Abstract

The post-polymerization modification of unsaturated polyesters, three polymaleates and a polyfumarate, was performed by the Michael addition of N-heterocyclic carbenes (NHCs) to produce thermally stable unsaturated polyesters. The model reactions of NHCs, 1,3,4-triphenyl-4,5-dihydro-1H-1,2,4-triazol-5-ylidene (TPT), and 1,3-bis(2,6-diisopropylphenyl)imidazol-2-ylidene (IDipp), with dibutyl fumarate and dibutyl maleate selectively proceeded to give the corresponding Michael adducts, whereas 1,3-di-tert-butylimidazol-2-ylidene (ItBu) exclusively catalyzed the isomerization of dibutyl maleate. Based on these results, reactions of the unsaturated polyesters with TPT and IDipp were investigated. The polyesters bearing NHCs as side chains were obtained in good-to-high yields. The number of NHC-incorporated units can be controlled by the amount of added NHCs, and the obtained polyesters showed better solubility in common organic solvents. It is noteworthy that the glass transition temperatures (Tgs) were widely tunable and increased linearly with increasing NHC content because of the stiff and bulky structure. In addition, reactions of the unsaturated polyesters with TPT in the presence of water allowed Michael addition and transfer hydrogenation to occur simultaneously. Radical cross-linking of the NHC-incorporated unsaturated polyesters with styrene produced thermally stable and fully miscible polyester resins.

Similar content being viewed by others

Introduction

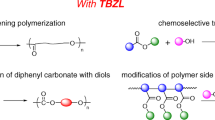

Unsaturated polyester resins1, 2 are important raw materials for fiber-reinforced plastics. They are generally synthesized by the polycondensation of maleic anhydride and diols to produce unsaturated polyesters, followed by radical cross-linking with vinyl monomers, such as styrene. Recent advances in the synthetic procedures for unsaturated polyesters, that is, polycondensation catalyzed by Lewis acids3 or Brønsted acids4 and metal-catalyzed ring-opening copolymerization of maleic anhydride and epoxides,5, 6, 7 would lead to further applications thereof. Post-polymerization modification,8, 9, 10, 11, 12, 13 in general, facilitates the synthesis of a variety of polymers from a single polymeric precursor by changing the reactants and their incorporation ratios to advance the understanding of structure–property relationships. However, except for radical cross-linking, there are only a few examples of the post-polymerization modification of unsaturated polyesters derived from maleic anhydride. Specifically, selective reaction of the highly reactive double bonds of unsaturated polyesters has allowed for the preparation of micelles,14, 15 reversible cross-linked materials,16 water-soluble polyesters,17 and double-network gels.18 To control the glass transition temperature (Tg) of unsaturated polyesters, phthalic anhydride is generally used as a comonomer, in which the aromatic group introduced in the polyester main chain reduces the mobility of the polymer chain to result in an increase in Tg. However, the effects of the phthalic unit are not large; poly(butylene phthalate) shows a higher Tg than poly(butylene maleate) by only 30 °C.4

N-Heterocyclic carbenes (NHCs)19 are neutral Lewis bases and are extensively used as organocatalysts.20 NHCs undergo Michael addition21, 22, 23 to catalyze cyclization,24, 25, 26 tail-to-tail dimerization,27, 28, 29, 30, 31, 32, 33 and polyaddition34, 35 through deoxy-Breslow intermediates. In contrast, the intermediates generated from TPT (1,3,4-triphenyl-4,5-dihydro-1H-1,2,4-triazol-5-ylidene) with fumarates and maleates are quite stable and isolable, such that no further Michael addition occurs.36 In the field of polymer chemistry, various organocatalytic polymerizations by NHC have been studied for more than a decade,37, 38, 39 whereas much less attention has been paid to the use of NHCs as the structural component of polymeric materials.40, 41, 42, 43 In fact, there is only one report on post-polymerization modification; NHC-incorporated polystyrenes were synthesized by the NHC-azide coupling reaction.44 Our attention was directed towards such NHC modification for unsaturated polyesters, as the bulky aromatic groups can be introduced as polymer side chains.

Herein, we examined the Michael addition of NHCs to butyl fumarate and maleate and applied them to the post-polymerization modification of unsaturated polyesters to effectively increase and tune their Tg. Transfer hydrogenation in the presence of NHCs and water, developed by us,45 was also used for post-polymerization.

Experimental Procedure

All the reactions were performed under nitrogen atmosphere. TPT,36 IDipp (1,3-bis(2,6-diisopropylphenyl)imidazol-2-ylidene),46 and ItBu (1,3-di-tert-butylimidazol-2-ylidene)46, 47 were synthesized according to previous reports. Anhydrous tetrahydrofuran (THF) and CH2Cl2 were used as received. Other solvents, 1a, 1b, 1,4-butanediol, diethylene glycol, and styrene were distilled from CaH2 before use. AIBN was recrystallized from methanol. 1H and 13C NMR spectra were recorded on a Bruker Avance III HD (400 MHz for 1H, 100 MHz for 13C) NMR spectrometer. Chemical shifts were referenced to an internal TMS standard (0.0 p.p.m. for 1H) or CDCl3 resonance (77.1 p.p.m. for 13C). DSC (differential scanning calorimetry) measurement was performed using a SSC/5200 SII DSC220C (Seiko, Tokyo, Japan) with a heating rate of 10 °C min−1. The Tgs were taken as the onset of the transition for the average of the second and third scans. Gel permeation chromatography (GPC) using THF as the eluent was performed on a Shodex GPC-104 system equipped with two tandem LF-404 columns (Shodex, Tokyo, Japan) and a Shimadzu SPD-20A UV detector with a flow rate of 1.0 ml min−1 at 40 °C. GPC using CHCl3 as the eluent was performed with a TSKgel MultiporeHXL column and UV-1570 detector (JASCO) with a flow rate of 1.0 ml min−1 at 20 °C. The columns were calibrated with polystyrene standards. Electrospray ionization mass spectrometry was measured in methanol solution using a Waters Synapt G2 HDMS tandem quadrupole orthogonal acceleration time-of-flight instrument equipped with a Z-spray nanoelectrospray ionization source. Infrared spectra were obtained on a JASCO FT/IR-460 Plus spectrometer. Microwave-assisted reactions were performed using a Biotage Initiator microwave reactor, the temperature of which was measured by a surface sensor.

Typical procedure for the Michael addition of NHCs with 1a or 1b

To a two-necked flask equipped with three-way stopcock, TPT (0.20 mmol, 59.5 mg), CH2Cl2 (1.0 ml), and 1a (0.20 mmol, 45.7 mg) were added in this order. After the mixture was stirred for 2 h at room temperature, CS2 (0.1 ml) was added to quench the active NHC. After evaporation of the solvent, the crude product was subjected to 1H NMR spectrometry. The 1H NMR yield was measured by the integral ratio between the alkenyl group of maleate and the methylene protons (CCH2C=O, 2.90 p.p.m. for 2-TPT, 2.88 p.p.m. for 2-IDipp) of the products.

2-TPT

1H NMR (400 MHz, CDCl3) δ: 0.81 (t, J=7.1 Hz, 3H), 0.90 (t, J=7.3 Hz, 3H), 1.19 (m, 4H), 1.31 (m, 2H), 1.54 (m, 2H), 2.90 (s, 2H), 3.47 (t, J=6.6 Hz, 2H), 3.97 (t, J=6.9 Hz, 2H), 7.22–7.77 (m, 15H). 13C NMR (100 MHz, CDCl3) δ: 13.8, 13.9, 19.2, 30.8, 31.2, 33.5, 61.9, 62.3, 64.3, 119.0, 122.8, 125.4, 127.3, 127.4, 127.9, 128.5, 128.7, 129.2, 129.4, 129.7, 130.6, 135.8, 140.8, 150.4, 155.7, 167.4, 174.2. HRMS (ESI) m/z: calculated for C32H35N3O4 [M+H]+ 526.27058, found 526.2706. IR (ATR): 2959, 1724, 1642, 1594, 1524, 1494, 1455, 1407, 1284, 1260, 1167, 1092, 1025, 966, 917, 801, 758, 731, 692 cm−1.

2-IDipp

1H NMR (400 MHz, CDCl3) δ: 0.72 (t, J=7.3 Hz, 3H), 0.85 (t, J=7.3 Hz, 3H), 1.00–1.41 (m, 32H), 2.88 (s, 2H), 2.97 (m, 4H), 3.41 (t, J=6.6 Hz, 2H), 3.61 (t, J=6.9 Hz, 2H), 6.52 (s, 2H), 7.17–7.37 (m, 6H). 13C NMR (100 MHz, CDCl3) δ: 13.8, 13.9, 19.1, 22.7, 25.5, 28.8, 30.7, 31.5, 34.5, 61.2, 63.3, 119.5, 123.9, 124.3, 129.1, 135.1, 146.1, 156.0, 166.6, 172.8. HRMS (ESI) m/z: calculated for C39H56N2O4 [M+H]+ 617.4318, found 617.4318. IR (ATR): 2960, 2870, 1740, 1658, 1518, 1456, 1414, 1384, 1362, 1259, 1231, 1200, 1156, 1113, 1060, 1034, 931, 802, 731 cm−1.

Synthesis of unsaturated polyesters

P1 and P4 were prepared from maleic anhydride and 1,4-butanediol or diethylene glycol using 0.5 mol% Sc(OTf)3 according to a previous report.4 P1: cis selective, Mn=6800, Mw/Mn=1.5 (GPC using THF as the eluent), Mn=3900, Mw/Mn=5.0 (GPC using CHCl3 as the eluent), Tg=−30 °C, Tm=27 °C. P4: Mn=4000, Mw/Mn=1.5, (GPC using THF as the eluent), Tg=−13 °C. P2 was prepared by the isomerization of P1 catalyzed by NHEt2 according to previous reports.4, 18 P2: trans selective, Mn=3300, Mw/Mn=3.7 (GPC using CHCl3 as the eluent), Tg=16 °C. P3 was prepared from maleic anhydride and ethylene glycol using 0.5 mol% p-toluenesulfonic acid according to a previous report.48 P3: cis/trans=89/11, Mn=2500, Mw/Mn=1.3 (GPC using THF as the eluent), Tg=−5 °C.

Post-polymerization modification by the Michael addition of NHC

TPT (71 mg, 0.24 mmol) was added to a solution of P1 (201 mg, 1.18 mmol (monomer unit)) in CH2Cl2 (5.9 ml). The mixture was stirred for 2 h at room temperature, and then CS2 (0.1 ml) was added. After the evaporation of volatiles, the crude mixture was dissolved in a small amount of CHCl3, followed by precipitation into a mixture of Et2O and MeOH (16/1) to give P1-TPT (180 mg, 66%). The other polymers, P1-IDipp, P2-TPT, P3-TPT, and P4-TPT, were synthesized in the same way. For 1H and 13C NMR spectra, see the Supplementary Information.

Post-polymerization modification by the Michael addition of NHC and transfer hydrogenation

P1 (156 mg), distilled water (1.38 mmol, 24.8 mg), TPT (0.46 mmol, 137 mg), and THF (5.0 ml) were added to a vial for microwave experiment. The vial was sealed and stirred at 120 °C for 2 h. CS2 (0.1 ml) was added to the mixture and the volatiles were evaporated. The crude product was dissolved in a small amount of CHCl3, and precipitated into Et2O/MeOH (16:1) to give the product (169 mg) in 82% yield. The other polymers, P1-TPT-H, P3-TPT-H, and P4-TPT-H were synthesized in the same way.

Cross-linking of P1-TPT with styrene

P1-TPT (118 mg), styrene (176 mg, 1.69 mmol), and AIBN (14.7 mg, 0.0895 mmol) were added to a test tube. After three freeze–pump–thaw cycles, the mixture was stirred at 60 °C for 20 h. The evaporation of styrene gave quantitative amounts of the resin (294 mg).

Results and Discussion

We first examined the Michael addition of NHCs to dibutyl maleate (1a) and fumarate (1b) in THF and CH2Cl2. The reaction of TPT or IDipp with 1a proceeds at room temperature in both the solvents to give the corresponding adduct 2-TPT or 2-IDipp in moderate-to-high yields (entries 1–4 in Table 1). For the reaction of TPT, CH2Cl2 was a better solvent, whereas the use of THF led to a higher yield in the reaction of IDipp. The reaction with 0.5 equivalents of IDipp in THF under reflux gave a product that was quantitatively based on the amount of IDipp (entry 5). Reactions of 1b with NHCs were examined only in CH2Cl2 (entries 6–9), as the unsaturated polyester with the trans diastereomer used in this study showed poor solubility in THF. The reactions of both NHCs gave products in moderate-to-high yields. Quantitative formation was also observed with 0.5 equivalents of TPT under reflux (entry 7). Although a trace amount of a dimeric product (NHC+two substrate molecules) was detected in the electrospray ionization mass spectrometry spectra of the reaction mixtures, all of the reactions proceed selectively without forming any byproducts. In contrast to TPT and IDipp, the reaction of ItBu did not give the corresponding adduct at all. In this case, the selective isomerization of 1a to 1b occurred with 0.2 equivalents of ItBu at room temperature (entry 10). The solvent effect on the isomerization was examined using THF, DMF (N,N-dimethylformamide), and toluene with 0.02 equivalents of ItBu (entries 11–13). The catalytic turnover was greater than 20 in THF and toluene. As shown in Scheme 1, the Michael addition of ItBu to 1a gave the zwitterionic intermediate (3), but the subsequent proton transfer to produce 2-ItBu did not occur because of electronic effects or steric hindrance of the tert-butyl group. Instead, electron transfer in 3 resulted in isomerization to give the more stable trans diastereomer 1b.

In general, a model reaction for post-polymerization modification requires high yield and high selectivity. Thus, we envisioned that the Michael addition of TPT and IDipp could be applied for the post-polymerization modification of polymaleates (P1, 3, and 4) and a polyfumarate (P2). Based on the above results of the reactions of 1a with TPT, reactions of P1 with 0.2, 0.5, or 1.0 equivalents of TPT were carried out in CH2Cl2 at room temperature (entries 1–3 in Table 2). The corresponding polymer, P1-TPT, was obtained in moderate-to-good yields. The polymer structure was confirmed by comparing the 1H NMR spectrum of each reaction with that of 2-TPT. The characteristic signal of the α-methylene group was observed at 2.89 p.p.m. in the resulting spectra. The composition ratio (x) of the TPT-introduced unit was estimated by the 1H NMR integral ratio between the unreacted vinylene group and the α-methylene group. More than half of the feed TPT was incorporated. The reaction of an equivalent of TPT under reflux reached a composition ratio of 0.76 (entry 4). It is interesting to note that the glass transition temperature (Tg) increases with increasing values of x. The Tg increased from −30 °C (P1) to −6 °C, even with the low composition ratio of 0.11 (entry 1), and reached 100 °C with 0.76 (entry 4). The reaction of IDipp with P1 similarly proceeded in THF (entries 5–7). The reaction with an equivalent of IDipp under reflux gave the polymer with the highest composition ratio of 0.92 and the highest Tg of 111 °C. This thermal stability can be explained by the fact that the segmental mobility of polymer chains is significantly reduced by the stiff and bulky structure of the NHCs. As shown in Figure 1, the Tg increases almost linearly with increasing composition ratio, and TPT and IDipp have a similar effect on the values of Tg. Importantly, the Tg is tunable within a temperature range as wide as 140 °C. The DSC endothermic peaks corresponding to the Tgs are single and not broad, suggesting that the NHCs were randomly incorporated. Polyester P2, the trans analog of P1, similarly undergoes post-polymerization modification in CH2Cl2 under reflux (entries 8 and 9). The reaction with 0.50 equivalents of TPT produced P2-TPT in 82% yield with a high TPT incorporation of 0.44 and a high Tg of 80 °C. The melting points (Tms) of P1 and P2 were observed at 28 and 138 °C, respectively, whereas all DSC profiles of the resulting polymers bearing NHCs did not show any Tm, indicating that they are amorphous. The reactions of P3 and P4 with TPT also proceeded to give the corresponding P3-TPT and P4-TPT products with high NHC incorporation (entries 10–13). The Tgs increased with increasing composition ratio, but their values were not as high as those of P1-TPT, P1-IDipp, and P2-TPT, suggesting that the rate at which Tg increases is somehow dependent on the structure of the polymer main chain.

The obtained NHC-incorporated polymers show good solubility in various organic solvents, such as CHCl3, CH2Cl2, 1,4-DOX, THF, MeCN, DMF, and DMSO (Table 3). Interestingly, all resulting polymers are more soluble than the substrate polymers, P1–P4. Specifically, P2 is only soluble in CHCl3 and CH2Cl2 (entry 5), whereas P2-TPT, with a composition ratio of only 0.16, is soluble in all the above solvents (entry 6). In addition, P2-TPT, with a composition ratio of 0.44, was partially soluble in toluene, acetone, and MeOH, showing that the solubility increased with an increasing composition ratio (entry 7). The addition of NHC renders the crystalline portion of P2 amorphous, and P2-TPTs are readily miscible in these solvents. The obtained polymers showed good solubility, but they could not be filtered through a 0.45 μm pore size filter. Thus, GPC measurement could not be performed. We suggest that a trace amount of TPT would react with two equivalents of maleate unit, resulting in cross-linking with quite low density.

We previously reported that the combination of TPT and water promotes the transfer hydrogenation of fumarates, maleates, and imines.45 Given that dibutyl fumarate and maleate selectively undergo hydrogenation at 150 °C through the intermediate 2-TPT, we envisioned that the reaction under more ambient conditions may lead to simultaneous Michael addition and hydrogenation to produce a polyester (P-TPT-H) with TPT-incorporated (x) and hydrogenated (y) units. The reactions of P1 with 0.2 or 0.5 equivalents of TPT and water in THF under reflux produce a polyester (P1-TPT-H) with a composition of x=14, y=3 or x=36, y=9, respectively (entries 1 and 2 in Table 4). Since a stoichiometric amount of TPT is required for both Michael addition and transfer hydrogenation, the total values of x and y indicate that TPT works efficiently. Reaction at 120 °C using sealed vials under microwave irradiation increased the content of the hydrogenated unit (entries 3 and 4). The reaction of P2, which is insoluble in THF, was attempted in 1,2-dichloroethane under the same conditions, but hydrogenation did not occur. In contrast, P3 and P4 underwent this post-polymerization modification in THF. Except for entry 6, the composition ratios of the hydrogenated unit were comparable to those of the TPT-incorporated unit. Compared with the saturated analogs of P1 and P3, the Tgs of which are reported to be −45 °C (ref. 49) and −10 °C,50 respectively, the obtained polyesters showed high thermal stability.

The obtained polyesters still have reactive vinylene groups, leading us to demonstrate radical cross-linking with styrene. P1 and P1-TPT (x=0.28, Tg=44 °C) are miscible with styrene, and the mixtures (P1-TPT/styrene weight ratio of 2:3) were heated in the presence of AIBN at 60 °C for 20 h to produce the cross-linked resins quantitatively. The resin derived from P1 showed two Tgs at 16 and 85 °C, corresponding to the polyester and polystyrene. In contrast, the resin derived from P1-TPT and styrene showed a single Tg at 87 °C, suggesting that polystyrene is miscible with P1-TPT probably because of π–π interactions among the phenyl groups. The cross-linking of P1-TPT with styrene increased not only the Tg but also the decomposition temperature, as the 10% weight loss temperature measured by TGA increased from 280 to 365 °C.

Conclusion

We have demonstrated a post-polymerization modification method for unsaturated polyesters to increase the thermal stability, solubility, and miscibility. The values of Tg linearly increased with an increasing amount of NHC-incorporated units and can be controlled in a range as wide as 140 °C. The use of stiff and bulky NHCs as a structural component of the polymer side chain resulted in the effective reduction of the mobility of the polymer chain. This Michael addition is suitable for post-polymerization modification, as it proceeds chemoselectively without any catalyst at ambient temperature. Transfer hydrogenation promoted by TPT and water was also applied to the post-polymerization modification. By using NHCs as stoichiometric reagents and promoters for transfer hydrogenation, the unsaturated polyesters can be converted into various structures. This work successfully demonstrates that, in addition to the developed coordination and organocatalytic chemistries, NHCs work as rigid structural modifiers in materials chemistry.

Isomerization of 1a catalyzed by ItBu.

References

Selley, J. Polyesters, unsaturated. in Kirk-Othmer Encyclopedia of Chemical Technology (John Wiley and Sons, Inc, 2000).

Penczek, P., Czub, P. & Pielichowski, J. Unsaturated polyester resins: chemistry and technology. Adv. Polym. Sci. 184, 1–95 (2005).

Kricheldorf, H. R., Yashiro, T. & Weidner, S. Isomerization-free polycondensations of maleic anhydride with α,ω-alkanediols. Macromolecules 42, 6433–6439 (2009).

Tang, T., Moyori, T. & Takasu, A. Isomerization-free polycondensations of cyclic anhydrides with diols and preparation of polyester gels containing cis or trans carbon double bonds via photo-cross-linking and isomerization in the gels. Macromolecules 46, 5464–5472 (2013).

DiCiccio, A. M. & Coates, G. W. Ring-opening copolymerization of maleic anhydride with epoxides: a chain-growth approach to unsaturated polyesters. J. Am. Chem. Soc. 133, 10724–10727 (2011).

Liu, J., Bao, Y.-Y., Liu, Y., Ren, W.-M. & Lu, X.-B. Binuclear chromium–salan complex catalyzed alternating copolymerization of epoxides and cyclic anhydrides. Polym. Chem. 4, 1439–1444 (2013).

DiCiccio, A. M., Longo, J. M., Rodríguez-Calero, G. G. & Coates, G. W. Development of highly active and regioselective catalysts for the copolymerization of epoxides with cyclic anhydrides: an unanticipated effect of electronic variation. J. Am. Chem. Soc. 138, 7107–7113 (2016).

Boaen, N. K. & Hillmyer, M. A. Post-polymerization functionalization of polyolefins. Chem. Soc. Rev. 34, 267–275 (2005).

Gauthier, M. A., Gibson, M. I. & Klok, H.-A. Synthesis of functional polymers by post-polymerization modification Angew. Chem. Int. Ed. 48, 48–58 (2009).

Günay, K. A., Theato, P. & Klok, H.-A. Standing on the shoulders of Hermann Staudinger: post-polymerization modification from past to present. J. Polym. Sci. A Polym. Chem. 51, 1–28 (2013).

Goldmann, A. S., Glassner, M., Inglis, A. J. & Barner-Kowollik, C. Post-functionalization of polymers via orthogonal ligation chemistry. Macromol. Rapid Commun. 34, 810–849 (2013).

Romulus, J., Henssler, J. T. & Weck, M. Post-polymerization modification of block copolymers. Macromolecules 47, 5437–5449 (2014).

Das, A. & Theato, P. Activated ester containing polymers: opportunities and challenges for the design of functional macromolecules. Chem. Rev. 116, 1434–1495 (2016).

Alemdar, N., Erciyes, A. T. & Bicak, N. Preparation of unsaturated polyesters using boric acid as mild catalyst and their sulfonated derivatives as new family of degradable polymer surfactants. Polymer 51, 5044–5050 (2010).

Wu, S., Zheng, L., Li, C., Huo, S., Xiao, Y., Guan, G. & Zhu, W. A facile and versatile strategy to efficiently synthesize sulfonated poly(butylene succinate), self-assembly behavior and biocompatibility. Polym. Chem. 6, 1495–1501 (2015).

Kuang, X., Liu, G., Zheng, L., Li, C. & Wang, D. Functional polyester with widely tunable mechanical properties: the role of reversible cross-linking and crystallization. Polymer 65, 202–209 (2015).

Hao, Q., Yang, J., Li, Q., Li, Y., Jia, L., Fang, Q. & Cao, A. New facile approach to novel water-soluble aliphatic poly(butylene tartarate)s bearing reactive hydroxyl pendant groups. Biomacromolecules 6, 3474–3480 (2005).

Tang, T. & Takasu, A. Facile synthesis of unsaturated polyester-based double-network gels via chemoselective crosslinking using Michael addition and subsequent UV-initiated radical polymerization. RSC Adv. 5, 819–829 (2015).

Hopkinson, M. N., Richter, C., Schedler, M. & Glorius, F. An overview of N-heterocyclic carbenes. Nature 510, 485–496 (2014).

Flanigan, D. M., Romanov-Michailidis, F., White, N. A. & Rovis, T. Organocatalytic reactions enabled by N-heterocyclic carbenes. Chem. Rev. 115, 9307–9387 (2015).

Ryan, S. J., Candish, L. & Lupton, D. W. Acyl anion free N-heterocyclic carbene organocatalysis. Chem. Soc. Rev. 42, 4906–4917 (2013).

Chen, X.-Y. & Ye, S. N-Heterocyclic carbene-catalyzed reactions of C–C unsaturated bonds. Org. Biomol. Chem. 11, 7991–7998 (2013).

Matsuoka, S. N-Heterocyclic carbene-catalyzed dimerization, cyclotetramerization and polymerization of Michael acceptors. Polym. J. 47, 713–718 (2015).

Fischer, C., Smith, S. W., Powell, D. A. & Fu, G. C. Umpolung of Michael acceptors catalyzed by N-heterocyclic carbenes. J. Am. Chem. Soc. 128, 1472–1473 (2006).

Matsuoka, S., Namera, S., Washio, A., Takagi, K. & Suzuki, M. N-Heterocyclic carbene-catalyzed cyclotetramerization of acrylates. Org. Lett. 15, 5916–5919 (2013).

Nakano, Y. & Lupton, D. W. Enantioselective N-heterocyclic carbene catalysis by the umpolung of α,β-unsaturated ketones. Angew. Chem. Int. Ed. 55, 3135–3139 (2016).

Matsuoka, S., Ota, Y., Washio, A., Katada, A., Ichioka, K., Takagi, K. & Suzuki, M. Organocatalytic tail-to-tail dimerization of olefin: umpolung of methyl methacrylate mediated by N-heterocyclic carbene. Org. Lett. 13, 3722–3725 (2011).

Biju, A. T., Padmanaban, M., Wurz, N. E. & Glorius, F. N-Heterocyclic carbene catalyzed umpolung of Michael acceptors for intermolecular reactions. Angew. Chem. Int. Ed. 50, 8412–8415 (2011).

Kato, T., Ota, Y., Matsuoka, S., Takagi, K. & Suzuki, M. Experimental mechanistic studies of the tail-to-tail dimerization of methyl methacrylate catalyzed by N-heterocyclic carbene. J. Org. Chem. 78, 8739–8747 (2013).

Kato, T., Matsuoka, S. & Suzuki, M. Cooperative N-heterocyclic carbene/Brønsted acid catalysis for the tail-to-tail (co)dimerization of methacrylonitrile. J. Org. Chem. 79, 4484–4491 (2014).

Schedler, M., Wurz, N. E., Daniliuc, C. G. & Glorius, F. N-Heterocyclic carbene catalyzed umpolung of styrenes: mechanistic elucidation and selective tail-to-tail dimerization. Org. Lett. 16, 3134–3137 (2014).

Matsuoka, S., Nakazawa, M. & Suzuki, M. Expanding the scope of the tail-to-tail dimerization of vinyl compounds catalyzed by N-heterocyclic carbene. Bull. Chem. Soc. Jpn 88, 1093–1099 (2015).

Rajachan, O., Paul, M., Yatham, V. R., Neudörfl, J.-M., Kanokmedhakul, K., Kanokmedhakul, S. & Berkessel, A. N-Heterocyclic carbene catalyzed tail-to-tail oligomerization of N,N-dimethylacrylamide (DMAA) and the search for the Stetter reaction of DMAA with benzaldehyde. Tetrahedron Lett. 56, 6537–6540 (2015).

Hong, M. & Chen, E. Y.-X. Proton-transfer polymerization (HTP): converting methacrylates to polyesters by an N-heterocyclic carbene. Angew. Chem. Int. Ed. 53, 11900–11906 (2014).

Hong, M., Tang, X., Falivene, L., Caporaso, L., Cavallo, L. & Chen, E. Y.-X. Proton-transfer polymerization by N-heterocyclic carbenes: monomer and catalyst scopes and mechanism for converting dimethacrylates into unsaturated polyesters. J. Am. Chem. Soc. 138, 2021–2035 (2016).

Enders, D., Breuer, K., Raabe, G., Runsink, J., Teles, J. H., Melder, J.-P., Ebel, K. & Brode, S. Preparation, structure, and reactivity of 1,3,4-triphenyl-4,5-dihydro-lH-l,2,4-triazol-5-ylidene, a new stable carbene. Angew. Chem. Int. Ed. 34, 1021–1023 (1995).

Kiesewetter, M. K., Shin, E. J., Hedrick, J. L. & Waymouth, R. M. Organocatalysis: opportunities and challenges for polymer synthesis. Macromolecules 43, 2093–2107 (2010).

Naumann, S. & Dove, A. P. N-Heterocyclic carbenes as organocatalysts for polymerizations: trends and frontiers. Polym. Chem. 6, 3185–3200 (2015).

Naumann, S. & Dove, A. P. N-Heterocyclic carbenes for metal-free polymerization catalysis: an update. Polym. Int. 65, 16–27 (2016).

Fèvre, M., Pinaud, J., Gnanou, Y., Vignolle, J. & Taton, D. N-Heterocyclic carbenes (NHCs) as organocatalysts and structural components in metal-free polymer synthesis. Chem. Soc. Rev. 42, 2142–2172 (2013).

Boydston, A. J., Williams, K. A. & Bielawski, C. W. A modular approach to main-chain organometallic polymers. J. Am. Chem. Soc. 127, 12496–12497 (2005).

Boydston, A. J., Rice, J. D., Sanderson, M. D., Dykhno, O. L. & Bielawski, C. W. Synthesis and study of bidentate benzimidazolylidene−group 10 metal complexes and related main-chain organometallic polymers. Organometallics 25, 6087–6098 (2006).

Boydston, A. J. & Bielawski, C. W. Bis(imidazolylidene)s as modular building blocks for monomeric and macromolecular organometallic materials. Dalton Trans. 4073–4077 (2006).

Coady, D. J. & Bielawski, C. W. N-Heterocyclic carbenes: versatile reagents for post-polymerization modification. Macromolecules 39, 8895–8897 (2006).

Kato, T., Matsuoka, S. & Suzuki, M. Transfer hydrogenation promoted by N-heterocyclic carbene and water. Chem. Commun. 51, 13906–13909 (2015).

Arduengo, A. J. III, Krafczyk, R & Schmutzler, R. Imidazolylidenes, imidazolinylidenes and imidazolidines. Tetrahedron 55, 14523–14534 (1999).

Serpell, C. J., Cookson, J., Thompson, A. L., Brown, C. M. & Beer, P. D. Haloaurate and halopalladate imidazolium salts: structures, properties, and use as precursors for catalytic metal nanoparticles. Dalton Trans. 42, 1385–1393 (2013).

Bietz, J. & Ritter, H. Novel UV-absorbing nitrones: synthesis and 1,3-dipolar cycloaddition onto poly(urethane)s. Macromol. Chem. Phys. 210, 1114–1119 (2009).

Ye, H.-M., Wang, R.-D., Liu, J., Xu, J. & Guo, B.-H. Isomorphism in poly(butylene succinate-co-butylene fumarate) and its application as polymeric nucleating agent for poly(butylene succinate). Macromolecules 45, 5667–5675 (2012).

Karavelidis, V., Giliopoulos, D., Karavas, E. & Bikiaris, D. Nanoencapsulation of a water soluble drug in biocompatible polyesters. Effect of polyesters melting point and glass transition temperature on drug release behavior. Eur. J. Pharm. Sci. 41, 636–643 (2010).

Acknowledgements

This work was financially supported by the Tatematsu Foundation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Matsuoka, Si., Kamijo, Y. & Suzuki, M. Post-polymerization modification of unsaturated polyesters by Michael addition of N-heterocyclic carbenes. Polym J 49, 423–428 (2017). https://doi.org/10.1038/pj.2017.2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2017.2