For example, SWNT and MWNT coated sensors had been found to have similar sensitivity toward NH3 at concentrations ranging from 100 to 400 ppm7. Detection of NH3 at 5 ppm had been achieved with pristine SWNTs in purified air27 as well as polymer coated SWNTs in N29, while a DL of 262 ppb had been derived from a SWNT chemiresistor in N224. DL as low as 50 ppb diluted in Ar had been reported on functionalized SWNTs14. Compared with those results, our pristine SWNT based sensor has at least 3 orders of magnitude better sensitivity owing to continuous surface cleaning. In addition, the sensor was fully recoverable and we had not observed any obvious device degradation for these 3 gases (NO, NO2 and NH3) studied here in an inert atmosphere.

Comparison of sensor responses to NH3.

(a) Conductance change versus time recorded with the sensor exposed to increasing NH3 concentrations without UV light illumination. The inset shows sensor response with concentration. DL is estimated to be 5.67 ppm. (b) Sensor response under in situ UV light illumination. DL is estimated to be 27.8 ppt. (c) Reproducibility of the sensor response at 200 ppt of NH3 exposures under in situ UV light illumination. Successive experiments were done after the device had been recovered.

Discussion

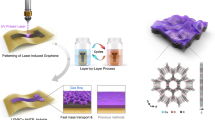

Sensitivity is only one aspect of sensor performance, while selectivity is also required for a practical sensor. As an attempt to address this issue, we have studied the sensitivity dependence of an individual S-SWNT based field effect transistor (FET) device on an applied electrical gate voltage. Importantly, this feature can open the prospect for selective detection. Although the concept is not completely new1, here we demonstrate how this can be done at very low level of gas detection (Fig. 7). The basic idea is that you can set up the initial conducting state of an individual S-SWNT through an external gate bias which in principle, depending on its gate dependent I-V characteristics profile, determines whether and how sensitive the sensor will respond to an analyte gas. An individual S-SWNT based device was fabricated in FET geometry by e-beam lithography for this purpose16, where the heavily doped Si substrate was used as the back gate. Due to the vulnerability of the device, no UV light had been used for this study, while we kept all other conditions (e.g., gas dilution and device cleaning) in analogy to the case of a SWNT film. The utilized nanotube appears to be p-type before molecular sensing (Fig. 7b). Careful device preparation enabled us to use 5 ppb of NO2 as the target gas. As an electron acceptor, the adsorption of NO2 is equivalent to applying a negative chemical gate voltage. According to the Ids versus Vg curve, we expect to see drastically different responses from this device when we apply the following gate voltages: a) Vg = −10 V. We predict the sensor to have weak response since the Ids versus Vg profile has a small slope (|dIds/dVg| < 0.1 µS) at this gate bias. (b) Vg = 12 V. Because this Vg is on the right-hand side just before the threshold of a sharp slope (|dIds/dVg| > 0.4 µS), we should see large response due to negative chemical gate effect of NO2 adsorption. (c) Vg = 20 V. No obvious response is expected since |dIds/dVg| ~ 0 at this gate voltage. The experimental results as shown in the insets of Fig. 7b agree pretty well with this analysis, e.g., we have observed very weak response at Vg = −10 V, over 300 fold current increase at Vg = 12 V and no response at Vg = 20 V. This experiment clearly demonstrates that, by setting up the initial conducting state via applying an electrical gate bias, one can tune and maximize the sensitivity of a SWNT-based sensor. Because opposite electron affinities will move the Ids versus Vg profile in different directions, this effect can be thoughtfully utilized for selective detection between electron donor and acceptor gas species, but to be more specific will be challenging although possible with well calibrated sensitivity for each gas. As can be seen from this discussion, gate bias dependent gas selectivity seems more feasible from individual S-SWNT based sensor than that based on a film with wide nanotube chirality distribution since where metallic tubes don’t have significant response to a gate and the effect from semiconducting tubes will be mostly smeared out due to averaging from tubes of varied electronic transition energies. However, it becomes almost equally promising to address selectivity from a film based sensor after recent success on selective growth of semiconducting SWNTs with narrow chirality distribution30,31.

Electrical gate effect on the sensitivity of an individual S-SWNT.

(a) AFM image of the SWNT before device fabrication. Numbers and characters were used as a coordinate for e-beam lithography. The nanotube diameter is ~1.4 nm. (b) Ids dependence on gate voltage Vg, where Vds = 1V. Squares indicate 3 different gate voltages applied to sense 5 ppb of NO2 whose results are shown on the insets. Successive experiments at each gate bias were carried out after the device had been recovered.

In conclusion we have demonstrated the effect of continuous in situ UV light illumination on a SWNT sensor’s performance. The comparative studies unambiguously support that UV light induced surface cleaning should be responsible for SWNT’s ultrahigh sensitivity reported here. The effect of in situ UV light illumination is presumably reflected by: (1) Affecting the background conductance; (2) Cleaning the nanotube surface so that it is more accessible for gas adsorption; (3) Dynamically removing all adsorbed gas species from nanotubes. The first aspect shouldn’t affect a sensor’s performance dramatically. The second one has the potential to drastically enhance a sensor’s sensitivity, while the third one will only reduce it. It is thus intuitive to assume that optimized UV light illumination can probably further improve a sensor’s performance. It seems logic to extend the idea of continuous in situ cleaning to other sensing materials where a material-specific method of cleaning may be required. Although UV light induced loss/degradation of active sensing materials hinders long term usage of UV light on SWNTs in air, yet it could still be utilized for fast gas detection at much enhanced sensitivity (2 orders of magnitude in this study). Certainly application of in situ cleaning is more powerful in a controlled environment where either the method of cleaning doesn’t cause any damage to the sensing material or by removing any problematic species with special filters as well as other technologies, e.g., here we have demonstrated a DL down to ppq level for NO detection in N2. Because of its simplicity we believe the concept of continuous in situ cleaning can be deployed in existing sensor platforms which has great promise to significantly improve their performance. In the meantime the combination of observed ultrasensitivity from pristine SWNTs with potentially-achievable selectivity can be fully utilized to detect a range of substances that have a significant impact on the betterment of humanity. Although many challenges remain to be addressed, with increased interest and the development of related technologies, SWNTs are still one of the most promising candidates for developing the next generation of ultrasensitive sensors.

Methods

Device fabrication

All SWNT films were as-grown on Si substrates (SiO2 thickness 400 nm) by CVD method without any post-synthesis chemical treatment. Typical SEM image of the SWNT network is shown in Fig. 1. Two electrical pads (Au/Ti with thicknesses of 120 nm/30 nm) were applied 2 mm apart on top of a SWNT film through vacuum thermal evaporation. The device was then annealed in a CVD chamber at 300°C for 3 hours under flowing Ar. For gas sensing in air, two tungsten needle probes (radius: 100 µm) were applied ~5 mm apart on top of the SWNT film as contacts. For individual SWNT based FETs, see reference 16 about the details of device fabrication.

Electrical conductance measurements

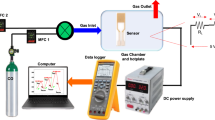

Electrical measurements were done on a customized flowing cell that has electrical feedthrough connections for both temperature and electrical measurements. The current was monitored with a Keithley 4200-SCS instrument at atmospheric pressure and 25°C on a sample stage where the temperature was controlled through a temperature controller equipped with automatic resistive heating and liquid N2 cooling assemblies (temperature stability better than 0.1°C). For experiments involving UV light illumination, a pencil light (λ = 253.7 nm and estimated I ~ 1.7 mW/cm2) was applied ~5 mm above the center of the SWNT film through a quartz window.

Gas sensing experiments

For gas sensing in air, the carrier gas was from compressed dry air with a dew point of −70°C through a desiccant dryer. Certified 1000 ppm mixture gas of NO in N2 was used for dilution. For gas sensing in an inert atmosphere, research-grade (99.9999% purity) N2 or Ar was used as the carrier gas. Certified 50 (200) ppb mixture gas of NO (NO2) in N2 was used for dilution, where the concentration was confirmed by chemiluminescence measurements at an error of 5%. For NH3 detection, certified 1 ppm of NH3 in Ar was used, where the concentration was determined by Gravimetric method at 10% uncertainty. A total flow rate of 1000 ml/min was used for all gas sensing experiments. In order to minimize experimental errors, gas dilution was restricted to a simple one step mixing of carrier and analyte gases controlled by two digital mass flow controllers (MFCs) (Brooks Model # 5850S) with a full scale of 2000 ml/min and 20 ml/min, respectively. Both MFCs were calibrated using a multipoint calibration curve with gas measurement equipment (DHI) accurate to 0.01 ml/min. The flow uncertainty of these MFCs is 0.7% of the flow rate or 0.2% of the full scale, whichever is greater. Based on the accuracy of MFCs, flow rates and certified gas concentrations, assuming these errors are uncorrelated, simple error propagation calculation shows that the error will be ~21% at 10 ppt of NO detection. Therefore, a DL of 590 ppq for NO detection has an error of ± 120 ppq. Similar calculation shows that the DLs would be 1.51 ± 0.32 ppt and 27.8 ± 6.2 ppt for NO2 and NH3 detections, respectively.

Detection limit (DL) estimation

DL can be derived from the signal to noise (s/n) ratio. Both s/n = 1 and s/n = 3 have been commonly used in the literature. We have used s/n = 3 for all DL calculations presented here. The noise refers to the root-mean-square (rms) noise of the baseline. To calculate the rms noise, we have used a third-order polynomial equation to fit the data and then the noise is computed by comparing the experimental data with the fitted curve. For gas detection at a constant analyte concentration (Fig. 2), DL is calculated by DL = 3 Concentration/(s/n), where a median value of s/n is used. For gas detection with varied analyte concentrations (Fig. 4–6), DL = 3 rms/slope, where the slope refers to a line fit to the signal Δ(ΔG/G0) versus concentration in the sensor’s quasi-linear response region.

References

Kong, J. et al. Nanotube molecular wires as chemical sensors. Science 287, 622–625 (2000).

Modi, A., Koratkar, N., Lass, E., Wei, B. Q. & Ajayan, P. M. Miniaturized gas ionization sensors using carbon nanotubes. Nature 424, 171–174 (2003).

Snow, E. S., Perkins, F. K., Houser, E. J., Badescu, S. C. & Reinecke, T. L. Chemical detection with a single-walled carbon nanotube capacitor. Science 307, 1942–1945 (2005).

Baughman, R. H., Zakhidov, A. A. & de Heer, W. A. Carbon Nanotubes--the Route Toward Applications. Science 297, 787–792 (2002).

Dresselhaus, M. S., Dresselhaus, G. & Eklund, P. C. Science of fullerenes and carbon nanotubes (Academic Press, San Diego, 1996).

Iijima, S. & Ichihashi, T. Single-Shell Carbon Nanotubes of 1-Nm Diameter. Nature 363, 603–605 (1993).

Chopra, S., Pham, A., Gaillard, J., Parker, A. & Rao, A. M. Carbon-nanotube-based resonant-circuit sensor for ammonia. Applied Physics Letters 80, 4632–4634 (2002).

Suehiro, J., Zhou, G. B. & Hara, M. Fabrication of a carbon nanotube-based gas sensor using dielectrophoresis and its application for ammonia detection by impedance spectroscopy. Journal of Physics D-Applied Physics 36, L109–L114 (2003).

Bekyarova, E. et al. Chemically Functionalized Single-Walled Carbon Nanotubes as Ammonia Sensors. The Journal of Physical Chemistry B 108, 19717–19720 (2004).

Kim, J. H. et al. The rational design of nitric oxide selectivity in single-walled carbon nanotube near-infrared fluorescence sensors for biological detection. Nature Chemistry 1, 473–481 (2009).

Kuzmych, O., Allen, B. L. & Star, A. Carbon nanotube sensors for exhaled breath components. Nanotechnology 18, 375502 (2007).

Young, P., Lu, Y. J., Terrill, R. & Li, J. High-sensitivity NO2 detection with carbon nanotube-gold nanoparticle composite films. Journal of Nanoscience and Nanotechnology 5, 1509–1513 (2005).

Qi, P. et al. Toward large arrays of multiplex functionalized carbon nanotube sensors for highly sensitive and selective molecular detection. Nano Letters 3, 347–351 (2003).

Zhang, T., Nix, M. B., Yoo, B. Y., Deshusses, M. A. & Myung, N. V. Electrochemically functionalized single-walled carbon nanotube gas sensor. Electroanalysis 18, 1153–1158 (2006).

Collins, P. G., Bradley, K., Ishigami, M. & Zettl, A. Extreme oxygen sensitivity of electronic properties of carbon nanotubes. Science 287, 1801–1804 (2000).

Chen, G., Paronyan, T. M., Pigos, E. M., Sumanasekera, G. U. & Harutyunyan, A. R. The performance volatility of carbon nanotube-based devices: Impact of ambient oxygen. Applied Physics Letters 95, 123118 (2009).

Zahab, A. et al. Water-vapor effect on the electrical conductivity of a single-walled carbon nanotube mat. Physical Review B 62, 10000 (2000).

Chen, R. J. et al. Molecular photodesorption from single-walled carbon nanotubes. Applied Physics Letters 79, 2258–2260 (2001).

Hoheisel, W., Jungmann, K., Vollmer, M., Weidenauer, R. & Trager, F. Desorption Stimulated by Laser-Induced Surface-Plasmon Excitation. Physical Review Letters 60, 1649–1652 (1988).

Chen, G. et al. Chemically doped double-walled carbon nanotubes: Cylindrical molecular capacitors. Physical Review Letters 90, 257403 (2003).

Harutyunyan, A. R. et al. Preferential Growth of Single-Walled Carbon Nanotubes with Metallic Conductivity. Science 326, 116–120 (2009).

Mawhinney, D. B. et al. Infrared spectral evidence for the etching of carbon nanotubes: Ozone oxidation at 298 K. Journal of the American Chemical Society 122, 2383–2384 (2000).

Calbi, M. M., Cole, M. W., Gatica, S. M., Bojan, M. J. & Stan, G. Condensed phases of gases inside nanotube bundles. Reviews of Modern Physics 73, 857 (2001).

Li, J. et al. Carbon nanotube sensors for gas and organic vapor detection. Nano Letters 3, 929–933 (2003).

Liang, Y. X., Chen, Y. J. & Wang, T. H. Low-resistance gas sensors fabricated from multiwalled carbon nanotubes coated with a thin tin oxide layer. Applied Physics Letters 85, 666–668 (2004).

Valentini, L. et al. Role of defects on the gas sensing properties of carbon nanotubes thin films: experiment and theory. Chemical Physics Letters 387, 356–361 (2004).

Karthigeyan, A., Minami, N. & Iakoubovskii, K. Highly sensitive, room-temperature gas sensors prepared from cellulose derivative assisted dispersions of single-wall carbon nanotubes. Japanese Journal of Applied Physics 47, 7440–7443 (2008).

Schedin, F. et al. Detection of individual gas molecules adsorbed on graphene. Nat Mater 6, 652–655 (2007).

Landau, O., Rothschild, A. & Zussman, E. Processing-Microstructure-Properties Correlation of Ultrasensitive Gas Sensors Produced by Electrospinning. Chemistry of Materials 21, 9–11 (2009).

Li, Y. et al. Preferential Growth of Semiconducting Single-Walled Carbon Nanotubes by a Plasma Enhanced CVD Method. Nano Letters 4, 317–321 (2004).

Ding, L. et al. Selective Growth of Well-Aligned Semiconducting Single-Walled Carbon Nanotubes. Nano Letters 9, 800–805 (2009).

A patent related to this work has been submitted. (U.S. patent application No 61/483,733).

Acknowledgements

The authors are grateful to Christopher J. Brooks for assistance with gas flow controls.

Author information

Authors and Affiliations

Contributions

G.C. designed and carried out experiments and analyzed the data. T.M.P. and E.M.P. synthesized nanotubes and prepared devices. A.R.H. initiated and supervised the research. G.C. and A.R.H. wrote the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-No Derivative Works 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Chen, G., Paronyan, T., Pigos, E. et al. Enhanced gas sensing in pristine carbon nanotubes under continuous ultraviolet light illumination. Sci Rep 2, 343 (2012). https://doi.org/10.1038/srep00343

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep00343

This article is cited by

-

A review of gas sensors based on carbon nanomaterial

Carbon Letters (2022)

-

Strategy and Future Prospects to Develop Room-Temperature-Recoverable NO2 Gas Sensor Based on Two-Dimensional Molybdenum Disulfide

Nano-Micro Letters (2021)

-

A review on chemiresistive room temperature gas sensors based on metal oxide nanostructures, graphene and 2D transition metal dichalcogenides

Microchimica Acta (2018)

-

Ultrasensitive H2S gas sensors based on p-type WS2 hybrid materials

Nano Research (2018)

-

A cross-functional nanostructured platform based on carbon nanotube-Si hybrid junctions: where photon harvesting meets gas sensing

Scientific Reports (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.